Ultrasonic plastic welding machine | ultrasonic thermoplastic welder | ultra sonic plastic welding equipment with Automatic Frequency Chasing

Ultrasonic plastic welding is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When applied to metals, a notable characteristic of this method is that the temperature stays well below the melting point of the involved materials thus preventing any unwanted properties which may arise from high temperature exposure of the materials.

♦Fully automatic frequency chasing, suitable for various sizes of welding die and different design mold, automatic chasing frequency range:±400HZ

Example: 15KHZ ultrasonic, mold frequency in 14.4-15.2KHZ can Automatic frequency traceability

♦The use of CPU computer to monitor various programs is fast and adaptable. The built-in protection system "system protection monitoring" function will respond to the following situations: the temperature is too high and the pressure is too high, which leads to overload. Excessive current of ultrasonic generator, loosening of solder head, transducer or transducer, failure of generator circuit, etc.

♦Automatic tuning enables the ultrasonic generator to automatically track and compensate for changes in welding head frequency. When the temperature is too high, wear on the surface of the welding head or debris on the head, this frequency change will occur.

♦Built-in automatic constant amplitude system. The ultrasonic amplitude can be adjusted from 50% to 100% stepless to adapt to different welding work.

♦With IGBT, the reaction speed is 100 times faster than that of traditional silica gel power tube.

| Model |

1520A |

1526A |

1532A |

1542A |

| Frequency |

15KHz |

| Power |

2000W |

2600W |

3200W |

4200W |

| Voltage |

220V |

| Capacity |

10-20 times/min |

| Driving form |

Pneumatic |

| Stroke Length(Horn Journy) |

75mm |

100mm |

| Output Time |

0.01-9.99S Adjustable |

| Welding Area |

Φ100 |

Φ200 |

Φ300 |

Φ400 |

| Electricity |

AC |

| Control mode |

Numerical control |

| Working air pressure |

1-7 Bar |

| Weight |

90KG |

90KG |

90KG |

120KG |

| Dimensions |

450*750*1100mm |

760*1000*1950mm |

Main Features

Main Features

1. Ultrasonic Welding Plastic Machine, manually tuning, simple to use and maintenance.

2. Welding by time, delay time, weld time and hold time. Working pressure is adjustable.

4. Precise and high quality imported pneumatic parts

5. High quality transducer and booster.

6. Self-protection: Over-Current, Frequency Deviation, Over-Temperature

7. Available in 4 frequencies – 15 KHz, 20 KHz ,35 KHz and 40 KHz.

8. Quick application changeover, high welding seam strength.

9. Suitable for high cadences and short cycle times.

Ultrasonic Welding Horns/ultrasonic welding mold:

