Ultrasonic welding plastic machine | ultrasonic welder | ultra sonic plastic welding device with Automatic Frequency Chasing

♦Fully automatic frequency chasing, suitable for various sizes of welding die and different design mold, automatic chasing frequency range:±400HZ

Example: 15KHZ ultrasonic, mold frequency in 14.4-15.2KHZ can Automatic frequency traceability

♦The use of CPU computer to monitor various programs is fast and adaptable. The built-in protection system "system protection monitoring" function will respond to the following situations: the temperature is too high and the pressure is too high, which leads to overload. Excessive current of ultrasonic generator, loosening of solder head, transducer or transducer, failure of generator circuit, etc.

♦Automatic tuning enables the ultrasonic generator to automatically track and compensate for changes in welding head frequency. When the temperature is too high, wear on the surface of the welding head or debris on the head, this frequency change will occur.

♦Built-in automatic constant amplitude system. The ultrasonic amplitude can be adjusted from 50% to 100% stepless to adapt to different welding work.

♦With IGBT, the reaction speed is 100 times faster than that of traditional silica gel power tube.

| Model |

1520A |

1526A |

1532A |

1542A |

| Frequency |

15KHz |

| Power |

2000W |

2600W |

3200W |

4200W |

| Voltage |

220V |

| Capacity |

10-20 times/min |

| Driving form |

Pneumatic |

| Stroke Length(Horn Journy) |

75mm |

100mm |

| Output Time |

0.01-9.99S Adjustable |

| Welding Area |

Φ100 |

Φ200 |

Φ300 |

Φ400 |

| Electricity |

AC |

| Control mode |

Numerical control |

| Working air pressure |

1-7 Bar |

| Weight |

90KG |

90KG |

90KG |

120KG |

| Dimensions |

450*750*1100mm |

760*1000*1950mm |

Main Features

1. Ultrasonic Welding Plastic Machine, manually tuning, simple to use and maintenance.

2. Welding by time, delay time, weld time and hold time. Working pressure is adjustable.

4. Precise and high quality imported pneumatic parts

5. High quality transducer and booster.

6. Self-protection: Over-Current, Frequency Deviation, Over-Temperature

7. Available in 4 frequencies – 15 KHz, 20 KHz ,35 KHz and 40 KHz.

8. Quick application changeover, high welding seam strength.

9. Suitable for high cadences and short cycle times.

Ultrasonic Welding Horns/Ultrasonic Welding Molds:

