Objective

The objective of the application test is induction brazing aluminum tubing to aluminum parts in less than 15 seconds. We have aluminum tubing and an aluminum “receiver”. The brazing alloy is an alloy ring, and has a flow temperature of 1030°F (554°C).

Equipment

DW-HF-15kw induction heating machine

[caption id="attachment_97" align="alignnone" width="267"] induction heating machine HF-15[/caption]

Induction heating coil

Materials

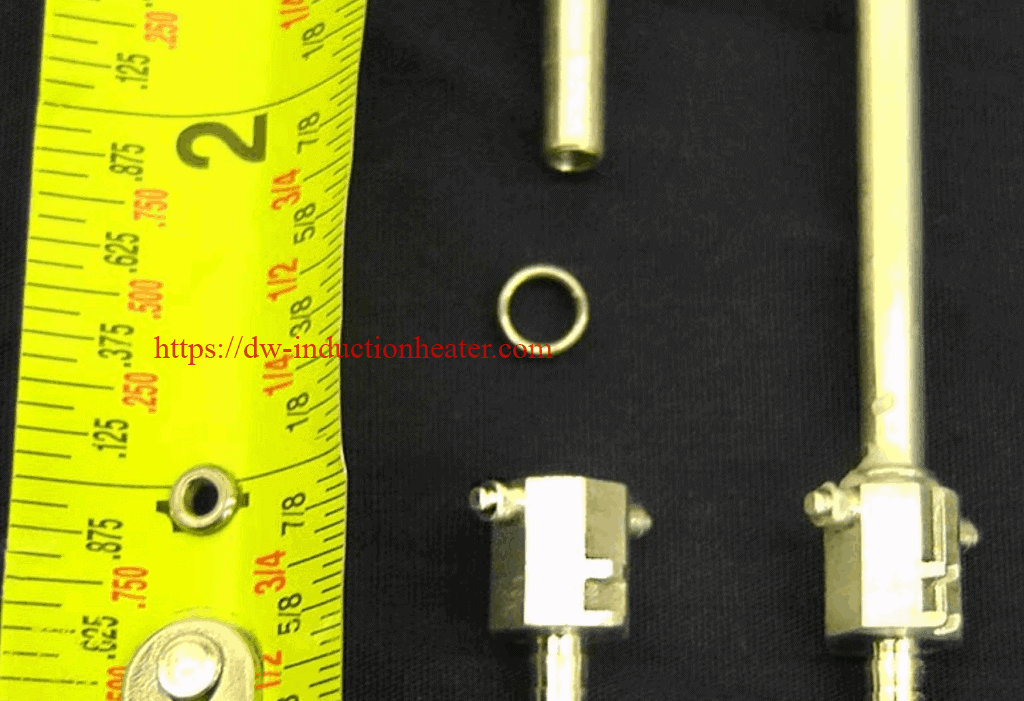

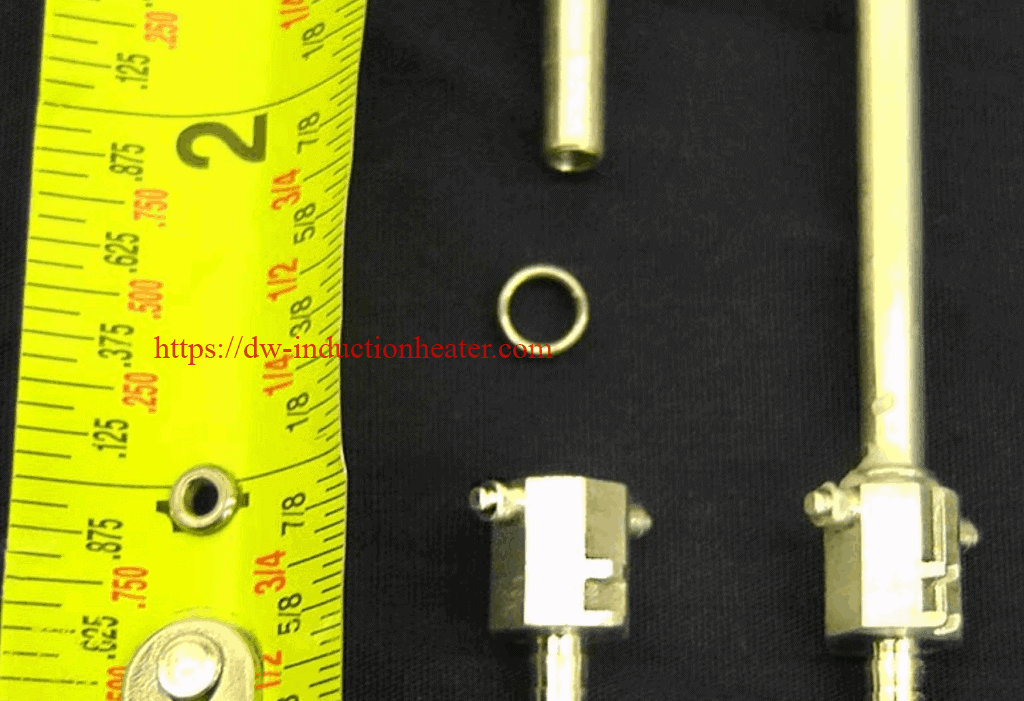

• Aluminum tube: 0.167” (4.242mm) OD, 0.108” (2.743mm) ID

• Aluminum component: ID .1675” (4.255mm), depth .288” (7.315mm),

chamfer at top area is 0.2375” (6.033mm) ID max

• Braze alloy in the form of two-turn alloy ring

• Flux

induction heating machine HF-15[/caption]

Induction heating coil

Materials

• Aluminum tube: 0.167” (4.242mm) OD, 0.108” (2.743mm) ID

• Aluminum component: ID .1675” (4.255mm), depth .288” (7.315mm),

chamfer at top area is 0.2375” (6.033mm) ID max

• Braze alloy in the form of two-turn alloy ring

• Flux

Key Parameters

Temperature: 1030°F (554°C)

Power: 5 kW

Time: 14 seconds

Key Parameters

Temperature: 1030°F (554°C)

Power: 5 kW

Time: 14 seconds

induction heating machine HF-15[/caption]

Induction heating coil

Materials

• Aluminum tube: 0.167” (4.242mm) OD, 0.108” (2.743mm) ID

• Aluminum component: ID .1675” (4.255mm), depth .288” (7.315mm),

chamfer at top area is 0.2375” (6.033mm) ID max

• Braze alloy in the form of two-turn alloy ring

• Flux

induction heating machine HF-15[/caption]

Induction heating coil

