Applications and Advantages of Induction Heating Steam Boiler - Induction Steam System in Manufacturing and Process Industry.

Steam for Process Heating

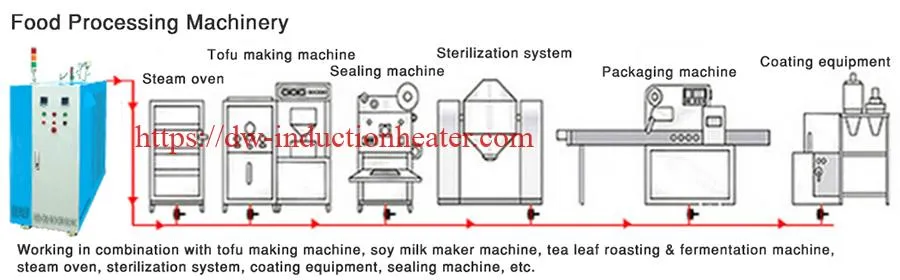

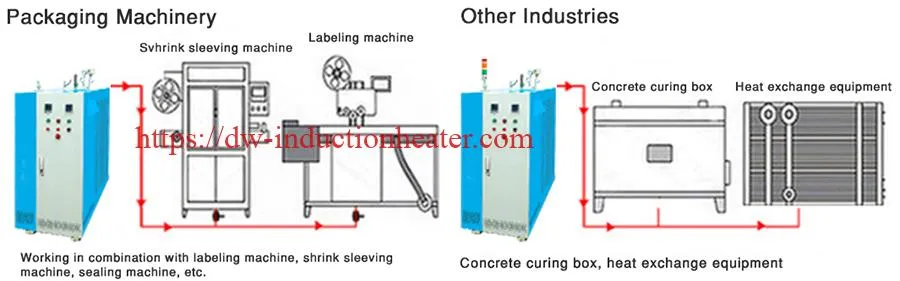

Steam is largely used for the purpose of process heating. Using steam for processing heating offers multiple benefits over other heating media. Numerous benefits, simplicity of the system and high efficiency and reliability make steam the first choice for process heating. Steam can be used either for direct heating or indirect heating.

Steam can be used either for direct heating or indirect heating.

- Direct HeatingIn direct heating, steam is directly injected in the substance which is to be heated. Care should be taken that proper mixing takes place to ensure uniform heating. It is also essential to take care that no temperature overshoots are observed. Sparge pipes should be used to ensure that steam does not escape to the environment without heating the product.In pharmaceutical or food and beverages industry, steam of highest purity (safe to be consumed by humans) should always be used for direct heating purposes.

- Indirect HeatingThe indirect method of heating uses steam to heat the product with the help of heat exchangers so that the product does not come physically in contact with steam. The indirect heating can be done through use of various heating equipment such as cookers, jacketed vessels, plate type or shell and tube type heat exchangers etc.

Steam for Atomization

The process of atomization ensures a better combustion of fuels. The word atomization literally means breaking in to tiny particles. In burners, steam is used for the purpose of atomizing the fuel. This ensures a larger surface area of the fuel available for the combustion. As a result of atomization, soot formation is minimized and overall efficiency of combustion goes up.Steam for Power Generation

The very first commercial central electrical generating stations in New York and London, in 1882, also used reciprocating steam engines For decades, steam is being used for the purpose of power generation in form of electricity. The steam power plants work on the Rankine Cycle. In Rankine cycle, superheated steam is generated and then taken to steam turbine. The steam drives the turbine which in turn generates the electricity. The used steam is again converted in to water using a condenser. This recovered water is again fed back to the boiler to generate steam. The efficiency of the power plant is directly dependent on difference between pressure and temperature of steam at the inlet and outlet of turbine. Hence, use of high temperature and high pressure steam is advisable. Hence, power generation plants are most efficient when superheated steam is used. As high pressure is involved, water tube boilers are used for steam generation.Steam for Humidification

Maintaining humidity is a crucial aspect of HVAC systems as humidity lower or higher than desired has adverse effects on humans, machines and materials. Humidity lower than desired might lead to drying of mucus membranes which ultimately results in respiratory distress. Low humidity also leads to increased static electricity problems which might damage the costly equipment.

Steam can be used for the purpose of humidification. Using steam for the purpose of humidification offers added advantages over other media. There are different types of humidifiers from evaporating humidifiers to ultrasonic ones to suit different applications.

Low humidity also leads to increased static electricity problems which might damage the costly equipment.

