induction hardening the teeth of saw blade with high frequency induction hardening machine

Objective

Induction Hardening the teeth of a large saw blade for a hardening surface application; the objective is to reduce the heating time

Material : Section of the saw blade

Temperature: 1650 ºF (899 ºC)

Frequency: 134 kHz

Equipment :

--DW-UHF-40kW 50-150 kHz

induction heating system equipped with a remote workhead containing eight 1.0 μF capacitors

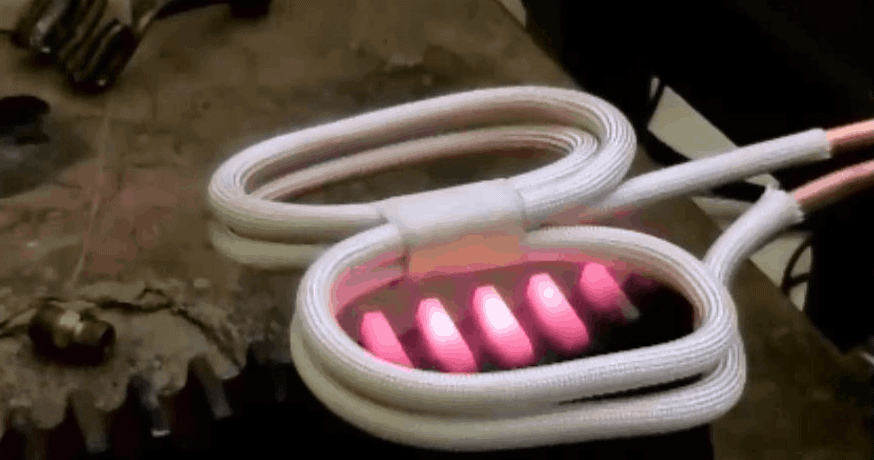

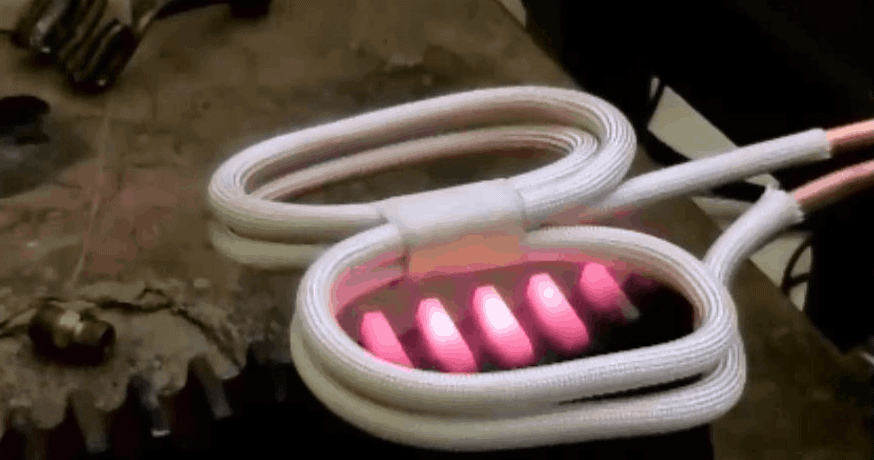

--A multiple position two-turn helical induction heating coil designed and developed specifically for this application

Process: The

induction heating coil was developed so that it would not concentrate heat in the outside edge valley of the tooth. The part was placed under the coil approximately 1/8” (3.2 mm) away and the power was turned on. With the 40 kW DW-UHF series induction heating power supply the part heated to temperature within the targeted rate of five teeth per four seconds.

Results/Benefits

--Speed: The customer was already using induction, but wanted to upgrade to a higher power system to increase

their production rate (Prior to first using induction from HLQ, the client used a torch.)

--Precision and Repeatability: A torch isn’t as precise as induction nor is it repeatable, whereas induction can be

implemented to be highly repeatable

--Efficiency:

Induction heating uses less energy than a torch and offers instant on/off heating

--A multiple position two-turn helical induction heating coil designed and developed specifically for this application

Process: The induction heating coil was developed so that it would not concentrate heat in the outside edge valley of the tooth. The part was placed under the coil approximately 1/8” (3.2 mm) away and the power was turned on. With the 40 kW DW-UHF series induction heating power supply the part heated to temperature within the targeted rate of five teeth per four seconds.

--A multiple position two-turn helical induction heating coil designed and developed specifically for this application

Process: The induction heating coil was developed so that it would not concentrate heat in the outside edge valley of the tooth. The part was placed under the coil approximately 1/8” (3.2 mm) away and the power was turned on. With the 40 kW DW-UHF series induction heating power supply the part heated to temperature within the targeted rate of five teeth per four seconds.

Results/Benefits

--Speed: The customer was already using induction, but wanted to upgrade to a higher power system to increase

their production rate (Prior to first using induction from HLQ, the client used a torch.)

--Precision and Repeatability: A torch isn’t as precise as induction nor is it repeatable, whereas induction can be

implemented to be highly repeatable

--Efficiency: Induction heating uses less energy than a torch and offers instant on/off heating

Results/Benefits

--Speed: The customer was already using induction, but wanted to upgrade to a higher power system to increase

their production rate (Prior to first using induction from HLQ, the client used a torch.)

--Precision and Repeatability: A torch isn’t as precise as induction nor is it repeatable, whereas induction can be

implemented to be highly repeatable

--Efficiency: Induction heating uses less energy than a torch and offers instant on/off heating