2023年8月31日星期四

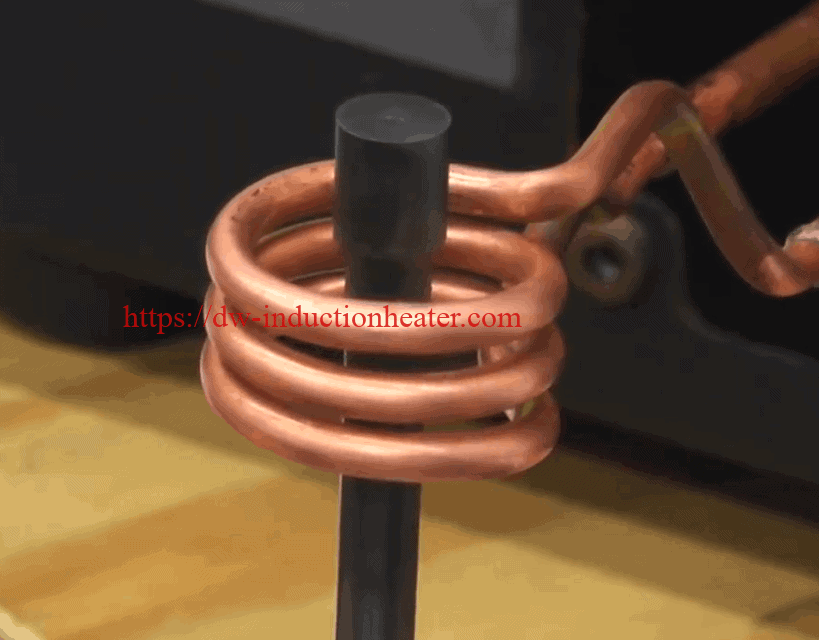

Induction Brazing Brass Faucet

Induction Brazing Brass Faucet

Objective Brazing two joints on a brass bathroom faucet assembly

Material Brass bathroom fittings 1” OD, brazing rings, flux

Temperature 1148 ºF (620 ºC)

Frequency 90 kHz

Equipment • DW-UHF-30 kW induction heating system, equipped with a remote workhead containing eight 1.0 μF capacitors for a total of 8.0 μF

• An induction heating coil designed and developed specifically for this application.

Process A two turn C shaped coil is used to braze the faucet assembly.

The braze rings are placed at the joint, the parts assembled and fluxed. The first braze joint is heated for 30 seconds and the braze ring flows. The assembly is rotated & the second joint is heated for 30 seconds to flow the braze ring. The two brazes are completed in 60 seconds.

Results/Benefits Induction heating provides:

• Faster, repeatable and consistent results

• Localized heat produces neat and clean joints

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

Aluminum Billet Heating Furnace

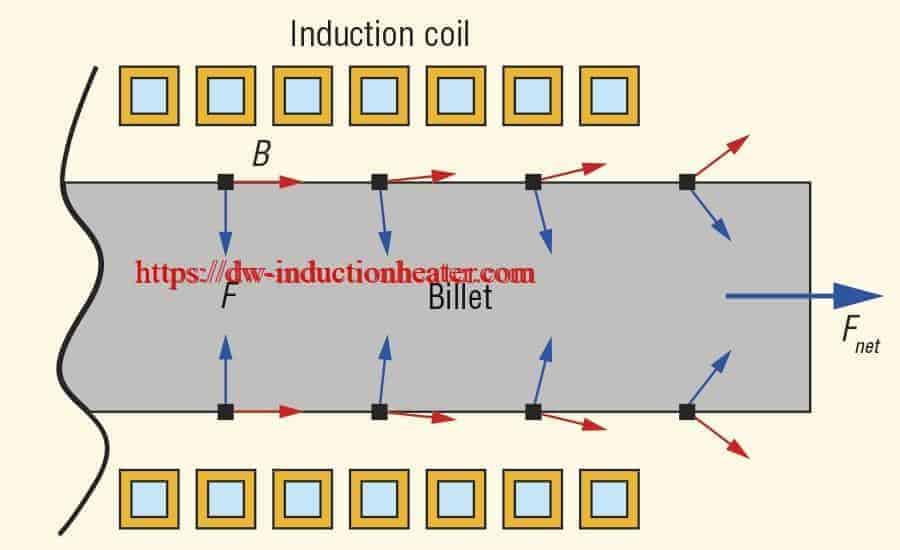

Continous Aluminum Billet Heating Furnace/Aluminium Alloys Billet Heater for the heating Aluminum Billets/Rods/Bars before the hot formging, extrusion, hot rolling and cutting,etc.

Induction Heating is a proven, reliable and efficient method of heating hot forming aluminum alloys. However, aluminum alloys have material properties that, if unaccounted for, can result in unexpected challenges. Understanding the unique facets of the induction heating of aluminum can be achieved by considering the properties that make aluminum alloys such advantageous materials. Given that aluminum and its alloys offer numerous advantages over many other metals, it is not surprising that inquiries about induction billet-heating equipment increasingly involve the heating of aluminum alloys. Many of these inquiries focus on how the induction heating of aluminum differs from the induction heating of other materials – typically steels – and how these differences affect heating quality, efficiency and productivity. Electromagnetic induction is well-suited for the heating of aluminum-alloy billets. However, there are some critical, yet easily overlooked, realities of aluminum billet heating that should be considered when designing, operating and maintaining this type of equipment. Fundamentally, the induction heating of aluminum alloys is no different than that of other common materials (e.g., carbon-steel and stainless steel alloys). It is ultimately material-property differences that set apart the induction heating of aluminum alloys from other metals. These material-property differences, if unaccounted for, can result in unexpected equipment performance and practical challenges. Because the users of most continuous induction billet-heating systems are familiar with the induction heating of steels and carbon-steel and stainless steel alloys, they provide a convenient point of reference in the consideration of the continuous heating of aluminum-alloy billets. HLQ Induction Equipment Co.,Ltd specializes in continous aluminum billet heating furnace/aluminium billet heater for heating aluminum billets/bars/rods before the hot formging, extrusion, hot rolling and cutting,etc.

