Plastic Injection Molding with Induction Heating Machine

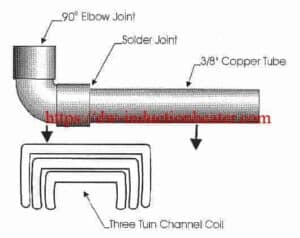

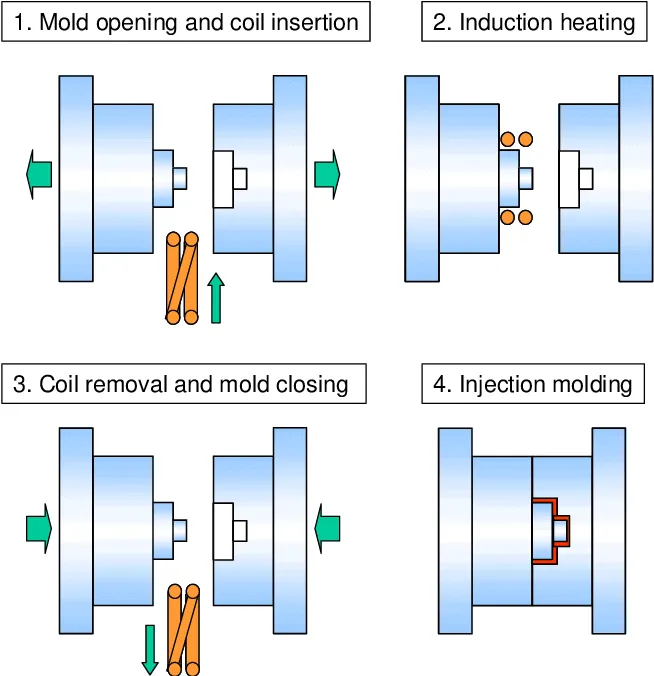

Plastic Injection molding with

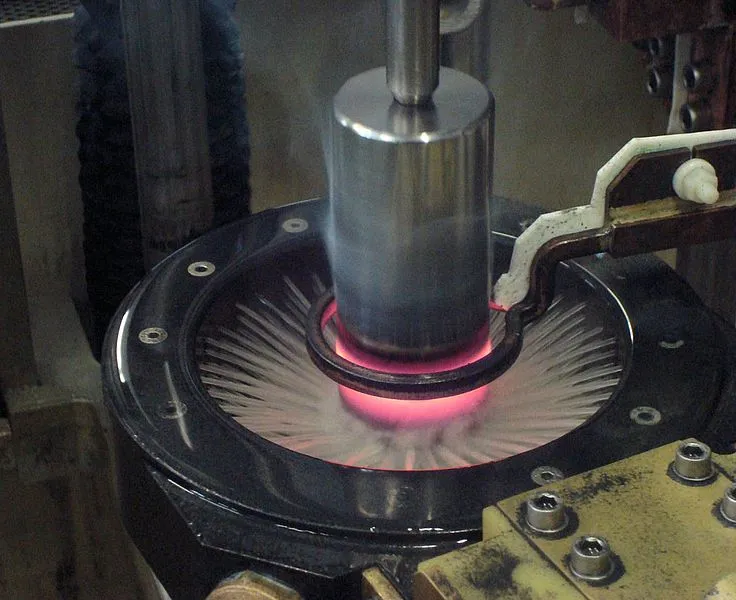

induction heating requires pre-heating of the molds to a higher temperature, to ensure the proper flow or curing of the injection-molded material. Typical heating methods used in the industry are steam or resistive heating, but they are messy, inefficient, and unreliable. Induction heating is a clean, fast and energy-efficient alternative which has been widely used in recent years to replace steam, gas or resistive heating of molds and dies.

What is Injection Moulding?