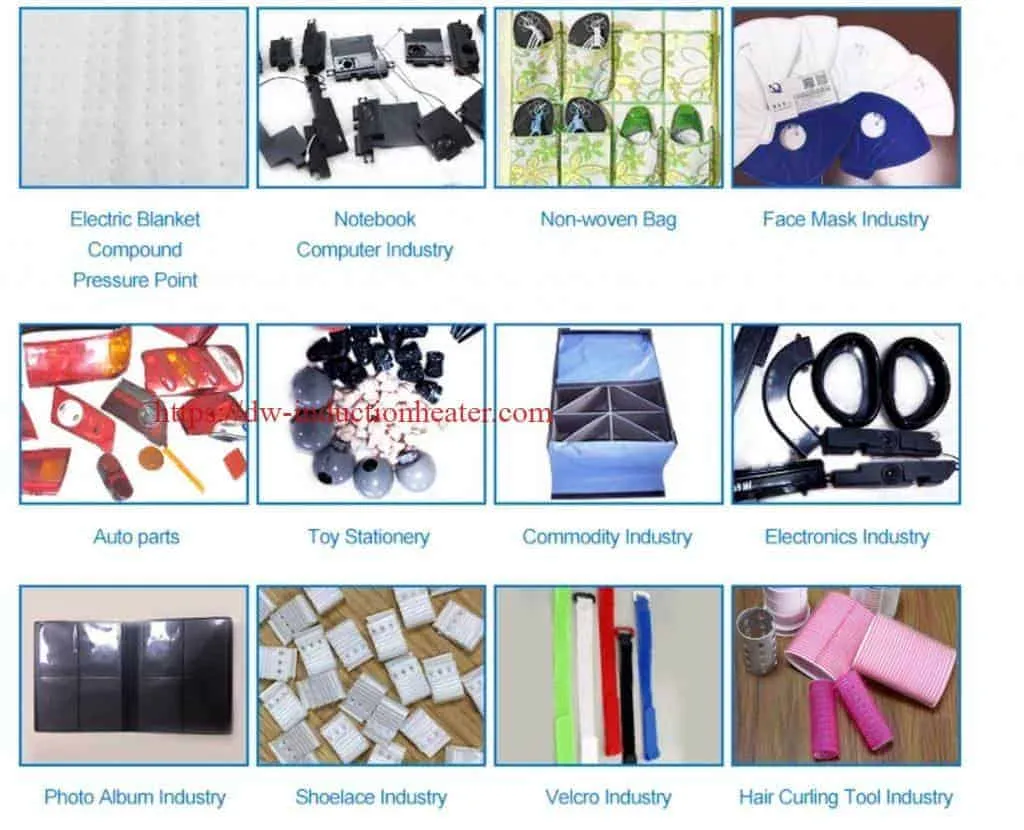

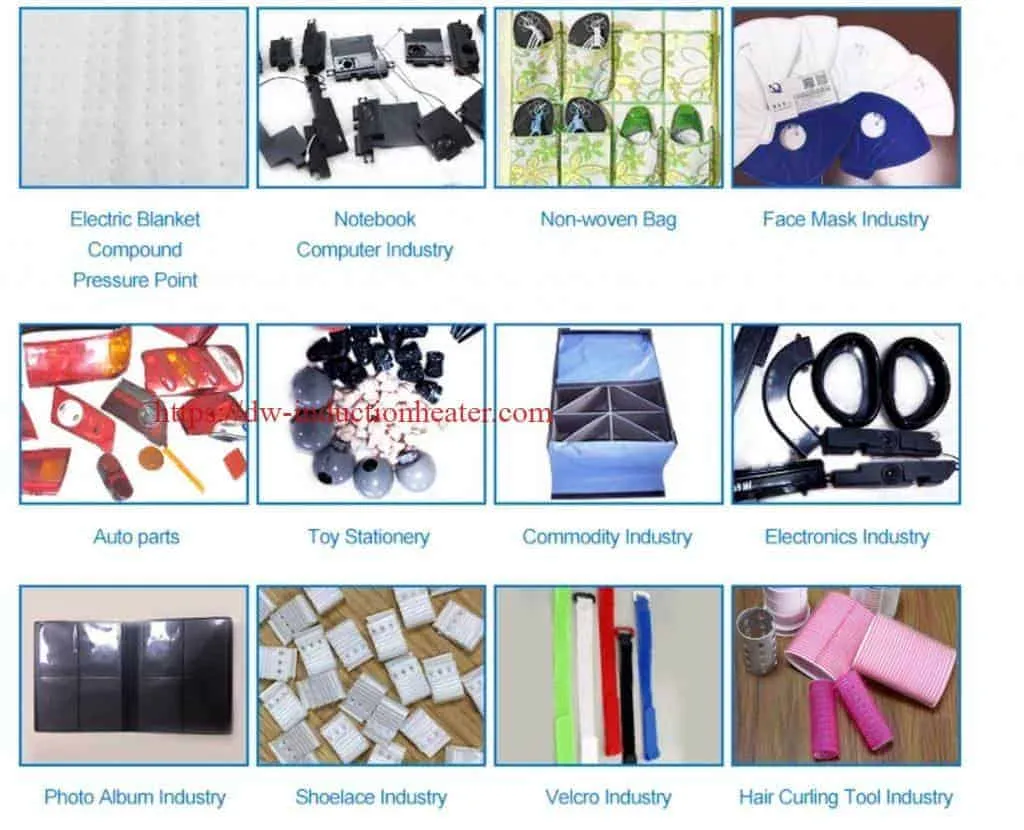

Applications:

Applications:

The applications of ultrasonic welding are extensive and are found in many industries including electrical and computer, automotive and aerospace, medical, and packaging. Whether two items can be ultrasonically welded is determined by their thickness. If they are too thick this process will not join them. This is the main obstacle in the welding of metals. However, wires, microcircuit connections, sheet metal, foils, ribbons and meshes are often joined using ultrasonic welding. Ultrasonic welding is a very popular technique for bonding thermoplastics. It is fast and easily automated with weld times often below one second and there is no ventilation system required to remove heat or exhaust. This type of welding is often used to build assemblies that are too small, too complex, or too delicate for more common welding techniques.

Automotive industry: plastic body parts, car doors, automotive dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, plastic filter for motorcycle , Radiator, brake fluid tank, oil cups, water tanks, fuel tank, air hose, exhaust purifiers, the tray plate, and so on.

Plastic Electronics: prepaid water meters, communications equipment, cordless phones, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connection, Bluetooth devices, and so on.

Stationery: folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges, and so on.

Medical and Daily products: watches, kitchen utensils, oral liquid bottle caps, drip caps, mobile phone accessories, golden soft brush, and daily necessities, handle, security caps, cosmetics bottle, coffee pot, washing machines, air dehumidifiers, Electric irons, electric kettles, vacuum cleaners, speakers, cover and metal face grille and other civil engineering and so on.

Health products: children's products, air mattresses, clothes hangers, gardening supplies, kitchenware sanitary ware, shower, shower head, and so on.

[wpforms id="3947"]

♦Fully automatic frequency chasing, suitable for various sizes of welding die and different design mold, automatic chasing frequency range:±400HZ

Example: 15KHZ ultrasonic, mold frequency in 14.4-15.2KHZ can Automatic frequency traceability

♦The use of CPU computer to monitor various programs is fast and adaptable. The built-in protection system "system protection monitoring" function will respond to the following situations: the temperature is too high and the pressure is too high, which leads to overload. Excessive current of ultrasonic generator, loosening of solder head, transducer or transducer, failure of generator circuit, etc.

♦Automatic tuning enables the ultrasonic generator to automatically track and compensate for changes in welding head frequency. When the temperature is too high, wear on the surface of the welding head or debris on the head, this frequency change will occur.

♦Built-in automatic constant amplitude system. The ultrasonic amplitude can be adjusted from 50% to 100% stepless to adapt to different welding work.

♦With IGBT, the reaction speed is 100 times faster than that of traditional silica gel power tube.

♦Fully automatic frequency chasing, suitable for various sizes of welding die and different design mold, automatic chasing frequency range:±400HZ

Example: 15KHZ ultrasonic, mold frequency in 14.4-15.2KHZ can Automatic frequency traceability

♦The use of CPU computer to monitor various programs is fast and adaptable. The built-in protection system "system protection monitoring" function will respond to the following situations: the temperature is too high and the pressure is too high, which leads to overload. Excessive current of ultrasonic generator, loosening of solder head, transducer or transducer, failure of generator circuit, etc.

♦Automatic tuning enables the ultrasonic generator to automatically track and compensate for changes in welding head frequency. When the temperature is too high, wear on the surface of the welding head or debris on the head, this frequency change will occur.

♦Built-in automatic constant amplitude system. The ultrasonic amplitude can be adjusted from 50% to 100% stepless to adapt to different welding work.

♦With IGBT, the reaction speed is 100 times faster than that of traditional silica gel power tube.

Main Features

1. Ultrasonic Welding Plastic Machine, manually tuning, simple to use and maintenance.

2. Welding by time, delay time, weld time and hold time. Working pressure is adjustable.

4. Precise and high quality imported pneumatic parts

5. High quality transducer and booster.

6. Self-protection: Over-Current, Frequency Deviation, Over-Temperature

7. Available in 4 frequencies – 15 KHz, 20 KHz ,35 KHz and 40 KHz.

8. Quick application changeover, high welding seam strength.

9. Suitable for high cadences and short cycle times.

Ultrasonic Welding Horns/ultrasonic welding mold:

Main Features

1. Ultrasonic Welding Plastic Machine, manually tuning, simple to use and maintenance.

2. Welding by time, delay time, weld time and hold time. Working pressure is adjustable.

4. Precise and high quality imported pneumatic parts

5. High quality transducer and booster.

6. Self-protection: Over-Current, Frequency Deviation, Over-Temperature

7. Available in 4 frequencies – 15 KHz, 20 KHz ,35 KHz and 40 KHz.

8. Quick application changeover, high welding seam strength.

9. Suitable for high cadences and short cycle times.

Ultrasonic Welding Horns/ultrasonic welding mold:

Applications:

The applications of ultrasonic welding are extensive and are found in many industries including electrical and computer, automotive and aerospace, medical, and packaging. Whether two items can be ultrasonically welded is determined by their thickness. If they are too thick this process will not join them. This is the main obstacle in the welding of metals. However, wires, microcircuit connections, sheet metal, foils, ribbons and meshes are often joined using ultrasonic welding. Ultrasonic welding is a very popular technique for bonding thermoplastics. It is fast and easily automated with weld times often below one second and there is no ventilation system required to remove heat or exhaust. This type of welding is often used to build assemblies that are too small, too complex, or too delicate for more common welding techniques.

Automotive industry: plastic body parts, car doors, automotive dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, plastic filter for motorcycle , Radiator, brake fluid tank, oil cups, water tanks, fuel tank, air hose, exhaust purifiers, the tray plate, and so on.

Plastic Electronics: prepaid water meters, communications equipment, cordless phones, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connection, Bluetooth devices, and so on.

Stationery: folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges, and so on.

Medical and Daily products: watches, kitchen utensils, oral liquid bottle caps, drip caps, mobile phone accessories, golden soft brush, and daily necessities, handle, security caps, cosmetics bottle, coffee pot, washing machines, air dehumidifiers, Electric irons, electric kettles, vacuum cleaners, speakers, cover and metal face grille and other civil engineering and so on.

Health products: children's products, air mattresses, clothes hangers, gardening supplies, kitchenware sanitary ware, shower, shower head, and so on.

Applications:

The applications of ultrasonic welding are extensive and are found in many industries including electrical and computer, automotive and aerospace, medical, and packaging. Whether two items can be ultrasonically welded is determined by their thickness. If they are too thick this process will not join them. This is the main obstacle in the welding of metals. However, wires, microcircuit connections, sheet metal, foils, ribbons and meshes are often joined using ultrasonic welding. Ultrasonic welding is a very popular technique for bonding thermoplastics. It is fast and easily automated with weld times often below one second and there is no ventilation system required to remove heat or exhaust. This type of welding is often used to build assemblies that are too small, too complex, or too delicate for more common welding techniques.

Automotive industry: plastic body parts, car doors, automotive dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, plastic filter for motorcycle , Radiator, brake fluid tank, oil cups, water tanks, fuel tank, air hose, exhaust purifiers, the tray plate, and so on.

Plastic Electronics: prepaid water meters, communications equipment, cordless phones, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connection, Bluetooth devices, and so on.

Stationery: folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges, and so on.

Medical and Daily products: watches, kitchen utensils, oral liquid bottle caps, drip caps, mobile phone accessories, golden soft brush, and daily necessities, handle, security caps, cosmetics bottle, coffee pot, washing machines, air dehumidifiers, Electric irons, electric kettles, vacuum cleaners, speakers, cover and metal face grille and other civil engineering and so on.

Health products: children's products, air mattresses, clothes hangers, gardening supplies, kitchenware sanitary ware, shower, shower head, and so on.

[wpforms id="3947"]

[wpforms id="3947"]