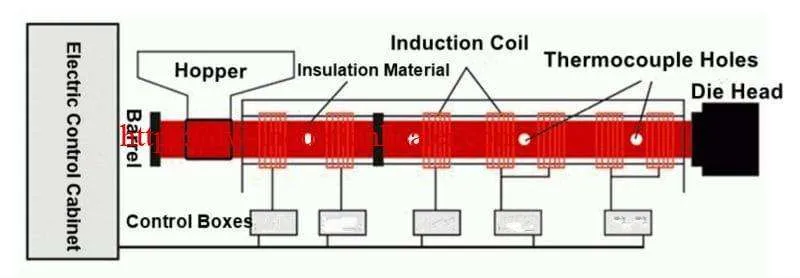

Electromagnetic Induction Heater & 20KW Magnetic Heater for heating plastic injection molding machine

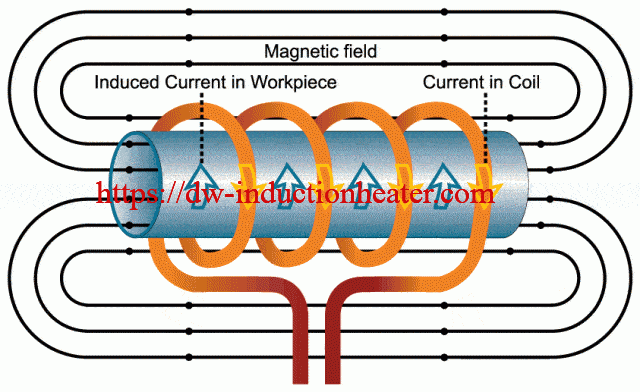

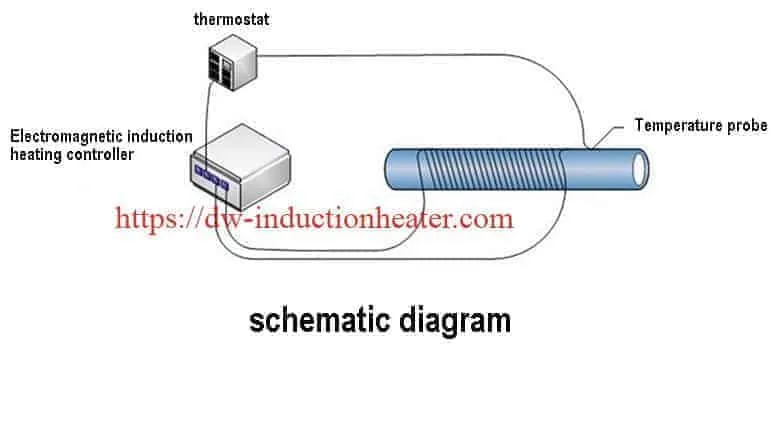

Principle of Electromagnetic Induction Heating:

Most of the metal is heated by the high-frequency magnetic field and uses this principle to pass the high-frequency current through the coil, so that the coil generates a high-frequency magnetic field, so that the metal rod in the coil is induced to generate heat. The electrical energy can be converted into metal thermal energy by the above process. During the whole process, the metal rod does not have any physical contact with the coil, and the energy conversion is completed by the magnetic field eddy current and the metal induction.

Principle of Electromagnetic Induction Heating:

Most of the metal is heated by the high-frequency magnetic field and uses this principle to pass the high-frequency current through the coil, so that the coil generates a high-frequency magnetic field, so that the metal rod in the coil is induced to generate heat. The electrical energy can be converted into metal thermal energy by the above process. During the whole process, the metal rod does not have any physical contact with the coil, and the energy conversion is completed by the magnetic field eddy current and the metal induction.

Advantages of electromagnetic induction heater:

1.Energy saving and emission reduction (30-85%)

2.higher thermal efficiency

3.Reduced operating temperature

4.warm up fast

5'long service life

6.Maintenance is simple and convenient

What Advantages Does Electromagnetic Induction Heater Have Compared With Traditional Heaters?