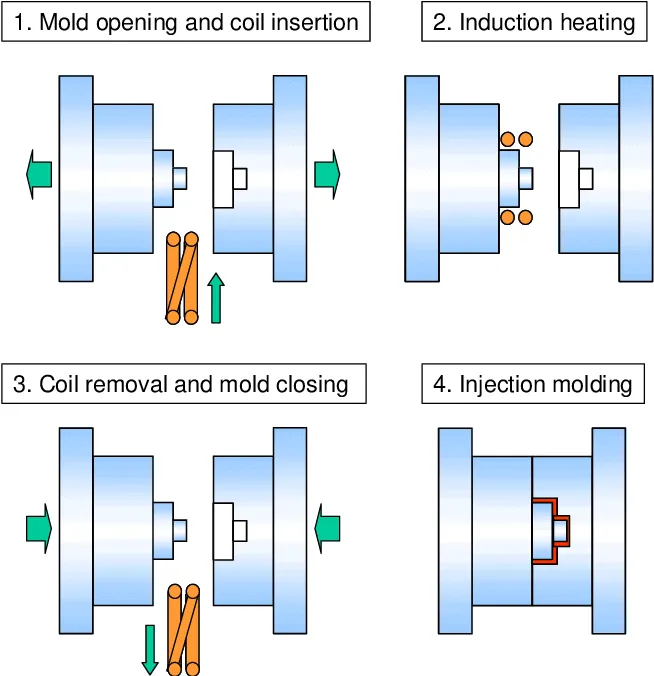

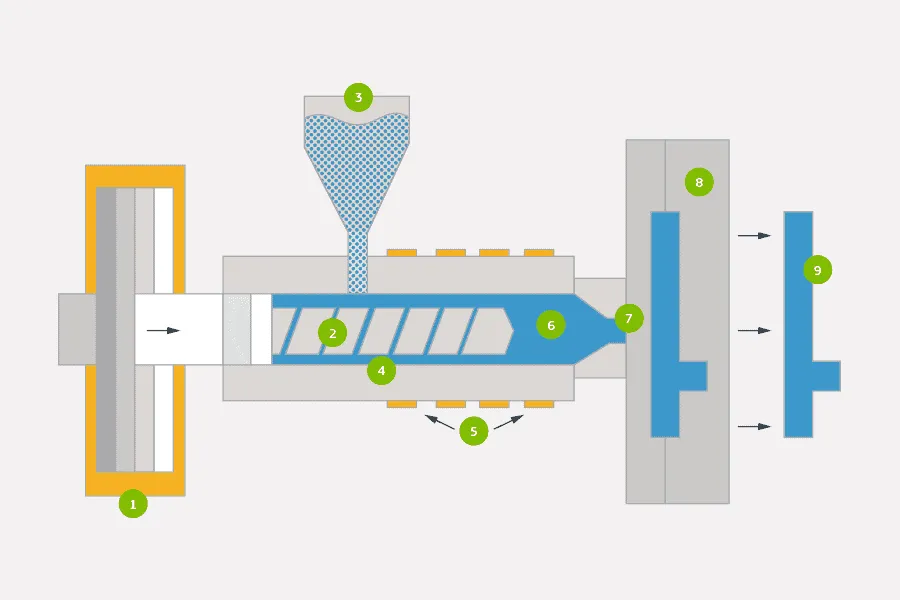

Plastic injection moulding with induction heating is the process of melting plastic pellets (thermosetting/ thermoplastic polymers) that once malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product.

How Does Plastic Injection Moulding Work?

How Does Plastic Injection Moulding Work?

The plastic injection moulding process at Protolabs is a standard process involving an aluminium mould. Aluminium transfers heat much more efficiently than steel, so does not require cooling channels - which means the time we save on cooling can be applied to monitoring fill pressure, cosmetic concerns and producing a quality part.

Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mould’s runner system. Hot resin is shot into the mould cavity through the gates and the part is moulded. Ejector pins facilitate removal of the part from the mould where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

