What Is Induction Melting?

Induction melting is a process where metal is melted into liquid form in an induction furnace's crucible. The molten metal is then poured from the crucible, usually into a cast.

What are the benefits?

Induction melting is extremely fast, clean and uniform. When correctly performed, induction melting is so clean that it is possible to skip the purification stage necessary with other methods. The uniform heat induced in the metal also contributes to a high-quality end result. DaWei Induction melting furnace have advanced ergonomic features. They not only make workplaces safer, they increase productivity by making the melting process faster and more comfortable. Where is it used? DaWei Induction melting systems are used in foundries, universities, laboratories and research centers. The systems melt everything from ferrous and non-ferrous metals to nuclear material and medical/dental alloys.

What equipment/furnace is available?

DaWei Induction Heating Machine Co offers many different induction furnace ranges to suit a wide variety of melting needs: single-axis tiltpour, dual-axis tilt-pour, moving coil, rollover and laboratory.

https://dw-inductionheater.com/what-is-induction-melting.html?feed_id=252154&_unique_id=668202adc2912

What Is Induction Melting?

Induction melting is a process where metal is melted into liquid form in an induction furnace's crucible. The molten metal is then poured from the crucible, usually into a cast.

What are the benefits?

Induction melting is extremely fast, clean and uniform. When correctly performed, induction melting is so clean that it is possible to skip the purification stage necessary with other methods. The uniform heat induced in the metal also contributes to a high-quality end result. DaWei Induction melting furnace have advanced ergonomic features. They not only make workplaces safer, they increase productivity by making the melting process faster and more comfortable. Where is it used? DaWei Induction melting systems are used in foundries, universities, laboratories and research centers. The systems melt everything from ferrous and non-ferrous metals to nuclear material and medical/dental alloys.

What equipment/furnace is available?

DaWei Induction Heating Machine Co offers many different induction furnace ranges to suit a wide variety of melting needs: single-axis tiltpour, dual-axis tilt-pour, moving coil, rollover and laboratory.

https://dw-inductionheater.com/what-is-induction-melting.html?feed_id=252154&_unique_id=668202adc2912

2024年6月30日星期日

What Is Induction Melting?

What Is Induction Melting?

Induction melting is a process where metal is melted into liquid form in an induction furnace's crucible. The molten metal is then poured from the crucible, usually into a cast.

What are the benefits?

Induction melting is extremely fast, clean and uniform. When correctly performed, induction melting is so clean that it is possible to skip the purification stage necessary with other methods. The uniform heat induced in the metal also contributes to a high-quality end result. DaWei Induction melting furnace have advanced ergonomic features. They not only make workplaces safer, they increase productivity by making the melting process faster and more comfortable. Where is it used? DaWei Induction melting systems are used in foundries, universities, laboratories and research centers. The systems melt everything from ferrous and non-ferrous metals to nuclear material and medical/dental alloys.

What equipment/furnace is available?

DaWei Induction Heating Machine Co offers many different induction furnace ranges to suit a wide variety of melting needs: single-axis tiltpour, dual-axis tilt-pour, moving coil, rollover and laboratory.

https://dw-inductionheater.com/what-is-induction-melting.html?feed_id=252154&_unique_id=668202adc2912

What Is Induction Melting?

Induction melting is a process where metal is melted into liquid form in an induction furnace's crucible. The molten metal is then poured from the crucible, usually into a cast.

What are the benefits?

Induction melting is extremely fast, clean and uniform. When correctly performed, induction melting is so clean that it is possible to skip the purification stage necessary with other methods. The uniform heat induced in the metal also contributes to a high-quality end result. DaWei Induction melting furnace have advanced ergonomic features. They not only make workplaces safer, they increase productivity by making the melting process faster and more comfortable. Where is it used? DaWei Induction melting systems are used in foundries, universities, laboratories and research centers. The systems melt everything from ferrous and non-ferrous metals to nuclear material and medical/dental alloys.

What equipment/furnace is available?

DaWei Induction Heating Machine Co offers many different induction furnace ranges to suit a wide variety of melting needs: single-axis tiltpour, dual-axis tilt-pour, moving coil, rollover and laboratory.

https://dw-inductionheater.com/what-is-induction-melting.html?feed_id=252154&_unique_id=668202adc2912

what is induction forging?

what is induction forging?

Induction forging uses induction to heat metal parts before they are shaped, or 'deformed' by presses or hammers.

What are the benefits?

Induction forging has several key advantages over furnace forging. The speed and controllability of induction ensures high throughput. Induction also minimizes oxidation and helps maintain metallurgical integrity. And since induction delivers precise, localized heat, it saves energy. The consistency and repeatability of induction make it ideal for integrating into automated production lines.

Where is it used?

Induction forging is widely used in the metal and foundry industries to heat billets, bars and bar ends. Metals commonly forged with DaWei Induction Heating systems include aluminum, brass, copper, steel and stainless steel.

What equipment is available?

Three families of DaWei Induction heating equipment can be used for forging applications: DW-MF series, KGPS series. However, DW-MF induction forging furnace includes various models that are specially designed for high-output forging of billets, bars, handlebars, bar ends, bolts and pre-formed components.

https://dw-inductionheater.com/what-is-induction-forging.html?feed_id=252086&_unique_id=66814b8ea1275

what is induction forging?

Induction forging uses induction to heat metal parts before they are shaped, or 'deformed' by presses or hammers.

What are the benefits?

Induction forging has several key advantages over furnace forging. The speed and controllability of induction ensures high throughput. Induction also minimizes oxidation and helps maintain metallurgical integrity. And since induction delivers precise, localized heat, it saves energy. The consistency and repeatability of induction make it ideal for integrating into automated production lines.

Where is it used?

Induction forging is widely used in the metal and foundry industries to heat billets, bars and bar ends. Metals commonly forged with DaWei Induction Heating systems include aluminum, brass, copper, steel and stainless steel.

What equipment is available?

Three families of DaWei Induction heating equipment can be used for forging applications: DW-MF series, KGPS series. However, DW-MF induction forging furnace includes various models that are specially designed for high-output forging of billets, bars, handlebars, bar ends, bolts and pre-formed components.

https://dw-inductionheater.com/what-is-induction-forging.html?feed_id=252086&_unique_id=66814b8ea1275

2024年6月29日星期六

Induction Brazing Aluminum Pipes

Induction Brazing Aluminum Pipes

Objective: Brazing two aluminum pipes simultaneously to an aluminum evaporator core

Material 2 aluminum pipes 0.72" (18.3mm) diameter, evaporator core 9.88" x 10.48" x 1.5" thick (251mm x 266.3mm x 38mm), braze rings

Temperature 610 ºF (321 ºC)

Frequency 250 kHz

Equipment • DW-UHF-20KW induction heating system, equipped with a remote workhead containing two 1.5μF capacitors for a total of 0.75μF • An induction heating coil designed and developed specifically for this application.

Process A four turn helical pancake coil is used to heat the 2 pipes simultaneously. Three braze rings are placed on each joint and power is applied for 90-100 seconds to create a leak proof joint on both pipes. Narrative • Customer is requiring a 40 seconds heat time for both brazes. In order to meet this requirement 3 units will be utilized to braze 2 joints each for a total of 6 joints in 90-100 seconds. The customer is currently using a flame process which can burn away the thin flange at the joint area and create scrap parts. By switching to induction for this application the customer is decreasing their scrap parts and also increasing their quality and production rate.

Results/Benefits Induction heating provides:

• Repeatable leak free joints

• Increased part quality, less scrap

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

https://dw-inductionheater.com/induction-brazing-aluminum-pipes.html?feed_id=252018&_unique_id=668094ca1f03f

Induction Brazing Aluminum Pipes

Objective: Brazing two aluminum pipes simultaneously to an aluminum evaporator core

Material 2 aluminum pipes 0.72" (18.3mm) diameter, evaporator core 9.88" x 10.48" x 1.5" thick (251mm x 266.3mm x 38mm), braze rings

Temperature 610 ºF (321 ºC)

Frequency 250 kHz

Equipment • DW-UHF-20KW induction heating system, equipped with a remote workhead containing two 1.5μF capacitors for a total of 0.75μF • An induction heating coil designed and developed specifically for this application.

