The Importance of Induction Hardening of Gear Teeth for Smooth and Efficient Machinery.

Induction Hardening of Gear Teeth is a process that is often overlooked by machinery users, but it is one of the most important aspects of ensuring the smooth and efficient operation of any machinery. Induction hardening is a process of heat treatment that is used to selectively harden the surface of a gear.

This process is essential for ensuring that the gear teeth can withstand the high loads and stresses that are placed upon them during operation. By hardening the gear teeth in this way, machinery users can ensure that their equipment runs smoothly, efficiently, and with minimal wear and tear on the gears. In this blog post, we will explore the importance of induction gear teeth hardening, how it works, and why it is essential for the proper functioning of industrial machinery.

1. Introduction to Induction Hardening of Gear Teeth

Induction Hardening of Gear Teeth is an important process for ensuring that gears are smooth and efficient in their operation. Gears are a fundamental part of many machines, and they require precise engineering and attention to detail to work correctly. One crucial component of this precision is the hardness of the gear teeth. By using

induction hardening, the teeth of a gear can be made much harder and more durable, allowing them to operate more smoothly and with greater efficiency.

This process involves using an electrical current to heat the gear teeth to a specific temperature, followed by rapid cooling. This causes a change in the molecular structure of the metal, making it much harder and more resistant to wear and tear. The result is a gear that is better able to withstand the stresses of operation, providing a smoother and more efficient performance.

2. The Importance of Induction Hardening of Gear Teeth

Induction Hardening of Gear Teeth is a critical process that ensures the smooth and efficient functioning of machinery. This process involves heating the gear teeth with high-frequency alternating currents and then rapidly cooling them. This results in the formation of a hardened layer that is more wear-resistant and has a longer lifespan than the original gear teeth. Induction hardening is especially important for gears because they are constantly under high stress and friction during operation. If the gear teeth are not hardened properly, they can wear out quickly, leading to machinery breakdowns and decreased efficiency. Induction gear teeth hardening can also improve the load-carrying capacity of the gears, making them more durable and reliable in operation. By increasing the lifespan of the gears, the need for maintenance and replacements is reduced, saving time and money. Therefore, it is crucial to ensure that gear teeth are properly hardened through induction hardening to ensure the smooth and efficient operation of machinery.