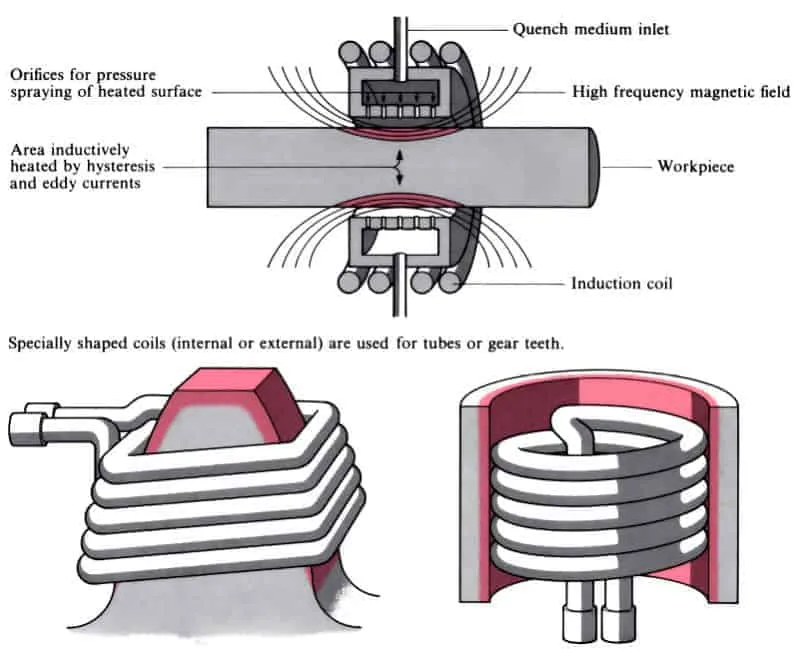

How Induction Heating is used in Dies & Molds Industry?

- Induction Preheating of tools and molds for plastic injection molding

- Heating of molding tools for curing of rubber product and automobile tires

- Die induction heating for catheter tipping and medical products manufacturing

- Die and platen heating for metal stamping and forming

- Induction Preheating of casting molds in the metal casting industry

- Induction Heat treating and hardening of stamping and punching tools and dies

Plastic Injection Molding with Induction Heating

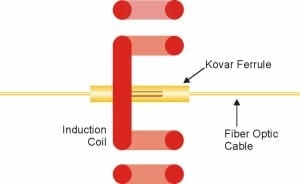

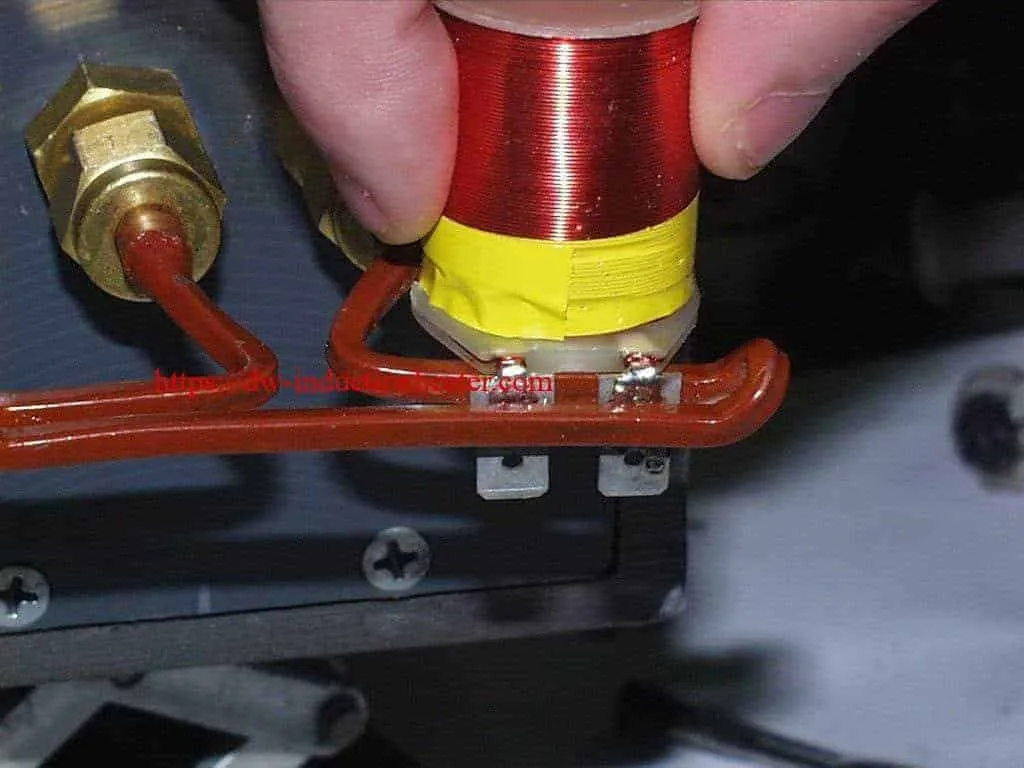

Soldering Fiber Optic Cable for Hermetic Sealing With IGBT Induction Soldering Heater

Objective To heat a Kovar ferrule and fiber optic cable to 297°F within 10 seconds for a soldering application, to form a hermetic seal

Material Gold-coated cable, Kovar ferrule, solder and flux

Temperature 297 ºF

Frequency 360 kHz

Equipment DW-UHF-4.5kW power supply with a specially designed induction coil

Process A specially designed, 4-turn “C” shape coil was used to provide uniform heat to the assembly near the joint area. With this design, the coil can be lowered directly onto the joint; it is not necessary to feed the ferrule assembly through the coil. Flux was applied to the assembly where the ferrule and fiber optic cable were to be joined. RF power was applied for 10 seconds, which caused the solder to melt and flow.