Process A four turn helical pancake coil is used to heat the 2 pipes simultaneously. Three braze rings are placed on each joint and power is applied for 90-100 seconds to create a leak proof joint on both pipes. Narrative • Customer is requiring a 40 seconds heat time for both brazes. In order to meet this requirement 3 units will be utilized to braze 2 joints each for a total of 6 joints in 90-100 seconds. The customer is currently using a flame process which can burn away the thin flange at the joint area and create scrap parts. By switching to induction for this application the customer is decreasing their scrap parts and also increasing their quality and production rate.

Results/Benefits Induction heating provides:

• Repeatable leak free joints

• Increased part quality, less scrap

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

https://dw-inductionheater.com/induction-brazing-aluminum-pipes.html?feed_id=252018&_unique_id=668094ca1f03f

Brazing Aluminum to Copper Tubes with Induction

Brazing Aluminum to Copper Tubes with Induction

Objective: To heat an aluminum manifold to 1050 ºF (566 ºC) for a brazing application:

Material :

Brazing Aluminum to Copper Tubes with Induction

Objective: To heat an aluminum manifold to 1050 ºF (566 ºC) for a brazing application:

Material :

- Cu tubes (3/4"/19mm)

- Cu tubes (5/8"/15.8mm)

- AI tubes (3/8"/9.5mm)

- AI manifold (5/8"/15.8mm)

- AI manifold (3/4"/19mm)

- Lucas-Milhaupt Handy One alloy 30-832

- Braze wire

- A two-turn oval helical induction heating coil designed and developed specifically for the aluminum assembly

- A five-turn helical induction heating coil designed and developed specifically for brazing the Cu tubes to AI joint assembly

- The client wanted more precise and repeatable heating than a torch could deliver, which induction was able to achieve .

- Temperature control: Induction allows for superior temperature control when compared to other methods, including a torch, which the client desired

2024年6月28日星期五

Brazing Aluminum Pipes Assembly With Induction

Brazing Aluminum Pipes Assembly With Induction

Objective: Braze an aluminum assembly to 968 ºF (520 ºC) within 20 seconds

Material : Customer supplied 1.33" (33.8 mm) O.D. aluminum tube and aluminum mating part ,Aluminum braze alloy

Temperature: 968 ºF (520 ºC)

Frequency 50 kHz

Equipment: DW-HF-35KW,30-80 kHz induction heating system equipped with a remote heat station containing one 53 μF capacitor A two-position helical induction heating coil designed and developed specifically for this application.

Process: Braze material was applied between the tubing and the mating part. The assembly was placed inside the coil and heated for approximately 40 seconds. With a two-position coil, two parts can be heated simultaneously, which means one part would be completed every 15-20 seconds. Braze material was stick fed, which created a good joint. The heating time with two parts being heated simultaneously meets the client's objective, and represents a significant improvement in regards to speed over using a torch.

Results/Benefits

Brazing Aluminum Pipes Assembly With Induction

Objective: Braze an aluminum assembly to 968 ºF (520 ºC) within 20 seconds

Material : Customer supplied 1.33" (33.8 mm) O.D. aluminum tube and aluminum mating part ,Aluminum braze alloy

Temperature: 968 ºF (520 ºC)

Frequency 50 kHz

Equipment: DW-HF-35KW,30-80 kHz induction heating system equipped with a remote heat station containing one 53 μF capacitor A two-position helical induction heating coil designed and developed specifically for this application.

Process: Braze material was applied between the tubing and the mating part. The assembly was placed inside the coil and heated for approximately 40 seconds. With a two-position coil, two parts can be heated simultaneously, which means one part would be completed every 15-20 seconds. Braze material was stick fed, which created a good joint. The heating time with two parts being heated simultaneously meets the client's objective, and represents a significant improvement in regards to speed over using a torch.

Results/Benefits

- Speed: The recommended approach cut their heating time in half when compared to using a torch

- Part quality: Induction heating is a repeatable method with more consistency than a torch can generally deliver

- Safety: Induction heating is a clean, precise method that does not involve an open flame like a torch, which results in a safer work environment

Induction Aluminum Brazing Process

Induction Aluminum Brazing Process

Induction aluminum brazing is becoming more and more common in industry. A typical example is brazing various pipes to an automotive heat exchanger body. Aluminum requires a lot of energy to heat using induction and its thermal conductivity is 60% compared to copper. Coil design and time for the heat to flow is critical in a successful induction brazing process for aluminum parts. Recent advances in lower temperature aluminum braze materials have allowed induction to effectively replace flame and furnace heating in high volume brazing of aluminum assemblies.

Successful Induction brazing of aluminum parts requires the correct braze filler material for the aluminum alloy used in the parts and the correct flux for the braze alloy. Braze filler manufacturers have their own proprietary aluminum braze alloys and flux materials that work with their alloys.

https://dw-inductionheater.com/induction-aluminum-brazing-process.html?feed_id=251814&_unique_id=667e70353f5d3

Induction Aluminum Brazing Process

Induction aluminum brazing is becoming more and more common in industry. A typical example is brazing various pipes to an automotive heat exchanger body. Aluminum requires a lot of energy to heat using induction and its thermal conductivity is 60% compared to copper. Coil design and time for the heat to flow is critical in a successful induction brazing process for aluminum parts. Recent advances in lower temperature aluminum braze materials have allowed induction to effectively replace flame and furnace heating in high volume brazing of aluminum assemblies.

Successful Induction brazing of aluminum parts requires the correct braze filler material for the aluminum alloy used in the parts and the correct flux for the braze alloy. Braze filler manufacturers have their own proprietary aluminum braze alloys and flux materials that work with their alloys.

https://dw-inductionheater.com/induction-aluminum-brazing-process.html?feed_id=251814&_unique_id=667e70353f5d3

2024年6月27日星期四

What Is Induction Heating Coil&Inductor?

What is induction heating coil & inductor?

The varying magnetic field required for induction heating is developed in the induction heating coil via the flow of AC (alternating current) in the coil. The coil can be made in many shapes and sizes to custom fit a specific application. The coils can range from tiny coils made of copper tubing used for precise heating of extremely small parts in applications such as soldering and ferrule heating to large coil assemblies of copper tubing used in applications such as strip metal heating and pipe heating.

What is the importance of the induction heating coil (inductor)?

The induction coil design is one of the most important aspects of an induction heating system. The coil is a custom design to give your work piece or part the proper heating pattern, maximize efficiency of the induction heating power supply’s load matching system, and to accomplish these tasks while still permitting ease of loading and unloading your part.

https://dw-inductionheater.com/what-is-induction-heating-coil-inductor.html?feed_id=251746&_unique_id=667db9912459d

What is induction heating coil & inductor?

The varying magnetic field required for induction heating is developed in the induction heating coil via the flow of AC (alternating current) in the coil. The coil can be made in many shapes and sizes to custom fit a specific application. The coils can range from tiny coils made of copper tubing used for precise heating of extremely small parts in applications such as soldering and ferrule heating to large coil assemblies of copper tubing used in applications such as strip metal heating and pipe heating.

What is the importance of the induction heating coil (inductor)?

The induction coil design is one of the most important aspects of an induction heating system. The coil is a custom design to give your work piece or part the proper heating pattern, maximize efficiency of the induction heating power supply’s load matching system, and to accomplish these tasks while still permitting ease of loading and unloading your part.

https://dw-inductionheater.com/what-is-induction-heating-coil-inductor.html?feed_id=251746&_unique_id=667db9912459d

2024年6月26日星期三

Brazing Carbide To Steel With Induction

Brazing Carbide To Steel With Induction

Objective: Braze carbide rotary file assemblies with uniform concentricity in an aerospace application

Material :

• Carbide blank

• High speed steel shank

• Temperature indicating paint

• Braze shim and black flux

Temperature 1400°F (760°C)

Frequency 252 kHz

Equipment DW-UHF-10kw induction heating system, equipped with a remote heat station containing two 0.33 μF capacitors (total 0.66 μF) An induction heating coil designed and developed specifically for this application.

Process A multi-turn helical coil is used. The part is heated to determine the time required to reach the desired temperature and required heat pattern. It takes approximately 30 - 45 seconds to reach 1400°F (760°C) depending on the various part sizes. Flux is applied to the entire part. A braze shim is sandwiched between the steel shank and carbide. Induction heating power is applied until the braze flows. With proper fixturing, concentricity of the part can be achieved.