https://dw-inductionheater.com/continous-aluminum-billet-heating-furnace-manufacturer.html?feed_id=225661&_unique_id=64f0aa5f601a6

https://dw-inductionheater.com/continous-aluminum-billet-heating-furnace-manufacturer.html?feed_id=225661&_unique_id=64f0aa5f601a6

Induction Preheat Welding Systems

Portable Post Weld Heating Treatment System With Induction

Main Application:

l Preheat: weld heat,coating, spraying, bending, fitting&unfitting heat

l Post-weld heat treatment: tank, boile, pipeline, steel sheet or other metal jobs

l InductionHeat: mold heating, shipboard, zinc bath, large& irregular metal parts

l Pipeline material heat: pipeline oil, pipeline gas, pipeline water, pipeline petrochemical and other pipeline material

Main Features:

* High speed: 70%

* Low tolerance

* Energy Saving

* High efficiency

* Accurate heating

* Simple operation

* Non-contact heating

* Environmental protection

* Hypothermia circumstance

* Air cooling is suitable for low-temperature environment

* Induction heating is more uniform than oil,gas,flame heating

| MYD-20KW | MYD-10KW | |

| Input voltage | 3*380V, 50/60Hz, 4 Wires | |

| Input Current | 1~30A | 1~15A |

| Output Current | 0~300A | 0~200A |

| Output Power | 1~20KW | 1~10KW, Max 15KW, 150% duty cycle |

| Output Frequency | 5~30KHZ | |

| Thermocouple | K type | |

| Temperature system | Build in induction machine | |

| Heating Temperature | Max800℃ | Max500℃ |

| Size | 700 x 330 x 410 mm | 650 x 310 x 410 mm |

| Weight | 32kg | 26 kg |

| Induction Heating coil | ||

| Length | 10~20 M | |

| Diameter | 15 mm | |

| Working temperature | -30~45℃ | |

| Pipeline Size | OD: 50~500mm or equivalent | |

2023年8月30日星期三

Induction Brazing Stainless Steel

Induction Brazing Stainless Steel

Objective

1st Application: Braze hub assembly to needle holder

2nd Application: Braze Large tube to ring joint

Material: 1st Application: Steel hub assembly and needle 0.1" dia(2.5mm) 2nd Application: Steel tube 1" OD (25.4 mm) and ring

Temperature 1400 ºF (760 ºC)

Frequency 325 kHz for brazing the needle 0.1" dia (2.5mm) 259 kHz for brazing ring to steel tube 1" OD (25.4 mm)

Equipment • DW-UHF-4.5KW induction heating system, equipped with a

remote workhead containing two .66 μF capacitors for a total of 1.32 μF

• Two induction heating coils, designed and developed specifically for this dual application.

Process 1st application: A two-turn helical coil is used to heat the hub assembly on the needle holder for 10 seconds. The coil concentrates the heat on the hub only, as the needle is magnetic and the hub material is non-magnetic. A small

diameter braze wire is used to supply sufficient amount of braze creating a strong aesthetically pleasing bond. 2nd application: A three-turn helical coil is used for brazing the large tube to the ring joint for 3-5 minutes. A braze ring is

used to supply sufficient amount of braze to create an aesthetically pleasing bond.

Results/Benefits Induction heating provides:

• Even distribution of heating, provides even flow of braze alloy for an aesthetically pleasing bond

• System flexibility allows for the same unit to be used for two different applications which is a cost saving.

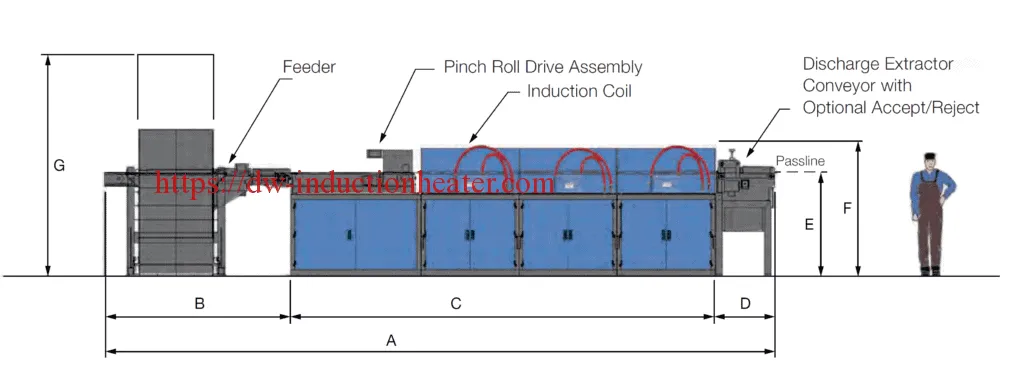

Billet Heating Furnace with Induction Heating

24h Continous Billet Heating Furnace with induction for the heating of copper/aluminum/iron steel billets before hot forming

Product Description

For heating various of bar materials: such as steel & iron, bronze, brass, aluminum alloy, etc.

Picture just for reference, color is changable with different power.

Functions and special specifications customized by customer's requirements.

Features and Advantages:

1.Automatic:Automatic feeding, automatic selection of the work-piece is good or bad, automatic measurement of temperature, automatic discharge.

2. Integrated design: Save installation time,cost and space.

3. Operation panel embedded displays machine operating states, to facilitate fault diagnosis.

Product Description

For heating various of bar materials: such as steel & iron, bronze, brass, aluminum alloy, etc.

Picture just for reference, color is changable with different power.

Functions and special specifications customized by customer's requirements.

Features and Advantages:

1.Automatic:Automatic feeding, automatic selection of the work-piece is good or bad, automatic measurement of temperature, automatic discharge.

