Aluminium Scraps Recycling Melting

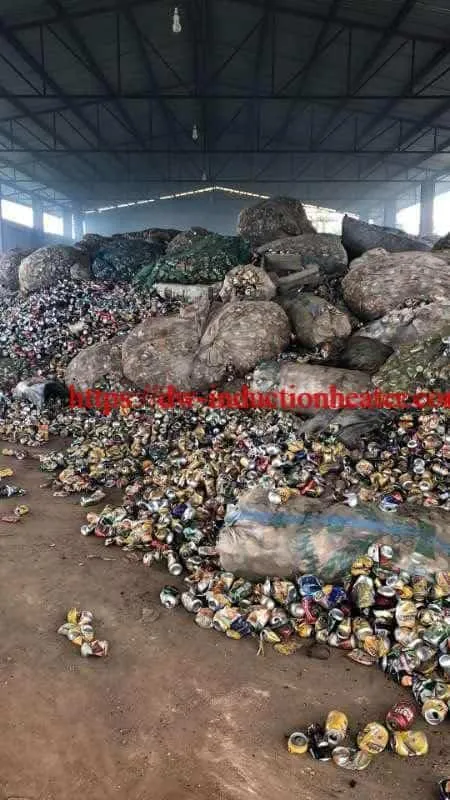

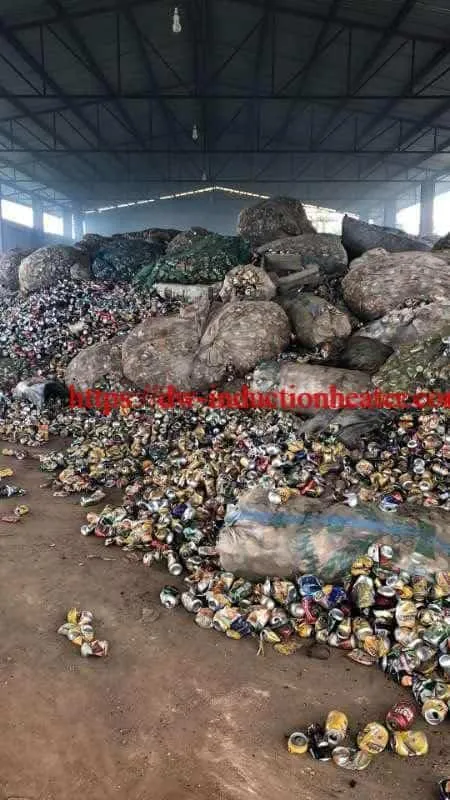

Aluminium Scraps Recycling Melting is the process by which scraps aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy-intensive than creating new aluminium through the electrolysis of aluminium oxide (Al2O3), which must first be mined from bauxite ore and then refined using the Bayer process. Recycling scraps aluminium requires only 5% of the energy used to make new aluminium from the raw ore. For this reason, approximately 36% of all aluminium produced in the United States comes from old recycled scrap. Used beverage containers are the largest component of processed aluminum scraps, and most of it is manufactured back into aluminium cans.

HLQ Induction Equipment Co provides the leading

Aluminium Scraps Recycling Melting Furnace for recycling aluminium Scraps/cans/ingots and dross for industry aluminum recycling filed.

Operation Steps:

- A Aluminum scraps/ingots/cans recycling furnace operator will place aluminum parts or aluminum ingot/scrap as a charge in the induction melting aluminum recycling furnace and start the furnace to begin the melting process. Adding more aluminum charge this process is advisable as molten aluminum transmits the heat better.

- When temperature of the aluminum reaches 1220.66°F it turns to liquid. Any residue from the coating and paint from the cans will float on the surface. This byproduct is called dross and can be skimmed by a steel ladle. This needs to cool before it can be disposed off safely.

- Next, the crucible (furnace) will pour out pure aluminum. Usually, Hydraulic tilting mechanism provided to pour large quantities of liquid metals.

- Finally, with care, the molten aluminum will be poured into mould to cool down and then slide out for use.