Results/Benefits • Repeatable, consistent precise heat.

https://dw-inductionheater.com/brazing-carbide-to-steel-with-induction.html?feed_id=251678&_unique_id=667d02fb8f6ce

Brazing Carbide To Steel With Induction

Objective: Braze carbide rotary file assemblies with uniform concentricity in an aerospace application

Material :

• Carbide blank

• High speed steel shank

• Temperature indicating paint

• Braze shim and black flux

Temperature 1400°F (760°C)

Frequency 252 kHz

Equipment DW-UHF-10kw induction heating system, equipped with a remote heat station containing two 0.33 μF capacitors (total 0.66 μF) An induction heating coil designed and developed specifically for this application.

Process A multi-turn helical coil is used. The part is heated to determine the time required to reach the desired temperature and required heat pattern. It takes approximately 30 - 45 seconds to reach 1400°F (760°C) depending on the various part sizes. Flux is applied to the entire part. A braze shim is sandwiched between the steel shank and carbide. Induction heating power is applied until the braze flows. With proper fixturing, concentricity of the part can be achieved.

Results/Benefits • Repeatable, consistent precise heat.

https://dw-inductionheater.com/brazing-carbide-to-steel-with-induction.html?feed_id=251678&_unique_id=667d02fb8f6ce

Brazing Brass to Aluminum with Induction

Brazing Brass to Aluminum with Induction

Objective: Copper 'tees' and 'ells' are to be brazed to the aluminum body of a refrigeration valve

Material customer's valve copper fittings braze

Temperature 2550 ºF (1400°C)

Frequency 360 kHz

Equipment DW-UHF-10KW induction heating system including a workhead containing two 1.5μF capacitors (total 0.75μF) and a three-turn helical coil

Process The valve is placed inside the coil and RF power is applied until the part is heated to the required temperature and the braze is seen to flow into the joint. Two tube sizes were run using the same induction system settings with differing cycle times.

Results/Benefits • energy is applied only to the zone to be heated • heating of the joint/braze is uniform and repeatable

https://dw-inductionheater.com/brazing-brass-to-aluminum-with-induction.html?feed_id=251610&_unique_id=667c4c29db306

Brazing Brass to Aluminum with Induction

Objective: Copper 'tees' and 'ells' are to be brazed to the aluminum body of a refrigeration valve

Material customer's valve copper fittings braze

Temperature 2550 ºF (1400°C)

Frequency 360 kHz

Equipment DW-UHF-10KW induction heating system including a workhead containing two 1.5μF capacitors (total 0.75μF) and a three-turn helical coil

Process The valve is placed inside the coil and RF power is applied until the part is heated to the required temperature and the braze is seen to flow into the joint. Two tube sizes were run using the same induction system settings with differing cycle times.

Results/Benefits • energy is applied only to the zone to be heated • heating of the joint/braze is uniform and repeatable

https://dw-inductionheater.com/brazing-brass-to-aluminum-with-induction.html?feed_id=251610&_unique_id=667c4c29db306

2024年6月25日星期二

Brazing Carbide Tool Tips With Induction

Brazing Carbide Tool Tips With Induction

Objective: Attaching carbide cutters to a steel meat cutter impeller

Material carbide blocks; steel shank fitting

Temperature 1400 °F (760 °C)

Frequency 300 kHz

Equipment DW-UHF-30KW induction heating systems including: Induction heating coil Workhead: two-cap 1.0μF (Total 0.5 μF) Process The entire part is placed in a five-turn helical coil, the power is applied until the part is heated to the required temperature and a uniform heat pattern is achieved. The coil allows for easy fixturing and uniformity of heating between the carbide and the steel shank for a premium braze joint.

Results/Benefits

Precision: Due to the size of the induction coil, the process allows for precise placement of the carbides on the steel shanks

Economy: Power is consumed only during the heat cycle

Repeatability: joint quality is maintained in this repeatable process

https://dw-inductionheater.com/brazing-carbide-tool-tips-with-induction.html?feed_id=251542&_unique_id=667b95093f9fb

Brazing Carbide Tool Tips With Induction

Objective: Attaching carbide cutters to a steel meat cutter impeller

Material carbide blocks; steel shank fitting

Temperature 1400 °F (760 °C)

Frequency 300 kHz

Equipment DW-UHF-30KW induction heating systems including: Induction heating coil Workhead: two-cap 1.0μF (Total 0.5 μF) Process The entire part is placed in a five-turn helical coil, the power is applied until the part is heated to the required temperature and a uniform heat pattern is achieved. The coil allows for easy fixturing and uniformity of heating between the carbide and the steel shank for a premium braze joint.

Results/Benefits

Precision: Due to the size of the induction coil, the process allows for precise placement of the carbides on the steel shanks

Economy: Power is consumed only during the heat cycle

Repeatability: joint quality is maintained in this repeatable process

https://dw-inductionheater.com/brazing-carbide-tool-tips-with-induction.html?feed_id=251542&_unique_id=667b95093f9fb

Reducing Heavy Oil Viscosity and Enhancing Fluidity With Induction Heating

Electromagnetic Transformation: Reducing Heavy Oil Viscosity and Enhancing Fluidity With Induction Heating

-

Introduction

-

Fundamentals of Induction Heating

-

Challenges of Heavy Oil Viscosity

-

Mechanism of Viscosity Reduction through Induction Heating

Induction heating effectively reduces the viscosity of heavy oil through direct and localized heating, which increases the temperature of the oil and decreases its viscosity. The process involves the generation of heat through electromagnetic induction, which in turn influences the molecular dynamics and rheological properties of the oil. Induction Heating Process Placement of Induction Coils: The first step in the induction heating process involves the strategic placement of induction coils. These coils can be installed within the wellbore or around the pipeline carrying the heavy oil. The placement is crucial to ensure that the electromagnetic field generated by the coils effectively interacts with the oil to induce the desired heating effect. Generation of Eddy Currents: When alternating current (AC) flows through the induction coil, it creates a rapidly changing magnetic field around the coil. This alternating magnetic field penetrates the conductive material of the heavy oil. As a result, eddy currents are induced within the oil. These currents circulate within the oil and are responsible for generating heat due to electrical resistance. Heat Production: The heat generated by the eddy currents is a result of the Joule effect, where electrical energy is converted into thermal energy. As the eddy currents flow through the oil, they encounter resistance, which produces heat. This localized heating raises the temperature of the oil, effectively reducing its viscosity. Molecular Dynamics and Thermal Effects Increased Molecular Kinetic Energy: The heat produced by the induction process raises the kinetic energy of the oil molecules. As the temperature increases, the molecules gain more energy and move more freely. This increased molecular motion reduces the internal friction within the oil, making it less viscous. Weakening of Intermolecular Forces: Heavy oil contains large hydrocarbon molecules with strong intermolecular forces, such as van der Waals forces and hydrogen bonding, which contribute to its high viscosity. As the temperature rises, these intermolecular forces weaken, allowing the molecules to move past each other more easily. This reduction in intermolecular forces is a key factor in lowering the viscosity of the oil. Enhanced Fluidity: The combination of increased molecular kinetic energy and weakened intermolecular forces results in enhanced fluidity of the heavy oil. The oil becomes more mobile and easier to pump and transport through pipelines. This improved flow characteristic is essential for efficient extraction and transportation. Changes in Rheological Properties Viscosity Reduction: One of the most significant changes in the rheological properties of heavy oil due to induction heating is the reduction in viscosity. As the temperature of the oil increases, its viscosity decreases significantly. This change can be quantitatively measured using rheometers or viscometers, and the relationship between temperature and viscosity can be plotted to understand the effectiveness of the induction heating process. Improved Flow: The reduction in viscosity translates to improved flow characteristics of the heavy oil. Enhanced fluidity means that the oil can be more easily mobilized within the reservoir, leading to better extraction rates. In pipelines, the reduced viscosity minimizes frictional losses, allowing for smoother and more efficient transportation of the oil.

By understanding the mechanism of viscosity reduction through induction heating, it becomes evident how this technology can revolutionize the extraction and transportation of heavy oil. The direct and localized heating provided by induction heating offers a highly efficient and controlled method to address the challenges posed by high-viscosity heavy oil, making it a valuable tool in the oil industry's efforts to optimize production and reduce operational costs.