2. Integrated design: Save installation time,cost and space.

3. Operation panel embedded displays machine operating states, to facilitate fault diagnosis.

| Features | Detail | |

| 1 | Heating fast and stable | saving 20%- 30% electric energy than traditional way; High efficiency and low energy consumption |

| 2 | Small in size | Easy to install, operate and repair |

| 3 | Safe and reliable | No high voltage, very safe to your workers. |

| 4 | A cooling circulation system | Able to operate continuously 24 hours |

| 5 | complete self-protect function | many types of alarm lamps: over-current, over-voltage, over hot, water shortage etc. These lamps can control and protect machine. |

| 6 | Environmental protection | Almost no oxide layer, produced no exhaust, no waste-water |

| 7 | IGBT Type | Avoid the interruption of unrelated electric net; Ensure the long-life of the machine. |

| DW-MF-200 | DW-MF-250 | DW-MF-300 | DW-MF-400 | DW-MF-500 | DW-MF-600 | ||

| Input Voltage | 3phases, 380V/410V/440V , 50/60Hz | ||||||

| Max Input Current | 320A | 400A | 480A | 640A | 800A | 960A | |

| Oscillating frequency | 0.5KHz^20KHz ( Oscillating frequency will be customized according to the size of heating parts) | ||||||

| Duty Cycle Loading | 100%,24h continuously work | ||||||

| Cooling Water Desires | 0.1MPa | ||||||

| Dimension | Host | 1000X800X1500mm | 1500X800X2800mm | 850X1700X1900mm | |||

| Extension | extension will be customized according to the material and size of heating parts | ||||||

| Weight | 110kg | 150kg | 160kg | 170kg | 200kg | 220kg | |

| Depend on the dimension of extension | |||||||

https://dw-inductionheater.com/billet-heating-furnace-with-induction-heating.html?feed_id=225511&_unique_id=64ef3c8e67126

https://dw-inductionheater.com/billet-heating-furnace-with-induction-heating.html?feed_id=225511&_unique_id=64ef3c8e67126