Advantages of electromagnetic induction heater:

1.Energy saving and emission reduction (30-85%)

2.higher thermal efficiency

3.Reduced operating temperature

4.warm up fast

5'long service life

6.Maintenance is simple and convenient

What Advantages Does Electromagnetic Induction Heater Have Compared With Traditional Heaters?

| Advantage Comparison | ||

| Electromagnetic Induction Heater | Traditional Heater | |

| Heating Principles | Electromagnetic Induction | Heating the Resdistance Wire |

| Heated Part | Charging barrel is heated directly to get higher efficiency ,but the induction coil itself is not heated to guaratte longer using life | heater itself,then heat transfered to the charging barrel |

| Surface Temperature & Safety | Max. 60 Degree Centigrade,safe to touch by hands. | The same with your heating temperature, Dangerous to touch |

| Heating Rate | High Efficiency:save 50%-70%warming -up time | Low Efficiency:No time-saving |

| Energy Saving | Save 30-80% Power Consumption | No Saving |

| Temperature Control | High precision | Low Precision |

| Using life | 4-5year | 2-3year |

| Working Environment | Normal temperature for workers,easy and comfortable | Hot,especially for low latitude Area |

| Cost | Cost-effective,with30-80% energy-saving rate,it takes 6-10 months to recover the cost. The higher the rate is,the less time it takes. | Low |

Application of electromagnetic induction:

1.Plastic rubber industry: plastic film blowing machine, wire drawing machine, injection molding machine, granulator, rubber extruder, vulcanizing machine, cable production extruder, etc.;

2.Pharmaceutical and chemical industry: pharmaceutical infusion bags, plastic equipment production lines, liquid heating pipelines for the chemical industry;

3.Energy, food industry: heating of crude oil pipelines, food machinery, super freighters and other equipment that require electric heating;

4.Industrial high-power heating industry: machine for killing machine, reaction axe, steam generator (boiler);

5.Smelting heating industry: die casting furnace zinc alloy, aluminum alloy and other equipment;

6.Building materials industry: gas pipe production line, plastic pipe production line, PE plastic hard flat net, geonet net unit, automatic blow molding machine, PE honeycomb board production line, single and double wall corrugated pipe extrusion production line, composite air cushion film unit, PVC hard Tube, PP extrusion transparent sheet production line, extruded polystyrene foam tube, PE winding film unit;

7.high power commercial induction cooker movement;

8.Dry heating in printing equipment;

9.other similar industry heating;

Application of electromagnetic induction:

1.Plastic rubber industry: plastic film blowing machine, wire drawing machine, injection molding machine, granulator, rubber extruder, vulcanizing machine, cable production extruder, etc.;

2.Pharmaceutical and chemical industry: pharmaceutical infusion bags, plastic equipment production lines, liquid heating pipelines for the chemical industry;

3.Energy, food industry: heating of crude oil pipelines, food machinery, super freighters and other equipment that require electric heating;

4.Industrial high-power heating industry: machine for killing machine, reaction axe, steam generator (boiler);

5.Smelting heating industry: die casting furnace zinc alloy, aluminum alloy and other equipment;

6.Building materials industry: gas pipe production line, plastic pipe production line, PE plastic hard flat net, geonet net unit, automatic blow molding machine, PE honeycomb board production line, single and double wall corrugated pipe extrusion production line, composite air cushion film unit, PVC hard Tube, PP extrusion transparent sheet production line, extruded polystyrene foam tube, PE winding film unit;

7.high power commercial induction cooker movement;

8.Dry heating in printing equipment;

9.other similar industry heating;