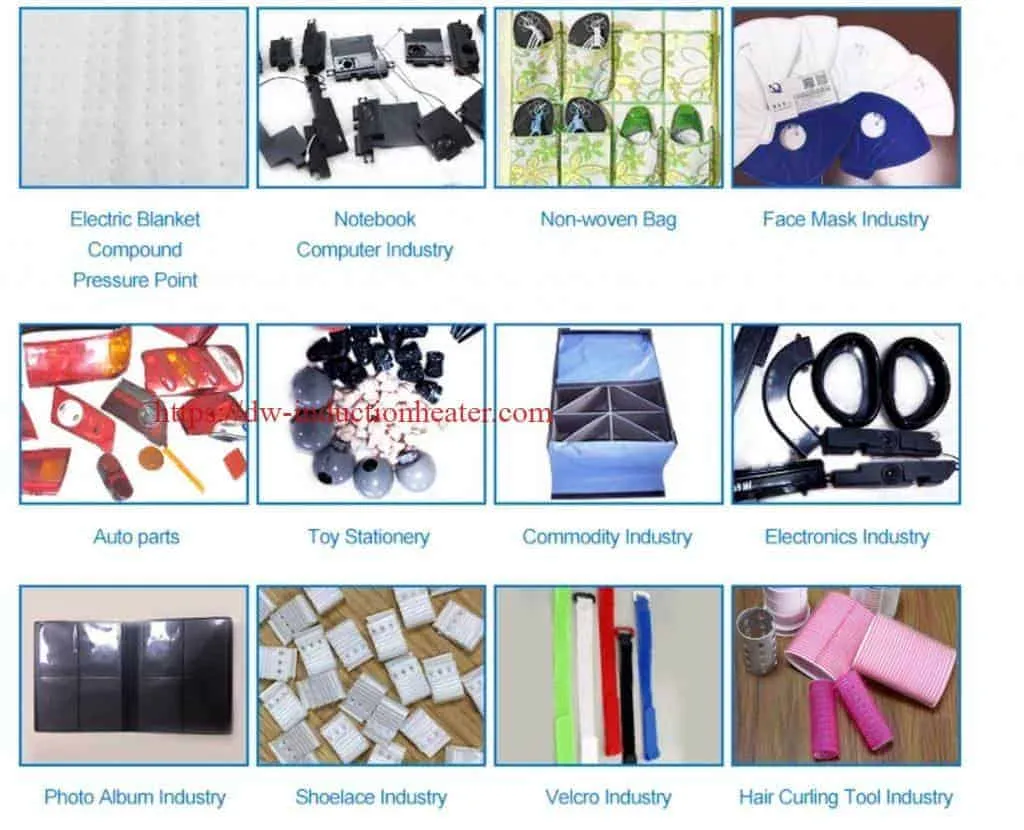

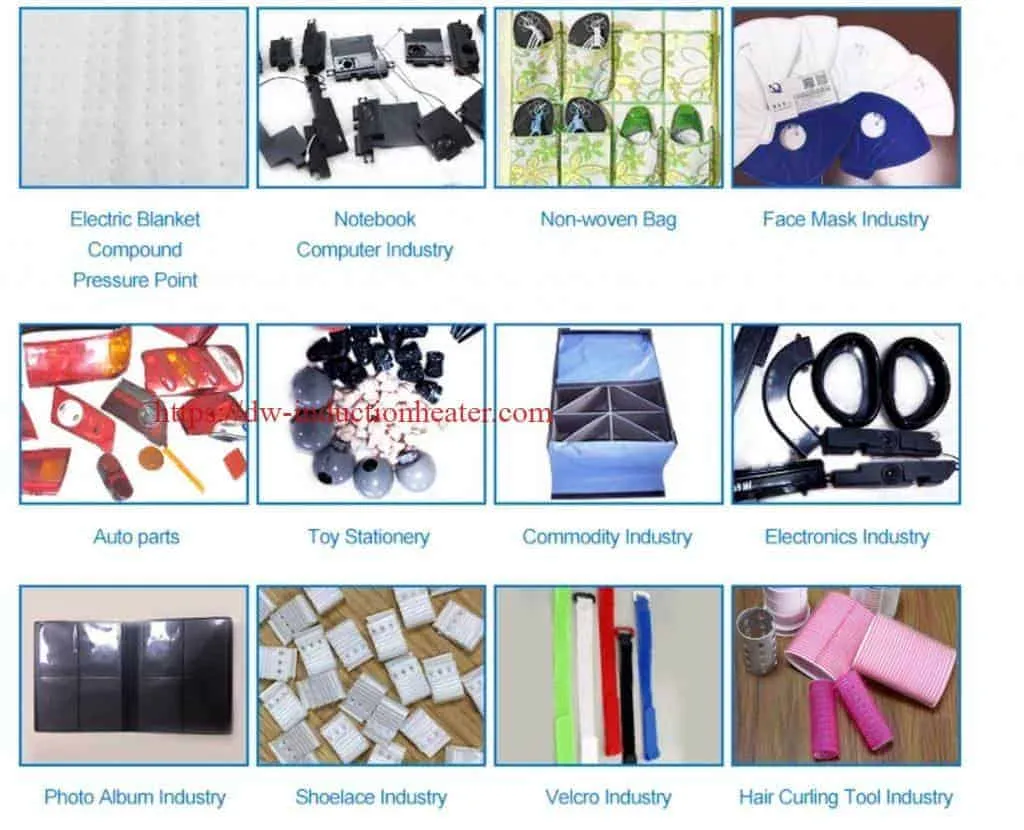

Applications:

Applications:

Ultrasonic welding plastic machine is widely used in automotive industry, electronic industry, medical industry, household appliances, woven apparel, office supplies, packaging industry, toy industry, and so on.

Automotive industry: plastic body parts, car doors, automotive dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, plastic filter for motorcycle , Radiator, brake fluid tank, oil cups, water tanks, fuel tank, air hose, exhaust purifiers, the tray plate, and so on.

Plastic Electronics: prepaid water meters, communications equipment, cordless phones, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connection, Bluetooth devices, and so on.

Stationery: folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges, and so on.

Medical and Daily products: watches, kitchen utensils, oral liquid bottle caps, drip caps, mobile phone accessories, golden soft brush, and daily necessities, handle, security caps, cosmetics bottle, coffee pot, washing machines, air dehumidifiers, Electric irons, electric kettles, vacuum cleaners, speakers, cover and metal face grille and other civil engineering and so on.

Health products: children's products, air mattresses, clothes hangers, gardening supplies, kitchenware sanitary ware, shower, shower head, and so on.

[wpforms id="3947"]

The success of these processes depends upon the assembly’s design, clearance between the surfaces to be joined, cleanliness, process control and the correct selection of equipment needed to perform a repeatable process.

Cleanliness is ordinarily obtained by introducing a flux which covers and dissolves dirt or oxides displacing them from the braze joint.

Many operations are now conducted in a controlled atmosphere with a blanket of inert gas or combination of inert / active gasses to shield the operation and eliminate the need for a flux. These methods have been proven on a wide variety of material and part configurations replacing or complimenting atmosphere furnace technology with a just in time - single piece flow process.

Brazing Filler Materials

Brazing filler metals can come in a variety of forms, shapes, sizes and alloys depending on their intended use. Ribbon, preformed rings, paste, wire and preformed washers are just a few of the shapes and forms alloys that can be found.

The success of these processes depends upon the assembly’s design, clearance between the surfaces to be joined, cleanliness, process control and the correct selection of equipment needed to perform a repeatable process.