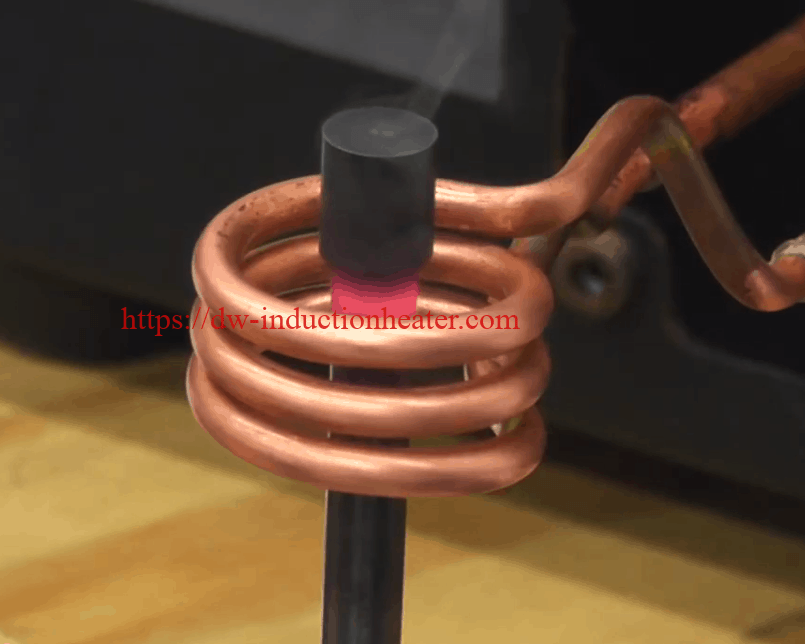

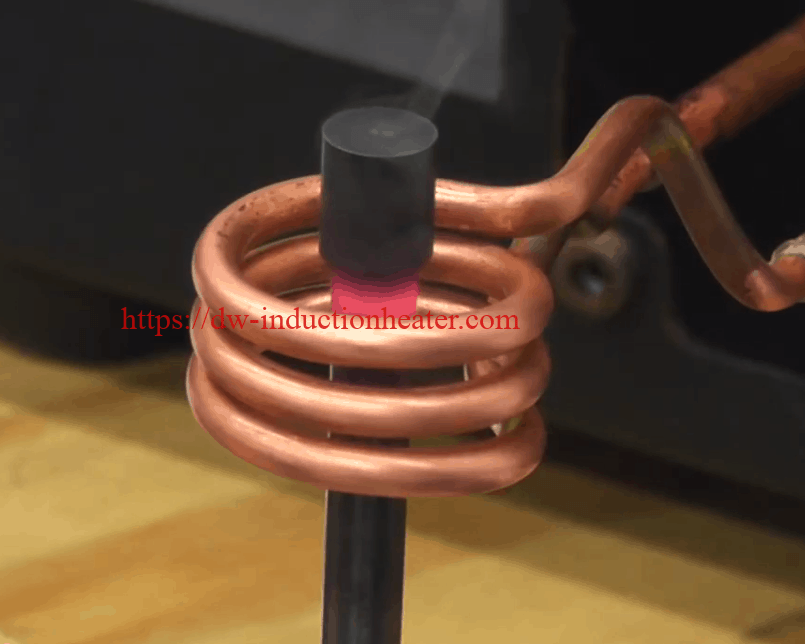

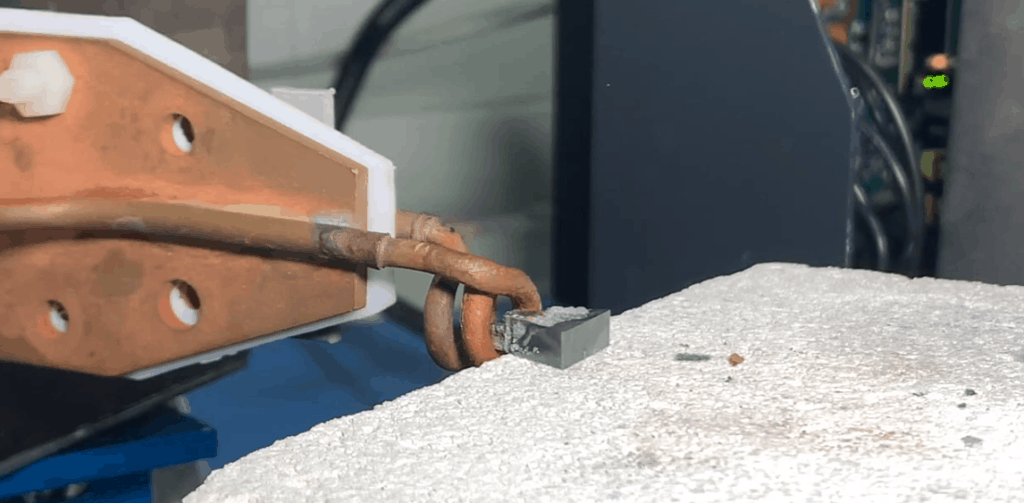

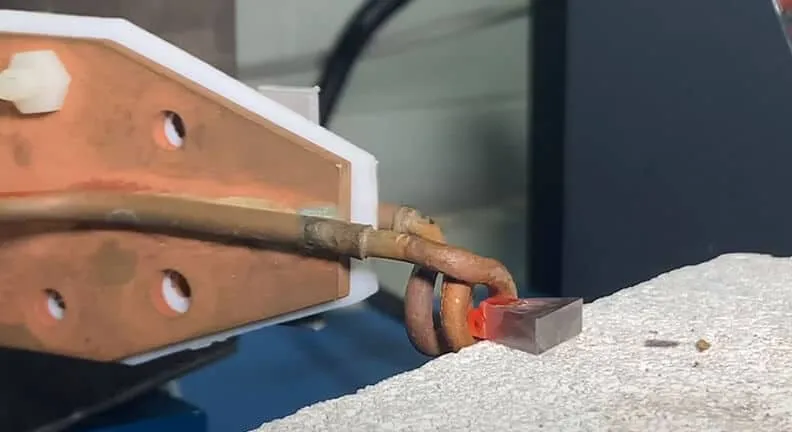

induction brazing steel carbide cap to shaft

Objective

High Frequency Induction brazing steel carbide cap to shaft. Customer currently uses a torch process, but would like to change to induction brazing in order to reduce scrap and rework and improve the quality of the braze.

Equipment

DW-UHF-6kw-III handheld induction brazing heater

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Process:

- Paste alloy was applied to the cone shape top of each steel shaft.

- The cap was set on top and rotated to distribute the paste alloy.

- Each assembly was positioned in the coil and heated.

- Preliminary heat tests were conducted using tempilaq paint to estimate the heat cycle to 1450 degrees F.

- Precise control of the time and temperature resulting in improved quality and consistent result

- Power on demand with rapid heat cycles

- Repeatable process, not operator dependent

- Safe induction heating with no open flames

- Energy efficient heating

2023年8月29日星期二

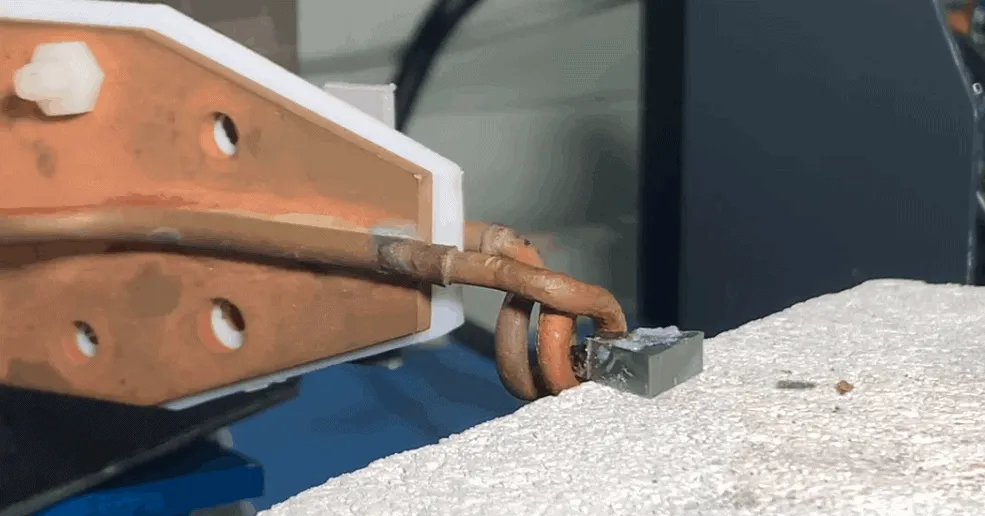

Induction Soldering Cable to Metallic Plate

Objective

The purpose of this test is to demonstrate the induction soldering cable to metallic plate process.

Recommended Equipment

The recommended equipment for this test is the DW-UHF-6kw-I handheld induction heater.

Results and Conclusions:

The results were satisfactory at 14 seconds. The complete process can be achieved in less than 5 seconds by increasing the frequency from under 200 kHz to over 300 kHz, as well as by increasing the induction heating power

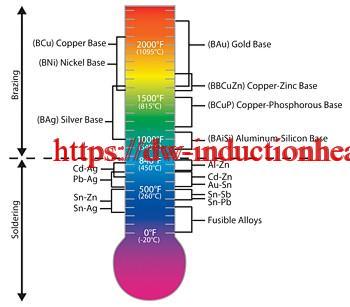

Induction Brazing Principle-Theory

Induction Brazing Technology

Induction Brazing Principle|Theory Brazing and soldering are processes of joining similar or dissimilar materials using a compatible a filler material. Filler metals include lead, tin, copper, silver, nickel and their alloys. Only the alloy melts and solidifies during these processes to join the work piece base materials. The filler metal is pulled into the joint by capillary action. Soldering processes are conducted below 840°F (450°C) while brazing applications are conducted at temperatures above 840°F (450°C) up to 2100°F (1150°C). The success of these processes depends upon the assembly’s design, clearance between the surfaces to be joined, cleanliness, process control and the correct selection of equipment needed to perform a repeatable process.

Cleanliness is ordinarily obtained by introducing a flux which covers and dissolves dirt or oxides displacing them from the braze joint.

Many operations are now conducted in a controlled atmosphere with a blanket of inert gas or combination of inert / active gasses to shield the operation and eliminate the need for a flux. These methods have been proven on a wide variety of material and part configurations replacing or complimenting atmosphere furnace technology with a just in time - single piece flow process.