Results/Benefits Consistent and repeatable results were achieved with the DW-UHF-4.5kW power supply and a 10-second heat cycle. The solder flowed evenly and bonded the fiber optic cable to

the Kovar ferrule. With the induction coil’s compact design, a very small surface area was heated with pinpoint accuracy.

Soldering Fiber Optic Cable for Hermetic Sealing With IGBT Induction Soldering Heater

Objective To heat a Kovar ferrule and fiber optic cable to 297°F within 10 seconds for a soldering application, to form a hermetic seal

Material Gold-coated cable, Kovar ferrule, solder and flux

Temperature 297 ºF

Frequency 360 kHz

Equipment DW-UHF-4.5kW power supply with a specially designed induction coil

Process A specially designed, 4-turn “C” shape coil was used to provide uniform heat to the assembly near the joint area. With this design, the coil can be lowered directly onto the joint; it is not necessary to feed the ferrule assembly through the coil. Flux was applied to the assembly where the ferrule and fiber optic cable were to be joined. RF power was applied for 10 seconds, which caused the solder to melt and flow.

Results/Benefits Consistent and repeatable results were achieved with the DW-UHF-4.5kW power supply and a 10-second heat cycle. The solder flowed evenly and bonded the fiber optic cable to

the Kovar ferrule. With the induction coil’s compact design, a very small surface area was heated with pinpoint accuracy.

https://dw-inductionheater.com/soldering-fiber-optic-for-hermetic-sealing.html?feed_id=228191&_unique_id=6518aaeb13cef

https://dw-inductionheater.com/soldering-fiber-optic-for-hermetic-sealing.html?feed_id=228191&_unique_id=6518aaeb13cef

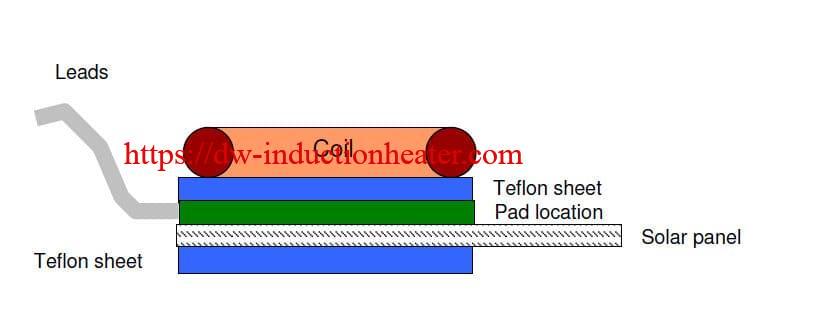

Soldering Solar Panels With Induction Heating Units

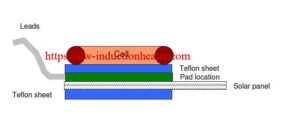

Objective Heat multiple joints on solar flex circuit strips to 500°F (260ºC) within ten seconds for a soldering application.

Material Flexible solar panel, Solder Plus Paste 63NC-A, 0.0625” (1.59mm) thick Teflon sheets

Temperature 500 °F(260ºC)

Frequency 278 kHz

Equipment • DW-UHF-4.5kW induction heating system equipped with a remote workhead with one 1.2 μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A specially-designed induction coil is used to provide even heat in the area where the wires on the solar circuits overlap. A very light coat of solder paste is applied to the circuit connections and a small amount of pressure is applied to the Teflon sheets to hold the circuits together. Power is applied for 10 seconds to flow the solder paste and bond the wires to the flex circuits

Results/Benefits Induction heating provides:

• Consistent and repeatable results

• Non-contact clean heating

• Flameless process

Soldering Solar Panels With Induction Heating Units

Objective Heat multiple joints on solar flex circuit strips to 500°F (260ºC) within ten seconds for a soldering application.

