Induction Heating Device Supply

HLQ Induction Heating Machine Co manufactures a wide range of

induction heating device supplies including high frequency power series,medium frequency power series,ultrahigh frequency heater series for heating,brazing,forging,melting,bonding,welding,hardening and heating treatment surface applications and for replacement.

Main Characteristics:

Main Characteristics:

- IGBT module and soft switching inverting technologies are as in the production of the generator,higher reliability can be do.

- Small and portable ,compared with SCR controlled machine only 1/10 working space is needed. High efficiency to save energy,high efficiency and power far can be maintained

- The generator is adaptable in a large frequency range from 1KHz to 2.0MHz,installation can be done very easily according to our manual.

- 100%duty cycle ,continuous working ability at maximum power.

- Constant power or constant voltage control mode.

- Display of output power,output frequency,and output voltage.

| Series |

Model |

Input power Max |

Input current Max |

Oscillate frequency |

Input Voltage |

Duty cycle |

| M.F

. |

DW-MF-15 Induction Generator |

15KW |

23A |

1KHz-20KHz According to the application |

3phases380V±10% |

100% |

| DW-MF-25 Induction Generator |

25KW |

36A |

| DW-MF-35Induction Generator |

35KW |

51A |

| DW-MF-45 Induction Generator |

45KW |

68A |

| DW-MF-70 Induction Generator |

70KW |

105A |

| DW-MF-90 Induction Generator |

90KW |

135A |

| DW-MF-110 Induction Generator |

110KW |

170A |

| DW-MF-160 Induction Generator |

160KW |

240A |

| DW-MF-300 Induction Generator |

300KW |

400A |

| DW-MF-45 Induction Heating Rod Forging Furnace |

45KW |

68A |

1KHz-20KHz |

3phases380V±10% |

100% |

| DW-MF-70 Induction Heating Rod Forging Furnace |

70KW |

105A |

| DW-MF-90 Induction Heating Rod Forging Furnace |

90KW |

135A |

| DW-MF-110 Induction Heating Rod Forging Furnace |

110KW |

170A |

| DW-MF-160 Induction Heating Rod Forging Furnace |

160KW |

240A |

| DW-MF-15 Induction Melting Furnace |

15KW |

23A |

1K-20KHz |

3phases380V±10% |

100% |

| DW-MF-25 Induction Melting Furnace |

25KW |

36A |

| DW-MF-35 Induction Melting Furnace |

35KW |

51A |

| DW-MF-45 Induction Melting Furnace |

45KW |

68A |

| DW-MF-70 Induction Melting Furnace |

70KW |

105A |

| DW-MF-90 Induction Melting Furnace |

90KW |

135A |

| DW-MF-110 Induction Melting Furnace |

110KW |

170A |

| DW-MF-160 Induction Melting Furnace |

160KW |

240A |

| DW-MF-110 Induction Hardening Equipment |

110KW |

170A |

1K-8KHz |

3phases380V±10% |

100% |

| DW-MF-160Induction Hardening Equipment |

160KW |

240A |

| H.F

. |

DW-HF-15 Series |

DW-HF-15KW |

15KVA |

32A |

30-100KHz |

Single phase 220V |

80% |

| DW-HF-25 Series |

DW-HF-25KW-A |

25KVA |

23A |

20K-80KHz |

3phases380V±10% |

100% |

| DW-HF-25KW-B |

| DW-HF-35 Series |

DW-HF-35KW-B |

35KVA |

51A |

| DW-HF-45 Series |

DW-HF-45KW-B |

45KVA |

68A |

| DW-HF-60 Series |

DW-HF-60KW-B |

60KVA |

105A |

| DW-HF-80 Series |

DW-HF-80KW-B |

80KVA |

130A |

| DW-HF-90 Series |

DW-HF-90KW-B |

90KVA |

160A |

| DW-HF-120 Series |

DW-HF-120KW-B |

120KVA |

200A |

|

DW-HF-160 Series |

DW-HF-160KW-B |

160KVA |

260A |

|

|

|

| U.H

.

F

.