3. How Induction Hardening of Gear TeethWorks

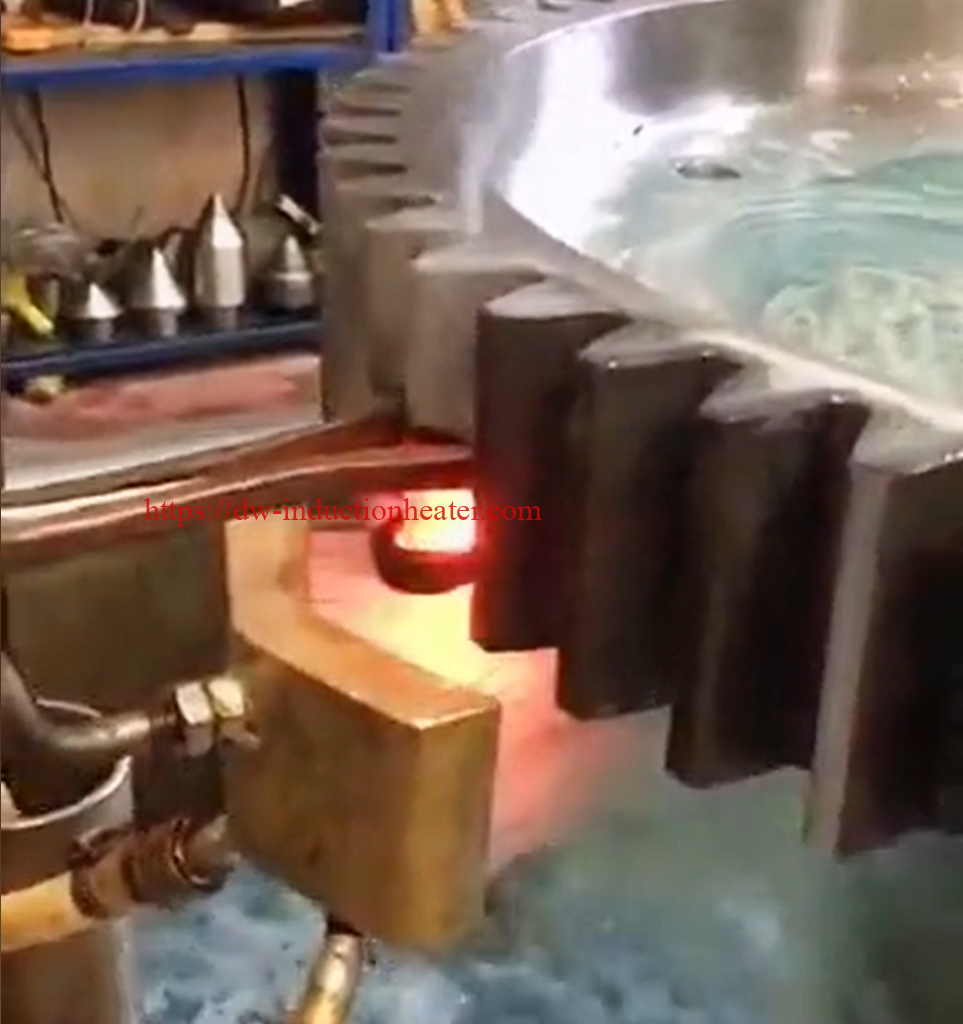

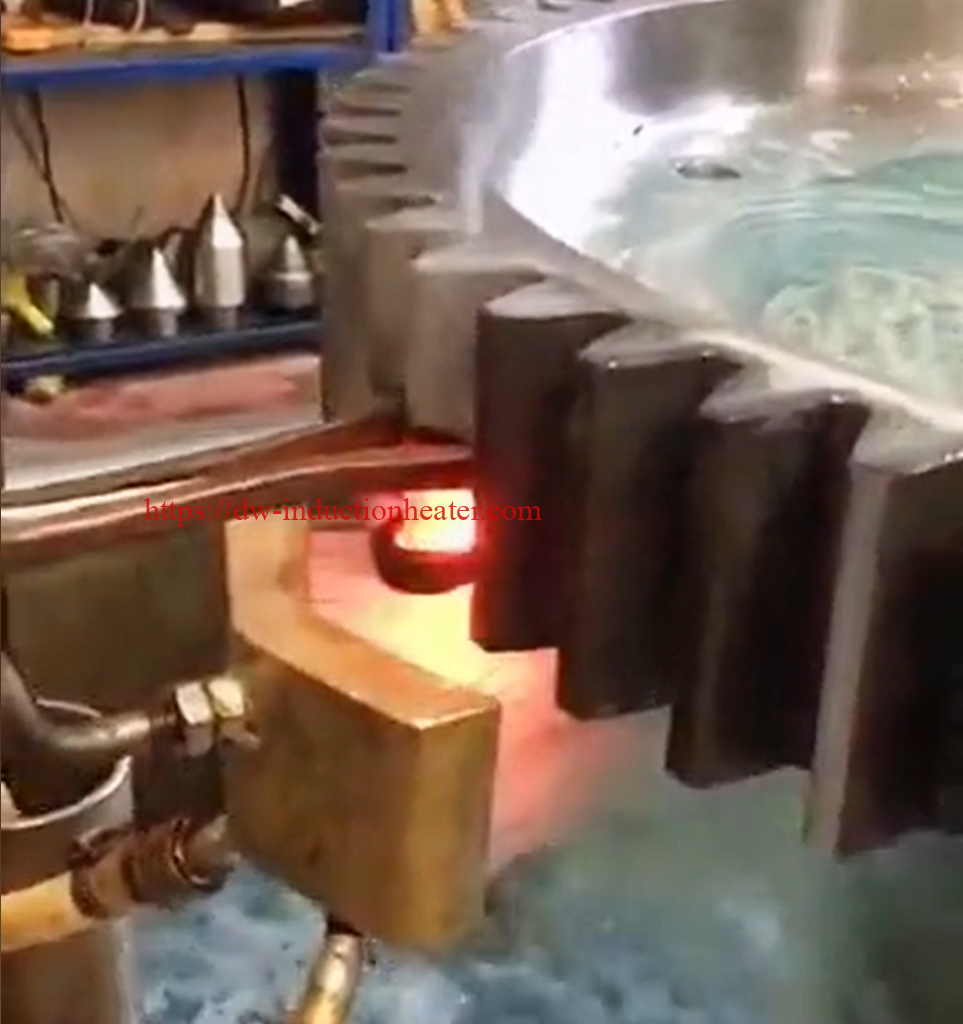

Induction gear teeth hardening is a process that involves heating the surface of the gear tooth with an induction coil to harden it. This process is important because it ensures that the gear teeth will remain strong and durable even after years of use. Induction gear teeth hardening works by heating the surface of the gear tooth to a specific temperature. This temperature is high enough to cause the surface of the gear tooth to change its crystal structure, which in turn hardens it.

The process is quick and efficient, and the result is a gear tooth that is much harder and more resistant to wear and tear than it was before. Induction gear teeth hardening is often used in industries where machinery is subject to constant use and wear, such as in manufacturing or transportation. By ensuring that the gear teeth are strong and durable, the machinery can continue to operate smoothly and efficiently for longer periods of time.

4. Benefits of Induction Gear Teeth Hardening for Machinery

Induction Hardening of Gear Teeth is a process that is crucial to the smooth and efficient operation of machinery. The benefits of induction gear teeth hardening are many and include increased strength, durability, and wear resistance. Induction hardening is a heat treatment process that uses high-frequency current to heat the surface of the gear teeth and then rapidly cools them. This creates a hard outer layer while maintaining the ductility and toughness of the core of the gear. One of the most significant benefits of induction gear teeth hardening is that it makes the gear more resistant to wear and tear. This, in turn, can help to extend the life of the gear and reduce the need for frequent replacements.

Induction hardening also helps to improve the gear's strength, making it less likely to warp or break under heavy loads. Another advantage of induction hardening is that it makes the gear more resistant to fatigue failure. This is important in machinery that is subjected to repeated loading and unloading. Fatigue failure occurs when a material is subjected to cyclic loading and unloading, causing micro-cracks to form. Induction hardening helps to prevent these micro-cracks from forming, making the gear less susceptible to fatigue failure. Finally, induction hardening can also improve the efficiency of the machinery. By reducing the amount of friction between the gear and other moving parts, the gear can operate more smoothly and with less energy. This can lead to a reduction in energy consumption, resulting in cost savings for the operator. Overall, induction gear teeth hardening is a process that is essential for the smooth and efficient operation of machinery. Its benefits include increased strength, durability, wear resistance, and improved efficiency, making it an important consideration for anyone looking to maintain and improve the performance of their machinery.