Steam can be used for the purpose of humidification. Using steam for the purpose of humidification offers added advantages over other media. There are different types of humidifiers from evaporating humidifiers to ultrasonic ones to suit different applications.

Steam for Drying

Product drying is another application of steam where steam is used to remove moisture from the product. Conventionally, hot air is used for product drying. Using steam to dry makes the system simple, easy to control drying rates and compact. The overall capital investment is also low. On the other hand, use of steam is cheaper on operational basis compared to hot air. It is also a safer alternative. The use of steam for drying purpose also ensures a better product quality when compared with hot air.

The principle of induction steam boilers|electromagnetic induction steam generators|induction heating steam boilers

This invention relates to an induction steram boiler|electromagnetic induction steam generator which operates with a low-frequency alternating current electric power source. More specifically, this invention relates to an electromagnetic induction steam boiler which is compact and highly efficient being capable of continuous operation, intermittent operation and empty-heating operation.Steamers in current use, such as cooking steamers, convection ovens, cooking steam warmers, steamers for defrosting frozen food, steamers for processing tea leaves, steam baths for household use, steamers for cleaning, and steamers used in restaurants and hotels, are widely used as equipment for utilizing the steam they generate.Generally, fossil fuels (gas, petroleum, crude petroleum, coal and so forth) are burned as heat sources for large steamers in current use. This heating method, however, is not economical for compact steamers.

Relatively compact steamers in current use commonly employ electrical resistance heaters as a heat source. Such steamers obtain steam intermittently by spraying water on an iron plate which has been heated in advance with a heater or the heater's protecting tube from inside or beneath the plate.

Energy saving rate of electromagnetic induction steam boiler:

Because the iron container heats itself, the heat conversion rate is particularly high, which can reach more than 95%; the working principle of electromagnetic steam generator is that when some water enters the container, it will be heated into steam Drain, to ensure a fixed way of replenishing water, there will be continuous steam utilization.