Improved Flow: The reduction in viscosity translates to improved flow characteristics of the heavy oil. Enhanced fluidity means that the oil can be more easily mobilized within the reservoir, leading to better extraction rates. In pipelines, the reduced viscosity minimizes frictional losses, allowing for smoother and more efficient transportation of the oil.

By understanding the mechanism of viscosity reduction through induction heating, it becomes evident how this technology can revolutionize the extraction and transportation of heavy oil. The direct and localized heating provided by induction heating offers a highly efficient and controlled method to address the challenges posed by high-viscosity heavy oil, making it a valuable tool in the oil industry's efforts to optimize production and reduce operational costs. -

Experimental Studies and Results

Results and Analysis:

- Temperature-Velocity Correlation: A clear correlation was observed between the increase in temperature and the decrease in viscosity. - Optimal Heating Parameters: Specific frequencies and power levels were identified as optimal for reducing viscosity without causing thermal degradation of the oil. - Case Studies: Field applications in locations such as Canada’s oil sands demonstrated practical effectiveness, with significant improvements in extraction rates and cost reductions.-

Advantages of Induction Heating for Heavy Oil

-

Applications in the Oil Industry

Induction heating offers several advantages in the oil industry, particularly in enhancing oil recovery processes, achieving practical successes in field applications, and integrating with existing extraction infrastructure. This section delves into how induction heating is being applied in various contexts to optimize oil extraction and transportation. Enhanced Oil Recovery (EOR) Techniques Enhanced Oil Recovery (EOR) methods are designed to increase the amount of crude oil that can be extracted from an oil field. Induction heating has shown significant promise in improving the efficiency and effectiveness of various EOR techniques. Steam-Assisted Gravity Drainage (SAGD): Steam-Assisted Gravity Drainage (SAGD) is a widely used EOR technique, particularly in the extraction of bitumen from oil sands. In SAGD, steam is injected into the reservoir to reduce the viscosity of the bitumen, allowing it to flow more easily to a production well. Induction heating can be used to preheat the reservoir, which enhances the efficiency of the SAGD process. By raising the initial temperature of the bitumen, induction heating reduces the amount of steam required, thereby lowering operational costs and improving overall energy efficiency. Additionally, preheating the reservoir with induction can shorten the startup time for the SAGD process, leading to faster production rates. Cyclic Steam Stimulation (CSS): Cyclic Steam Stimulation (CSS), also known as the "huff and puff" method, involves injecting steam into a well, allowing it to soak, and then producing the heated oil. The cyclic nature of CSS can benefit significantly from the integration of induction heating. By combining CSS with induction heating, the oil's mobility and extraction rates can be further enhanced. The heat generated by induction can be precisely controlled and applied where needed, ensuring uniform heating of the oil and reducing the thermal stress on the reservoir. This approach not only improves the efficiency of CSS but also extends the life of the wells and maximizes oil recovery. Field Applications and Success Stories The practical application of induction heating in the field has yielded impressive results, demonstrating its potential to revolutionize oil extraction processes. Canada’s Oil Sands: Canada’s oil sands are one of the largest reserves of bitumen, and the extraction of this heavy oil poses significant challenges due to its high viscosity. The successful deployment of induction heating in Canada’s oil sands has led to improved recovery rates and reduced costs. In pilot projects, induction heating has been used to preheat bitumen reservoirs, enhancing the effectiveness of traditional EOR techniques like SAGD and CSS. These projects have reported increased production rates, lower steam-to-oil ratios, and reduced greenhouse gas emissions. The success in Canada’s oil sands serves as a testament to the viability of induction heating in large-scale heavy oil extraction. Venezuela’s Orinoco Belt: The Orinoco Belt in Venezuela contains some of the most viscous heavy oil reserves in the world. Induction heating has been employed to enhance the extraction of this highly viscous oil, demonstrating significant benefits. Field applications in the Orinoco Belt have shown that induction heating can effectively reduce the viscosity of the heavy oil, making it more fluid and easier to extract. This has led to improved production rates and a more cost-effective extraction process. The ability to target specific areas of the reservoir with induction heating has also minimized environmental impact and reduced the need for extensive infrastructure modifications. Integration with Existing Extraction Processes One of the key advantages of induction heating is its compatibility with existing extraction processes and infrastructure, making it a versatile and scalable solution for the oil industry. Compatibility: Induction heating can be seamlessly integrated with existing extraction infrastructure, providing a straightforward addition to current operations. The technology can be implemented in both new and existing wells, allowing operators to enhance oil recovery without the need for significant modifications. The adaptability of induction heating systems means they can be tailored to fit various well configurations and reservoir conditions. This compatibility ensures that the benefits of induction heating can be realized with minimal disruption to ongoing operations. Scalability: The technology is scalable, making it suitable for both small and large-scale operations. Induction heating systems can be designed to meet the specific needs of different oil fields, from small pilot projects to extensive commercial operations. The scalability of induction heating allows for incremental implementation, enabling operators to start with smaller installations and expand as needed based on performance and results. This flexibility makes induction heating an attractive option for a wide range of applications, from enhancing production in mature fields to developing new heavy oil reserves. In summary, the applications of induction heating in the oil industry are vast and varied. By improving the efficiency of EOR techniques, achieving practical success in field applications, and seamlessly integrating with existing infrastructure, induction heating is poised to play a crucial role in the future of oil extraction. The technology’s ability to reduce viscosity, enhance fluidity, and optimize production processes offers significant economic and environmental benefits, making it a valuable tool for the industry.

-

Future Prospects and Innovations

Challenges and Solutions for Wider Adoption:

- Technical Challenges: Addressing issues such as equipment durability and performance in harsh environments.

- Economic Factors: Reducing costs and demonstrating clear economic benefits to encourage wider adoption.

Challenges and Solutions for Wider Adoption:

- Technical Challenges: Addressing issues such as equipment durability and performance in harsh environments.

- Economic Factors: Reducing costs and demonstrating clear economic benefits to encourage wider adoption.

-

Conclusion

Brazing Brass To Copper With Induction

Brazing Brass To Copper With Induction

Objective: To braze brass end-connectors to copper tubes used in aircraft assembly air lines Material brass end connectors, copper tubes of different diameters

Temperature 1400 ºF 750°C

Frequency 350 kHz

Equipment DW-UHF-4.5KW induction heating system, including a three turn helical induction coil using two 0.33μF capacitors (total 0.66μF)

Process For smaller diameter parts, flux is applied to the entire part and the copper tube to brass joint is assembled using brazing preforms (allowing for the same amount of braze in each joint). The assembly is placed in the coil and heated for 20-30 seconds reaching a temperature of 1400°F. For larger copper tube assemblies, the same process is used, but the braze alloy is stick-fed to the joint to prevent the alloy from flowing out of the joint. A foot switch control is recommended to enable better control of the process.

Results/Benefits

Economy: Power is consumed during the heating only

Consistency: the results of braze joints are repeatable and uniform

https://dw-inductionheater.com/brazing-brass-to-copper-with-induction.html?feed_id=251408&_unique_id=667ade3ae905e

Brazing Brass To Copper With Induction

Objective: To braze brass end-connectors to copper tubes used in aircraft assembly air lines Material brass end connectors, copper tubes of different diameters

Temperature 1400 ºF 750°C

Frequency 350 kHz

Equipment DW-UHF-4.5KW induction heating system, including a three turn helical induction coil using two 0.33μF capacitors (total 0.66μF)

Process For smaller diameter parts, flux is applied to the entire part and the copper tube to brass joint is assembled using brazing preforms (allowing for the same amount of braze in each joint). The assembly is placed in the coil and heated for 20-30 seconds reaching a temperature of 1400°F. For larger copper tube assemblies, the same process is used, but the braze alloy is stick-fed to the joint to prevent the alloy from flowing out of the joint. A foot switch control is recommended to enable better control of the process.

