Steel die induction heating in a thermal process of an enclosed powder

Objective : A steel die is heated with induction in a thermal process of an enclosed powder

Material: Steel die with a compressed powder solid inside

Temperature: 400 ºC (750 ºF)

Frequency: 22 kHz

Induction Heating Equipment:

Induction Heating Equipment: DW-MF-70kW/30kHz

induction heating system, equipped with a remote workhead containing one 53μF capacitor

- An induction heating coil designed and developed specifically for this application.

Process

Induction Heating is evaluated to replace an oven/batch process.

Advantages include reduced heating/cooling ramp times and floor space requirements.

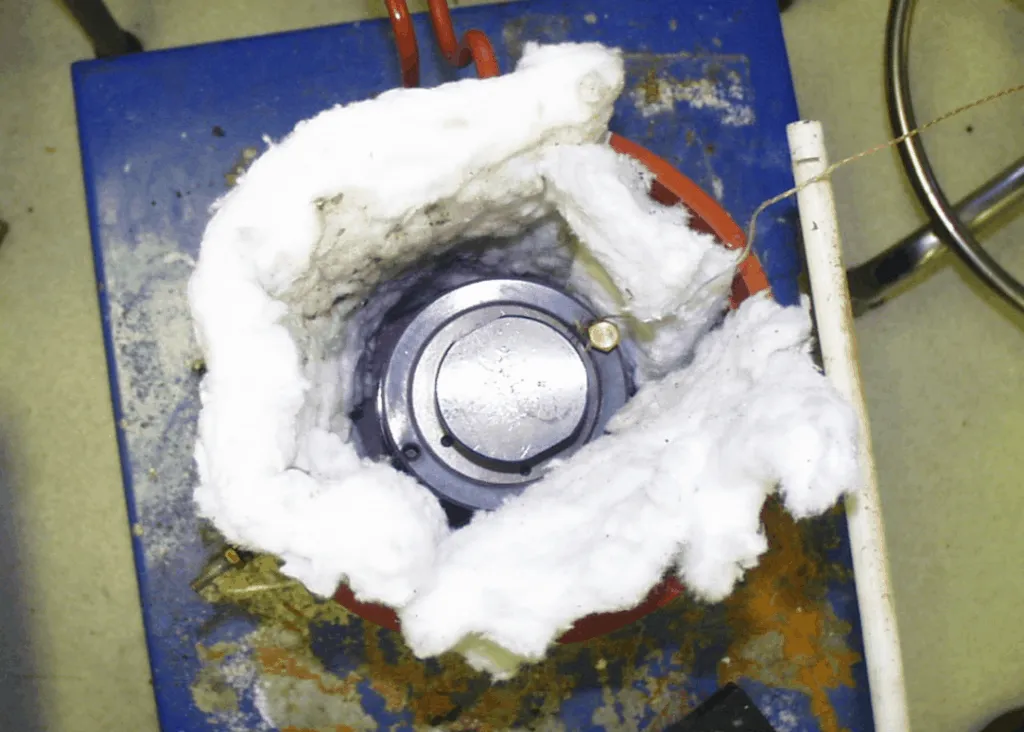

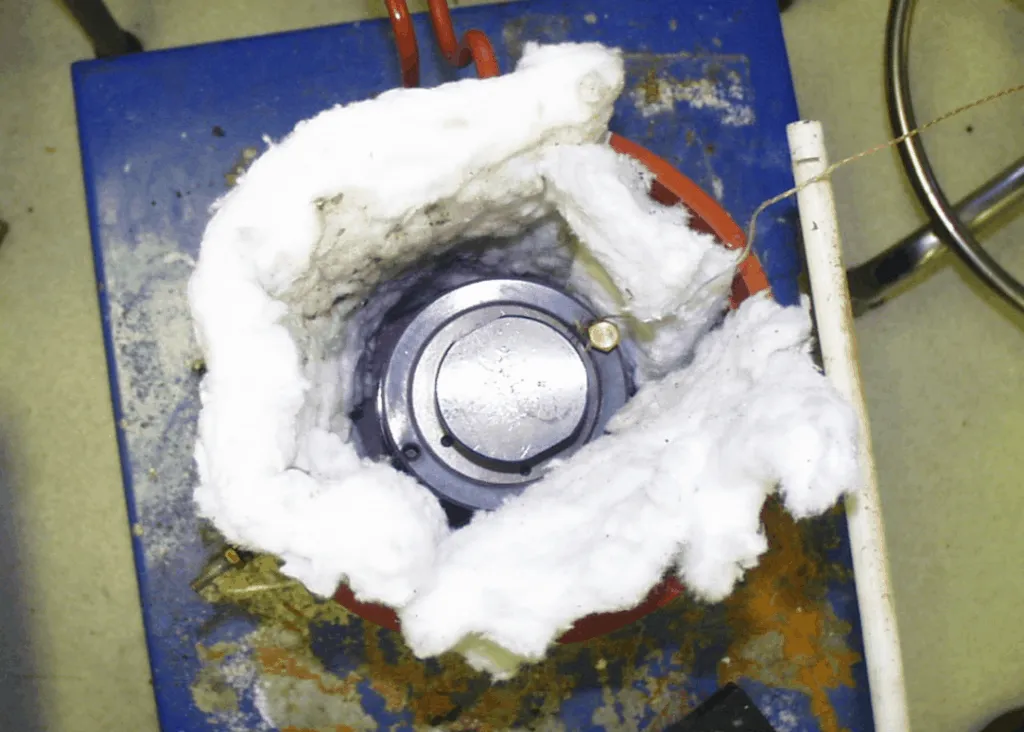

A nine-turn helical

induction heating coil is used to heat the steel die while temperature of the die is monitored with a thermocouple. Die heating soak time is one hour.

Results/Benefits Induction heating provides:

Results/Benefits Induction heating provides:

- heat generated within the part, saving energy and time

- easy integration with a press

- anticipated process energy savings

- greatly reduced footprint compared with oven, batch, carts

- precise controllable heat

- rapid ramp-up and cool-down times

- automatic ramp and soak capability

Induction Heating Equipment: DW-MF-70kW/30kHz induction heating system, equipped with a remote workhead containing one 53μF capacitor

- An induction heating coil designed and developed specifically for this application.

Process Induction Heating is evaluated to replace an oven/batch process.

Advantages include reduced heating/cooling ramp times and floor space requirements.

A nine-turn helical induction heating coil is used to heat the steel die while temperature of the die is monitored with a thermocouple. Die heating soak time is one hour.

Induction Heating Equipment: DW-MF-70kW/30kHz induction heating system, equipped with a remote workhead containing one 53μF capacitor

- An induction heating coil designed and developed specifically for this application.

Process Induction Heating is evaluated to replace an oven/batch process.

Advantages include reduced heating/cooling ramp times and floor space requirements.

A nine-turn helical induction heating coil is used to heat the steel die while temperature of the die is monitored with a thermocouple. Die heating soak time is one hour.

Results/Benefits Induction heating provides:

- heat generated within the part, saving energy and time

- easy integration with a press

- anticipated process energy savings

- greatly reduced footprint compared with oven, batch, carts

- precise controllable heat

- rapid ramp-up and cool-down times

- automatic ramp and soak capability

Results/Benefits Induction heating provides:

- heat generated within the part, saving energy and time

- easy integration with a press

- anticipated process energy savings

- greatly reduced footprint compared with oven, batch, carts

- precise controllable heat

- rapid ramp-up and cool-down times

- automatic ramp and soak capability