Electromagnetic Induction heating thermal conductive oil boiler--Induction Fluid Boiler--Induction Fluid Heating Generator

Product Description

Induction heating thermal conductive oil

Product Description

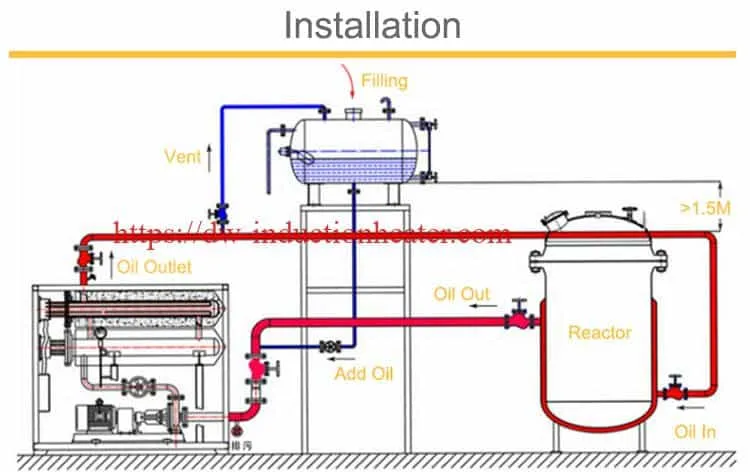

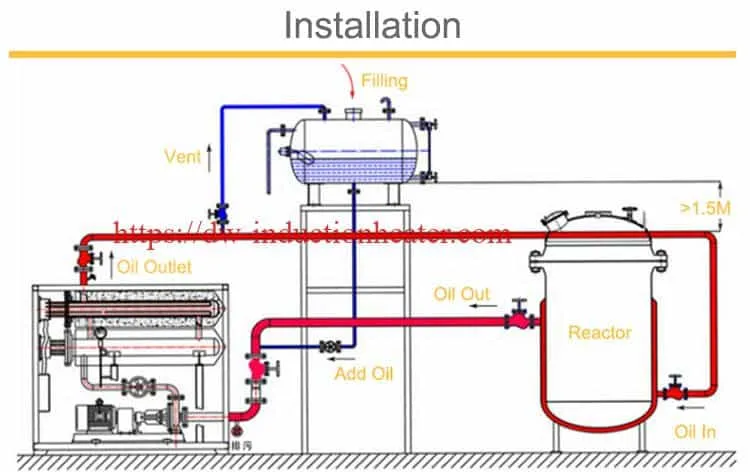

Induction heating thermal conductive oil boiler is a new type of electromagnetic induction heating equipment that is safe, energy-saving, low-pressure and capable of providing high-temperature heat energy. It uses electromagnetic induction as heat source, heat thermal conductive oil as heat carrier, and uses hot-oil pump to transport the heated thermal conductive oil liquid to the equipment that needs to be heated. The heat source and the equipment form a circulating heat loop to achieve strong continuous transfer of heat energy, and so on and on again to meet the technological requirements of heating. It has industrial special heating equipment with simple operation, no pollution and small footprint.

Technical Parameter

Technical Parameter

| Induction heating thermal conductive oil boiler |

|

| Model Specifications |

DWOB-80 |

DWOB-100 |

DWOB-150 |

DWOB-300 |

DWOB-600 |

|

| Design pressure (MPa) |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

|

| Working pressure (MPa) |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

|

| Rated power (KW) |

80 |

100 |

150 |

300 |

600 |

|

| Rated current (A) |

120 |

150 |

225 |

450 |

900 |

|

| Rated voltage (V) |

380 |

380 |

380 |

380 |

380 |

|

| Precision |

±1°C |

|

| Temperature range (℃) |

0-350 |

0-350 |

0-350 |

0-350 |

0-350 |

|

| Thermal efficiency |

98% |

98% |

98% |

98% |

98% |

|

| Pump head |

25/38 |

25/40 |

25/40 |

50/50 |

55/30 |

|

| Pump flow |

40 |

40 |

40 |

50/60 |

100 |

|

| Motor Power |

5.5 |

5.5/7.5 |

20 |

21 |

22 |

|

Performance advantage: Induction heating thermal conductive oil boiler

Performance advantage: Induction heating thermal conductive oil boiler

1. Green and environmental protection: Compared with traditional boilers, it does not burn and emits no pollutants during heating. It is fully in line with the national long-term plan for pollution control, green environmental protection and low-carbon life.