Brazing Filler Materials

Brazing filler metals can come in a variety of forms, shapes, sizes and alloys depending on their intended use. Ribbon, preformed rings, paste, wire and preformed washers are just a few of the shapes and forms alloys that can be found.

The success of these processes depends upon the assembly’s design, clearance between the surfaces to be joined, cleanliness, process control and the correct selection of equipment needed to perform a repeatable process.

Cleanliness is ordinarily obtained by introducing a flux which covers and dissolves dirt or oxides displacing them from the braze joint.

Many operations are now conducted in a controlled atmosphere with a blanket of inert gas or combination of inert / active gasses to shield the operation and eliminate the need for a flux. These methods have been proven on a wide variety of material and part configurations replacing or complimenting atmosphere furnace technology with a just in time - single piece flow process.

Brazing Filler Materials

Brazing filler metals can come in a variety of forms, shapes, sizes and alloys depending on their intended use. Ribbon, preformed rings, paste, wire and preformed washers are just a few of the shapes and forms alloys that can be found. The decision to use a particular alloy and/or shape is largely dependent on the parent materials to be joined, placement during processing and the service environment for which the final product is intended.

Clearance Affects Strength

Clearance between the faying surfaces to be joined determines the amount of braze alloy, capillary action / penetration of the alloy and subsequently the strength of the finished joint. The best fit up condition for conventional silver brazing applications are 0.002 inches (0.050 mm) to 0.005 inches (0.127 mm) total clearance. Aluminum is typically 0.004 inches (0.102 mm) to 0.006 inches (0.153 mm). Larger clearances up to 0.015 inches (0.380 mm) usually lack sufficient capillary action for a successful braze.

Brazing with copper (above 1650°F / 900°C) requires the joint tolerance kept to an absolute minimum and in some cases press fit at ambient temperatures to assure minimum joint tolerances while at the brazing temperature.

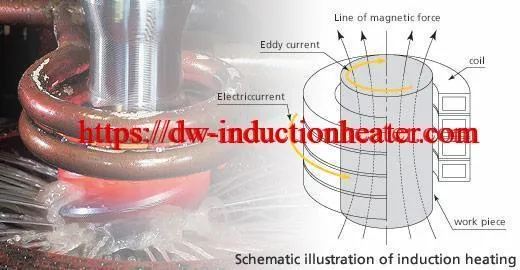

Induction Heating Theory

Induction systems provide a convenient and precise way to quickly and efficiently heat a selected area of an assembly. Consideration must be given to the selection of power supply operating frequency, power density (kilowatt applied per square inch), heating time, and induction coil design to provide the required depth of heating in a specific braze joint.

Induction heating is non-contact heating by means of transformer theory. The power supply is an AC source to the induction coil that becomes the primary windings of the transformer while the part to be heated is the transformer’s secondary. The work piece heats by the base materials’ inherent electrical resistivity to the induced current flowing in the assembly.

The decision to use a particular alloy and/or shape is largely dependent on the parent materials to be joined, placement during processing and the service environment for which the final product is intended.

Clearance Affects Strength

Clearance between the faying surfaces to be joined determines the amount of braze alloy, capillary action / penetration of the alloy and subsequently the strength of the finished joint. The best fit up condition for conventional silver brazing applications are 0.002 inches (0.050 mm) to 0.005 inches (0.127 mm) total clearance. Aluminum is typically 0.004 inches (0.102 mm) to 0.006 inches (0.153 mm). Larger clearances up to 0.015 inches (0.380 mm) usually lack sufficient capillary action for a successful braze.

Brazing with copper (above 1650°F / 900°C) requires the joint tolerance kept to an absolute minimum and in some cases press fit at ambient temperatures to assure minimum joint tolerances while at the brazing temperature.

Induction Heating Theory

Induction systems provide a convenient and precise way to quickly and efficiently heat a selected area of an assembly. Consideration must be given to the selection of power supply operating frequency, power density (kilowatt applied per square inch), heating time, and induction coil design to provide the required depth of heating in a specific braze joint.

Induction heating is non-contact heating by means of transformer theory. The power supply is an AC source to the induction coil that becomes the primary windings of the transformer while the part to be heated is the transformer’s secondary. The work piece heats by the base materials’ inherent electrical resistivity to the induced current flowing in the assembly. Current passing through an electrical conductor (the workpiece) results in heating as current meets resistance to its flow. These losses are low in current flowing through aluminum, copper and their alloys. These non-ferrous materials require additional power to heat than their carbon steel counterpart.

The alternating current tends to flow on the surface. The relationship between the frequency of the alternating current and the depth it penetrates the part is known as the reference depth of heating. Part diameter, material type and wall thickness can have an effect on heating efficiency based on the reference depth.

https://dw-inductionheater.com/induction-brazing-principle.html?feed_id=225361&_unique_id=64edcee3f21e2

Current passing through an electrical conductor (the workpiece) results in heating as current meets resistance to its flow. These losses are low in current flowing through aluminum, copper and their alloys. These non-ferrous materials require additional power to heat than their carbon steel counterpart.

The alternating current tends to flow on the surface. The relationship between the frequency of the alternating current and the depth it penetrates the part is known as the reference depth of heating. Part diameter, material type and wall thickness can have an effect on heating efficiency based on the reference depth.

https://dw-inductionheater.com/induction-brazing-principle.html?feed_id=225361&_unique_id=64edcee3f21e2

2023年8月28日星期一

aluminum scrap melting induction furnace

The top 200^2000kg aluminum scrap melting induction furnace for casting and melting aluminium scraps,ingots,cans and dross material.

Operation Steps:- An Aluminium melting induction furnace operator will place aluminum parts or aluminum ingot/scrap as a charge in the induction melting aluminum recycling furnace and start the furnace to begin the melting process. Adding more aluminum charge this process is advisable as molten aluminum transmits the heat better.

- When temperature of the aluminum reaches 1220.66°F it turns to liquid. Any residue from the coating and paint from the cans will float on the surface. This byproduct is called dross and can be skimmed by a steel ladle. This needs to cool before it can be disposed off safely.

- Next, the crucible (furnace) will pour out pure aluminum. Usually, Hydraulic tilting mechanism provided to pour large quantities of liquid metals.

- Finally, with care, the molten aluminum will be poured into mould to cool down and then slide out for use.

| Type | Input Power | Melting Capacity | Max Temperature | ||

| steel, stainless steel | copper, gold, silver (scrap, Slag) | aluminum, aluminum alloy, Aluminum scrap, Aluminum slag, pop can | 1800℃ | ||

| SMJD-463 | 60 KW | 200 KG | 500 KG | 200 KG | |

| SMJD-480 | 60 KW | 150 KG | 500 KG | 150 KG | |

| SMJD-580 | 80 KW | 200 KG | 600 KG | 200 KG | |

| SMJD-600 | 60 KW | 230 KG | 560 KG | 230 KG | |

| SMJD-900 | 120 KW | 300 KG | 900 KG | 300 KG | |

| SMJD-905 | 80 KW | 300 KG | 900 KG | 300 KG | |

| SMJD-1250 | 80 KW | 400 KG | 1200 KG | 400 KG | |

| SMJD-1250 | 120 KW | 450 KG | 1350 KG | 450 KG | |

| SMJD-1500 | 120 KW | 500 KG | 1500 KG | 500 KG | |

| SMJD-1550 | 120 KW | 520 KG | 1560 KG | 520 KG | |

| SMJD-1700 | 160KW | 600 KG | 1700 KG | 600 KG | |

| SMJD-2300 | 160KW | 800 KG | 2000 KG | 800 KG | |

| SMJD-3100 | 200KW | 1200 KG | 3000 KG | 1200 KG | |

https://dw-inductionheater.com/aluminum-scrap-melting-induction-furnace.html?feed_id=225286&_unique_id=64ed17eba468b

https://dw-inductionheater.com/aluminum-scrap-melting-induction-furnace.html?feed_id=225286&_unique_id=64ed17eba468b

Induction Brazing Steel Tips

Induction Brazing Steel Tips with Hihg Frequency Heating System

Objective To heat a steel tip and shank assembly to 1300°F (704°C) within 3 seconds for brazing with induction heating instead of torch brazing.

Material 0.1” (2.54mm) diameter steel tip & shank, 0.07” (1.78mm) diameter braze ring

Temperature 1300°F (704°C)

Frequency 800kHz

Equipment DW-UHF-4.5kW induction heating system, remote heat station containing one 1.2 microfarad capacitor.

Process A two turn helical coil is used to braze the dental parts. The braze ring is placed at the joint area of the steel tip and shank. Black flux is applied to the joint area. RF power is applied for 3 seconds to heat the parts to the established target temperature and the braze paste flows evenly and consistantly.

Results/Benefits Induction heating provides:

• Fast, accurate, repeatable heat

• Ability to heat very small areas within precise production tolerances

• Better joint quality, reduced oxidation

• Increased production rates and reduced labor costs

Aluminum Scrap Melting Recycling Induction Furnace

The top 200^1500kg Induction Aluminum Scrap Melting Recycling Induction Furnace for recycling and melting aluminum scraps,ingots,cans and dross material.

Operation Steps:- An Aluminum scraps/ingots/cans recycling furnace operator will place aluminum parts or aluminum ingot/scrap as a charge in the induction melting aluminum recycling furnace and start the furnace to begin the melting process. Adding more aluminum charge this process is advisable as molten aluminum transmits the heat better.

- When temperature of the aluminum reaches 1220.66°F it turns to liquid. Any residue from the coating and paint from the cans will float on the surface. This byproduct is called dross and can be skimmed by a steel ladle. This needs to cool before it can be disposed off safely.

- Next, the crucible (furnace) will pour out pure aluminum. Usually, Hydraulic tilting mechanism provided to pour large quantities of liquid metals.

- Finally, with care, the molten aluminum will be poured into mould to cool down and then slide out for use.

| Type | Input Power | Melting Capacity | Max Temperature | ||

| steel, stainless steel | copper, gold, silver (scrap, Slag) | aluminum, aluminum alloy, Aluminum scrap, Aluminum slag, pop can | 1800℃ | ||

| SMJD-463 | 60 KW | 200 KG | 500 KG | 200 KG | |

| SMJD-480 | 60 KW | 150 KG | 500 KG | 150 KG | |

| SMJD-580 | 80 KW | 200 KG | 600 KG | 200 KG | |

| SMJD-600 | 60 KW | 230 KG | 560 KG | 230 KG | |

| SMJD-900 | 120 KW | 300 KG | 900 KG | 300 KG | |

| SMJD-905 | 80 KW | 300 KG | 900 KG | 300 KG | |

| SMJD-1250 | 80 KW | 400 KG | 1200 KG | 400 KG | |

| SMJD-1250 | 120 KW | 450 KG | 1350 KG | 450 KG | |

| SMJD-1500 | 120 KW | 500 KG | 1500 KG | 500 KG | |

| SMJD-1550 | 120 KW | 520 KG | 1560 KG | 520 KG | |

| SMJD-1700 | 160KW | 600 KG | 1700 KG | 600 KG | |

| SMJD-2300 | 160KW | 800 KG | 2000 KG | 800 KG | |

| SMJD-3100 | 200KW | 1200 KG | 3000 KG | 1200 KG | |

https://dw-inductionheater.com/aluminum-scrap-melting-recycling-induction-furnace.html?feed_id=225211&_unique_id=64ec60d2ae23a

https://dw-inductionheater.com/aluminum-scrap-melting-recycling-induction-furnace.html?feed_id=225211&_unique_id=64ec60d2ae23a

Induction Brazing Carbide Tipping on Cutting Steel Tool

Induction Brazing Carbide Tipping on Cutting Steel Tool Applications

Objective : A leading manufacturer of CBN and PCD cutting tools wants to increase their productivity by focusing heat on a very small area in order to decrease heat loss and improve a carbide tipping process. Induction Brazing Process:

The customer provided a triangle steel body, each side ~16.5 mm (0.65 inches). The induction brazing carbide tipping must be performed on a 3 mm (0.11 inches) equilateral triangle on the edge. The heating zone of the tool steel body is 43 mm (1.69 inches) OD x 25 mm (0.98 inches) in length. DW-UHF-6kW-II induction heating system was utilized to reach 1600 °F (870 °C) and complete the process in 8 seconds. A custom-designed coil concentrated the heat in the carbide tipping zone and minimized cycle time.

Induction Brazing Process:

The customer provided a triangle steel body, each side ~16.5 mm (0.65 inches). The induction brazing carbide tipping must be performed on a 3 mm (0.11 inches) equilateral triangle on the edge. The heating zone of the tool steel body is 43 mm (1.69 inches) OD x 25 mm (0.98 inches) in length. DW-UHF-6kW-II induction heating system was utilized to reach 1600 °F (870 °C) and complete the process in 8 seconds. A custom-designed coil concentrated the heat in the carbide tipping zone and minimized cycle time.

Induction Brazing Equipment:

DW-UHF-6kW-II induction heating system with a customized induction brazing coil was used to fit the process requirements.

Industry: Tools & Equipment

Induction Brazing Equipment:

DW-UHF-6kW-II induction heating system with a customized induction brazing coil was used to fit the process requirements.

Industry: Tools & Equipment

2023年8月27日星期日

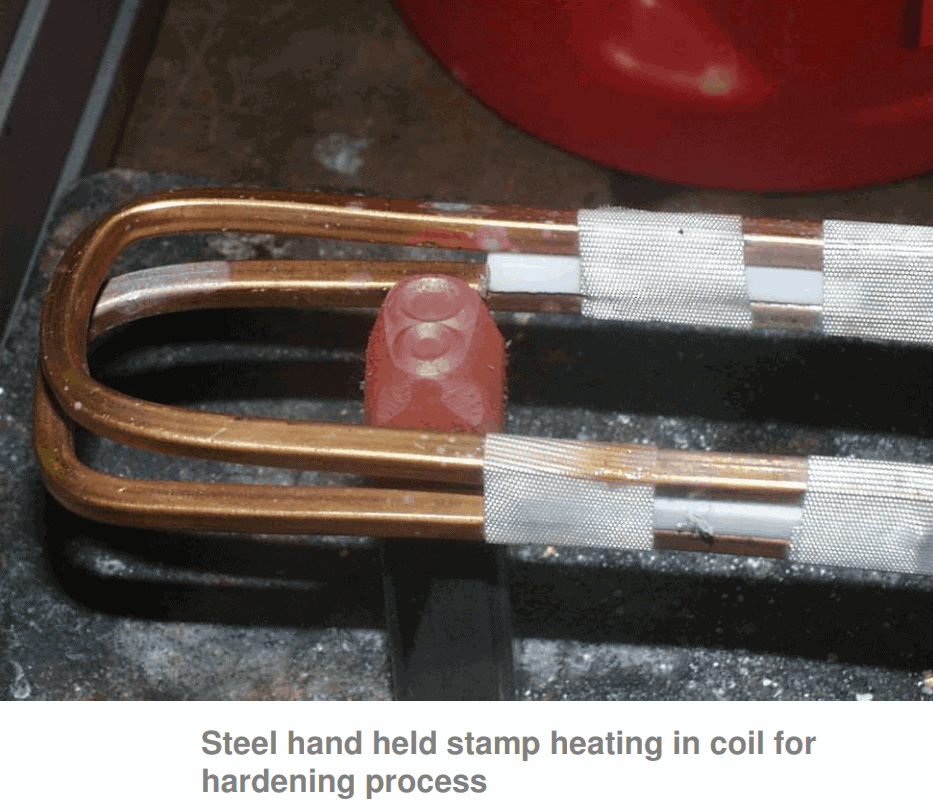

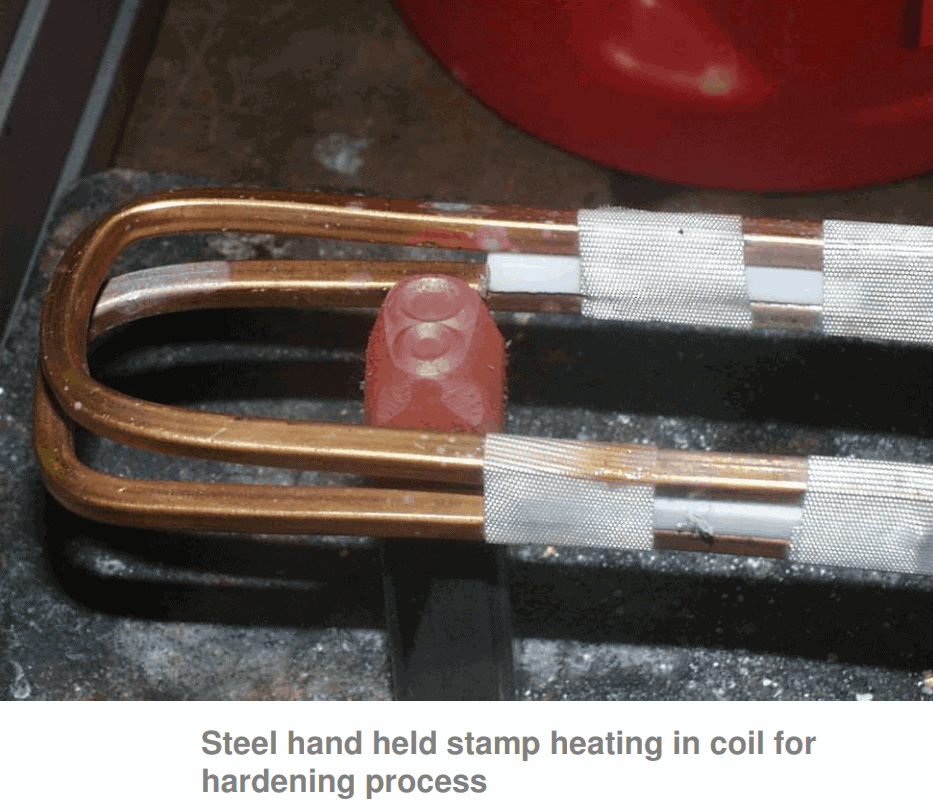

induction hardening steel handheld stamps

induction hardening steel handheld stamps

Objective Induction hardening various size ends of handheld marking stamps. The area to be hardened is 3/4” (19mm) up the shank. Material : Steel stamps 1/4” (6.3mm), 3/8” (9.5mm), 1/2” (12.7mm) and 5/8” (15.8mm) square Temperature :1550 ºF (843 ºC) Frequency 99 kHz Equipment • DW-HF-45kW induction heating system, equipped with a remote workhead containing eight 1.0µF capacitors for a total of 2.0µF • An induction heating coil designed and developed specifically for this application. Induction Hardening Process:

A two turn channel coil is used to cover the range of steel stamps being heated. The 5/8” steel stamp is heated for 60 seconds to reach 1550 ºF (843 ºC) and the desired hardness. Smaller parts will also heat easily.

Results/Benefits

Induction heating provides:

• Faster process time and production rates

• Hands-free heating that involves no operator skill for manufacturing

• Controlled precise application of heat

Induction Hardening Process:

A two turn channel coil is used to cover the range of steel stamps being heated. The 5/8” steel stamp is heated for 60 seconds to reach 1550 ºF (843 ºC) and the desired hardness. Smaller parts will also heat easily.

Results/Benefits

Induction heating provides:

• Faster process time and production rates

• Hands-free heating that involves no operator skill for manufacturing

• Controlled precise application of heat

订阅:

评论 (Atom)

关注者

博客归档

-

▼

2023

(1696)

-

▼

八月

(129)

- Induction Brazing Brass Faucet

- Aluminum Billet Heating Furnace

- Induction Preheat Welding Systems

- Induction Brazing Stainless Steel

- Billet Heating Furnace with Induction Heating

- induction brazing steel carbide cap to shaft

- Induction Soldering Cable to Metallic Plate

- Induction Brazing Principle-Theory

- Induction Hardening Inner

- aluminum scrap melting induction furnace

- Induction Brazing Steel Tips

- Aluminum Scrap Melting Recycling Induction Furnace

- Induction Brazing Carbide Tipping on Cutting Steel...

- induction hardening steel handheld stamps

- Melting Aluminum Tilting Crucible Induction Furnace

- ultrasonic welding fabric machine for bonding nonw...

- Tilting Crucible Melting Induction Furnace

- Ultrasonic Plastic Welding Machine For Bonding The...

- Electromagnetic Induction Steam Generator

- Why Choose Induction Heating and what are its adva...

- Induction Hardening Surface Process

- How to design induction heating coil

- Induction annealing copper wires

- Induction Preheat Welding Systems

- Induction forging and induction hot forming

- Induction Soldering Wire To Aluminum Lug

- Magnetic Induction Heating Boiler

- portable ultrasonic mask welding machine for weldi...

- Induction Soldering Electrical Circuits

- Induction Heating Basic

- Induction Wire and Cable Heating

- Induction annealing stainless steel wire

- Induction Soldering Stainless Steel Tubes to Brass...

- Induction Heating Basic

- Induction Annealing Copper Tubes

- Brazing stainless steel with induction

- Induction Shrink Fitting Aluminum Pump Housing Part

- Induction Heating Steel Mold

- Soldering Steel To Brass With Induction Heater

- Induction Brazing Aluminum to Aluminum Tube

- Induction Brazing Copper Tube of Heat Exchanger

- How Induction Heating works?

- induction brazing stainless steel to steel

- Induction Brazing Carbide Onto Steel Part

- Small High Frequency Induction Melting Furnace

- Efficient and Versatile Induction Heating Coils fo...

- Small High Frequency Induction Melting Furnace

- handbook of induction heating eddy current

- Efficient and Versatile Induction Heating Coils fo...

- Efficient and Versatile Induction Heating Coils fo...

- Induction Soldering Brass Tube-Pipe

- RPR Induction Stripping-Induction Rust & Paint Coa...

- Heating Shrink Fitting Camshaft Gear

- Handheld Brazing Stainless Steel Tube

- induction brazing copper and brass rods

- High frequency induction brazing steel tube to ste...

- Handheld Induction Brazing Copper Tubing and Fitting

- induction brazing brass pipe to brass part

- Induction Brazing Copper Tube For Refrigeration

- Induction annealing stainless steel wire

- Brazing Stainless Steel To Copper With Induction

- Induction Brazing Aluminum Tube T Joints

- Induction Handheld Brazing Copper To Steel Tube

- Induction Soldering Process Video

- Induction Brazing Aluminum to Aluminum Tube

- induction brazing copper and brass rods

- High Frequency Brazing Stainless Steel Fittings

- Induction Hot Forming Steel Pipe

- Induction Brazing Heating Exchanger Copper Pipes

- Induction Brazing Steel Parts to Tungsten Carbide ...

- what is induction forging?

- High Frequency Induction Brazing Copper Wire

- Small High Frequency Induction Melting Furnace

- Induction Soldering Copper Wire Connectors

- Induction inline wire heating process

- Induction Soldering Brass Assembly

- induction heating stainless steel wire cable

- Brazing Carbide To Steel With Induction

- Induction Hardening Steel Part with High Frequency...

- Induction Brazing Carbide To Steel

- high frequency induction hardening camshafts process

- Aluminium Scraps Recycling Melting and Process

- Shrink Fittting Part Removal application with Indu...

- Why Choose Induction Heating and what are its adva...

- induction soldering copper tubing to brass valves

- Induction Soldering Wire To Aluminum Lug

- Induction Soldering Brass Corner Joint

- Induction Shrink Fit Aluminum Shaft

- Induction Soldering Copper Wire Connectors

- high frequency induction soldering wire to connector

- Brazing Automotive Parts With Induction

- Induction Soldering Copper Pipes to PCB Board

- Brazing Golf Ball With Induction

- Induction Soldering Stainless Steel Tubes to Brass...

- induction brazing steel tube to copper tube

- Brazing Aluminum to Copper Tubes with Induction

- Induction Soldering Wire To Aluminum Lug

- Brazing Joining Copper Connectors With Induction

- high frequency induction soldering wire to connector

- Induction Heating Steel Mold

-

▼

八月

(129)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.