Induction hardening of gear teeth

Induction hardening of gear teeth is a process that involves heating the teeth of a gear with an induction coil and then rapidly cooling them with a spray of water or other cooling medium. This process is used to improve the wear resistance and durability of gear teeth, making them less likely to wear down or break over time. Induction gear teeth hardening is a popular choice for many industrial applications where gears are subjected to heavy use and need to last a long time. If you're interested in learning more about induction gear teeth hardening and how it can benefit your business, contact a reputable induction heating company today.

https://dw-inductionheater.com/improve-gear-performance-with-induction-hardening-of-gear-teeth.html?feed_id=231793&_unique_id=659d7e41049f3

This process is essential for ensuring that the gear teeth can withstand the high loads and stresses that are placed upon them during operation. By hardening the gear teeth in this way, machinery users can ensure that their equipment runs smoothly, efficiently, and with minimal wear and tear on the gears. In this blog post, we will explore the importance of induction gear teeth hardening, how it works, and why it is essential for the proper functioning of industrial machinery.

1. Introduction to Induction Hardening of Gear Teeth

Induction Hardening of Gear Teeth is an important process for ensuring that gears are smooth and efficient in their operation. Gears are a fundamental part of many machines, and they require precise engineering and attention to detail to work correctly. One crucial component of this precision is the hardness of the gear teeth. By using induction hardening, the teeth of a gear can be made much harder and more durable, allowing them to operate more smoothly and with greater efficiency.

This process is essential for ensuring that the gear teeth can withstand the high loads and stresses that are placed upon them during operation. By hardening the gear teeth in this way, machinery users can ensure that their equipment runs smoothly, efficiently, and with minimal wear and tear on the gears. In this blog post, we will explore the importance of induction gear teeth hardening, how it works, and why it is essential for the proper functioning of industrial machinery.