Advantages of induction aluminum scraps recycling furnace:

1, save energy and reduce the environmental temperature

Original diesel furnace workshop on pollution, but also the auxiliary exhaust pipeline, inside and outside the furnace heat has a large number of distribution in the workshop, resulting in high temperature workshop. So is the original furnace condition, most escapes to the air, there is heat conduction loss, the production of large power consumption, increase the cost of production. At the same time, the ambient temperature increases. The electromagnetic induction heating process, the heating element is through magnetic field heating, in order to reduce the loss of heat conduction, fast heating, melting rapidly, thus reducing energy consumption. Reduce electricity consumption. After the comparison of the experimental test and modification, the power saving effect is 20%-40%.

2, rapid heating, temperature control accurate real-time

Electromagnetic induction heating method is through the magnetic field lines make heating rapid heating, the rapid melting Aluminum Alloy. The temperature control is real-time and accurate, which improves the quality of the product and improves the production efficiency!

3 and long service life, simple maintenance

The traditional electric melting induction furnace heating method is to use resistance wire heating, resistance wire in the high temperature environment for a long time in the use of oxidation will result in reducing its service life, high maintenance costs. The electromagnetic heating coil is made of insulating material and high temperature wire, so the service life is long and without any maintenance.

4, power

Electromagnetic induction heating with the development and maturity of the technology, the production process and technology of components, software, such as reliable protection of the current power can be 2-200KW.

5, safe

The utility model adopts the electromagnetic induction heating, which can reduce the surface temperature of the machine, and the human body can be safely touched, so as to avoid the occurrence of burn and scald accidents caused by the traditional heating mode and protect the production safety of the employees.

Features

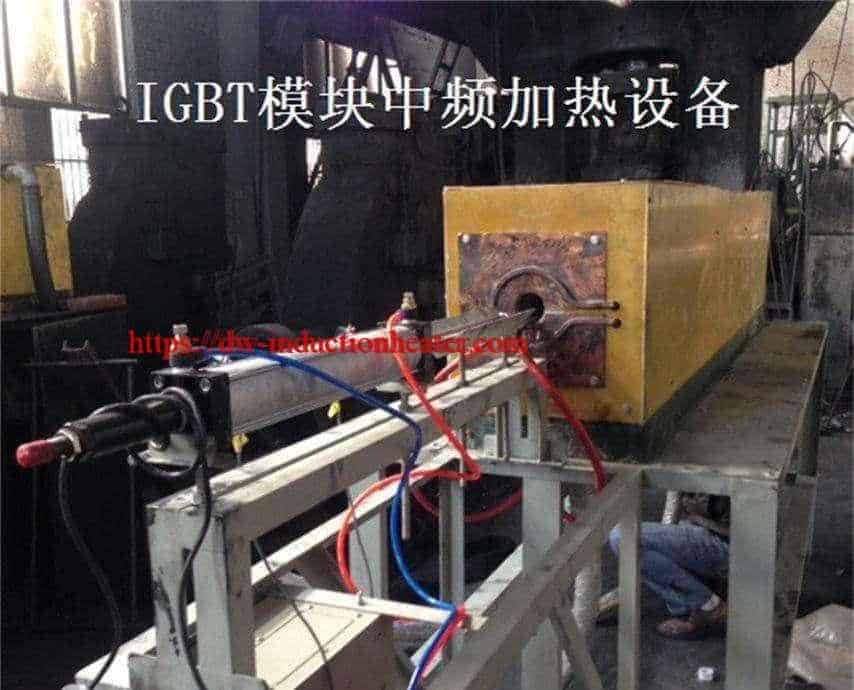

1 energy saving and environmental protection, Germany's IGBT power devices, high reliability, stable operation and low maintenance costs.

2) the frequency of the digital phase locked loop tracking, automatic load impedance matching.

3 power closed-loop control, to avoid the temperature change caused by the power down.

4) over voltage, under voltage, lack of phase, over current, over heat protection, real-time display of the parameters, fault diagnosis and alarm; leakage automatic alarm, cut off the power supply and the working state of real-time display.

5) PID heating control system, uniform heating temperature, prevent molten aluminum temperature drift, burning less, homogeneous metal components to improve the product qualification rate.

6 (LED) digital temperature controller, measuring and controlling the temperature accuracy of up to 3 degrees centigrade, the quality of aluminum soup is good, the melting temperature rises quickly, the furnace temperature is easy to control, the production efficiency is high;

7) the integral structure of polycrystalline mullite fibers of furnace, small volume, good insulation property, low energy consumption, high efficiency, temperature above 1200 degrees, long service life;

8. The operation is simple and the power can be adjusted with the work;

9 (100%) load duration, maximum power, to ensure the operation of 24 hours.