Results/Benefits

Economy: Power is consumed during the heating only

Consistency: the results of braze joints are repeatable and uniform

https://dw-inductionheater.com/brazing-brass-to-copper-with-induction.html?feed_id=251408&_unique_id=667ade3ae905e

Reducing Heavy Oil Viscosity and Enhancing Fluidity With Induction Heating

Electromagnetic Transformation: Reducing Heavy Oil Viscosity and Enhancing Fluidity With Induction Heating

-

Introduction

-

Fundamentals of Induction Heating

-

Challenges of Heavy Oil Viscosity

-

Mechanism of Viscosity Reduction through Induction Heating

Induction heating effectively reduces the viscosity of heavy oil through direct and localized heating, which increases the temperature of the oil and decreases its viscosity. The process involves the generation of heat through electromagnetic induction, which in turn influences the molecular dynamics and rheological properties of the oil. Induction Heating Process Placement of Induction Coils: The first step in the induction heating process involves the strategic placement of induction coils. These coils can be installed within the wellbore or around the pipeline carrying the heavy oil. The placement is crucial to ensure that the electromagnetic field generated by the coils effectively interacts with the oil to induce the desired heating effect. Generation of Eddy Currents: When alternating current (AC) flows through the induction coil, it creates a rapidly changing magnetic field around the coil. This alternating magnetic field penetrates the conductive material of the heavy oil. As a result, eddy currents are induced within the oil. These currents circulate within the oil and are responsible for generating heat due to electrical resistance. Heat Production: The heat generated by the eddy currents is a result of the Joule effect, where electrical energy is converted into thermal energy. As the eddy currents flow through the oil, they encounter resistance, which produces heat. This localized heating raises the temperature of the oil, effectively reducing its viscosity. Molecular Dynamics and Thermal Effects Increased Molecular Kinetic Energy: The heat produced by the induction process raises the kinetic energy of the oil molecules. As the temperature increases, the molecules gain more energy and move more freely. This increased molecular motion reduces the internal friction within the oil, making it less viscous. Weakening of Intermolecular Forces: Heavy oil contains large hydrocarbon molecules with strong intermolecular forces, such as van der Waals forces and hydrogen bonding, which contribute to its high viscosity. As the temperature rises, these intermolecular forces weaken, allowing the molecules to move past each other more easily. This reduction in intermolecular forces is a key factor in lowering the viscosity of the oil. Enhanced Fluidity: The combination of increased molecular kinetic energy and weakened intermolecular forces results in enhanced fluidity of the heavy oil. The oil becomes more mobile and easier to pump and transport through pipelines. This improved flow characteristic is essential for efficient extraction and transportation. Changes in Rheological Properties Viscosity Reduction: One of the most significant changes in the rheological properties of heavy oil due to induction heating is the reduction in viscosity. As the temperature of the oil increases, its viscosity decreases significantly. This change can be quantitatively measured using rheometers or viscometers, and the relationship between temperature and viscosity can be plotted to understand the effectiveness of the induction heating process. Improved Flow: The reduction in viscosity translates to improved flow characteristics of the heavy oil. Enhanced fluidity means that the oil can be more easily mobilized within the reservoir, leading to better extraction rates. In pipelines, the reduced viscosity minimizes frictional losses, allowing for smoother and more efficient transportation of the oil.

By understanding the mechanism of viscosity reduction through induction heating, it becomes evident how this technology can revolutionize the extraction and transportation of heavy oil. The direct and localized heating provided by induction heating offers a highly efficient and controlled method to address the challenges posed by high-viscosity heavy oil, making it a valuable tool in the oil industry's efforts to optimize production and reduce operational costs.

Improved Flow: The reduction in viscosity translates to improved flow characteristics of the heavy oil. Enhanced fluidity means that the oil can be more easily mobilized within the reservoir, leading to better extraction rates. In pipelines, the reduced viscosity minimizes frictional losses, allowing for smoother and more efficient transportation of the oil.

By understanding the mechanism of viscosity reduction through induction heating, it becomes evident how this technology can revolutionize the extraction and transportation of heavy oil. The direct and localized heating provided by induction heating offers a highly efficient and controlled method to address the challenges posed by high-viscosity heavy oil, making it a valuable tool in the oil industry's efforts to optimize production and reduce operational costs. -

Experimental Studies and Results

Results and Analysis:

- Temperature-Velocity Correlation: A clear correlation was observed between the increase in temperature and the decrease in viscosity. - Optimal Heating Parameters: Specific frequencies and power levels were identified as optimal for reducing viscosity without causing thermal degradation of the oil. - Case Studies: Field applications in locations such as Canada’s oil sands demonstrated practical effectiveness, with significant improvements in extraction rates and cost reductions.-

Advantages of Induction Heating for Heavy Oil

-

Applications in the Oil Industry

Induction heating offers several advantages in the oil industry, particularly in enhancing oil recovery processes, achieving practical successes in field applications, and integrating with existing extraction infrastructure. This section delves into how induction heating is being applied in various contexts to optimize oil extraction and transportation. Enhanced Oil Recovery (EOR) Techniques Enhanced Oil Recovery (EOR) methods are designed to increase the amount of crude oil that can be extracted from an oil field. Induction heating has shown significant promise in improving the efficiency and effectiveness of various EOR techniques. Steam-Assisted Gravity Drainage (SAGD): Steam-Assisted Gravity Drainage (SAGD) is a widely used EOR technique, particularly in the extraction of bitumen from oil sands. In SAGD, steam is injected into the reservoir to reduce the viscosity of the bitumen, allowing it to flow more easily to a production well. Induction heating can be used to preheat the reservoir, which enhances the efficiency of the SAGD process. By raising the initial temperature of the bitumen, induction heating reduces the amount of steam required, thereby lowering operational costs and improving overall energy efficiency. Additionally, preheating the reservoir with induction can shorten the startup time for the SAGD process, leading to faster production rates. Cyclic Steam Stimulation (CSS): Cyclic Steam Stimulation (CSS), also known as the "huff and puff" method, involves injecting steam into a well, allowing it to soak, and then producing the heated oil. The cyclic nature of CSS can benefit significantly from the integration of induction heating. By combining CSS with induction heating, the oil's mobility and extraction rates can be further enhanced. The heat generated by induction can be precisely controlled and applied where needed, ensuring uniform heating of the oil and reducing the thermal stress on the reservoir. This approach not only improves the efficiency of CSS but also extends the life of the wells and maximizes oil recovery. Field Applications and Success Stories The practical application of induction heating in the field has yielded impressive results, demonstrating its potential to revolutionize oil extraction processes. Canada’s Oil Sands: Canada’s oil sands are one of the largest reserves of bitumen, and the extraction of this heavy oil poses significant challenges due to its high viscosity. The successful deployment of induction heating in Canada’s oil sands has led to improved recovery rates and reduced costs. In pilot projects, induction heating has been used to preheat bitumen reservoirs, enhancing the effectiveness of traditional EOR techniques like SAGD and CSS. These projects have reported increased production rates, lower steam-to-oil ratios, and reduced greenhouse gas emissions. The success in Canada’s oil sands serves as a testament to the viability of induction heating in large-scale heavy oil extraction. Venezuela’s Orinoco Belt: The Orinoco Belt in Venezuela contains some of the most viscous heavy oil reserves in the world. Induction heating has been employed to enhance the extraction of this highly viscous oil, demonstrating significant benefits. Field applications in the Orinoco Belt have shown that induction heating can effectively reduce the viscosity of the heavy oil, making it more fluid and easier to extract. This has led to improved production rates and a more cost-effective extraction process. The ability to target specific areas of the reservoir with induction heating has also minimized environmental impact and reduced the need for extensive infrastructure modifications. Integration with Existing Extraction Processes One of the key advantages of induction heating is its compatibility with existing extraction processes and infrastructure, making it a versatile and scalable solution for the oil industry. Compatibility: Induction heating can be seamlessly integrated with existing extraction infrastructure, providing a straightforward addition to current operations. The technology can be implemented in both new and existing wells, allowing operators to enhance oil recovery without the need for significant modifications. The adaptability of induction heating systems means they can be tailored to fit various well configurations and reservoir conditions. This compatibility ensures that the benefits of induction heating can be realized with minimal disruption to ongoing operations. Scalability: The technology is scalable, making it suitable for both small and large-scale operations. Induction heating systems can be designed to meet the specific needs of different oil fields, from small pilot projects to extensive commercial operations. The scalability of induction heating allows for incremental implementation, enabling operators to start with smaller installations and expand as needed based on performance and results. This flexibility makes induction heating an attractive option for a wide range of applications, from enhancing production in mature fields to developing new heavy oil reserves. In summary, the applications of induction heating in the oil industry are vast and varied. By improving the efficiency of EOR techniques, achieving practical success in field applications, and seamlessly integrating with existing infrastructure, induction heating is poised to play a crucial role in the future of oil extraction. The technology’s ability to reduce viscosity, enhance fluidity, and optimize production processes offers significant economic and environmental benefits, making it a valuable tool for the industry.