|

DW-UHF-4.5KW |

4.5KW |

20A |

1.1-2.0MHz |

Single phase220V ±10% |

100% |

| DW-UHF-6.0KW |

6.0KW |

28A |

| DW-UHF-10KW |

10KW |

15A |

100-500KHz |

3phases380V±10% |

100% |

| DW-UHF-20KW |

20KW |

30A |

50-250KHz |

| DW-UHF-30KW |

30KW |

45A |

50-200KHz |

| DW-UHF-40KW |

40KW |

60A |

50-200KHz |

| DW-UHF-60KW |

60KW |

90A |

50-150KHz |

The theory of induction heating device

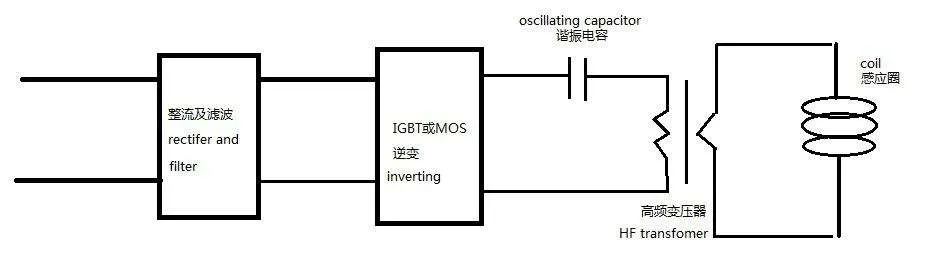

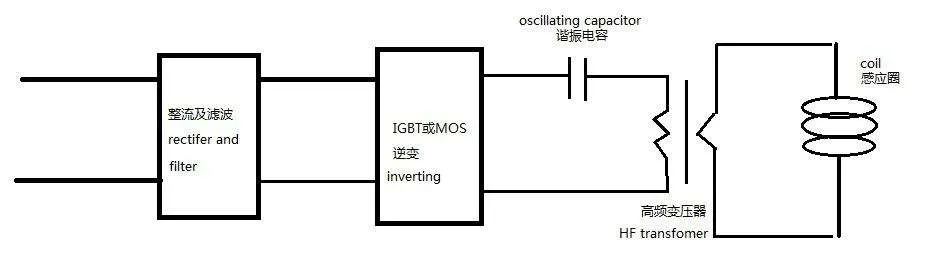

In these induction heating devices, series oscillating circuit is applied, through high frequency transformer, low voltage and high current power is output to go through the induction coil.

DW-HF-15KW and DW-HF-25KW series machines are the first models developed in our company, using MOSFET and IGBT components and our first generation inverting control technology, the machines are featured with simple structure, high reliability and low price, and they are easy to use and to repair, and are now the most widely used machines both in China and abroad.

In DW-HF-35KW and DW-HF-45KW series

induction heating machines, IGBT module and our second generation inverting control technology has been used, that is the dual control and inverting technology. In these new technologies, output power and oscillating frequency are controlled independently. we use IGBT components and high frequency voltage regulate control circuit to control the power and we use IGBT components, series oscillating and automatic tracing circuit to reach soft switching in the inverting course, all these make the machine to be more reliable and make the machine possible to work continuously with 100% duty cycle.

Compared to machines with first generation technology, second generation technology is more suitable for large power machines to get higher reliability.

Due to the adopting of advanced technology, DW-HF-35KW and DW-HF-45KW series machines are acetized by larger frequency range, smaller size, water cooled transformer, higher reliability and lower repair cost.

Inside DW-HF-70KW series

induction heating device, IGBT module and our third generation inverting control technology has been used, that is the soft and dual control and inverting technology. In this technology, output power and frequency can be controlled and adjusted separately, IGBT module and soft switching control technology are used in the high frequency switching circuit to control the output power. In the inverting circuit, the IGBT and frequency tracing circuit is applied to achieve high speed and accurate soft switching control. The adoption of new technologies not only improves the quality and reliability of the machine,but also solve the technology problem on large power

induction heating machine and makes it possible to work 100% duty cycle.

[wpforms id="3947"]

Main Characteristics:

Main Characteristics:

In DW-HF-35KW and DW-HF-45KW series induction heating machines, IGBT module and our second generation inverting control technology has been used, that is the dual control and inverting technology. In these new technologies, output power and oscillating frequency are controlled independently. we use IGBT components and high frequency voltage regulate control circuit to control the power and we use IGBT components, series oscillating and automatic tracing circuit to reach soft switching in the inverting course, all these make the machine to be more reliable and make the machine possible to work continuously with 100% duty cycle.

In DW-HF-35KW and DW-HF-45KW series induction heating machines, IGBT module and our second generation inverting control technology has been used, that is the dual control and inverting technology. In these new technologies, output power and oscillating frequency are controlled independently. we use IGBT components and high frequency voltage regulate control circuit to control the power and we use IGBT components, series oscillating and automatic tracing circuit to reach soft switching in the inverting course, all these make the machine to be more reliable and make the machine possible to work continuously with 100% duty cycle.

Compared to machines with first generation technology, second generation technology is more suitable for large power machines to get higher reliability.

Due to the adopting of advanced technology, DW-HF-35KW and DW-HF-45KW series machines are acetized by larger frequency range, smaller size, water cooled transformer, higher reliability and lower repair cost.

Compared to machines with first generation technology, second generation technology is more suitable for large power machines to get higher reliability.

Due to the adopting of advanced technology, DW-HF-35KW and DW-HF-45KW series machines are acetized by larger frequency range, smaller size, water cooled transformer, higher reliability and lower repair cost.

Inside DW-HF-70KW series induction heating device, IGBT module and our third generation inverting control technology has been used, that is the soft and dual control and inverting technology. In this technology, output power and frequency can be controlled and adjusted separately, IGBT module and soft switching control technology are used in the high frequency switching circuit to control the output power. In the inverting circuit, the IGBT and frequency tracing circuit is applied to achieve high speed and accurate soft switching control. The adoption of new technologies not only improves the quality and reliability of the machine,but also solve the technology problem on large power induction heating machine and makes it possible to work 100% duty cycle.

Inside DW-HF-70KW series induction heating device, IGBT module and our third generation inverting control technology has been used, that is the soft and dual control and inverting technology. In this technology, output power and frequency can be controlled and adjusted separately, IGBT module and soft switching control technology are used in the high frequency switching circuit to control the output power. In the inverting circuit, the IGBT and frequency tracing circuit is applied to achieve high speed and accurate soft switching control. The adoption of new technologies not only improves the quality and reliability of the machine,but also solve the technology problem on large power induction heating machine and makes it possible to work 100% duty cycle.

[wpforms id="3947"]

[wpforms id="3947"]