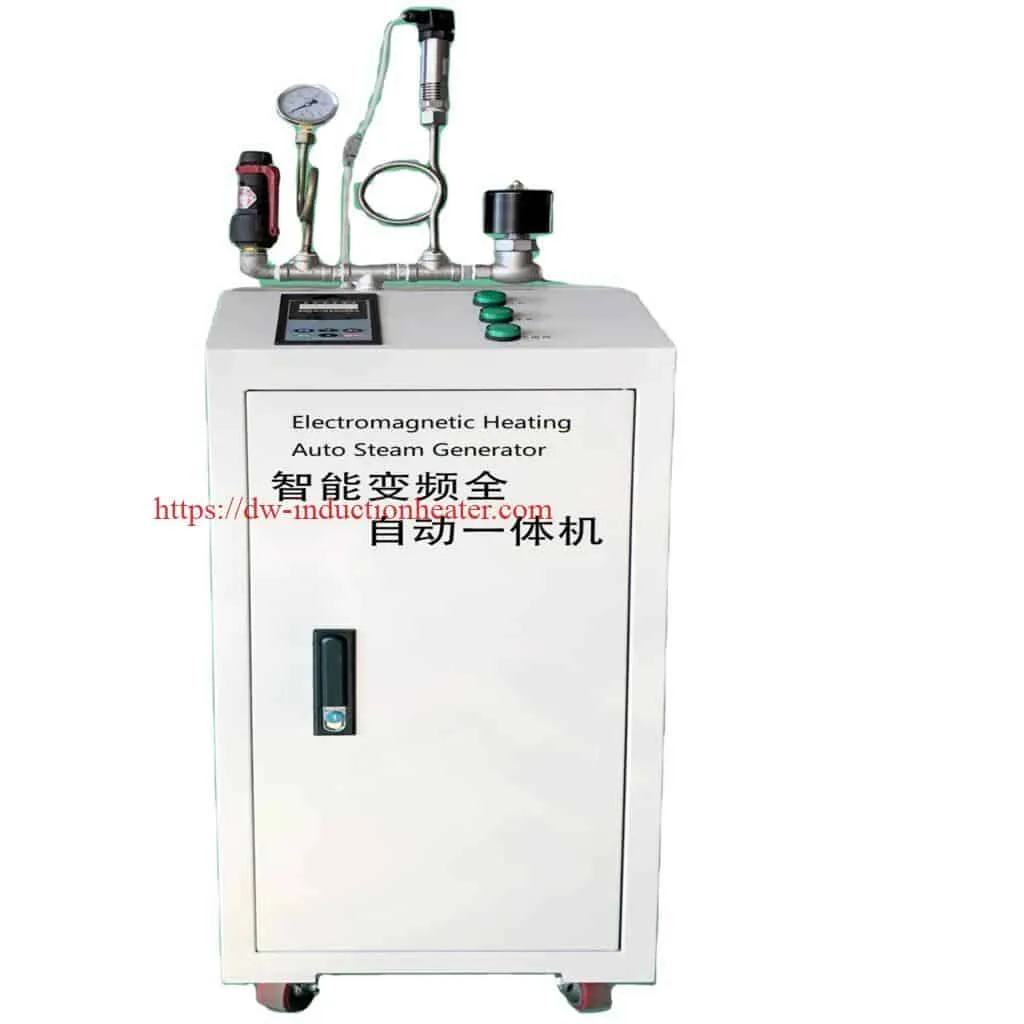

Product Description

Industrial quality high pressure induction steamist boiler pure steam generator from china manufacturers 1) LCD Full-Automatically Intelligent Electronic Control System 2) High-quality Core Component——Electromagnetic induction heater 3) High-quality Components and Parts——Famous Brand Delixi Electrical Appliance 4) Multiple Safety Interlock Protection 5) Scientific Design and Attractive Appearance 6) Easy and Rapid Installation 7) Magnetic induction coil heat up boiling water Generate steam - Is Much More Eco-Friendly and Economical 8) Wide Application Range| Item content / model | Rated power (KW) | Rated steam temperature (℃) | Rated current (A) | Rated steam pressure (mpa) | Evaporation (kg/h) | Thermal efficiency (%) | Input voltage (V/HZ) | Cross section of input power cord (MM2) | Steam outlet diameter | Relief valve diameter | Inlet diameter | Drainage diameter | Overall dimensions (mm) |