1. Introduction to Induction Hardening of Gear Teeth

Induction Hardening of Gear Teeth is an important process for ensuring that gears are smooth and efficient in their operation. Gears are a fundamental part of many machines, and they require precise engineering and attention to detail to work correctly. One crucial component of this precision is the hardness of the gear teeth. By using induction hardening, the teeth of a gear can be made much harder and more durable, allowing them to operate more smoothly and with greater efficiency.  This process involves using an electrical current to heat the gear teeth to a specific temperature, followed by rapid cooling. This causes a change in the molecular structure of the metal, making it much harder and more resistant to wear and tear. The result is a gear that is better able to withstand the stresses of operation, providing a smoother and more efficient performance.

2. The Importance of Induction Hardening of Gear Teeth

Induction Hardening of Gear Teeth is a critical process that ensures the smooth and efficient functioning of machinery. This process involves heating the gear teeth with high-frequency alternating currents and then rapidly cooling them. This results in the formation of a hardened layer that is more wear-resistant and has a longer lifespan than the original gear teeth. Induction hardening is especially important for gears because they are constantly under high stress and friction during operation. If the gear teeth are not hardened properly, they can wear out quickly, leading to machinery breakdowns and decreased efficiency. Induction gear teeth hardening can also improve the load-carrying capacity of the gears, making them more durable and reliable in operation. By increasing the lifespan of the gears, the need for maintenance and replacements is reduced, saving time and money. Therefore, it is crucial to ensure that gear teeth are properly hardened through induction hardening to ensure the smooth and efficient operation of machinery.

3. How Induction Hardening of Gear TeethWorks

Induction gear teeth hardening is a process that involves heating the surface of the gear tooth with an induction coil to harden it. This process is important because it ensures that the gear teeth will remain strong and durable even after years of use. Induction gear teeth hardening works by heating the surface of the gear tooth to a specific temperature. This temperature is high enough to cause the surface of the gear tooth to change its crystal structure, which in turn hardens it.

This process involves using an electrical current to heat the gear teeth to a specific temperature, followed by rapid cooling. This causes a change in the molecular structure of the metal, making it much harder and more resistant to wear and tear. The result is a gear that is better able to withstand the stresses of operation, providing a smoother and more efficient performance.

2. The Importance of Induction Hardening of Gear Teeth

Induction Hardening of Gear Teeth is a critical process that ensures the smooth and efficient functioning of machinery. This process involves heating the gear teeth with high-frequency alternating currents and then rapidly cooling them. This results in the formation of a hardened layer that is more wear-resistant and has a longer lifespan than the original gear teeth. Induction hardening is especially important for gears because they are constantly under high stress and friction during operation. If the gear teeth are not hardened properly, they can wear out quickly, leading to machinery breakdowns and decreased efficiency. Induction gear teeth hardening can also improve the load-carrying capacity of the gears, making them more durable and reliable in operation. By increasing the lifespan of the gears, the need for maintenance and replacements is reduced, saving time and money. Therefore, it is crucial to ensure that gear teeth are properly hardened through induction hardening to ensure the smooth and efficient operation of machinery.

3. How Induction Hardening of Gear TeethWorks

Induction gear teeth hardening is a process that involves heating the surface of the gear tooth with an induction coil to harden it. This process is important because it ensures that the gear teeth will remain strong and durable even after years of use. Induction gear teeth hardening works by heating the surface of the gear tooth to a specific temperature. This temperature is high enough to cause the surface of the gear tooth to change its crystal structure, which in turn hardens it.  The process is quick and efficient, and the result is a gear tooth that is much harder and more resistant to wear and tear than it was before. Induction gear teeth hardening is often used in industries where machinery is subject to constant use and wear, such as in manufacturing or transportation. By ensuring that the gear teeth are strong and durable, the machinery can continue to operate smoothly and efficiently for longer periods of time.

4. Benefits of Induction Gear Teeth Hardening for Machinery

Induction Hardening of Gear Teeth is a process that is crucial to the smooth and efficient operation of machinery. The benefits of induction gear teeth hardening are many and include increased strength, durability, and wear resistance. Induction hardening is a heat treatment process that uses high-frequency current to heat the surface of the gear teeth and then rapidly cools them. This creates a hard outer layer while maintaining the ductility and toughness of the core of the gear. One of the most significant benefits of induction gear teeth hardening is that it makes the gear more resistant to wear and tear. This, in turn, can help to extend the life of the gear and reduce the need for frequent replacements.