Cleanliness is ordinarily obtained by introducing a flux which covers and dissolves dirt or oxides displacing them from the braze joint.

Many operations are now conducted in a controlled atmosphere with a blanket of inert gas or combination of inert / active gasses to shield the operation and eliminate the need for a flux. These methods have been proven on a wide variety of material and part configurations replacing or complimenting atmosphere furnace technology with a just in time - single piece flow process.

Brazing Filler Materials

Brazing filler metals can come in a variety of forms, shapes, sizes and alloys depending on their intended use. Ribbon, preformed rings, paste, wire and preformed washers are just a few of the shapes and forms alloys that can be found. The decision to use a particular alloy and/or shape is largely dependent on the parent materials to be joined, placement during processing and the service environment for which the final product is intended.

Clearance Affects Strength

Clearance between the faying surfaces to be joined determines the amount of braze alloy, capillary action / penetration of the alloy and subsequently the strength of the finished joint. The best fit up condition for conventional silver brazing applications are 0.002 inches (0.050 mm) to 0.005 inches (0.127 mm) total clearance. Aluminum is typically 0.004 inches (0.102 mm) to 0.006 inches (0.153 mm). Larger clearances up to 0.015 inches (0.380 mm) usually lack sufficient capillary action for a successful braze.

Brazing with copper (above 1650°F / 900°C) requires the joint tolerance kept to an absolute minimum and in some cases press fit at ambient temperatures to assure minimum joint tolerances while at the brazing temperature.

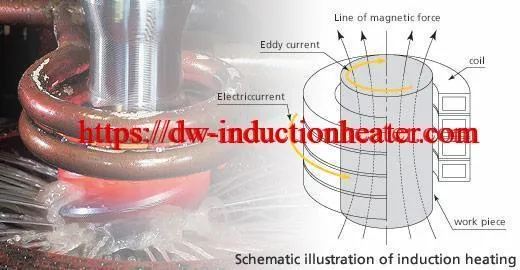

Induction Heating Theory

Induction systems provide a convenient and precise way to quickly and efficiently heat a selected area of an assembly. Consideration must be given to the selection of power supply operating frequency, power density (kilowatt applied per square inch), heating time, and induction coil design to provide the required depth of heating in a specific braze joint.

Induction heating is non-contact heating by means of transformer theory. The power supply is an AC source to the induction coil that becomes the primary windings of the transformer while the part to be heated is the transformer’s secondary. The work piece heats by the base materials’ inherent electrical resistivity to the induced current flowing in the assembly.

The decision to use a particular alloy and/or shape is largely dependent on the parent materials to be joined, placement during processing and the service environment for which the final product is intended.

Clearance Affects Strength

Clearance between the faying surfaces to be joined determines the amount of braze alloy, capillary action / penetration of the alloy and subsequently the strength of the finished joint. The best fit up condition for conventional silver brazing applications are 0.002 inches (0.050 mm) to 0.005 inches (0.127 mm) total clearance. Aluminum is typically 0.004 inches (0.102 mm) to 0.006 inches (0.153 mm). Larger clearances up to 0.015 inches (0.380 mm) usually lack sufficient capillary action for a successful braze.

Brazing with copper (above 1650°F / 900°C) requires the joint tolerance kept to an absolute minimum and in some cases press fit at ambient temperatures to assure minimum joint tolerances while at the brazing temperature.

Induction Heating Theory

Induction systems provide a convenient and precise way to quickly and efficiently heat a selected area of an assembly. Consideration must be given to the selection of power supply operating frequency, power density (kilowatt applied per square inch), heating time, and induction coil design to provide the required depth of heating in a specific braze joint.

Induction heating is non-contact heating by means of transformer theory. The power supply is an AC source to the induction coil that becomes the primary windings of the transformer while the part to be heated is the transformer’s secondary. The work piece heats by the base materials’ inherent electrical resistivity to the induced current flowing in the assembly. Current passing through an electrical conductor (the workpiece) results in heating as current meets resistance to its flow. These losses are low in current flowing through aluminum, copper and their alloys. These non-ferrous materials require additional power to heat than their carbon steel counterpart.

The alternating current tends to flow on the surface. The relationship between the frequency of the alternating current and the depth it penetrates the part is known as the reference depth of heating. Part diameter, material type and wall thickness can have an effect on heating efficiency based on the reference depth.

Current passing through an electrical conductor (the workpiece) results in heating as current meets resistance to its flow. These losses are low in current flowing through aluminum, copper and their alloys. These non-ferrous materials require additional power to heat than their carbon steel counterpart.

The alternating current tends to flow on the surface. The relationship between the frequency of the alternating current and the depth it penetrates the part is known as the reference depth of heating. Part diameter, material type and wall thickness can have an effect on heating efficiency based on the reference depth.

