induction Hardening Steel Cam Assembly

Objective :

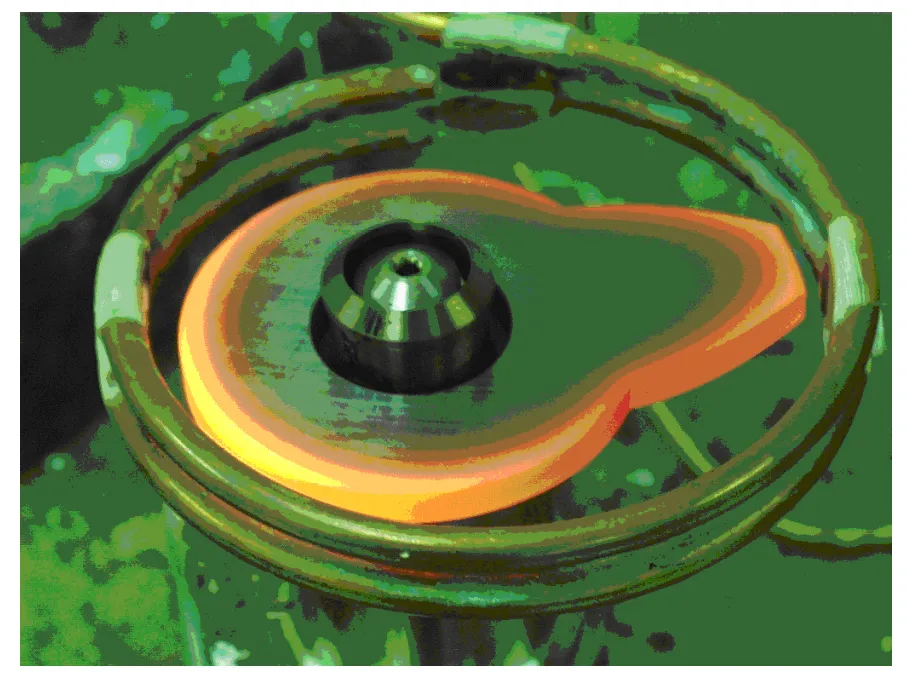

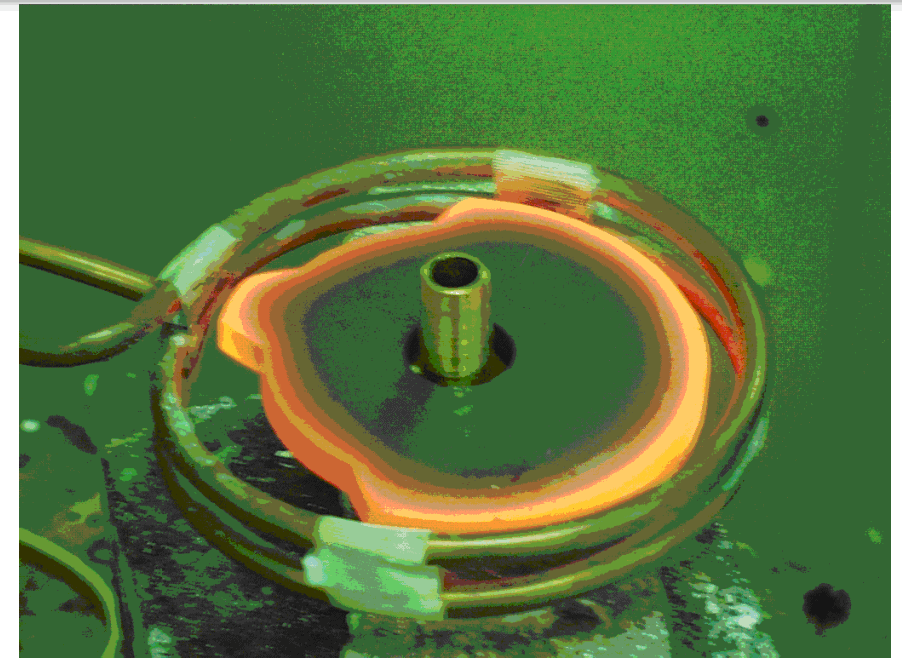

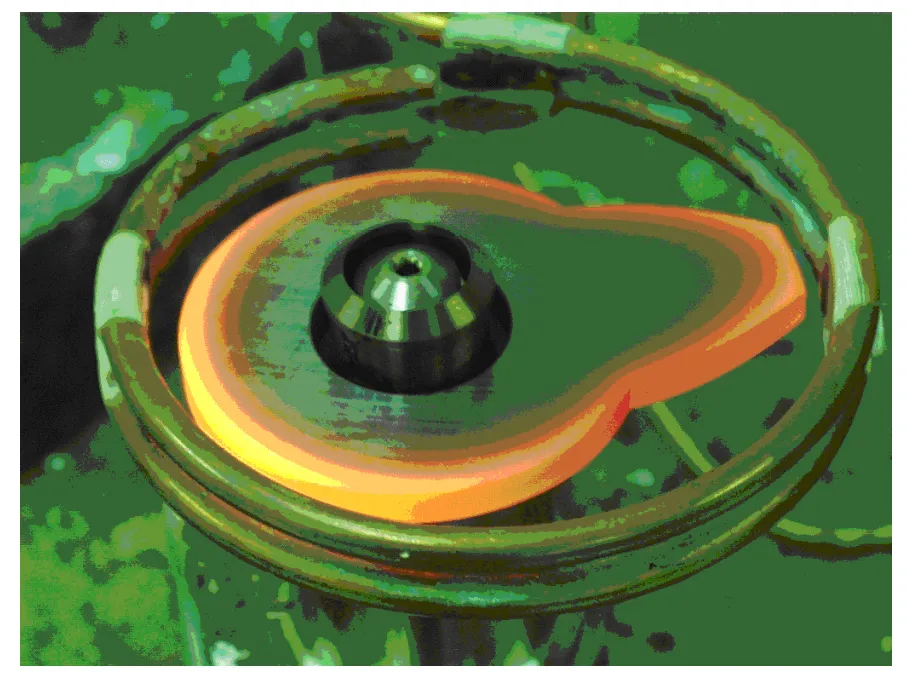

Induction hardening the perimeter of ¼” thick steel cam assemblies

Material: ¼” thick steel cam assemblies of varying geometries

Temperature : 1650 ºF (900 °C)

Frequency : 177 kHz

Equipment

DW-UHF-10kW

induction heating system, equipped with a remote heat station containing one 1.0µF capacitor and an induction heating coil designed and developed specifically for this application

