PDF handbook of induction heating eddy current

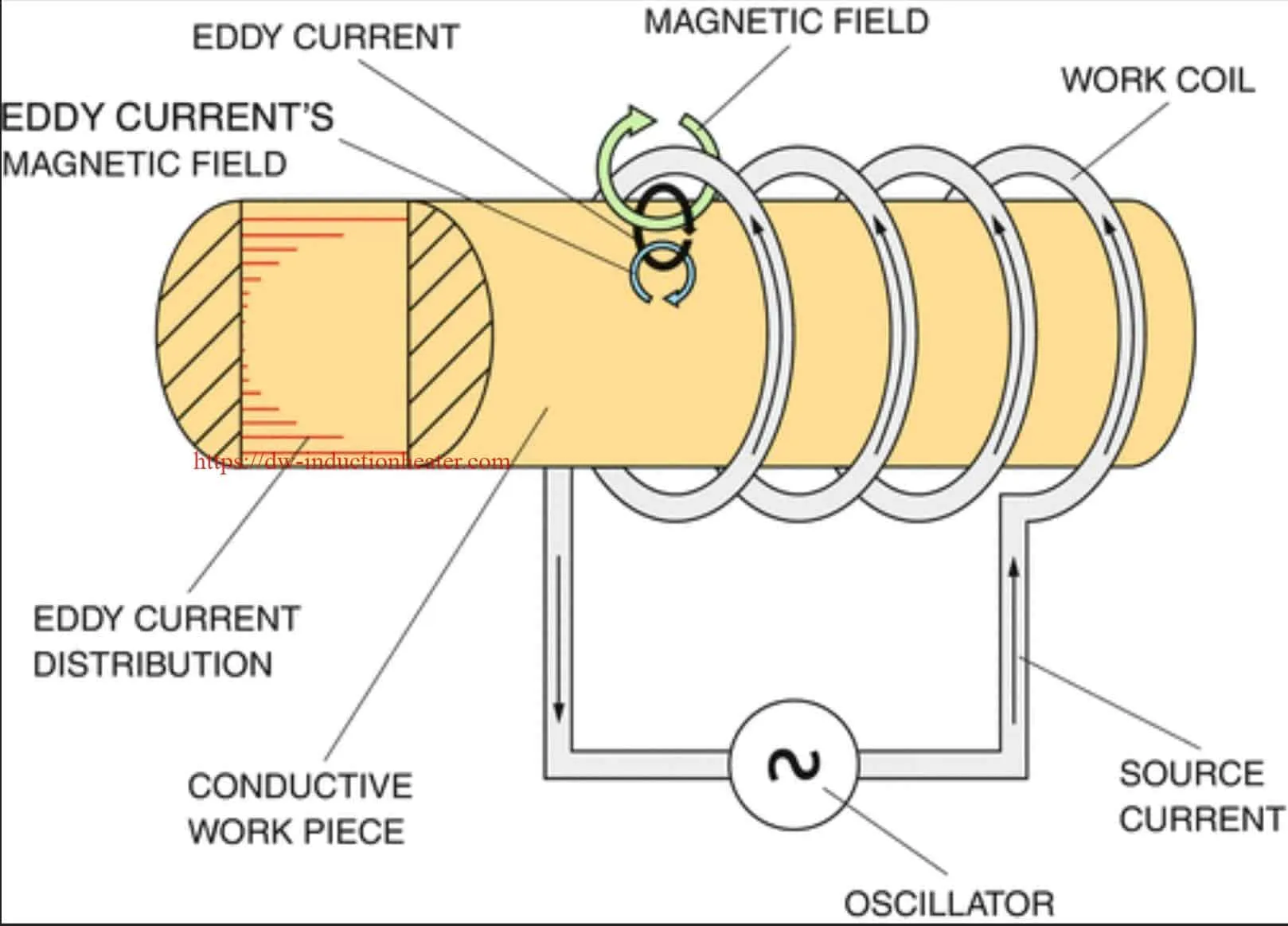

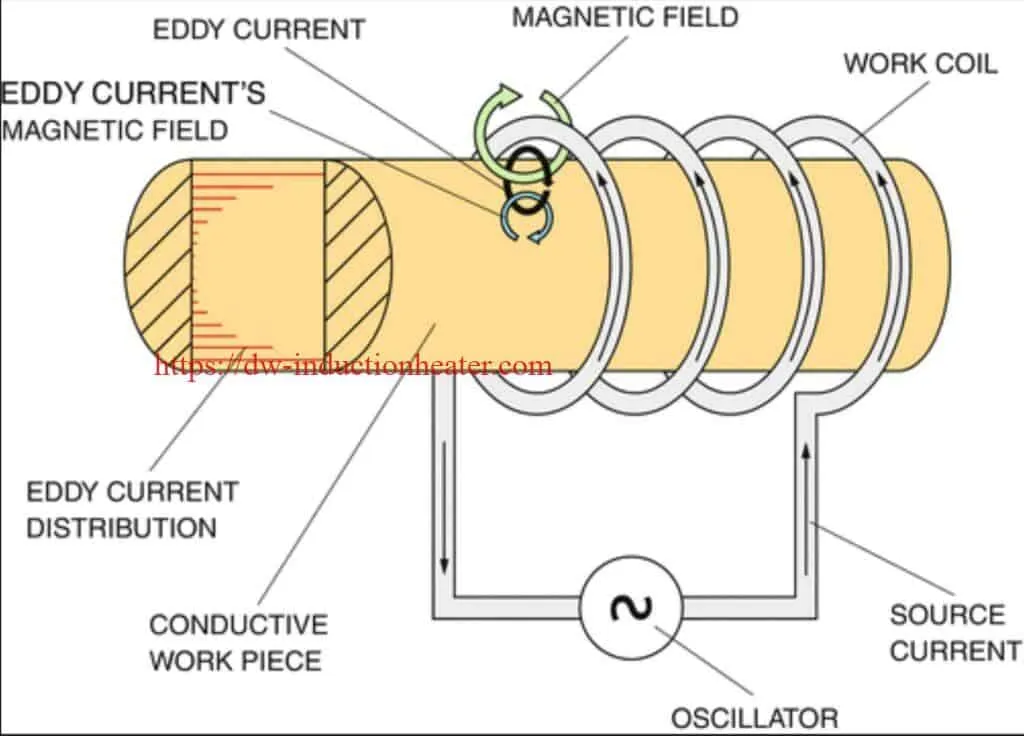

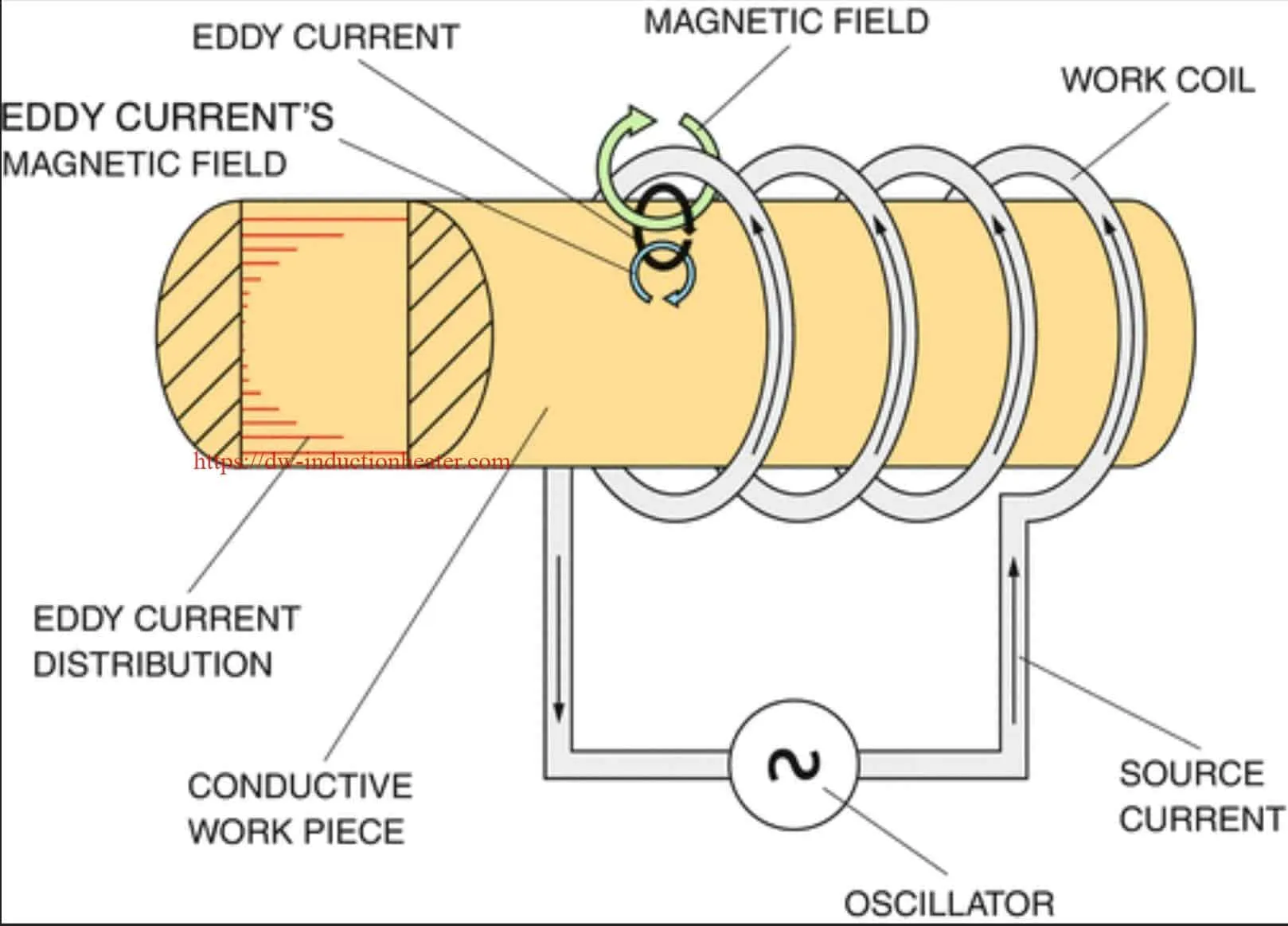

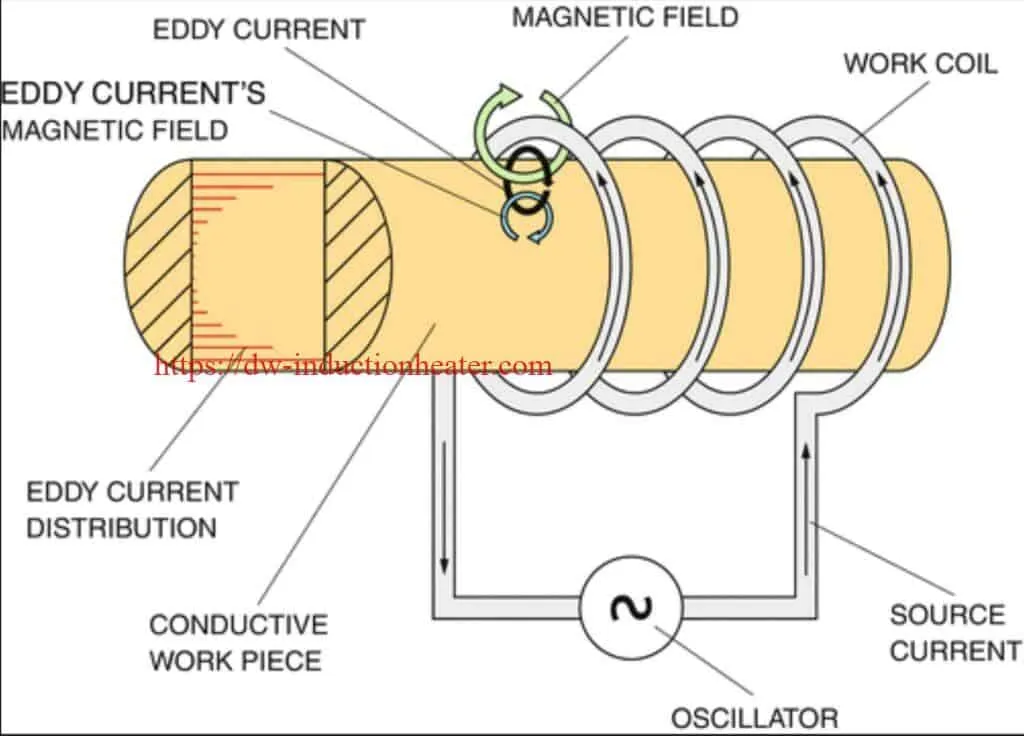

Both induction heating and eddy current testing work with coils, generators, ac-current and ac-voltage,

frequencies, field strength and induction law. Contrary to heating of the test parts, the eddy current

test does not want to heat the parts at all but wants to examine them for their metallurgical microstructure, thus for their mechanical features like hardness, case depth or alloy. The eddy current test

does not provide absolute values (e.g. "56 HRC" or "2.6 mm case depth").

The eddy current test does detect fine differences in micro-structure with high sensitivity. In the

production line, within a fraction of a second, a non-destructive 100 % test for

• hardness

• case depth

• hardness run out, hardness pattern

• tensile strength

• carbon content

• soft spots

• surface decarburisation

is completed, and thus quick corrective reactions to any variance from the specified structure can be