The process is quick and efficient, and the result is a gear tooth that is much harder and more resistant to wear and tear than it was before. Induction gear teeth hardening is often used in industries where machinery is subject to constant use and wear, such as in manufacturing or transportation. By ensuring that the gear teeth are strong and durable, the machinery can continue to operate smoothly and efficiently for longer periods of time.

4. Benefits of Induction Gear Teeth Hardening for Machinery

Induction Hardening of Gear Teeth is a process that is crucial to the smooth and efficient operation of machinery. The benefits of induction gear teeth hardening are many and include increased strength, durability, and wear resistance. Induction hardening is a heat treatment process that uses high-frequency current to heat the surface of the gear teeth and then rapidly cools them. This creates a hard outer layer while maintaining the ductility and toughness of the core of the gear. One of the most significant benefits of induction gear teeth hardening is that it makes the gear more resistant to wear and tear. This, in turn, can help to extend the life of the gear and reduce the need for frequent replacements.  Induction hardening also helps to improve the gear's strength, making it less likely to warp or break under heavy loads. Another advantage of induction hardening is that it makes the gear more resistant to fatigue failure. This is important in machinery that is subjected to repeated loading and unloading. Fatigue failure occurs when a material is subjected to cyclic loading and unloading, causing micro-cracks to form. Induction hardening helps to prevent these micro-cracks from forming, making the gear less susceptible to fatigue failure. Finally, induction hardening can also improve the efficiency of the machinery. By reducing the amount of friction between the gear and other moving parts, the gear can operate more smoothly and with less energy. This can lead to a reduction in energy consumption, resulting in cost savings for the operator. Overall, induction gear teeth hardening is a process that is essential for the smooth and efficient operation of machinery. Its benefits include increased strength, durability, wear resistance, and improved efficiency, making it an important consideration for anyone looking to maintain and improve the performance of their machinery.

Induction hardening also helps to improve the gear's strength, making it less likely to warp or break under heavy loads. Another advantage of induction hardening is that it makes the gear more resistant to fatigue failure. This is important in machinery that is subjected to repeated loading and unloading. Fatigue failure occurs when a material is subjected to cyclic loading and unloading, causing micro-cracks to form. Induction hardening helps to prevent these micro-cracks from forming, making the gear less susceptible to fatigue failure. Finally, induction hardening can also improve the efficiency of the machinery. By reducing the amount of friction between the gear and other moving parts, the gear can operate more smoothly and with less energy. This can lead to a reduction in energy consumption, resulting in cost savings for the operator. Overall, induction gear teeth hardening is a process that is essential for the smooth and efficient operation of machinery. Its benefits include increased strength, durability, wear resistance, and improved efficiency, making it an important consideration for anyone looking to maintain and improve the performance of their machinery. Induction hardening of gear teeth is a process that involves heating the teeth of a gear with an induction coil and then rapidly cooling them with a spray of water or other cooling medium. This process is used to improve the wear resistance and durability of gear teeth, making them less likely to wear down or break over time. Induction gear teeth hardening is a popular choice for many industrial applications where gears are subjected to heavy use and need to last a long time. If you're interested in learning more about induction gear teeth hardening and how it can benefit your business, contact a reputable induction heating company today.

https://dw-inductionheater.com/improve-gear-performance-with-induction-hardening-of-gear-teeth.html?feed_id=231793&_unique_id=659d7e41049f3

Induction hardening of gear teeth is a process that involves heating the teeth of a gear with an induction coil and then rapidly cooling them with a spray of water or other cooling medium. This process is used to improve the wear resistance and durability of gear teeth, making them less likely to wear down or break over time. Induction gear teeth hardening is a popular choice for many industrial applications where gears are subjected to heavy use and need to last a long time. If you're interested in learning more about induction gear teeth hardening and how it can benefit your business, contact a reputable induction heating company today.

https://dw-inductionheater.com/improve-gear-performance-with-induction-hardening-of-gear-teeth.html?feed_id=231793&_unique_id=659d7e41049f3