Process

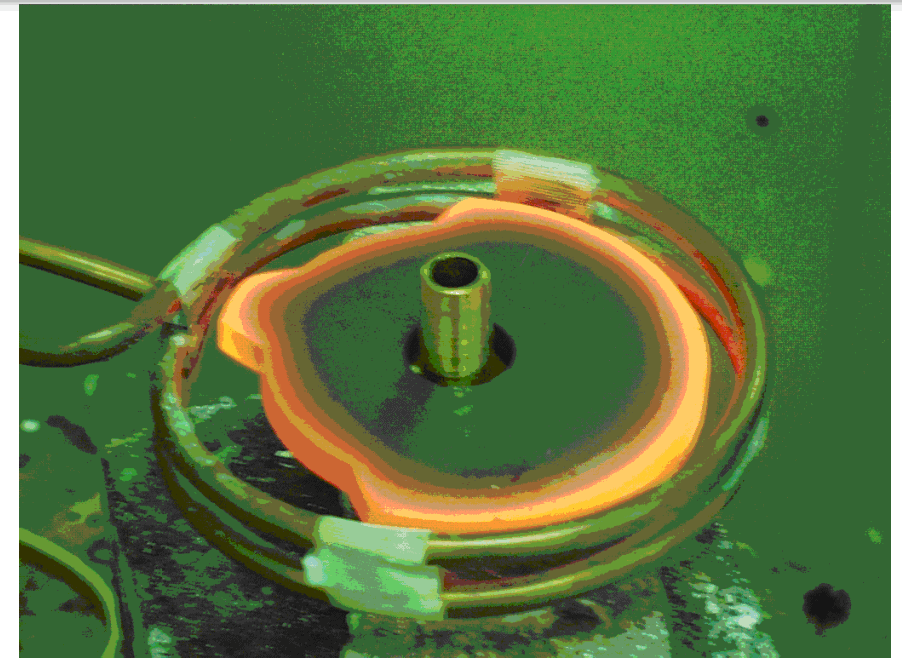

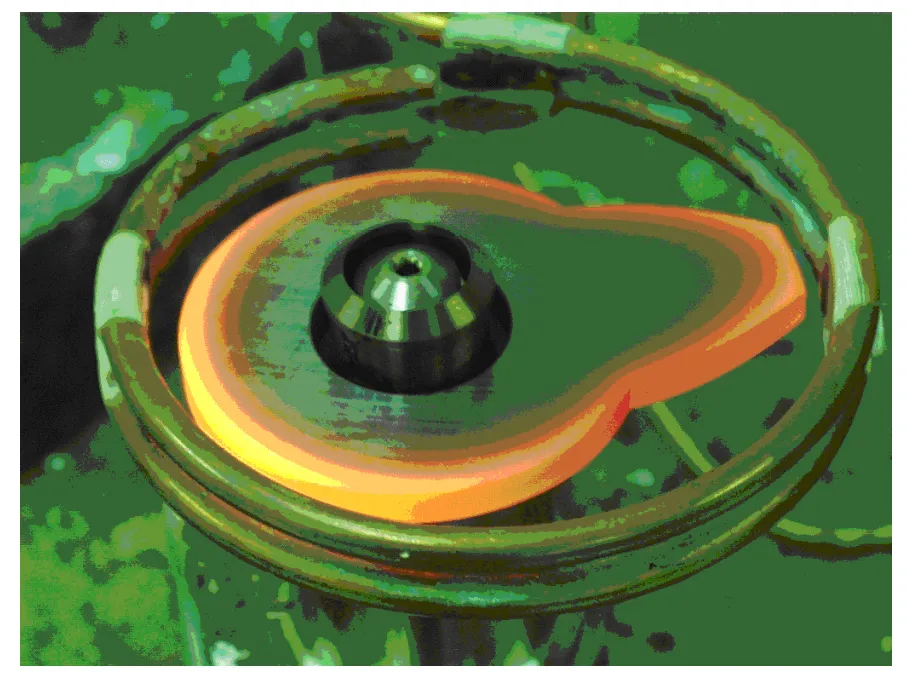

A two-turn helical coil is used to heat the cams. The heat time varies from 120-150 seconds. After heating, the parts are quenched in water.

Results/Benefits

Induction Hardening the cam outer surfaces with induction results in:

• uniform heating for uniform results

• one coil can be used for many geometries

• consistent results from piece to piece

There are thousands of highly successful

induction hardening machines that produce millions of parts supplied to various industry segments. Among the components that routinely undergo induction hardening (IH) are such parts as camshafts, crankshafts, gears, sprockets, transmission shafts, ball studs, pins, toothed racks, wheel spindles, bearing races, fasteners, working tools, track shoes for earth-moving machines — the list is essentially endless. As an example, Figure shows a small array of geometries that are routinely induction hardened.

Objective : Induction hardening the perimeter of ¼” thick steel cam assemblies

Material: ¼” thick steel cam assemblies of varying geometries

Temperature : 1650 ºF (900 °C)

Frequency : 177 kHz

Equipment

Objective : Induction hardening the perimeter of ¼” thick steel cam assemblies

Material: ¼” thick steel cam assemblies of varying geometries

Temperature : 1650 ºF (900 °C)

Frequency : 177 kHz

Equipment

DW-UHF-10kW induction heating system, equipped with a remote heat station containing one 1.0µF capacitor and an induction heating coil designed and developed specifically for this application

Process

A two-turn helical coil is used to heat the cams. The heat time varies from 120-150 seconds. After heating, the parts are quenched in water.