Material Flexible solar panel, Solder Plus Paste 63NC-A, 0.0625” (1.59mm) thick Teflon sheets

Temperature 500 °F(260ºC)

Frequency 278 kHz

Equipment • DW-UHF-4.5kW induction heating system equipped with a remote workhead with one 1.2 μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A specially-designed induction coil is used to provide even heat in the area where the wires on the solar circuits overlap. A very light coat of solder paste is applied to the circuit connections and a small amount of pressure is applied to the Teflon sheets to hold the circuits together. Power is applied for 10 seconds to flow the solder paste and bond the wires to the flex circuits

Results/Benefits Induction heating provides:

• Consistent and repeatable results

• Non-contact clean heating

• Flameless process

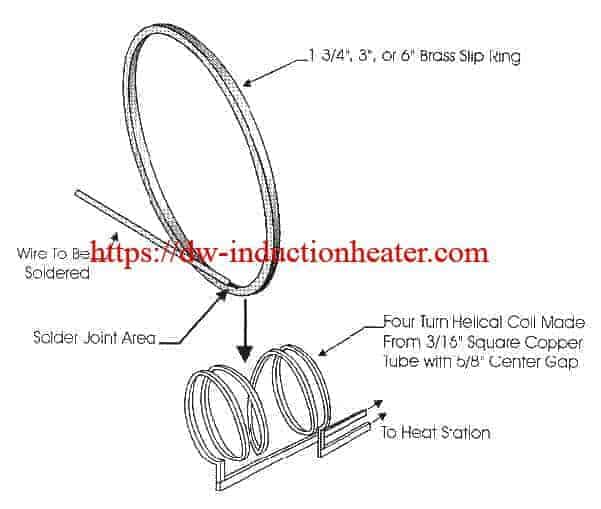

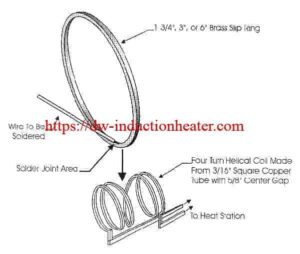

Induction Soldering Brass Rings With High Frequency IGBT Induction Heater

Objective: To heat 1 3/4", 3" and 6" diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick feeding rosin cored solder. This process leaves unwanted solder on the side of the slip ring where the soldering iron makes contact. The customer would like to see an increase in joint quality without sacrificing time.

Material: 303 Brass Slip Rings of 1 3/4", 3" and 6" diameters. Sheathed Copper Wire Assembly.

Resin Core Solder, 37% Pb, 63% Sn.

Temperature: 3750F

Application: Through laboratory testing, the DW-UHF-20kW output solid state induction power supply along with a unique four (4) turn "ear muff" type coil produced the following results:

Times to reach 3750 F are as listed below:

- 1 3/4" in 3 seconds

- 3" in 3-4 seconds

- 6" in 5 seconds

Adequate solder flow was observed producing a clean joint.

Solder preforms are recommended to speed up production.

Side loading was facilitated by the unique four (4) turn "ear muff" style coil.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.0 μFcapacitor, a 4-20mA input for fast ramp simulation, and a unique four (4) turn "ear muff" style coil.

Frequency: 265 kHz

Induction Soldering Brass Rings With High Frequency IGBT Induction Heater

Objective: To heat 1 3/4", 3" and 6" diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick feeding rosin cored solder. This process leaves unwanted solder on the side of the slip ring where the soldering iron makes contact. The customer would like to see an increase in joint quality without sacrificing time.

Material: 303 Brass Slip Rings of 1 3/4", 3" and 6" diameters. Sheathed Copper Wire Assembly.

Resin Core Solder, 37% Pb, 63% Sn.

Temperature: 3750F

Application: Through laboratory testing, the DW-UHF-20kW output solid state induction power supply along with a unique four (4) turn "ear muff" type coil produced the following results:

Times to reach 3750 F are as listed below:

- 1 3/4" in 3 seconds

- 3" in 3-4 seconds

- 6" in 5 seconds

Adequate solder flow was observed producing a clean joint.

Solder preforms are recommended to speed up production.

Side loading was facilitated by the unique four (4) turn "ear muff" style coil.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.0 μFcapacitor, a 4-20mA input for fast ramp simulation, and a unique four (4) turn "ear muff" style coil.

