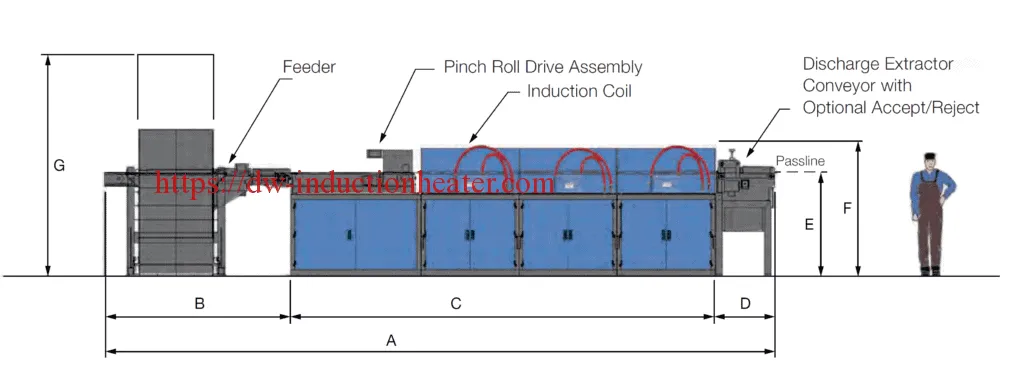

24h Continous Billet Heating Furnace with Induction for copper/brass,aluminum,iron steel before the hot formging, extrusion, hot rolling and cutting,etc.

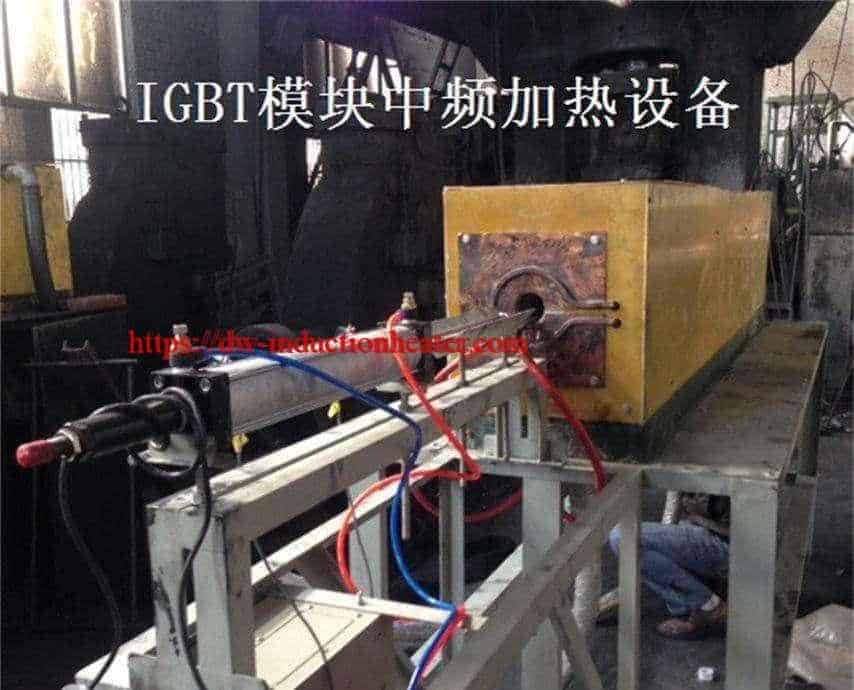

Application:Billet Heating Furnace mainly apply for the whole metal materials heating before the forging, extrusion, hot rolling and cutting,and metal materials quenching and tempering, annealing, tempering and other heat treatment as a whole. Power supply features: 1. Uses advanced electronic circuit control, with over-voltage, over-current, limiting pressure, current limiting, lack of phase, undervoltage, underwater pressure, phase sequence automatic identification, cooling water temperature alarm protection and many other protection features. Power factor automatic adjustment function. From the cold charge to the casting during the entire cycle regardless of how the furnace conditions change can be achieved, automatically maintain the power to the furnace, so that the maximum amount of molten metal per kilowatt, the shortest same power heating time, thus increasing the profits of manufacturers,increased labor productivity. 2.Control line dedicated integrated box and high pressure area are fully isolated, keep the control room clean and cool. Greatly improve the control circuit board life and system reliability. 3.High-power converter devices preferred from international and domestic well-known manufacturers, and run at 50% of the rated capacity, so with 100% design safety factor, increasing the overall system reliability. 4.The equipment uses large air cooling copper, compared with the water-cooled copper, more energy for heating, increased efficiency, don't need maintenance. 5.Power start using zero voltage sweep start, no impact, in the state of no-load, heavy load, cold steel and other states can be reliable from the dynamic, stable and reliable, trouble-free for a long time and facilitate to maintenance. Heating features: 1. Heating quickly, heating temperature uniformity, less oxidation loss, metal composition evenly. 2. Can be directly heated from the cold material, easy to replace. Features: Heating speed, less oxidation decarbonization: As the principle of medium frequency induction heating is electromagnetic induction, the heat generated by the workpiece itself, so this heating method heating quickly, oxidation very small and high heating efficiency, with good process repeatability. A high degree of automation,without automatic operation can be achieved : Automatic feeding and automatic discharge of the seizure device selected, coupled with the dedicated control software developed by our company, without automatic operation can be achieved. Heating uniformly, high temperature control accuracy: Heating uniformly, the core table temperature difference is small. The temperature can be precisely controlled by the temperature control system. Simple Induction Heating furnace replacement: According to the different size of the workpiece, to be equipped with different specifications of the induction induction furnace. Each furnace are designed with hydropower quick change connector, so that the furnace is easy, fast and convenient to replace. Equipment protection completely: A full set of equipment with water temperature, water pressure, over current, over voltage, lack of phase protection, and with over temperature, lower limit alarm device. So that reliable protection when the equipment in the fault, without damage to components. Low energy consumption, no pollution: High heating efficiency, compared with other heating methods, reducing energy consumption effectively. Equipment in line with environmental requirements, no pollution. In the forging industry, the energy consumption when heated to 1250 ºC is less than 390 kwh / t.