-

Future Prospects and Innovations

Challenges and Solutions for Wider Adoption:

- Technical Challenges: Addressing issues such as equipment durability and performance in harsh environments.

- Economic Factors: Reducing costs and demonstrating clear economic benefits to encourage wider adoption.

Challenges and Solutions for Wider Adoption:

- Technical Challenges: Addressing issues such as equipment durability and performance in harsh environments.

- Economic Factors: Reducing costs and demonstrating clear economic benefits to encourage wider adoption.

-

Conclusion

2024年6月24日星期一

Brazing Copper to Brass Pipe With Induction

Brazing Copper to Brass Pipe With Induction

Objective: Brazing several brass and copper assemblies used in water faucets Material braze, white flux

Temperature 1350 °F 730°C

Frequency 200 or 280 kHz (coil dependant)

Equipment DW-UHF-10KW induction heating system, remote work head with two 1μF capacitors and a 3-turn helical coil

Process: Three helical coils are used separately to braze a range of provided parts. Parts are assembled with flux and a braze alloy and then heated. The heat time varies from part to part with large parts taking less than 3 minutes and, the smaller parts heated in less than 20 seconds. After heating the parts are quench-cooled.

Results/Benefits

Repeatability: the inherent precision of induction heating supports a process which is highly repeatable.

Economy: the process allows for the use of higher temperature braze alloy than a flame process

https://dw-inductionheater.com/brazing-copper-to-brass-pipe-with-induction.html?feed_id=251311&_unique_id=667a27cda8d25

Brazing Copper to Brass Pipe With Induction

Objective: Brazing several brass and copper assemblies used in water faucets Material braze, white flux

Temperature 1350 °F 730°C

Frequency 200 or 280 kHz (coil dependant)

Equipment DW-UHF-10KW induction heating system, remote work head with two 1μF capacitors and a 3-turn helical coil

Process: Three helical coils are used separately to braze a range of provided parts. Parts are assembled with flux and a braze alloy and then heated. The heat time varies from part to part with large parts taking less than 3 minutes and, the smaller parts heated in less than 20 seconds. After heating the parts are quench-cooled.

Results/Benefits

Repeatability: the inherent precision of induction heating supports a process which is highly repeatable.

Economy: the process allows for the use of higher temperature braze alloy than a flame process

https://dw-inductionheater.com/brazing-copper-to-brass-pipe-with-induction.html?feed_id=251311&_unique_id=667a27cda8d25

Brazing Brass Pipe With Induction

Brazing Brass Pipe With Induction

Objective: Block is heated to 1400°F to braze trap tube to assembly

Material :brass block and pre-formed tubes braze pre-forms

Temperature: 1400 ºF (760°C)

Frequency: 350 kHz

Equipment DW-UHF-10KW induction heating system including • Coil: custom-designed 2-turn split-helical • Workhead: contains two 1.0μF capacitors (0.5 μF total)

Process The brass parts, braze pre-form and flux are assembled and located within the custom-designed coil. Induction heating of the joint is accomplished in 45 seconds.

Results/Benefits

Economy: induction heats only the material within the coil; no energy is wasted heating the surrounding materials and air; no flame or gasses required for heating Control: process lends itself to the use of braze pre-forms; process easily adapted to automation

Efficiency: energy is expended only during the joint formation

https://dw-inductionheater.com/brazing-brass-pipe-with-induction.html?feed_id=251243&_unique_id=667970acb082e

Brazing Brass Pipe With Induction

Objective: Block is heated to 1400°F to braze trap tube to assembly

Material :brass block and pre-formed tubes braze pre-forms

Temperature: 1400 ºF (760°C)

Frequency: 350 kHz

Equipment DW-UHF-10KW induction heating system including • Coil: custom-designed 2-turn split-helical • Workhead: contains two 1.0μF capacitors (0.5 μF total)

Process The brass parts, braze pre-form and flux are assembled and located within the custom-designed coil. Induction heating of the joint is accomplished in 45 seconds.

Results/Benefits

Economy: induction heats only the material within the coil; no energy is wasted heating the surrounding materials and air; no flame or gasses required for heating Control: process lends itself to the use of braze pre-forms; process easily adapted to automation

Efficiency: energy is expended only during the joint formation

https://dw-inductionheater.com/brazing-brass-pipe-with-induction.html?feed_id=251243&_unique_id=667970acb082e

2024年6月23日星期日

Brazing Carbide-Steel Tool with Induction

Brazing Carbide-Steel Tool with Induction

Objective: Provide a solution to this steel-carbide brazing application Material • Body 10mm; carbide tip 57 x 35 x 3 mm • Braze shim • Braze flux white

Temperature: 750°C (1382ºF)

Frequency: 150 kHz

Equipment DW-UHF-20KW induction heating system, equipped with a remote heat station containing (2) 1.0 μF capacitors (for a total of 0.5 μF) A 4.5" helical induction heating coil designed and developed specifically for this application.

Process: The body shim and carbide are cleaned and braze flux as applied to the entire surface of the assembly. The parts are placed together in the induction coil. Two ceramic tubes are then placed thru the coil opposing each other to hold the parts during heating. The flux on the parts is allowed to dry before heating. The induction heating power is applied until the braze flows in the joint.

Results/Benefits

• targeted heating of the braze joint is efficient

• flameless process is more precise, controllable

• results are reproducible

https://dw-inductionheater.com/brazing-carbide-steel-tool-with-induction.html?feed_id=251175&_unique_id=6678ba0cf1926

Brazing Carbide-Steel Tool with Induction

Objective: Provide a solution to this steel-carbide brazing application Material • Body 10mm; carbide tip 57 x 35 x 3 mm • Braze shim • Braze flux white

Temperature: 750°C (1382ºF)

Frequency: 150 kHz

Equipment DW-UHF-20KW induction heating system, equipped with a remote heat station containing (2) 1.0 μF capacitors (for a total of 0.5 μF) A 4.5" helical induction heating coil designed and developed specifically for this application.

Process: The body shim and carbide are cleaned and braze flux as applied to the entire surface of the assembly. The parts are placed together in the induction coil. Two ceramic tubes are then placed thru the coil opposing each other to hold the parts during heating. The flux on the parts is allowed to dry before heating. The induction heating power is applied until the braze flows in the joint.

Results/Benefits

• targeted heating of the braze joint is efficient

• flameless process is more precise, controllable

• results are reproducible

https://dw-inductionheater.com/brazing-carbide-steel-tool-with-induction.html?feed_id=251175&_unique_id=6678ba0cf1926

Wax and Hydrate Prevention in Oil and Gas Pipelines with Induction Heatin

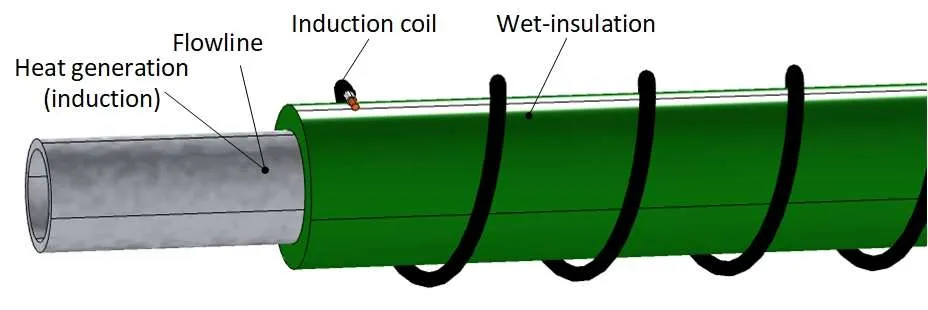

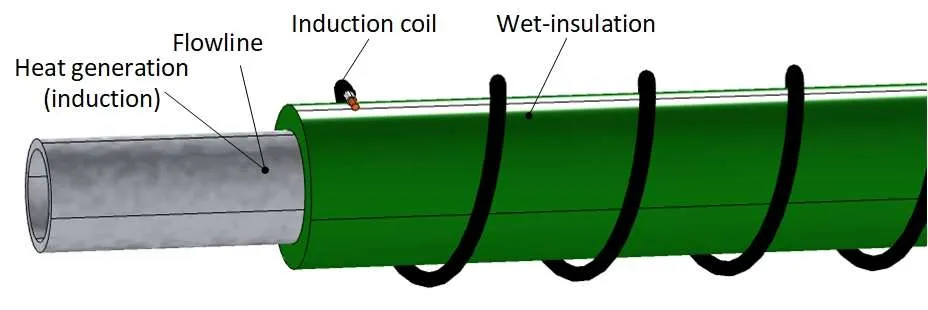

Ensuring Flow Assurance: Induction Heating for Wax and Hydrate Prevention in Oil and Gas Pipelines

Flow assurance is paramount in the oil and gas industry, where the uninterrupted transportation of hydrocarbons through pipelines is essential for operational efficiency and profitability. One of the significant challenges to flow assurance is the formation of wax and hydrates, which can obstruct pipelines and disrupt production. In addressing this challenge, induction heating has emerged as a highly effective and innovative solution.