Frequency: 265 kHz

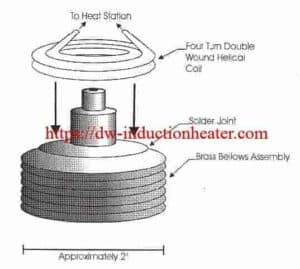

Induction Soldering Brass Assembly With High Frequency Soldering Units

Objective: To heat a brass bellows and end cap assembly to 4500F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality solder joint with minimal heating of the bellows to prevent annealing and performance losses. Solder preforms, in the form of flat washers, are to be used to complete this application.

Material: Brass Bellows measuring 2" in diameter Solder Preforms

Cadmium Free Flux

Temperature: 4500F

Application: The DW-UHF-20kW output solid state induction power supply along with a unique three (3) turn double wound helical coil was utilized to achieve the following results:

4500F was reached and solder flow completed in 6.3 seconds.

A quality repeatable solder joint was observed.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.2 μF capacitor, and a unique three (3) turn double wound helical coil with an inside diameter of 0.4".

Frequency: 307 kHz

Induction Soldering Brass Assembly With High Frequency Soldering Units

Objective: To heat a brass bellows and end cap assembly to 4500F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality solder joint with minimal heating of the bellows to prevent annealing and performance losses. Solder preforms, in the form of flat washers, are to be used to complete this application.

Material: Brass Bellows measuring 2" in diameter Solder Preforms

Cadmium Free Flux

Temperature: 4500F

Application: The DW-UHF-20kW output solid state induction power supply along with a unique three (3) turn double wound helical coil was utilized to achieve the following results:

4500F was reached and solder flow completed in 6.3 seconds.

A quality repeatable solder joint was observed.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.2 μF capacitor, and a unique three (3) turn double wound helical coil with an inside diameter of 0.4".

Frequency: 307 kHz

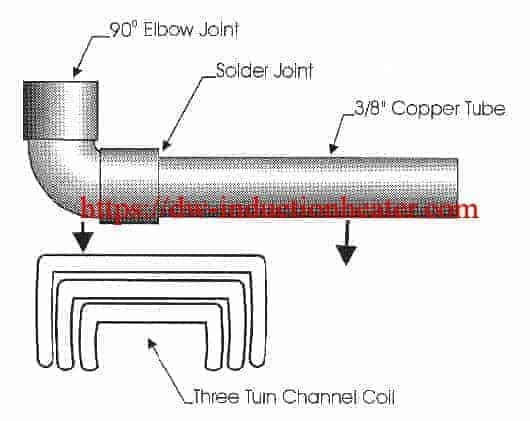

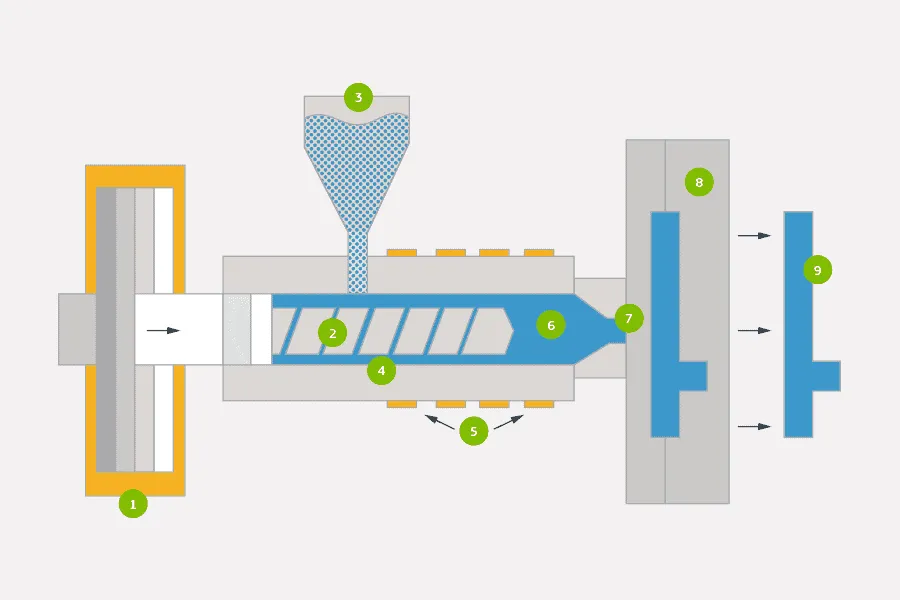

Induction Soldering Copper Tube With High Frequency Heating Units

Objective: To heat a section of 3/8" copper tubing along with a 900 elbow for soldering. The copper tubing is to be used in Ice Machine Evaporator Assemblies, and soldering takes place after the tubes have been placed within the assembly. Heating must take place in a channel type coil to provide easy access, once the tubing has been installed. Solder can be manually fed after temperature

has been reached.