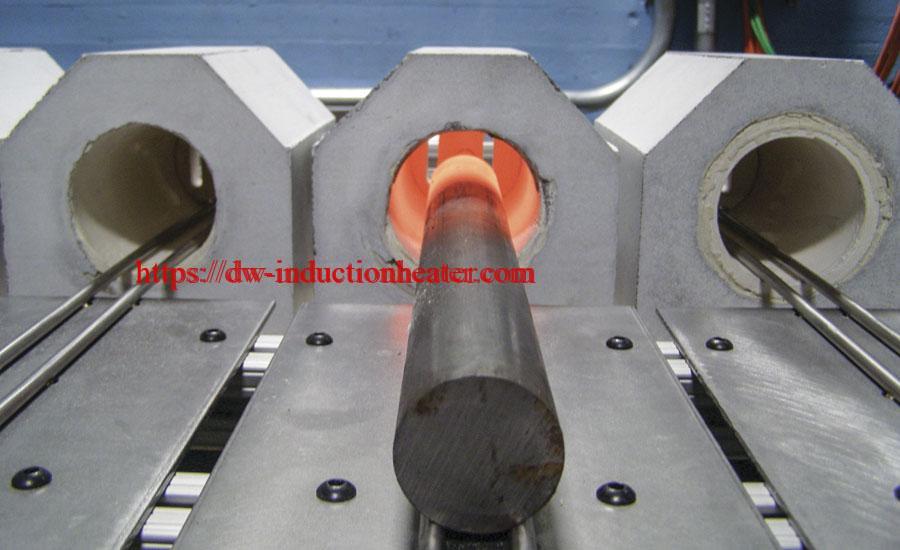

Brazing Steel To Steel Pipe With Induction

Objective: To braze O-ring Face (ORFS) sleeve or male connector to a steel tube.

Material

• Steel tube, 1 inch (2.54 cm) OD

• O-ring Face Seal sleeve and a male connector fittings

• Preform braze rings

• White SureFlow flux

• Steel support mandrel

Temperature 1300 ºF (704 ºC)

Frequency 200 kHz

Equipment

• DW-UHF-20KW induction heating system, equipped with a remote workhead containing two (2) 1.5 μF capacitors (for a total of 0.75 μF).

• An induction heating coil designed and developed specifically for this application.

Process A four-turn 2.75 inch (7.0 cm) ID helical coil is used for heating both the steel tube and the ORFS sleeve or the ORFS male connector. This coil is designed to braze either the sleeve or male connector to the tube. The parts to be brazed are assembled with flux and heated for 45 seconds. Pressure is applied to the tube to make sure it is inserted fully into the fittings as the braze ring flows.

Results/Benefits Advantages :

• Large Inner diameter of coil allows for easy loading and unloading of parts

• With efficient energy coupling of the coil to the fittings overheating is avoided.

Brazing Steel To Steel Pipe With Induction

Objective: To braze O-ring Face (ORFS) sleeve or male connector to a steel tube.

Material

• Steel tube, 1 inch (2.54 cm) OD

• O-ring Face Seal sleeve and a male connector fittings

• Preform braze rings

• White SureFlow flux

• Steel support mandrel

Temperature 1300 ºF (704 ºC)

Frequency 200 kHz

Equipment

• DW-UHF-20KW induction heating system, equipped with a remote workhead containing two (2) 1.5 μF capacitors (for a total of 0.75 μF).

• An induction heating coil designed and developed specifically for this application.

Process A four-turn 2.75 inch (7.0 cm) ID helical coil is used for heating both the steel tube and the ORFS sleeve or the ORFS male connector. This coil is designed to braze either the sleeve or male connector to the tube. The parts to be brazed are assembled with flux and heated for 45 seconds. Pressure is applied to the tube to make sure it is inserted fully into the fittings as the braze ring flows.

Results/Benefits Advantages :

• Large Inner diameter of coil allows for easy loading and unloading of parts

• With efficient energy coupling of the coil to the fittings overheating is avoided.

Induction Brazing Carbide to Steel

Objective: Braze a carbide sleeve to a steel 'T' shank

Material :2.0" (51mm) OD carbide sleeve, 1.0" (25.5mm) high braze joint, 1.5 " (38 mm) steel 'T' , 50% silver braze ring

Temperature: 1292 ºF (700 ºC)

Frequency: 257 kHz

Equipment

• DW-UHF-6KW-I induction heating system, equipped with a remote workhead containing two 0.66μF capacitors for a total of 1.32 μF.

• An induction heating coil designed and developed specifically for this application.

Process A pancake/helical combination coil is used to heat the assembly. The coil design allows easy loading and unloading of the parts without having to rotate them. A few minutes after the start of the heat cycle the heat pattern

normalizes and becomes very uniform. For better joint quality a chamfered groove is machined in the steel shank to locate and seat the braze ring. The braze alloy flows into the joint creating a strong, aesthetic bond. The amount of braze alloy heated each cycle is controlled well by the braze ring.

Results/Benefits Induction heating provides:

• Hands-free brazing which requires no special operator skills for manufacturing

• Precise, even heat is applied and is divided equally between the shank and the carbide. This provides an even flow of the braze alloy as the parts reach brazing temperatures.