Technical Parameters

|

Item |

Technical Parameters |

| rated power | 3phases, 20KW,50/60Hz,380V (Can be customized) |

| Rated input current | 27-30(A) |

| Rated output current | 30-50(A) |

| Rated voltage frequency | AC 380V/50Hz-60Hz |

| Voltage adaptation range | constant power output at 300 ~ 400V |

| Adapt to ambient temperature | -20ºC~50ºC |

| Adapt to environmental humidity | ≤95% |

| Power adjustment range | 20% ~ 100% stepless adjustment(That is: adjustment between 0.5 ~ 20KW) |

| Heat conversion efficiency | ≥95% |

| Effective power | ≥98%(Can be customized according to user needs) |

| working frequency | 5~40KHz |

| Main circuit structure | Full bridge series resonance |

| Control System | The DSP-based high-speed automatic phase-locking tracking control system |

| Application mode | Open application platform |

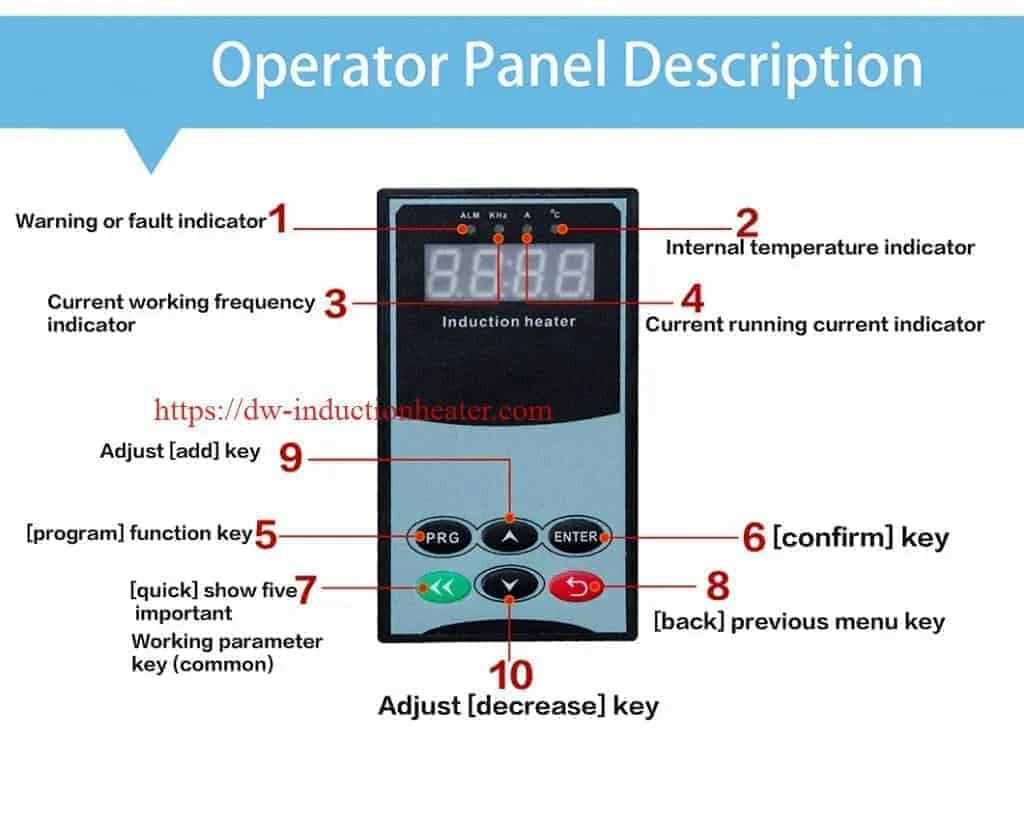

| monitor | Programmable digital display |

| start time | <1S |

| Instantaneous overcurrent protection time | ≤2US |

| Power overload protection | 130% instantaneous protection |

| Soft start mode | Fully electrically isolated soft start heating/stop mode |

| Support PID adjustment power | Identify 0-5V input voltage |

| Support 0 ~ 150 ºC load temperature detection | Accuracy up to ± 1 ºC |

| Adaptive coil parameters | 20KW 10 square line, length 60m, inductance 250 ~ 300uH |

| Coil to load distance(Thermal insulation thickness) |

20-25mm for circle, 15-20mm for a plane, 10-15mm for ellipse and within 10 mm for superellipse |