| HLQ-10 | 10 | 165 | 15 | 0.7 | 14 | 97 | 380/50HZ | 2.5 | DN20 | DN20 | DN15 | DN15 | 450*750*1000 |

| HLQ-20 | 20 | 165 | 30 | 0.7 | 28 | 97 | 380/50HZ | 6 | DN20 | DN20 | DN15 | DN15 | 450*750*1000 |

| HLQ-30 | 30 | 165 | 45 | 0.7 | 40 | 97 | 380/50HZ | 10 | DN20 | DN20 | DN15 | DN15 | 650*950*1200 |

| HLQ-40 | 40 | 165 | 60 | 0.7 | 55 | 97 | 380/50HZ | 16 | DN20 | DN20 | DN15 | DN15 | 780*950*1470 |

| HLQ-50 | 50 | 165 | 75 | 0.7 | 70 | 97 | 380/50HZ | 25 | DN20 | DN20 | DN15 | DN15 | 780*950*1470 |

| HLQ-60 | 60 | 165 | 90 | 0.7 | 85 | 97 | 380/50HZ | 25 | DN20 | DN20 | DN15 | DN15 | 780*950*1470 |

| HLQ-80 | 80 | 165 | 120 | 0.7 | 110 | 97 | 380/50HZ | 35 | DN25 | DN20 | DN15 | DN15 | 680*1020*1780 |

| HLQ-100 | 100 | 165 | 150 | 0.7 | 140 | 97 | 380/50HZ | 50 | DN25 | DN20 | DN25 | DN15 | 1150*1000*1730 |

| HLQ-120 | 120 | 165 | 180 | 0.7 | 165 | 97 | 380/50HZ | 70 | DN25 | DN20 | DN25 | DN15 | 1150*1000*1730 |

| HLQ-160 | 160 | 165 | 240 | 0.7 | 220 | 97 | 380/50HZ | 95 | DN25 | DN20 | DN25 | DN15 | 1150*1000*1880 |

| HLQ-240 | 240 | 165 | 360 | 0.7 | 330 | 97 | 380/50HZ | 185 | DN40 | DN20 | DN40 | DN15 | 1470*940*2130 |

| HLQ-320 | 320 | 165 | 480 | 0.7 | 450 | 97 | 380/50HZ | 300 | DN50 | DN20 | DN50 | DN15 | 1470*940*2130 |

| HLQ-360 | 360 | 165 | 540 | 0.7 | 500 | 97 | 380/50HZ | 400 | DN50 | DN20 | DN50 | DN15 | 2500*940*2130 |

| HLQ-480 | 480 | 165 | 720 | 0.7 | 670 | 97 | 380/50HZ | 600 | DN50 | DN20 | DN50 | DN15 | 3150*950*2130 |

| HLQ-640 | 640 | 165 | 960 | 0.7 | 900 | 97 | 380/50HZ | 800 | DN50 | DN20 | DN50 | DN15 | 2500*950*2130 |

| HLQ-720 | 720 | 165 | 1080 | 0.7 | 1000 | 97 | 380/50HZ | 900 | DN50 | DN20 | DN50 | DN15 | 3150*950*2130 |

| Comparison of Different Types of Steam Generators | ||||

| Steam Generator Type | Gas Steam Generator | Resistance Wire Steam Generator | Coal Steam Generator | Electromagnetic Heating Steam Generator |

| Energy Used | Gas by Fire | Resistance Wire by Electricity | Coal by Fire | Electromagnetic Heating by Electricity |

| Heat Exchange Rate | 85% | 88% | 75% | 96% |

| Need Someone on Duty | Yes | No | Yes | No |

| Temperature Control Accuracy | ±8℃ | ±6℃ | ±15℃ | ±3℃ |

| Heating Speed | Slow | Quick | Slow | Very quick |

| Working Environment | A little pollution after fired | Clean | pollution | Clean |

| Production Risk Index | Risk of gas leakage, complicated pipelines | Risk of electricity leakage pipe inner wall easy be scaling | Risk of high temperature, heavy pollution | No risk of leakage, water & electricity separated completely |

| Operational Performance | Complicated | Simple | Complicated | Simple |

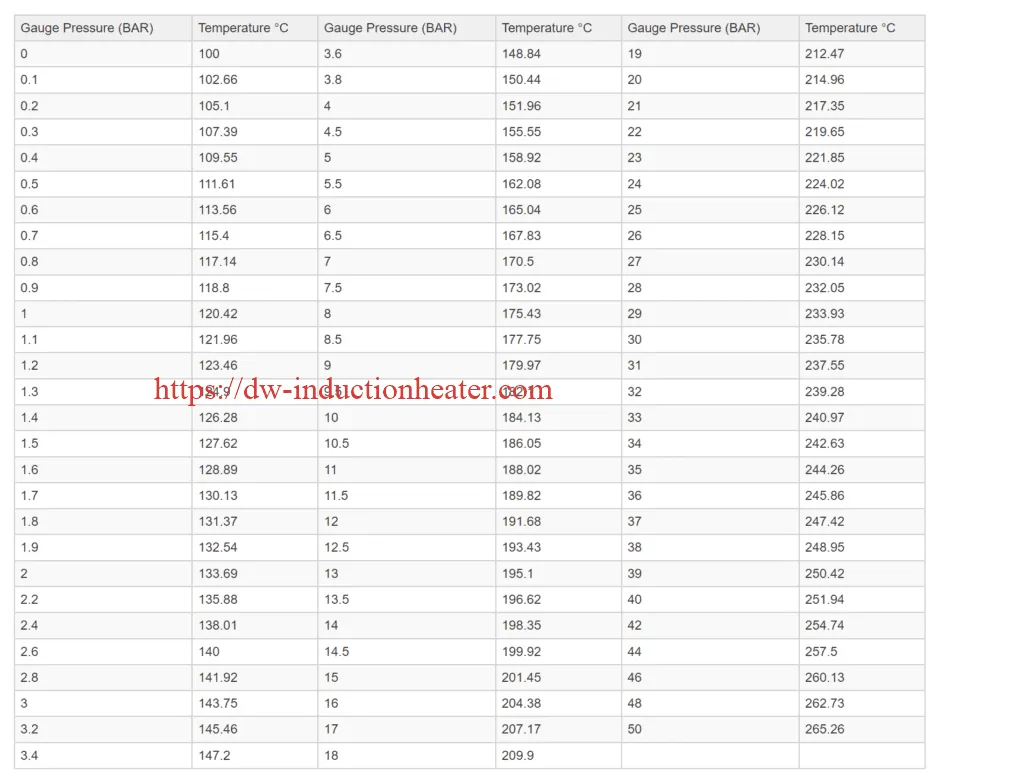

The steam temperature pressure chart

https://dw-inductionheater.com/applications-and-advantages-of-induction-heating-steam.html?feed_id=111029&_unique_id=6256c1c30afd7

https://dw-inductionheater.com/applications-and-advantages-of-induction-heating-steam.html?feed_id=111029&_unique_id=6256c1c30afd7