Melting capacity of SMJD series electric aluminum scraps recycling melting furnace:

| Type |

Input Power |

Melting Capacity |

Max Temperature |

| steel, stainless steel |

copper, gold, silver (scrap, Slag) |

aluminum, aluminum alloy,

Aluminum scrap, Aluminum slag, pop can |

1800℃ |

| SMJD-463 |

60 KW |

200 KG |

500 KG |

200 KG |

| SMJD-480 |

60 KW |

150 KG |

500 KG |

150 KG |

| SMJD-580 |

80 KW |

200 KG |

600 KG |

200 KG |

| SMJD-600 |

60 KW |

230 KG |

560 KG |

230 KG |

| SMJD-900 |

120 KW |

300 KG |

900 KG |

300 KG |

| SMJD-905 |

80 KW |

300 KG |

900 KG |

300 KG |

| SMJD-1250 |

80 KW |

400 KG |

1200 KG |

400 KG |

| SMJD-1250 |

120 KW |

450 KG |

1350 KG |

450 KG |

| SMJD-1500 |

120 KW |

500 KG |

1500 KG |

500 KG |

| SMJD-1550 |

120 KW |

520 KG |

1560 KG |

520 KG |

| SMJD-1700 |

160KW |

600 KG |

1700 KG |

600 KG |

| SMJD-2300 |

160KW |

800 KG |

2000 KG |

800 KG |

| SMJD-3100 |

200KW |

1200 KG |

3000 KG |

1200 KG |

[pdf-embedder url="https://dw-inductionheater.com/wp-content/uploads/2018/10/SMJD-melting-aluminum-furnace-parameter.pdf" title="SMJD melting aluminum furnace parameter"]

[pdf-embedder url="https://dw-inductionheater.com/wp-content/uploads/2019/03/Aluminium-Scraps-Recycling-Melting-Process.pdf" title="Aluminium Scraps Recycling Melting Process"]

https://dw-inductionheater.com/aluminium-scraps-recycling-melting-and-process.html?feed_id=242822&_unique_id=6628befa46bf4

Induction Brazing Basics for jointing copper,silver,brazing,steel and stainless steel,etc.

Induction Brazing uses heat and filler metal to join metals. Once melted, the filler flows between close-fitting base metals (the pieces being joined) by capillary action. The molten filler interacts with a thin layer of the base metal to form a strong, leak-proof joint. Different heat sources can be used for brazing: induction and resistance heaters, ovens, furnaces, torches, etc. There are three common brazing methods: capillary, notch and moulding. Induction brazing is concerned solely with the first of these. Having the correct gap between the base metals is crucial. A too-large gap can minimize the capillary force and lead to weak joints and porosity. Thermal expansion means gaps have to be calculated for metals at brazing, not room, temperatures. Optimum spacing is typically 0.05 mm – 0.1 mm. Before you braze Brazing is hassle-free. But some questions should be investigated — and answered — in order to assure successful, cost-effective joining. For instance: How suitable are the base metals for brazing; what’s the best coil design for specific time and quality demands; should the brazing be manual or automatic?

Induction Brazing Basics for jointing copper,silver,brazing,steel and stainless steel,etc.

Induction Brazing uses heat and filler metal to join metals. Once melted, the filler flows between close-fitting base metals (the pieces being joined) by capillary action. The molten filler interacts with a thin layer of the base metal to form a strong, leak-proof joint. Different heat sources can be used for brazing: induction and resistance heaters, ovens, furnaces, torches, etc. There are three common brazing methods: capillary, notch and moulding. Induction brazing is concerned solely with the first of these. Having the correct gap between the base metals is crucial. A too-large gap can minimize the capillary force and lead to weak joints and porosity. Thermal expansion means gaps have to be calculated for metals at brazing, not room, temperatures. Optimum spacing is typically 0.05 mm – 0.1 mm. Before you braze Brazing is hassle-free. But some questions should be investigated — and answered — in order to assure successful, cost-effective joining. For instance: How suitable are the base metals for brazing; what’s the best coil design for specific time and quality demands; should the brazing be manual or automatic?