Material: 3/8" Thin Walled Copper Tubing and 900 Elbow

Temperature: 6000F

Application: Through the use of the DW-UHF-20kW output solid state induction power supply and a unique three (3) turn channel coil, the following results were achieved:

6000F was reached in 10 seconds.

A quality solder joint was observed with adequate flow and surface texture.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.2 μF capacitor, and a unique three (3) turn channel coil.

Frequency: 200 kHz

Induction Soldering Copper Tube With High Frequency Heating Units

Objective: To heat a section of 3/8" copper tubing along with a 900 elbow for soldering. The copper tubing is to be used in Ice Machine Evaporator Assemblies, and soldering takes place after the tubes have been placed within the assembly. Heating must take place in a channel type coil to provide easy access, once the tubing has been installed. Solder can be manually fed after temperature

has been reached.

Material: 3/8" Thin Walled Copper Tubing and 900 Elbow

Temperature: 6000F

Application: Through the use of the DW-UHF-20kW output solid state induction power supply and a unique three (3) turn channel coil, the following results were achieved:

6000F was reached in 10 seconds.

A quality solder joint was observed with adequate flow and surface texture.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.2 μF capacitor, and a unique three (3) turn channel coil.

Frequency: 200 kHz

Induction Soldering Steel Parts,Wire,Tube,Pipe and Rod with IGBT Induction Heater

Objective To heat a special steel housing to 500(260) ºF(ºC) for a soldering application

Material Steel housing Solder wire and flux

Temperature 500(260) - 550(287.8) ºF(ºC)

Frequency 200 kHz

Equipment DW-UHF-6kW, 150-400 kHz solid state induction power supply with a remote heat station containing two 0.33 mF capacitors (total capacitance 0.66 mF). A custom-designed induction heating coil.

Process A two-turn induction coil is used to deliver the heat energy into the steel housing. A small diameter solder wire is used to form a solder ring for the assembly process. Solder flux is applied

generously to the joint area. Induction power is applied to the assembly until the solder ring flows into the joint. The same coil is used to solder multiple locations on the housing.

Results/Benefits · Ability to solder multiple locations with one coil. No need to change coils.

Induction Soldering Steel Parts,Wire,Tube,Pipe and Rod with IGBT Induction Heater

Objective To heat a special steel housing to 500(260) ºF(ºC) for a soldering application

Material Steel housing Solder wire and flux

Temperature 500(260) - 550(287.8) ºF(ºC)

Frequency 200 kHz

Equipment DW-UHF-6kW, 150-400 kHz solid state induction power supply with a remote heat station containing two 0.33 mF capacitors (total capacitance 0.66 mF). A custom-designed induction heating coil.

Process A two-turn induction coil is used to deliver the heat energy into the steel housing. A small diameter solder wire is used to form a solder ring for the assembly process. Solder flux is applied

generously to the joint area. Induction power is applied to the assembly until the solder ring flows into the joint. The same coil is used to solder multiple locations on the housing.

Results/Benefits · Ability to solder multiple locations with one coil. No need to change coils.

Induction Soldering Copper Tap on a Speaker Ring with IGBT Induction Heater

Objective Heat copper tab until the solder reflows.

Material Copper tab 0.25 X 0.25 inch square about 0.05 inches thick. Lead free solder material (higher melting temperature than regular solder.)

Temperature 500 ºF for 1.25 seconds

Frequency 286 kHz

Equipment DW-UHF-4.5 kW, 150-400 kHz solid state induction heating system equipped with a remote heat station containing one 1.2 μF capacitor and a specially-designed work coil..

A multi-turn helical coil about 3/16 inch internal diameter made out of 1/16 inch diameter tubing.

Process Solder wire is fed onto speaker tab area using an automatic wire feeder. It is then heated to re-flow the solder.

Results/Benefits With an efficient coil design induction heating easily reaches the desired reflow temperature in a very short amount of time.

Induction Soldering Copper Tap on a Speaker Ring with IGBT Induction Heater

Objective Heat copper tab until the solder reflows.