Understanding the Problem: Wax and Hydrate Formation

Wax and hydrates are natural by-products found in crude oil and natural gas. When transported through pipelines, the temperature of the hydrocarbons can drop below certain thresholds, causing these substances to solidify and adhere to pipeline walls. This buildup gradually restricts flow, leading to reduced throughput and potentially costly operational disruptions.The Role of Induction Heating

Induction heating technology utilizes electromagnetic induction to generate heat directly within pipeline walls or at critical points where wax and hydrates are likely to form. Unlike traditional methods that involve heating fluids externally or using chemical additives, induction heating offers several distinct advantages: 1. **Precision Heating:** Induction heating allows for precise control over temperature profiles, ensuring that pipeline temperatures remain above the wax appearance temperature (WAT) and hydrate formation temperature thresholds. This targeted approach minimizes energy consumption and maximizes efficiency. 2. **Continuous Monitoring and Control:** Advanced monitoring systems continuously assess pipeline conditions and adjust induction heating parameters in real-time. This proactive management prevents temperature fluctuations that could promote wax and hydrate deposition. 3. **Environmental Sustainability:** Induction heating is inherently cleaner and more environmentally friendly compared to methods involving combustion or chemical treatments. It reduces emissions and minimizes the use of chemicals, aligning with global sustainability goals.Practical Applications and Benefits

In practice, induction heating systems are strategically deployed along pipelines, particularly in subsea or cold climate regions where temperatures can drop significantly. Key applications include: - **Subsea Pipelines:** Induction heating protects pipelines operating in deepwater environments where temperatures are conducive to wax and hydrate formation. - **Arctic and Cold Climate Operations:** Essential for pipelines in regions experiencing extreme cold, where maintaining temperatures above critical thresholds is challenging yet crucial for uninterrupted flow.

Case Studies and Success Stories

Several oil and gas companies have successfully implemented induction heating for wax and hydrate prevention, achieving notable improvements in operational reliability and cost-effectiveness. For instance, in offshore fields where subsea pipelines are subjected to cold seawater temperatures, induction heating has significantly reduced the frequency of pipeline blockages and maintenance shutdowns. #### Future Directions and Innovations As technology advances, ongoing research and development are focused on enhancing the efficiency and scalability of induction heating systems. Innovations include improved coil designs for better heat distribution, enhanced monitoring capabilities for predictive maintenance, and integration with smart pipeline management systems.Here are the detailed steps involved in using induction heating for wax and hydrate prevention:

### 1. Understanding the Problem Wax and hydrates are natural components found in crude oil and natural gas. When these fluids are transported through pipelines, especially in subsea or cold climate environments, their temperature can drop below critical thresholds. This causes wax to solidify and hydrates to form crystals, leading to the accumulation of deposits along pipeline walls. Over time, these deposits can restrict flow, reduce throughput, and necessitate costly maintenance interventions. ### 2. Designing the Induction Heating System #### a. System Components: - **Induction Coils:** Custom-designed coils are wrapped around the pipeline at strategic locations susceptible to wax and hydrate formation. These coils generate electromagnetic fields. - **Power Supply:** Provides the electrical energy necessary to create the electromagnetic fields in the coils. - **Control and Monitoring System:** Includes sensors and controllers to monitor pipeline temperature, adjust heating parameters, and ensure precise control over the induction heating process. #### b. Coil Configuration: - **Placement:** Coils are positioned along the pipeline where temperature management is critical, such as near wellheads, onshore/offshore risers, or subsea pipeline sections. - **Size and Shape:** Coils are tailored to fit the diameter and length of the pipeline, ensuring uniform heat distribution and efficient energy transfer. ### 3. Operational Steps #### a. Heating Strategy: - **Startup and Warm-Up:** The induction heating system is activated as soon as hydrocarbons start flowing through the pipeline. During startup, the system gradually increases heat to bring the pipeline temperature above the wax appearance temperature (WAT) and hydrate formation temperature. - **Continuous Heating:** Once operational, the system maintains a consistent pipeline temperature by continuously adjusting the power supplied to the coils based on real-time temperature readings from sensors. #### b. Monitoring and Control: - **Temperature Monitoring:** Sensors installed along the pipeline monitor the temperature at multiple points. This data is fed back to the control system, which ensures that the pipeline temperature remains within the optimal range to prevent wax and hydrate deposition. - **Adjustments and Optimization:** The control system dynamically adjusts heating parameters, such as coil power and frequency, to respond to changes in external conditions (e.g., ambient temperature variations) and internal pipeline conditions (e.g., flow rate fluctuations). ### 4. Benefits and Advantages

#### a. Operational Efficiency:

- **Uninterrupted Flow:** By preventing wax and hydrate buildup, induction heating ensures continuous and efficient transportation of hydrocarbons through the pipeline.

- **Reduced Maintenance:** Minimizes the need for costly and disruptive maintenance interventions, such as pigging operations or chemical treatments to remove deposits.

#### b. Environmental Considerations:

- **Sustainability:** Induction heating is a clean technology that minimizes environmental impact compared to alternative methods, such as chemical inhibitors or combustion-based heating.

- **Energy Efficiency:** Directly heats the pipeline material, reducing energy consumption and optimizing operational costs over the long term.

### 5. Case Studies and Applications

#### a. Offshore Applications:

- **Subsea Pipelines:** Induction heating is particularly crucial for pipelines operating in deepwater environments, where cold seawater temperatures can lead to rapid wax and hydrate formation.

- **Arctic Operations:** In cold climate regions, induction heating systems ensure pipeline integrity and flow assurance despite extreme ambient temperatures.

#### b. Onshore Applications:

- **Pipeline Networks:** Used in onshore pipeline networks to maintain flow assurance across extensive infrastructure, enhancing reliability and reducing downtime.

### 6. Future Developments and Innovations

- **Advanced Materials:** Research continues into developing advanced materials for induction coils and pipeline coatings to further improve heat transfer efficiency and durability.

- **Automation and AI Integration:** Integration with artificial intelligence (AI) algorithms for predictive maintenance and optimized heating strategies based on real-time data analytics.

### 4. Benefits and Advantages

#### a. Operational Efficiency:

- **Uninterrupted Flow:** By preventing wax and hydrate buildup, induction heating ensures continuous and efficient transportation of hydrocarbons through the pipeline.

- **Reduced Maintenance:** Minimizes the need for costly and disruptive maintenance interventions, such as pigging operations or chemical treatments to remove deposits.

#### b. Environmental Considerations:

- **Sustainability:** Induction heating is a clean technology that minimizes environmental impact compared to alternative methods, such as chemical inhibitors or combustion-based heating.

- **Energy Efficiency:** Directly heats the pipeline material, reducing energy consumption and optimizing operational costs over the long term.

### 5. Case Studies and Applications

#### a. Offshore Applications:

- **Subsea Pipelines:** Induction heating is particularly crucial for pipelines operating in deepwater environments, where cold seawater temperatures can lead to rapid wax and hydrate formation.

- **Arctic Operations:** In cold climate regions, induction heating systems ensure pipeline integrity and flow assurance despite extreme ambient temperatures.

#### b. Onshore Applications:

- **Pipeline Networks:** Used in onshore pipeline networks to maintain flow assurance across extensive infrastructure, enhancing reliability and reducing downtime.

### 6. Future Developments and Innovations

- **Advanced Materials:** Research continues into developing advanced materials for induction coils and pipeline coatings to further improve heat transfer efficiency and durability.

- **Automation and AI Integration:** Integration with artificial intelligence (AI) algorithms for predictive maintenance and optimized heating strategies based on real-time data analytics.

Conclusion

Induction heating for wax and hydrate prevention represents a technological breakthrough in ensuring flow assurance in oil and gas pipelines. By effectively managing pipeline temperatures above critical thresholds, this method mitigates operational risks, reduces maintenance costs, and supports sustainable energy practices. As industry demands for efficiency and reliability grow, investments in advanced induction heating technologies are poised to play a pivotal role in enhancing pipeline integrity and optimizing hydrocarbon transportation worldwide. Induction heating represents a transformative approach to ensuring flow assurance in oil and gas pipelines by effectively preventing wax and hydrate formation. Its precision heating capabilities, coupled with environmental benefits and operational efficiencies, make it a preferred choice for industry leaders seeking reliable and sustainable solutions. As the demand for energy continues to grow, investments in technologies like induction heating are pivotal in ensuring the safe and efficient transportation of hydrocarbons while mitigating environmental impacts. Embracing these innovations not only safeguards pipeline integrity but also reinforces the industry's commitment to responsible resource management and operational excellence. https://dw-inductionheater.com/wax-and-hydrate-prevention-in-oil-and-gas-pipelines-with-induction-heatin.html?feed_id=251109&_unique_id=66789d8020e53Wax and Hydrate Prevention in Oil and Gas Pipelines with Induction Heatin

Ensuring Flow Assurance: Induction Heating for Wax and Hydrate Prevention in Oil and Gas Pipelines

Flow assurance is paramount in the oil and gas industry, where the uninterrupted transportation of hydrocarbons through pipelines is essential for operational efficiency and profitability. One of the significant challenges to flow assurance is the formation of wax and hydrates, which can obstruct pipelines and disrupt production. In addressing this challenge, induction heating has emerged as a highly effective and innovative solution.

Understanding the Problem: Wax and Hydrate Formation

Wax and hydrates are natural by-products found in crude oil and natural gas. When transported through pipelines, the temperature of the hydrocarbons can drop below certain thresholds, causing these substances to solidify and adhere to pipeline walls. This buildup gradually restricts flow, leading to reduced throughput and potentially costly operational disruptions.The Role of Induction Heating

Induction heating technology utilizes electromagnetic induction to generate heat directly within pipeline walls or at critical points where wax and hydrates are likely to form. Unlike traditional methods that involve heating fluids externally or using chemical additives, induction heating offers several distinct advantages: 1. **Precision Heating:** Induction heating allows for precise control over temperature profiles, ensuring that pipeline temperatures remain above the wax appearance temperature (WAT) and hydrate formation temperature thresholds. This targeted approach minimizes energy consumption and maximizes efficiency. 2. **Continuous Monitoring and Control:** Advanced monitoring systems continuously assess pipeline conditions and adjust induction heating parameters in real-time. This proactive management prevents temperature fluctuations that could promote wax and hydrate deposition. 3. **Environmental Sustainability:** Induction heating is inherently cleaner and more environmentally friendly compared to methods involving combustion or chemical treatments. It reduces emissions and minimizes the use of chemicals, aligning with global sustainability goals.Practical Applications and Benefits

In practice, induction heating systems are strategically deployed along pipelines, particularly in subsea or cold climate regions where temperatures can drop significantly. Key applications include: - **Subsea Pipelines:** Induction heating protects pipelines operating in deepwater environments where temperatures are conducive to wax and hydrate formation. - **Arctic and Cold Climate Operations:** Essential for pipelines in regions experiencing extreme cold, where maintaining temperatures above critical thresholds is challenging yet crucial for uninterrupted flow.

Case Studies and Success Stories

Several oil and gas companies have successfully implemented induction heating for wax and hydrate prevention, achieving notable improvements in operational reliability and cost-effectiveness. For instance, in offshore fields where subsea pipelines are subjected to cold seawater temperatures, induction heating has significantly reduced the frequency of pipeline blockages and maintenance shutdowns. #### Future Directions and Innovations As technology advances, ongoing research and development are focused on enhancing the efficiency and scalability of induction heating systems. Innovations include improved coil designs for better heat distribution, enhanced monitoring capabilities for predictive maintenance, and integration with smart pipeline management systems.Here are the detailed steps involved in using induction heating for wax and hydrate prevention:

### 1. Understanding the Problem Wax and hydrates are natural components found in crude oil and natural gas. When these fluids are transported through pipelines, especially in subsea or cold climate environments, their temperature can drop below critical thresholds. This causes wax to solidify and hydrates to form crystals, leading to the accumulation of deposits along pipeline walls. Over time, these deposits can restrict flow, reduce throughput, and necessitate costly maintenance interventions. ### 2. Designing the Induction Heating System #### a. System Components: - **Induction Coils:** Custom-designed coils are wrapped around the pipeline at strategic locations susceptible to wax and hydrate formation. These coils generate electromagnetic fields. - **Power Supply:** Provides the electrical energy necessary to create the electromagnetic fields in the coils. - **Control and Monitoring System:** Includes sensors and controllers to monitor pipeline temperature, adjust heating parameters, and ensure precise control over the induction heating process. #### b. Coil Configuration: - **Placement:** Coils are positioned along the pipeline where temperature management is critical, such as near wellheads, onshore/offshore risers, or subsea pipeline sections. - **Size and Shape:** Coils are tailored to fit the diameter and length of the pipeline, ensuring uniform heat distribution and efficient energy transfer. ### 3. Operational Steps #### a. Heating Strategy: - **Startup and Warm-Up:** The induction heating system is activated as soon as hydrocarbons start flowing through the pipeline. During startup, the system gradually increases heat to bring the pipeline temperature above the wax appearance temperature (WAT) and hydrate formation temperature. - **Continuous Heating:** Once operational, the system maintains a consistent pipeline temperature by continuously adjusting the power supplied to the coils based on real-time temperature readings from sensors. #### b. Monitoring and Control: - **Temperature Monitoring:** Sensors installed along the pipeline monitor the temperature at multiple points. This data is fed back to the control system, which ensures that the pipeline temperature remains within the optimal range to prevent wax and hydrate deposition. - **Adjustments and Optimization:** The control system dynamically adjusts heating parameters, such as coil power and frequency, to respond to changes in external conditions (e.g., ambient temperature variations) and internal pipeline conditions (e.g., flow rate fluctuations). ### 4. Benefits and Advantages

#### a. Operational Efficiency:

- **Uninterrupted Flow:** By preventing wax and hydrate buildup, induction heating ensures continuous and efficient transportation of hydrocarbons through the pipeline.

- **Reduced Maintenance:** Minimizes the need for costly and disruptive maintenance interventions, such as pigging operations or chemical treatments to remove deposits.

#### b. Environmental Considerations:

- **Sustainability:** Induction heating is a clean technology that minimizes environmental impact compared to alternative methods, such as chemical inhibitors or combustion-based heating.

- **Energy Efficiency:** Directly heats the pipeline material, reducing energy consumption and optimizing operational costs over the long term.

### 5. Case Studies and Applications

#### a. Offshore Applications:

- **Subsea Pipelines:** Induction heating is particularly crucial for pipelines operating in deepwater environments, where cold seawater temperatures can lead to rapid wax and hydrate formation.

- **Arctic Operations:** In cold climate regions, induction heating systems ensure pipeline integrity and flow assurance despite extreme ambient temperatures.

#### b. Onshore Applications:

- **Pipeline Networks:** Used in onshore pipeline networks to maintain flow assurance across extensive infrastructure, enhancing reliability and reducing downtime.

### 6. Future Developments and Innovations

- **Advanced Materials:** Research continues into developing advanced materials for induction coils and pipeline coatings to further improve heat transfer efficiency and durability.

- **Automation and AI Integration:** Integration with artificial intelligence (AI) algorithms for predictive maintenance and optimized heating strategies based on real-time data analytics.

### 4. Benefits and Advantages

#### a. Operational Efficiency:

- **Uninterrupted Flow:** By preventing wax and hydrate buildup, induction heating ensures continuous and efficient transportation of hydrocarbons through the pipeline.

- **Reduced Maintenance:** Minimizes the need for costly and disruptive maintenance interventions, such as pigging operations or chemical treatments to remove deposits.

#### b. Environmental Considerations:

- **Sustainability:** Induction heating is a clean technology that minimizes environmental impact compared to alternative methods, such as chemical inhibitors or combustion-based heating.