At DAWEI Induction we answer these and other key points before suggesting a brazing solution. Focus on flux Base metals must usually be coated with a solvent known as flux before they are brazed. Flux cleans the base metals, prevents new oxidation, and wets the brazing area prior to brazing. It is crucial to apply sufficient flux; too little and the flux may become

saturated with oxides and lose its ability to protect the base metals. Flux is not always needed. Phosphorous-bearing filler

can be used to braze copper alloys, brass and bronze. Flux-free brazing is also possible with active atmospheres and vacuums, but the brazing must then be performed in a controlled atmosphere chamber. Flux must normally be removed from the part once the metal filler has solidified. Different removal methods are used, the most common being water quenching, pickling and wire brushing.

https://dw-inductionheater.com/induction-brazing-basics.html?feed_id=243828&_unique_id=663150791ff90

At DAWEI Induction we answer these and other key points before suggesting a brazing solution. Focus on flux Base metals must usually be coated with a solvent known as flux before they are brazed. Flux cleans the base metals, prevents new oxidation, and wets the brazing area prior to brazing. It is crucial to apply sufficient flux; too little and the flux may become

saturated with oxides and lose its ability to protect the base metals. Flux is not always needed. Phosphorous-bearing filler

can be used to braze copper alloys, brass and bronze. Flux-free brazing is also possible with active atmospheres and vacuums, but the brazing must then be performed in a controlled atmosphere chamber. Flux must normally be removed from the part once the metal filler has solidified. Different removal methods are used, the most common being water quenching, pickling and wire brushing.

https://dw-inductionheater.com/induction-brazing-basics.html?feed_id=243828&_unique_id=663150791ff90

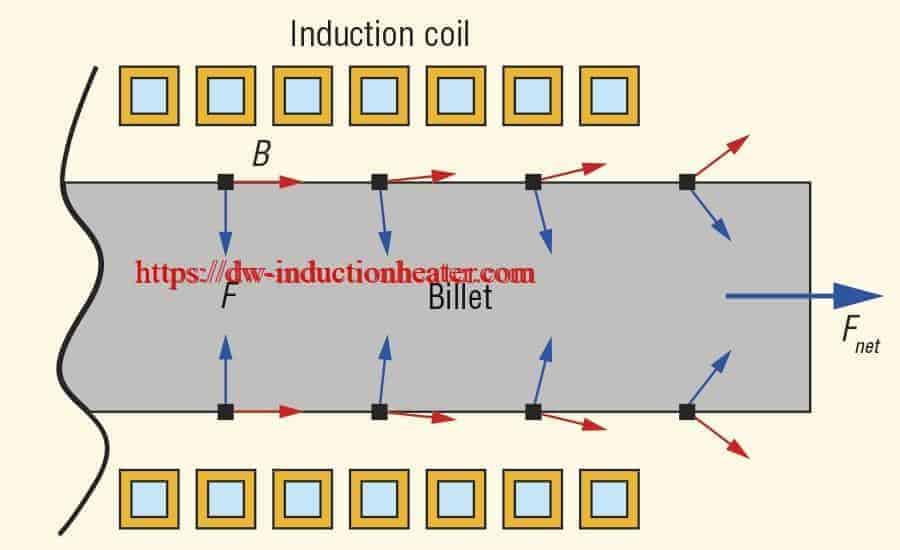

A source of high frequency electricity is used to drive a large alternating current through a induction coil. This induction heating coil is known as the work coil. See the picture opposite.

The passage of current through this induction heating coil generates a very intense and rapidly changing magnetic field in the space within the work coil. The workpiece to be heated is placed within this intense alternating magnetic field.

Depending on the nature of the workpiece material, a number of things happen...

The alternating magnetic field induces a current flow in the conductive workpiece. The arrangement of the work coil and the workpiece can be thought of as an electrical transformer. The work coil is like the primary where electrical energy is fed in, and the workpiece is like a single turn secondary that is short-circuited. This causes tremendous currents to flow through the workpiece. These are known as eddy currents.

In addition to this, the high frequency used in

A source of high frequency electricity is used to drive a large alternating current through a induction coil. This induction heating coil is known as the work coil. See the picture opposite.