Induction Brazing Carbide to Steel

Objective: Braze a carbide sleeve to a steel 'T' shank

Material :2.0" (51mm) OD carbide sleeve, 1.0" (25.5mm) high braze joint, 1.5 " (38 mm) steel 'T' , 50% silver braze ring

Temperature: 1292 ºF (700 ºC)

Frequency: 257 kHz

Equipment

• DW-UHF-6KW-I induction heating system, equipped with a remote workhead containing two 0.66μF capacitors for a total of 1.32 μF.

• An induction heating coil designed and developed specifically for this application.

Process A pancake/helical combination coil is used to heat the assembly. The coil design allows easy loading and unloading of the parts without having to rotate them. A few minutes after the start of the heat cycle the heat pattern

normalizes and becomes very uniform. For better joint quality a chamfered groove is machined in the steel shank to locate and seat the braze ring. The braze alloy flows into the joint creating a strong, aesthetic bond. The amount of braze alloy heated each cycle is controlled well by the braze ring.

Results/Benefits Induction heating provides:

• Hands-free brazing which requires no special operator skills for manufacturing

• Precise, even heat is applied and is divided equally between the shank and the carbide. This provides an even flow of the braze alloy as the parts reach brazing temperatures.

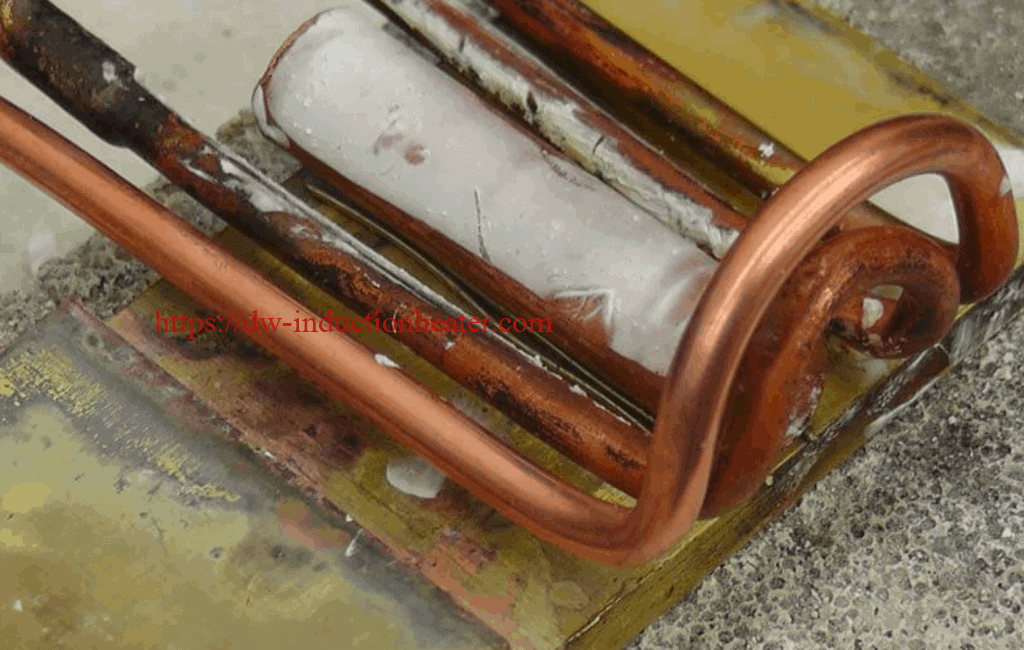

Brazing Copper Bars with Induction

Objective: To braze bus bar assemblies together

Material: • 2 copper bus bars 6" (152.4mm) wide, 2' (609.6mm)long, 2

copper bars 6"(152.4mm) wide, 18" (457.2)long & 3/8" (9.65mm) thick • braze shim preforms and white flux

Temperature: 1292 ºF (700 ºC)

Frequency: 80 kHz

Equipment • DW-UHF-60KW induction heating system, equipped with a

remote workhead containing eight 1.0 μF capacitors for a total of 2.0 μF.

• An induction heating coil, designed and developed specifically for this application

Process: A three-turn helical coil is used to heat the assembly. Three braze shim preforms are placed between the plates and white flux is applied to the assembly. It is heated for 5 minutes to evenly flow the braze alloy. A high current capable, aesthetic looking braze zone is produced.

Results/Benefits Induction heating provides:

• Consistently produced, quality parts

• Heat into the part that is divided equally between the copper pieces, allowing for even flow and consistent use of braze

• Hands-free operation that doesn't require skilled operators

Brazing Copper Bars with Induction

Objective: To braze bus bar assemblies together

Material: • 2 copper bus bars 6" (152.4mm) wide, 2' (609.6mm)long, 2

copper bars 6"(152.4mm) wide, 18" (457.2)long & 3/8" (9.65mm) thick • braze shim preforms and white flux

Temperature: 1292 ºF (700 ºC)

Frequency: 80 kHz

Equipment • DW-UHF-60KW induction heating system, equipped with a

remote workhead containing eight 1.0 μF capacitors for a total of 2.0 μF.

• An induction heating coil, designed and developed specifically for this application

Process: A three-turn helical coil is used to heat the assembly. Three braze shim preforms are placed between the plates and white flux is applied to the assembly. It is heated for 5 minutes to evenly flow the braze alloy. A high current capable, aesthetic looking braze zone is produced.

Results/Benefits Induction heating provides:

• Consistently produced, quality parts

• Heat into the part that is divided equally between the copper pieces, allowing for even flow and consistent use of braze

• Hands-free operation that doesn't require skilled operators

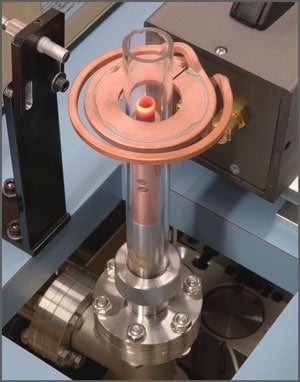

Induction Brazing Stainless Steel

Objective

1st Application: Braze hub assembly to needle holder

2nd Application: Braze Large tube to ring joint

Material: 1st Application: Steel hub assembly and needle 0.1" dia(2.5mm) 2nd Application: Steel tube 1" OD (25.4 mm) and ring

Temperature 1400 ºF (760 ºC)

Frequency 325 kHz for brazing the needle 0.1" dia (2.5mm) 259 kHz for brazing ring to steel tube 1" OD (25.4 mm)

Equipment • DW-UHF-4.5KW induction heating system, equipped with a

remote workhead containing two .66 μF capacitors for a total of 1.32 μF

• Two induction heating coils, designed and developed specifically for this dual application.

Process 1st application: A two-turn helical coil is used to heat the hub assembly on the needle holder for 10 seconds. The coil concentrates the heat on the hub only, as the needle is magnetic and the hub material is non-magnetic. A small

diameter braze wire is used to supply sufficient amount of braze creating a strong aesthetically pleasing bond. 2nd application: A three-turn helical coil is used for brazing the large tube to the ring joint for 3-5 minutes. A braze ring is

used to supply sufficient amount of braze to create an aesthetically pleasing bond.

Results/Benefits Induction heating provides:

• Even distribution of heating, provides even flow of braze alloy for an aesthetically pleasing bond

• System flexibility allows for the same unit to be used for two different applications which is a cost saving.

Induction Brazing Stainless Steel

Objective

1st Application: Braze hub assembly to needle holder

2nd Application: Braze Large tube to ring joint

Material: 1st Application: Steel hub assembly and needle 0.1" dia(2.5mm) 2nd Application: Steel tube 1" OD (25.4 mm) and ring

Temperature 1400 ºF (760 ºC)

Frequency 325 kHz for brazing the needle 0.1" dia (2.5mm) 259 kHz for brazing ring to steel tube 1" OD (25.4 mm)

Equipment • DW-UHF-4.5KW induction heating system, equipped with a

remote workhead containing two .66 μF capacitors for a total of 1.32 μF

• Two induction heating coils, designed and developed specifically for this dual application.

Process 1st application: A two-turn helical coil is used to heat the hub assembly on the needle holder for 10 seconds. The coil concentrates the heat on the hub only, as the needle is magnetic and the hub material is non-magnetic. A small

diameter braze wire is used to supply sufficient amount of braze creating a strong aesthetically pleasing bond. 2nd application: A three-turn helical coil is used for brazing the large tube to the ring joint for 3-5 minutes. A braze ring is

used to supply sufficient amount of braze to create an aesthetically pleasing bond.

Results/Benefits Induction heating provides:

• Even distribution of heating, provides even flow of braze alloy for an aesthetically pleasing bond

• System flexibility allows for the same unit to be used for two different applications which is a cost saving.

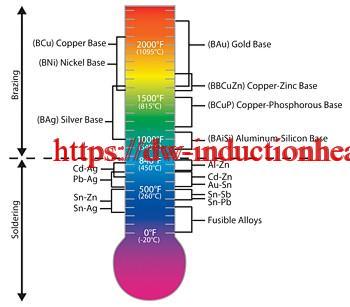

Induction Brazing & Soldering Principle

Brazing and soldering are processes of joining similar or dissimilar materials using a compatible a filler material. Filler metals include lead, tin, copper, silver, nickel and their alloys. Only the alloy melts and solidifies during these processes to join the work piece base materials. The filler metal is pulled into the joint by capillary action. Soldering processes are conducted below 840°F (450°C) while brazing applications are conducted at temperatures above 840°F (450°C) up to 2100°F (1150°C).

The success of these processes depends upon the assembly's design, clearance between the surfaces to be joined, cleanliness, process control and the correct selection of equipment needed to perform a repeatable process.

Cleanliness is ordinarily obtained by introducing a flux which covers and dissolves dirt or oxides displacing them from the braze joint.

Many operations are now conducted in a controlled atmosphere with a blanket of inert gas or combination of inert / active gasses to shield the operation and eliminate the need for a flux. These methods have been proven on a wide variety of material and part configurations replacing or complimenting atmosphere furnace technology with a just in time - single piece flow process.