Material Copper tab 0.25 X 0.25 inch square about 0.05 inches thick. Lead free solder material (higher melting temperature than regular solder.)

Temperature 500 ºF for 1.25 seconds

Frequency 286 kHz

Equipment DW-UHF-4.5 kW, 150-400 kHz solid state induction heating system equipped with a remote heat station containing one 1.2 μF capacitor and a specially-designed work coil..

A multi-turn helical coil about 3/16 inch internal diameter made out of 1/16 inch diameter tubing.

Process Solder wire is fed onto speaker tab area using an automatic wire feeder. It is then heated to re-flow the solder.

Results/Benefits With an efficient coil design induction heating easily reaches the desired reflow temperature in a very short amount of time.

Induction Soldering Wire of Co-axial With High Frequency Heating Units

Objective To solder center-conductor and shielding braid of wire assemblies to 500 (250) °F(°C).

Material • Customer-supplied assemblies

• Temperature indicating paint

• Flux-cored solder wire

Temperature 500 (250) °F (°C)

Frequency 272 kHz

Equipment DW-UHF-4.5kW induction heating system, equipped with a remote heat station containing two 0.33 μF capacitors. An induction heating coil designed and developed specifically for this application.

Process A multi-turn helical coil is used and temperature-indicating paint is applied to the joint area. The wire assembly is placed over the induction heating coil, and RF power is applied. The time-to-temperature and the heating pattern on the part are established. The next wire assembly is placed on the coil, the assembly is heated and solder wire is fed into the joint. The assembly heats well and reaches 500 °F in 10 seconds.

Results/Benefits • elimination of a crimp process

• more reliable connections are made

• faster process times

Induction Soldering Wire of Co-axial With High Frequency Heating Units

Objective To solder center-conductor and shielding braid of wire assemblies to 500 (250) °F(°C).

Material • Customer-supplied assemblies

• Temperature indicating paint

• Flux-cored solder wire

Temperature 500 (250) °F (°C)

Frequency 272 kHz

Equipment DW-UHF-4.5kW induction heating system, equipped with a remote heat station containing two 0.33 μF capacitors. An induction heating coil designed and developed specifically for this application.

Process A multi-turn helical coil is used and temperature-indicating paint is applied to the joint area. The wire assembly is placed over the induction heating coil, and RF power is applied. The time-to-temperature and the heating pattern on the part are established. The next wire assembly is placed on the coil, the assembly is heated and solder wire is fed into the joint. The assembly heats well and reaches 500 °F in 10 seconds.

Results/Benefits • elimination of a crimp process

• more reliable connections are made

• faster process times

Induction Soldering Wires Onto Connection With IGBT Induction Heating Units

Objective Heat connector assemblies for soldering

Material Device assembly

Tin plated brass terminals Solder paste

Temperature 500°F (260°C) 5-7 seconds

Frequency 360 kHz

Equipment DW-UHF-6kW induction heating system equipped with a remote heat station, containing two 0.66 μF capacitor. An induction heating coil designed and developed specifically for this application.

Process A single turn helical coil is used to heat the solder paste. The connectors are placed inside the induction heating coil and RF power is applied for 5-7 seconds until the connector heats.

Solder paste is applied to the joint in two ways, stick-fed or manually.

Results/Benefits • Compared to using a manual soldering iron, induction heating precisely applies heat to for higher quality solder joints

• This is ideal for integrating with an automated system. By stick- feeding the solder more aesthetically pleasing parts are produced.

Induction Soldering Wires Onto Connection With IGBT Induction Heating Units

Objective Heat connector assemblies for soldering

Material Device assembly

Tin plated brass terminals Solder paste

Temperature 500°F (260°C) 5-7 seconds

Frequency 360 kHz

Equipment DW-UHF-6kW induction heating system equipped with a remote heat station, containing two 0.66 μF capacitor. An induction heating coil designed and developed specifically for this application.

Process A single turn helical coil is used to heat the solder paste. The connectors are placed inside the induction heating coil and RF power is applied for 5-7 seconds until the connector heats.

Solder paste is applied to the joint in two ways, stick-fed or manually.

Results/Benefits • Compared to using a manual soldering iron, induction heating precisely applies heat to for higher quality solder joints

• This is ideal for integrating with an automated system. By stick- feeding the solder more aesthetically pleasing parts are produced.