Magnetic deburring & polishing machine Principle

Magnetic grinding machines (magnetic deburring & polishing machine)

use the magical force of magnetic field to make the stainless steel pins rotate very fast, and the pins de-burr, polish and clean the work pieces high-effectively and precisely. This machine does not make any harm to the environment when it is working.

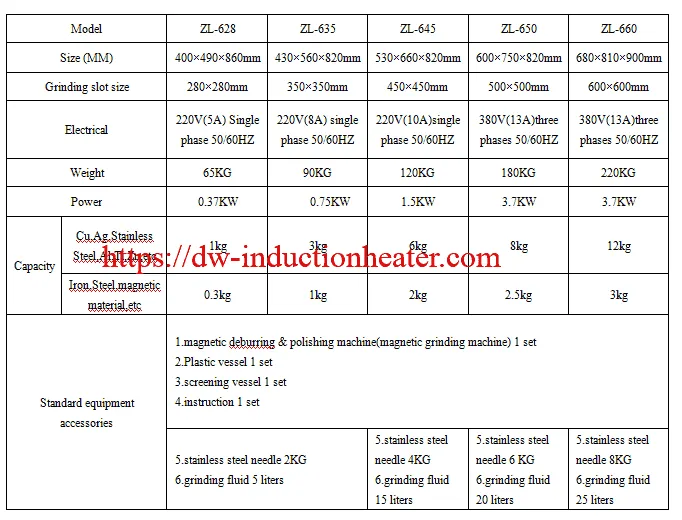

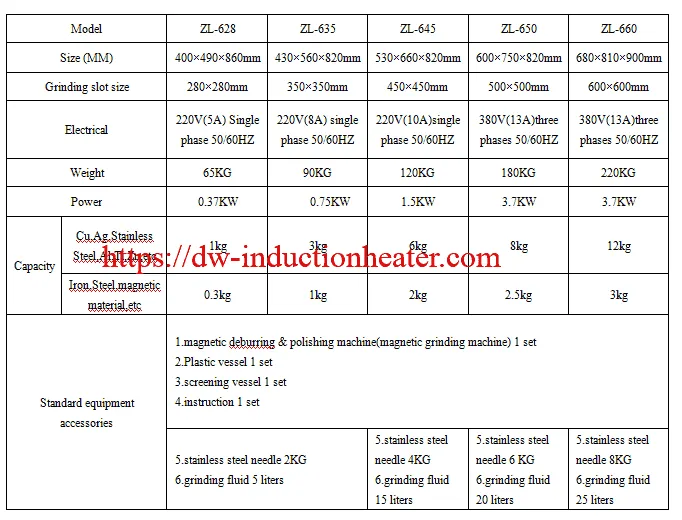

Magnetic Grinding Machine (magnetic deburring & polishing machine) Specifications

The

magnetic Grinding Machine(magnetic deburring & polishing machine) is SUPER large grinding trough designed, suitable for mass

grinding,

polishing or cleaning. The

magnetic grinding machine is running automatically, one person can operate multiple machines.

Magnetic grinding machines(magnetic deburring & polishing machine) use the magical force of magnetic field to make the stainless steel pins rotate very fast, to de-burr, polish and clean the work pieces high-effectively and precisely.

The magnetic grinding machines(magnetic deburring & polishing machine) are environmental friendly, NO pollution. They are

grindingand polishing fast, effectively. They have an excellent ability of fast de-burring, high efficiently

grinding small inner holes, inner pipes, crevices, etc. Make NO damage to the surface of workpieces, and DO NOT affect the accuracy of workpieces.

Magnetic grinding machines are of simple, safe and convenient operation, low cost and long working life.

Our products of

grinding machines are suitable for

grinding,

de-burring, chamfering and polishing all kinds of metal stamping parts, metal castings, rigid plastic, etc. And the

grinding machines are applied into the industries of horologe, eyeglass, lock manufacturing, ornaments & jewellery, electron, artware, machinery and hardware, etc.

Application:

Jewelry,handcrafts,collection, automatic lathe are parts, die-casting, punching machine parts, spring and shrapnel spare parts,electronic,telecommucation,medical spare parts.

Features:

Features:

1.Suitable for light iron metal,non-iron metal and tough plactic precious parts.

2.Realizing multi-effec such as burr wlimination, back angle,

polishing and cleaning, and so on

3.

Polishing dead angle of irregular parts,tubular,

4.blending timing, high speed,easy and safe operation

5.Adjustable can meet all polishing demands

6.No dead angle while polishing

7.Finish reminding,it can reminding when the polishing done,one can control several ones

8.Volage,current, frequency and time are controllable easily

9.

Polishing processure needs no manwork intervene

Function

Magnetic Grinding Machine (magnetic deburring & polishing machine) removes the rusted layer or burnt spots of the parts, deburr and finish the parts in a very short time. The machine is especially best workable for the parts with inner holes, complex shapes, crevices or screw threads. Magnetic polishing machine will not hurt the surface of the parts, and not change the accuracy of the parts after finishing. The machine works efficiently and only about 5~20 minutes is needed for the parts.

Magnetic Grinding Machine (magnetic deburring & polishing machine) can finish parts of metal materials and hard plastics.

[wpforms id="3947"]

Features:

1.Suitable for light iron metal,non-iron metal and tough plactic precious parts.

2.Realizing multi-effec such as burr wlimination, back angle,polishing and cleaning, and so on

3.Polishing dead angle of irregular parts,tubular,

4.blending timing, high speed,easy and safe operation

5.Adjustable can meet all polishing demands

6.No dead angle while polishing

7.Finish reminding,it can reminding when the polishing done,one can control several ones

8.Volage,current, frequency and time are controllable easily

9.Polishing processure needs no manwork intervene

Function

Magnetic Grinding Machine (magnetic deburring & polishing machine) removes the rusted layer or burnt spots of the parts, deburr and finish the parts in a very short time. The machine is especially best workable for the parts with inner holes, complex shapes, crevices or screw threads. Magnetic polishing machine will not hurt the surface of the parts, and not change the accuracy of the parts after finishing. The machine works efficiently and only about 5~20 minutes is needed for the parts. Magnetic Grinding Machine (magnetic deburring & polishing machine) can finish parts of metal materials and hard plastics.

Features:

1.Suitable for light iron metal,non-iron metal and tough plactic precious parts.

2.Realizing multi-effec such as burr wlimination, back angle,polishing and cleaning, and so on

3.Polishing dead angle of irregular parts,tubular,

4.blending timing, high speed,easy and safe operation

5.Adjustable can meet all polishing demands

6.No dead angle while polishing

7.Finish reminding,it can reminding when the polishing done,one can control several ones

8.Volage,current, frequency and time are controllable easily

9.Polishing processure needs no manwork intervene

Function

Magnetic Grinding Machine (magnetic deburring & polishing machine) removes the rusted layer or burnt spots of the parts, deburr and finish the parts in a very short time. The machine is especially best workable for the parts with inner holes, complex shapes, crevices or screw threads. Magnetic polishing machine will not hurt the surface of the parts, and not change the accuracy of the parts after finishing. The machine works efficiently and only about 5~20 minutes is needed for the parts. Magnetic Grinding Machine (magnetic deburring & polishing machine) can finish parts of metal materials and hard plastics.

[wpforms id="3947"]

[wpforms id="3947"]