Brazing Filler Materials

Brazing filler metals can come in a variety of forms, shapes, sizes and alloys depending on their intended use. Ribbon, preformed rings, paste, wire and preformed washers are just a few of the shapes and forms alloys that can be found. The decision to use a particular alloy and/or shape is largely dependent on the parent materials to be joined, placement during processing and the service environment for which the final product is intended.

Induction Brazing & Soldering Principle

Brazing and soldering are processes of joining similar or dissimilar materials using a compatible a filler material. Filler metals include lead, tin, copper, silver, nickel and their alloys. Only the alloy melts and solidifies during these processes to join the work piece base materials. The filler metal is pulled into the joint by capillary action. Soldering processes are conducted below 840°F (450°C) while brazing applications are conducted at temperatures above 840°F (450°C) up to 2100°F (1150°C).

The success of these processes depends upon the assembly's design, clearance between the surfaces to be joined, cleanliness, process control and the correct selection of equipment needed to perform a repeatable process.

Cleanliness is ordinarily obtained by introducing a flux which covers and dissolves dirt or oxides displacing them from the braze joint.

Many operations are now conducted in a controlled atmosphere with a blanket of inert gas or combination of inert / active gasses to shield the operation and eliminate the need for a flux. These methods have been proven on a wide variety of material and part configurations replacing or complimenting atmosphere furnace technology with a just in time - single piece flow process.

Brazing Filler Materials

Brazing filler metals can come in a variety of forms, shapes, sizes and alloys depending on their intended use. Ribbon, preformed rings, paste, wire and preformed washers are just a few of the shapes and forms alloys that can be found. The decision to use a particular alloy and/or shape is largely dependent on the parent materials to be joined, placement during processing and the service environment for which the final product is intended.

Brazing Carbide To Steel Shank with Induction

Objective :Brazing carbide teeth to a steel jaw in less than 5 minutes

Material: Steel pipe jaw, 0.5” (12.7mm) dia, 1.25” (31.75mm) long, 0.25”(6.35mm) thick carbide teeth, black flux and silver copper braze shims

Temperature: 1292ºF (700ºC)

Frequency: 300kHz

Equipment • DW-UHF-10kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process: A two turn rectangular helical coil is used to heat the carbide and steel to 1292ºF (700ºC) for 4 to 5 minutes. Three braze shims control the amount of braze and the even heat allows for

a good flow of braze creating an aesthetically pleasing bond.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Consistent, repeatable aesthetically pleasing brazes

• Even distribution of heating

Brazing Carbide To Steel Shank with Induction

Objective :Brazing carbide teeth to a steel jaw in less than 5 minutes

Material: Steel pipe jaw, 0.5” (12.7mm) dia, 1.25” (31.75mm) long, 0.25”(6.35mm) thick carbide teeth, black flux and silver copper braze shims

Temperature: 1292ºF (700ºC)

Frequency: 300kHz

Equipment • DW-UHF-10kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process: A two turn rectangular helical coil is used to heat the carbide and steel to 1292ºF (700ºC) for 4 to 5 minutes. Three braze shims control the amount of braze and the even heat allows for

a good flow of braze creating an aesthetically pleasing bond.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Consistent, repeatable aesthetically pleasing brazes

• Even distribution of heating

Brazing Automotive Parts With Induction

Objective: To braze a automotive steel tube to a steel “T” fitting

Material 1” (25.4mm) diameter steel tubing, steel fitting, braze slug and black flux

Temperature 1400ºF (760ºC)

Frequency 200 kHz

Equipment • DW-UHF-10 kW induction heating system, equipped with a remote workhead containing two 1.0μF capacitors for a total of 0.5 μF

• An induction heating coil designed and developed specifically for this application.

Process A four turn split helical coil is used to heat the steel assembly to 1400ºF (760ºC) for 85 seconds. The coil design allows for the steel fitting to expand away from the steel tube which allows braze to flow through the joint. The amount of braze alloy is controlled by the braze slug allowing for an aesthetically pleasing joint.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Precise and uniform distribution of heating

• The collection of flux on the coil is reduced due to efficient coil design.

Brazing Automotive Parts With Induction

Objective: To braze a automotive steel tube to a steel “T” fitting

Material 1” (25.4mm) diameter steel tubing, steel fitting, braze slug and black flux

Temperature 1400ºF (760ºC)

Frequency 200 kHz

Equipment • DW-UHF-10 kW induction heating system, equipped with a remote workhead containing two 1.0μF capacitors for a total of 0.5 μF

• An induction heating coil designed and developed specifically for this application.

Process A four turn split helical coil is used to heat the steel assembly to 1400ºF (760ºC) for 85 seconds. The coil design allows for the steel fitting to expand away from the steel tube which allows braze to flow through the joint. The amount of braze alloy is controlled by the braze slug allowing for an aesthetically pleasing joint.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Precise and uniform distribution of heating

• The collection of flux on the coil is reduced due to efficient coil design.

Brazing Golf Ball With Induction

Objective: Heating steel golf ball mold to brazing dimple insert

Material: Golf ball mold 2” in diameter, braze flux paste, dimple insert

Temperature: 1400 ºF (760 ºC)

Frequency: 260 kHz

Equipment • DW-UHF-10kW induction heating system, equipped with a remote workhead containing two 0.5μF capacitors for a total of 0.25 μF

• An induction heating coil designed and developed specifically for this application.

Process A four turn helical coil is used to heat the golf ball mold to 1400ºF (760 ºC) in 3 minutes and the dimple insert is brazed to the mold with braze flux paste.

Results/Benefits Induction heating provides:

• No flame process.

• Reliable, repeatable, non contact and energy efficient heat in minimal time.

• Even distribution of heating.

Brazing Golf Ball With Induction

Objective: Heating steel golf ball mold to brazing dimple insert

Material: Golf ball mold 2” in diameter, braze flux paste, dimple insert

Temperature: 1400 ºF (760 ºC)

Frequency: 260 kHz

Equipment • DW-UHF-10kW induction heating system, equipped with a remote workhead containing two 0.5μF capacitors for a total of 0.25 μF

• An induction heating coil designed and developed specifically for this application.

Process A four turn helical coil is used to heat the golf ball mold to 1400ºF (760 ºC) in 3 minutes and the dimple insert is brazed to the mold with braze flux paste.

Results/Benefits Induction heating provides:

• No flame process.

• Reliable, repeatable, non contact and energy efficient heat in minimal time.

• Even distribution of heating.

Induction Brazing Stainless Steel Car grill

Objective Braze an end plug on a stainless steel car grill before powder coating application

Material Stainless steel car grill 0.5” x 0.19” (12.7mm x 4.8mm), end plugs and braze ring

Temperature: 1350 ºF (732°C)

Frequency:400 kHz

Equipment •DW-UHF-6kW-III induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn square shaped helical coil is used to heat the end of the grill. End plugs are inserted into the grill and the assembly is inserted into the coil for 30 seconds. The braze flows to create a neat and clean leak-proof joint.

Results/Benefits Induction heating provides:

• Rapid localized heat to joint area only

• Minimized oxidation reduces cleaning time

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

Induction Brazing Stainless Steel Car grill

Objective Braze an end plug on a stainless steel car grill before powder coating application

Material Stainless steel car grill 0.5” x 0.19” (12.7mm x 4.8mm), end plugs and braze ring

Temperature: 1350 ºF (732°C)

Frequency:400 kHz

Equipment •DW-UHF-6kW-III induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A three turn square shaped helical coil is used to heat the end of the grill. End plugs are inserted into the grill and the assembly is inserted into the coil for 30 seconds. The braze flows to create a neat and clean leak-proof joint.

Results/Benefits Induction heating provides:

• Rapid localized heat to joint area only

• Minimized oxidation reduces cleaning time

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

Brazing Stainless Steel To Copper With Induction Heater

Objective Braze a stainless steel braided hose to copper elbows for a braided hose assembly.

Material Stainless steel braided hose 3/8” (9.5mm) OD, copper elbow 1/4” (6.3mm) OD, braze preform rings and black flux

Temperature 1400 ºF (760 ºC)

Frequency 300 kHz

Equipment • DW-UHF-6kW-III induction heating system, equipped with a remote workhead containing two 0.33μF capacitors for a total of 0.66μF

• An induction heating coil designed and developed specifically for this application.

Process: A two turn helical coil is used to heat the braided hose assembly. Braze rings are placed at the joint on the copper elbow and flux is applied to the entire surface of the assembly.

The assembly is placed in the heating coil and the braze flows within 30-45 seconds. This creates a liquid and gas tight braze between the copper and stainless steel braided hose.

Results/Benefits Induction heating provides:

• Liquid and gas-tight braze

• Energy efficient heat in a minimal amount of time

• Controllable braze flow through the use of braze rings

• Even distribution of heating

Brazing Stainless Steel To Copper With Induction Heater

Objective Braze a stainless steel braided hose to copper elbows for a braided hose assembly.

Material Stainless steel braided hose 3/8” (9.5mm) OD, copper elbow 1/4” (6.3mm) OD, braze preform rings and black flux

Temperature 1400 ºF (760 ºC)

Frequency 300 kHz

Equipment • DW-UHF-6kW-III induction heating system, equipped with a remote workhead containing two 0.33μF capacitors for a total of 0.66μF

• An induction heating coil designed and developed specifically for this application.

Process: A two turn helical coil is used to heat the braided hose assembly. Braze rings are placed at the joint on the copper elbow and flux is applied to the entire surface of the assembly.

The assembly is placed in the heating coil and the braze flows within 30-45 seconds. This creates a liquid and gas tight braze between the copper and stainless steel braided hose.

Results/Benefits Induction heating provides:

• Liquid and gas-tight braze

• Energy efficient heat in a minimal amount of time

• Controllable braze flow through the use of braze rings

• Even distribution of heating