realized. With a suitable mechanical part handling arrangement, the transport from the hardening

station to the test station takes only a few seconds. Faulty parts, caused by a damaged inductor, a

jammed quench nozzle or an unknown reason are immediately detected, providing an enormous

savings in time and costs!

[caption id="attachment_7309" align="alignright" width="1024"]

induction-heating-eddy-current.[/caption]

Different from the induction heating, the energy for eddy current testing is very small, in the milliwatt

range. Field strength is low and permeability is in the range of the initial permeability. Test frequencies

ranging from some Hz to some hundreds of kHz provide information on undesired structures via the

frequency dependent penetration depth of the eddy current and on the formation of permeability. Very

small electrical signals require a very precise evaluation in order to assure their differentiation from

ambient interferences. A small drift from variation in temperature and high long term stability are

absolutely necessary. Digitization of input voltages immediately at the front end of the electronic

evaluation is of huge advantage.

Handbook-Induction-Heating-Eddy-Current-Paper-EN

https://dw-inductionheater.com/handbook-of-induction-heating-eddy-current.html?feed_id=112212&_unique_id=625acc9fd84dd

induction-heating-eddy-current.[/caption]

Different from the induction heating, the energy for eddy current testing is very small, in the milliwatt

range. Field strength is low and permeability is in the range of the initial permeability. Test frequencies

ranging from some Hz to some hundreds of kHz provide information on undesired structures via the

frequency dependent penetration depth of the eddy current and on the formation of permeability. Very

small electrical signals require a very precise evaluation in order to assure their differentiation from

ambient interferences. A small drift from variation in temperature and high long term stability are

absolutely necessary. Digitization of input voltages immediately at the front end of the electronic

evaluation is of huge advantage.

Handbook-Induction-Heating-Eddy-Current-Paper-EN

https://dw-inductionheater.com/handbook-of-induction-heating-eddy-current.html?feed_id=112212&_unique_id=625acc9fd84dd

induction-heating-eddy-current.[/caption]

Different from the induction heating, the energy for eddy current testing is very small, in the milliwatt

range. Field strength is low and permeability is in the range of the initial permeability. Test frequencies

ranging from some Hz to some hundreds of kHz provide information on undesired structures via the

frequency dependent penetration depth of the eddy current and on the formation of permeability. Very

small electrical signals require a very precise evaluation in order to assure their differentiation from

ambient interferences. A small drift from variation in temperature and high long term stability are

absolutely necessary. Digitization of input voltages immediately at the front end of the electronic

evaluation is of huge advantage.

Handbook-Induction-Heating-Eddy-Current-Paper-EN

https://dw-inductionheater.com/handbook-of-induction-heating-eddy-current.html?feed_id=112212&_unique_id=625acc9fd84dd