The passage of current through this induction heating coil generates a very intense and rapidly changing magnetic field in the space within the work coil. The workpiece to be heated is placed within this intense alternating magnetic field.

Depending on the nature of the workpiece material, a number of things happen...

The alternating magnetic field induces a current flow in the conductive workpiece. The arrangement of the work coil and the workpiece can be thought of as an electrical transformer. The work coil is like the primary where electrical energy is fed in, and the workpiece is like a single turn secondary that is short-circuited. This causes tremendous currents to flow through the workpiece. These are known as eddy currents.

In addition to this, the high frequency used in

[embed]https://www.youtube.com/watch?v=fD89qj5t9Ig[/embed]

[embed]https://www.youtube.com/watch?v=fD89qj5t9Ig[/embed]

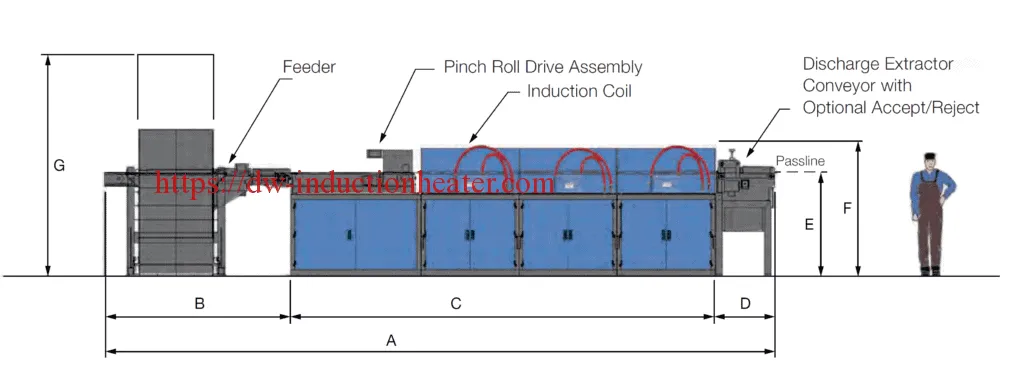

HLQ MYD series Pipeline Coating Systems

Renowned across the gas and pipeline processing industries, HLQ MYD series Pipeline and Tube Coating Systems are globally acknowledged for their ability to provide the highest levels of quality and performance in pipe coating, heat treatment and preparation applications. HLQ MYD series offshore systems revolve around field joint processing, with a series of induction systems utilized for heating and coating of field joints on pipe laying vessels.

HLQ MYD series Pipeline Coating Systems

Renowned across the gas and pipeline processing industries, HLQ MYD series Pipeline and Tube Coating Systems are globally acknowledged for their ability to provide the highest levels of quality and performance in pipe coating, heat treatment and preparation applications. HLQ MYD series offshore systems revolve around field joint processing, with a series of induction systems utilized for heating and coating of field joints on pipe laying vessels.

Aluminium Scraps Recycling Melting is the process by which scraps aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy-intensive than creating new aluminium through the electrolysis of aluminium oxide (Al2O3), which must first be mined from bauxite ore and then refined using the Bayer process. Recycling scraps aluminium requires only 5% of the energy used to make new aluminium from the raw ore. For this reason, approximately 36% of all aluminium produced in the United States comes from old recycled scrap. Used beverage containers are the largest component of processed aluminum scraps, and most of it is manufactured back into aluminium cans.

HLQ Induction Equipment Co provides the leading Aluminium Scraps Recycling Melting Furnace for recycling aluminium Scraps/cans/ingots and dross for industry aluminum recycling filed.

Operation Steps:

Aluminium Scraps Recycling Melting is the process by which scraps aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy-intensive than creating new aluminium through the electrolysis of aluminium oxide (Al2O3), which must first be mined from bauxite ore and then refined using the Bayer process. Recycling scraps aluminium requires only 5% of the energy used to make new aluminium from the raw ore. For this reason, approximately 36% of all aluminium produced in the United States comes from old recycled scrap. Used beverage containers are the largest component of processed aluminum scraps, and most of it is manufactured back into aluminium cans.

HLQ Induction Equipment Co provides the leading Aluminium Scraps Recycling Melting Furnace for recycling aluminium Scraps/cans/ingots and dross for industry aluminum recycling filed.

Operation Steps: