Objective

The customer preheats a variety of parts so they can then be threaded. The objective of this test is to preheat each part to 600°F (316°C) in under 30 seconds.

Equipment

DW-HF-15kw induction heating machine

[caption id="attachment_97" align="alignnone" width="267"] induction heating machine HF-15[/caption]

Materials

Sample parts were provided by the customer. These included:

• Part 1 composed of magnetic steel with 0.375” (9.525mm) OD

• Part 2 composed of magnetic steel with 0.5” (12.7mm) OD

• Part 3 composed of magnetic steel with 0.875” (22.225mm) OD

• Part 4 composed of magnetic steel with 1.5” (38.1mm) OD

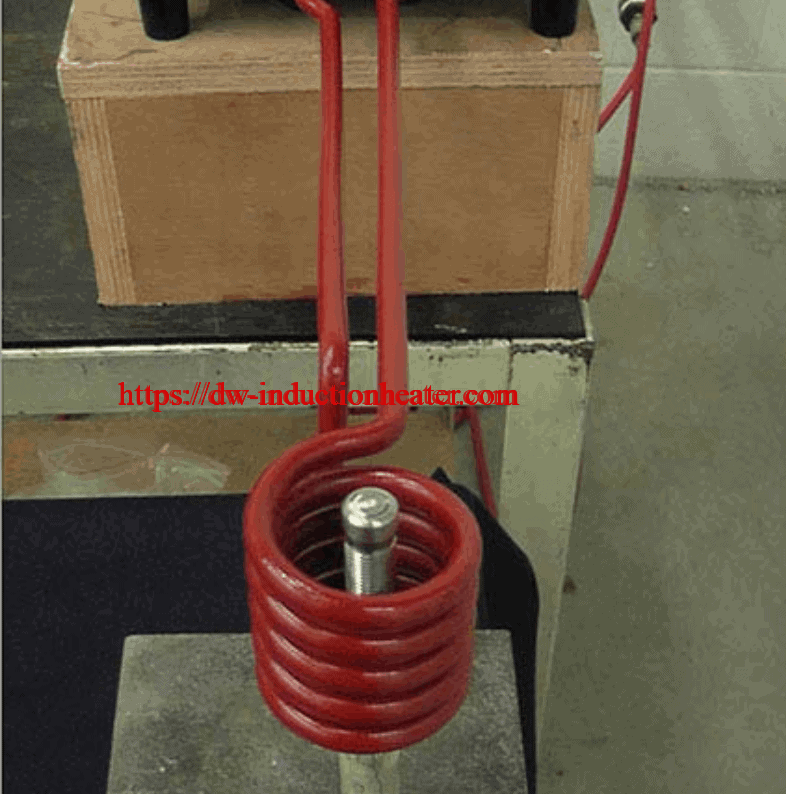

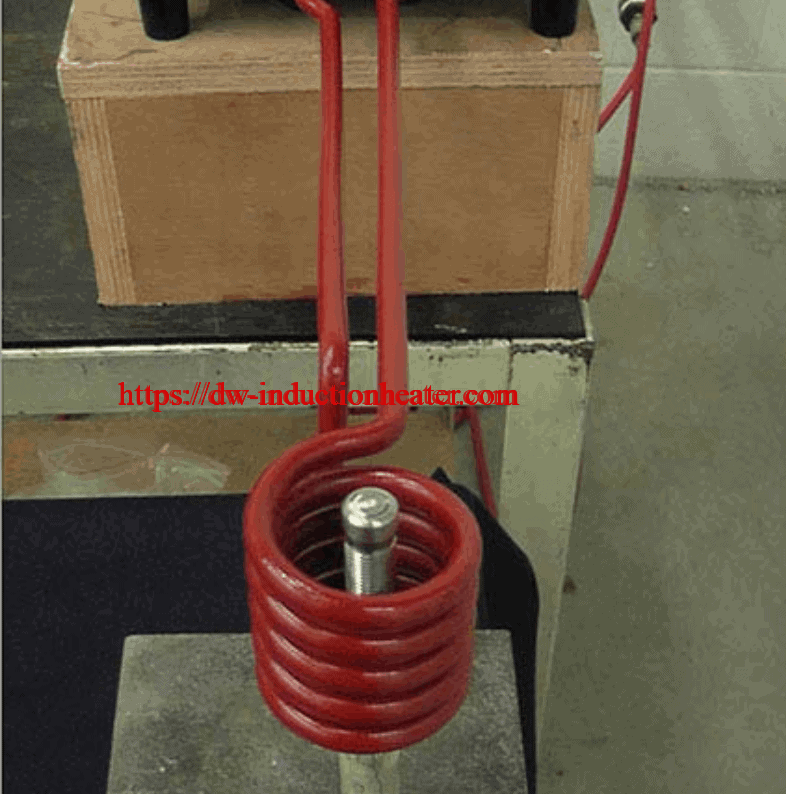

• Two coils were used. Coil 1 for heating part 4 with the 1.5” (38.1mm) OD. All other parts were heated with coil 2.

induction heating machine HF-15[/caption]

Materials

Sample parts were provided by the customer. These included:

• Part 1 composed of magnetic steel with 0.375” (9.525mm) OD

• Part 2 composed of magnetic steel with 0.5” (12.7mm) OD

• Part 3 composed of magnetic steel with 0.875” (22.225mm) OD

• Part 4 composed of magnetic steel with 1.5” (38.1mm) OD

• Two coils were used. Coil 1 for heating part 4 with the 1.5” (38.1mm) OD. All other parts were heated with coil 2.

induction heating machine HF-15[/caption]

Materials

Sample parts were provided by the customer. These included:

• Part 1 composed of magnetic steel with 0.375” (9.525mm) OD

• Part 2 composed of magnetic steel with 0.5” (12.7mm) OD

• Part 3 composed of magnetic steel with 0.875” (22.225mm) OD

• Part 4 composed of magnetic steel with 1.5” (38.1mm) OD

• Two coils were used. Coil 1 for heating part 4 with the 1.5” (38.1mm) OD. All other parts were heated with coil 2.

induction heating machine HF-15[/caption]

Materials

Sample parts were provided by the customer. These included:

• Part 1 composed of magnetic steel with 0.375” (9.525mm) OD

• Part 2 composed of magnetic steel with 0.5” (12.7mm) OD

• Part 3 composed of magnetic steel with 0.875” (22.225mm) OD

• Part 4 composed of magnetic steel with 1.5” (38.1mm) OD

• Two coils were used. Coil 1 for heating part 4 with the 1.5” (38.1mm) OD. All other parts were heated with coil 2.

Key Parameters

Temperature: about 600°F (316°C)

Power:

• Part 1:1.68 kW

• Part 2: 2.6 kW

• Part 3: 4.74 kW

• Part 4: 3.79 Kw

Time: less than 30 seconds

Process:

The part was centered in the coil.

The DW-HF-15kw Induction Heating Power Supply was turned on.

Temperature was monitored with an infrared camera and with Tempilaq paint.

All parts were able to be tested using the same equipment settings. No changes were required between heat cycles, other than to swap out the coil for Part 4. This is due to DW-HF-15kw Induction Heating Power Technologies’ flexible design that allows the induction heating system to tune to a wide variety of loads.

Results/Benefits:

Precise control of the time and temperature

Power on demand with rapid heat cycles

Repeatable process, not operator dependent when parts are set in a nest or fixture

Process:

The part was centered in the coil.

The DW-HF-15kw Induction Heating Power Supply was turned on.

Temperature was monitored with an infrared camera and with Tempilaq paint.

All parts were able to be tested using the same equipment settings. No changes were required between heat cycles, other than to swap out the coil for Part 4. This is due to DW-HF-15kw Induction Heating Power Technologies’ flexible design that allows the induction heating system to tune to a wide variety of loads.

Results/Benefits:

Precise control of the time and temperature

Power on demand with rapid heat cycles

Repeatable process, not operator dependent when parts are set in a nest or fixture

Process:

The part was centered in the coil.

The DW-HF-15kw Induction Heating Power Supply was turned on.

Temperature was monitored with an infrared camera and with Tempilaq paint.

All parts were able to be tested using the same equipment settings. No changes were required between heat cycles, other than to swap out the coil for Part 4. This is due to DW-HF-15kw Induction Heating Power Technologies’ flexible design that allows the induction heating system to tune to a wide variety of loads.

Results/Benefits:

Precise control of the time and temperature

Power on demand with rapid heat cycles

Repeatable process, not operator dependent when parts are set in a nest or fixture

Process:

The part was centered in the coil.

The DW-HF-15kw Induction Heating Power Supply was turned on.

Temperature was monitored with an infrared camera and with Tempilaq paint.

All parts were able to be tested using the same equipment settings. No changes were required between heat cycles, other than to swap out the coil for Part 4. This is due to DW-HF-15kw Induction Heating Power Technologies’ flexible design that allows the induction heating system to tune to a wide variety of loads.

Results/Benefits:

Precise control of the time and temperature

Power on demand with rapid heat cycles

Repeatable process, not operator dependent when parts are set in a nest or fixture