2. Energy saving. Compared with the electric heating tube boiler, the electromagnetic induction boiler can save 20% to 30% of the energy. It uses the eddy current phenomenon of high frequency electromagnetic to directly heat the boiler furnace body. Its magnetic resistance is small and the thermal efficiency is high, which can reach more than 95%.

3. Long service life. Its service life is three to four times that of coal-fired and gas-fired boilers. Traditional boilers continue to corrode the furnace body due to the high temperature generated by combustion, and the furnace will be damaged over time. The electromagnetic boiler uses the principle of high-frequency electromagnetic heating, no name fire, no combustion.

4. High degree of automation: Adopt programmable automation control PLC technology, MCU single chip technology, touch screen and film technology. The ease of these technologies enables the remote control of the

electromagnetic induction oil boiler without manual duty.

Features

The

electricmagnetic induction thermal conductive oil boiler has the characteristics of compact structure, small size, light weight, easy installation and operation, fast heating and no environmental pollution, etc. The computer automatically controls the temperature and can obtain a higher working temperature at a lower working pressure.

Product Description

Induction heating thermal conductive oil boiler is a new type of electromagnetic induction heating equipment that is safe, energy-saving, low-pressure and capable of providing high-temperature heat energy. It uses electromagnetic induction as heat source, heat thermal conductive oil as heat carrier, and uses hot-oil pump to transport the heated thermal conductive oil liquid to the equipment that needs to be heated. The heat source and the equipment form a circulating heat loop to achieve strong continuous transfer of heat energy, and so on and on again to meet the technological requirements of heating. It has industrial special heating equipment with simple operation, no pollution and small footprint.

Product Description

Induction heating thermal conductive oil boiler is a new type of electromagnetic induction heating equipment that is safe, energy-saving, low-pressure and capable of providing high-temperature heat energy. It uses electromagnetic induction as heat source, heat thermal conductive oil as heat carrier, and uses hot-oil pump to transport the heated thermal conductive oil liquid to the equipment that needs to be heated. The heat source and the equipment form a circulating heat loop to achieve strong continuous transfer of heat energy, and so on and on again to meet the technological requirements of heating. It has industrial special heating equipment with simple operation, no pollution and small footprint.

Technical Parameter

Technical Parameter

Performance advantage: Induction heating thermal conductive oil boiler

1. Green and environmental protection: Compared with traditional boilers, it does not burn and emits no pollutants during heating. It is fully in line with the national long-term plan for pollution control, green environmental protection and low-carbon life.

2. Energy saving. Compared with the electric heating tube boiler, the electromagnetic induction boiler can save 20% to 30% of the energy. It uses the eddy current phenomenon of high frequency electromagnetic to directly heat the boiler furnace body. Its magnetic resistance is small and the thermal efficiency is high, which can reach more than 95%.

3. Long service life. Its service life is three to four times that of coal-fired and gas-fired boilers. Traditional boilers continue to corrode the furnace body due to the high temperature generated by combustion, and the furnace will be damaged over time. The electromagnetic boiler uses the principle of high-frequency electromagnetic heating, no name fire, no combustion.

4. High degree of automation: Adopt programmable automation control PLC technology, MCU single chip technology, touch screen and film technology. The ease of these technologies enables the remote control of the electromagnetic induction oil boiler without manual duty.

Performance advantage: Induction heating thermal conductive oil boiler

1. Green and environmental protection: Compared with traditional boilers, it does not burn and emits no pollutants during heating. It is fully in line with the national long-term plan for pollution control, green environmental protection and low-carbon life.

2. Energy saving. Compared with the electric heating tube boiler, the electromagnetic induction boiler can save 20% to 30% of the energy. It uses the eddy current phenomenon of high frequency electromagnetic to directly heat the boiler furnace body. Its magnetic resistance is small and the thermal efficiency is high, which can reach more than 95%.

3. Long service life. Its service life is three to four times that of coal-fired and gas-fired boilers. Traditional boilers continue to corrode the furnace body due to the high temperature generated by combustion, and the furnace will be damaged over time. The electromagnetic boiler uses the principle of high-frequency electromagnetic heating, no name fire, no combustion.

4. High degree of automation: Adopt programmable automation control PLC technology, MCU single chip technology, touch screen and film technology. The ease of these technologies enables the remote control of the electromagnetic induction oil boiler without manual duty.