DW-UHF-10kW induction heating system, equipped with a remote heat station containing one 1.0µF capacitor and an induction heating coil designed and developed specifically for this application

Process

A two-turn helical coil is used to heat the cams. The heat time varies from 120-150 seconds. After heating, the parts are quenched in water.

Results/Benefits

Induction Hardening the cam outer surfaces with induction results in:

• uniform heating for uniform results

• one coil can be used for many geometries

• consistent results from piece to piece

There are thousands of highly successful induction hardening machines that produce millions of parts supplied to various industry segments. Among the components that routinely undergo induction hardening (IH) are such parts as camshafts, crankshafts, gears, sprockets, transmission shafts, ball studs, pins, toothed racks, wheel spindles, bearing races, fasteners, working tools, track shoes for earth-moving machines — the list is essentially endless. As an example, Figure shows a small array of geometries that are routinely induction hardened.

Results/Benefits

Induction Hardening the cam outer surfaces with induction results in:

• uniform heating for uniform results

• one coil can be used for many geometries

• consistent results from piece to piece

There are thousands of highly successful induction hardening machines that produce millions of parts supplied to various industry segments. Among the components that routinely undergo induction hardening (IH) are such parts as camshafts, crankshafts, gears, sprockets, transmission shafts, ball studs, pins, toothed racks, wheel spindles, bearing races, fasteners, working tools, track shoes for earth-moving machines — the list is essentially endless. As an example, Figure shows a small array of geometries that are routinely induction hardened.