Materials

• Aluminum tube: 0.167” (4.242mm) OD, 0.108” (2.743mm) ID

• Aluminum component: ID .1675” (4.255mm), depth .288” (7.315mm),

chamfer at top area is 0.2375” (6.033mm) ID max

• Braze alloy in the form of two-turn alloy ring

• Flux

Key Parameters

Temperature: 1030°F (554°C)

Power: 5 kW

Time: 14 seconds

Key Parameters

Temperature: 1030°F (554°C)

Power: 5 kW

Time: 14 seconds

Process:

Results/Benefits:

The 5 kW induction heating system requested by the customer, will meet the customer’s time requirements for induction brazing.

Results/Benefits:

The 5 kW induction heating system requested by the customer, will meet the customer’s time requirements for induction brazing.

- The Aluminum component and tube were assembled together with the alloy ring. Flux was added.

- The part was positioned in the induction coil.

- Several tests were conducted with different cycle times to confirm the heating time for a good braze.

- At 15 seconds the assembly melted.

- At 14 seconds, we had success for brazing aluminum to aluminum, and a good quality braze joint was achieved.

Results/Benefits:

The 5 kW induction heating system requested by the customer, will meet the customer’s time requirements for induction brazing.

Results/Benefits:

The 5 kW induction heating system requested by the customer, will meet the customer’s time requirements for induction brazing.

- Precise control of the time and temperature

- Power on demand with rapid heat cycles

- Repeatable process, not operator dependent

- Safe induction heating with no open flames

- Energy efficient heating