Objective

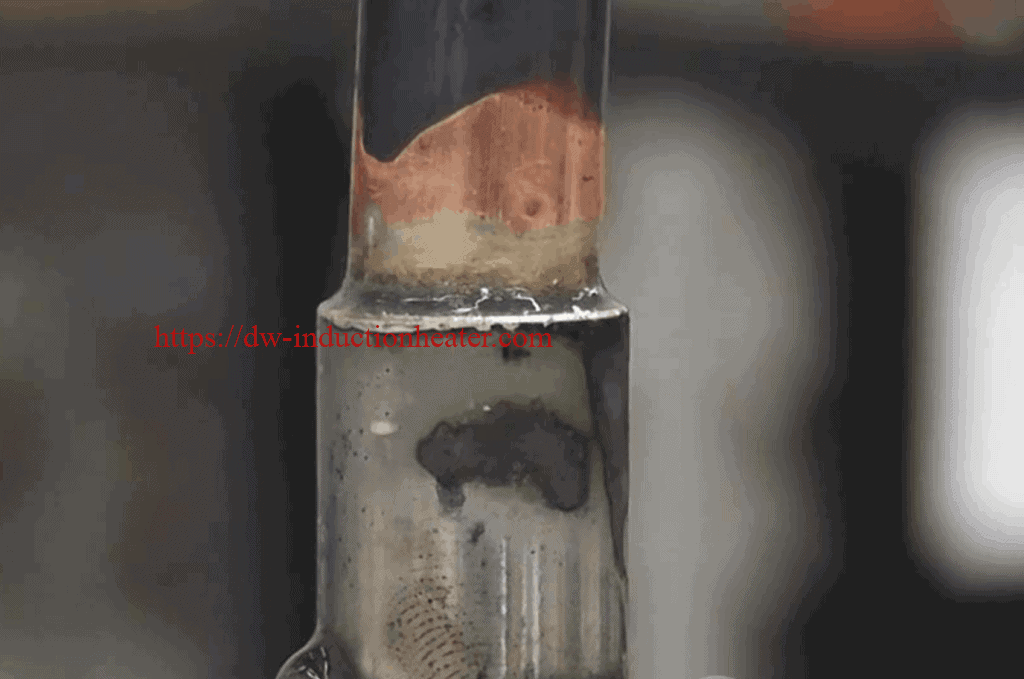

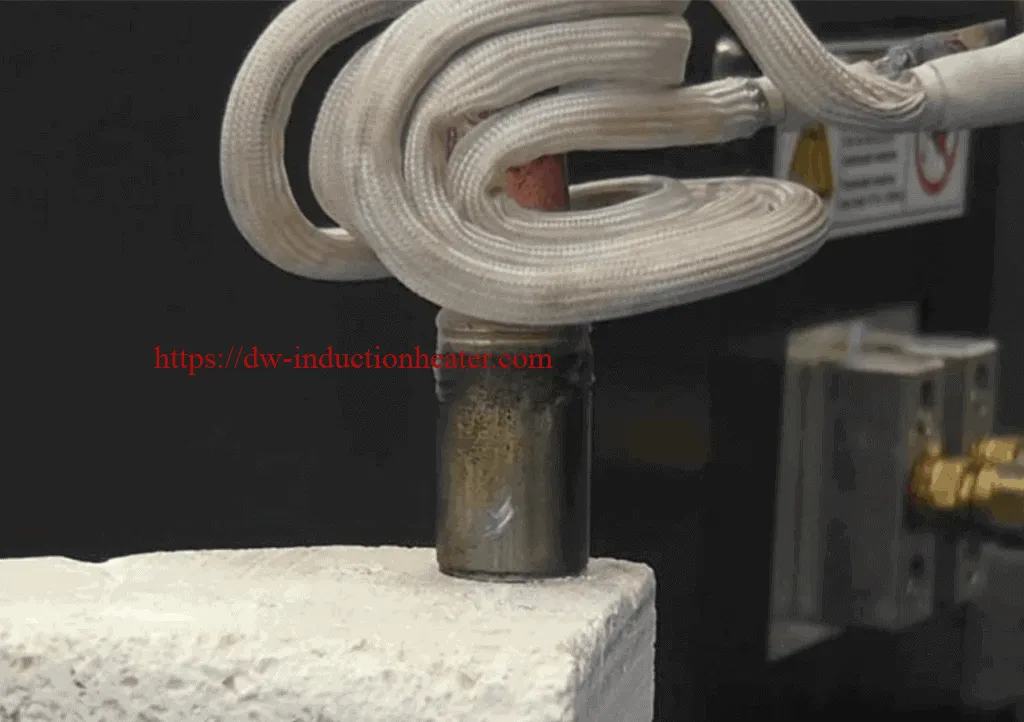

Induction Brazing stainless steel to copper tubing. Objective is to evaluate induction brazing solution. Customer is looking to reduce defects and for a cleaner brazing environment.

Due to different pipe size and lower volume – evaluation is performed with a UBraze system.

Test1

Equipment

DW-HF-25kw induction brazing machine

Materials

Copper to Stainless steel tube

Power: 12.5kW

Temperature: 1400ºF to 1600ºF (760ºC to 871ºC)

Time: 9 to 11 seconds

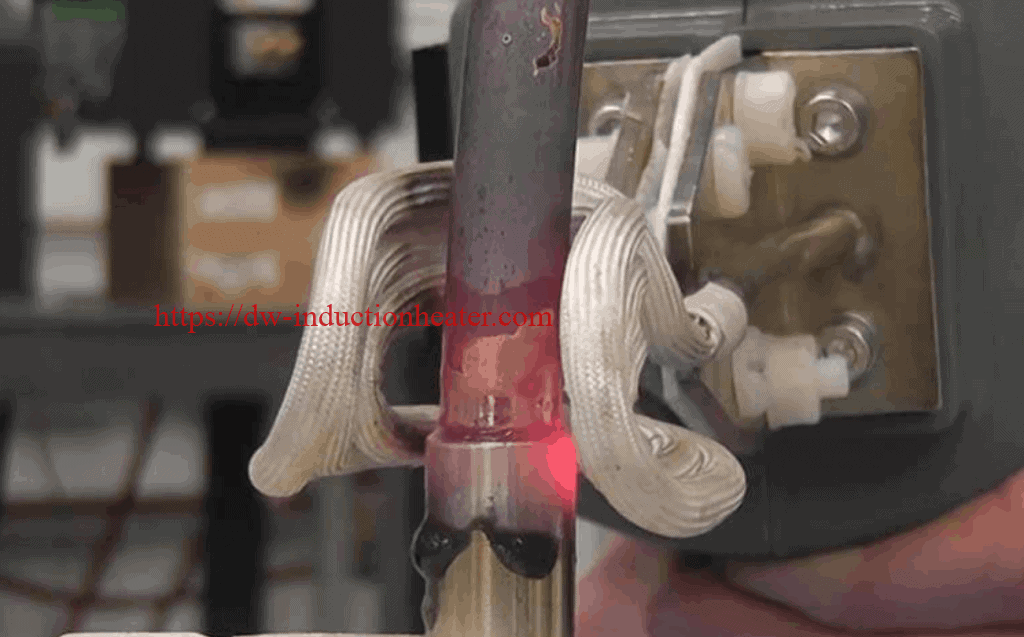

Test2

Equipment

DW-HF-25kw induction brazing machine

Materials

Copper to Stainless steel

Power: 12.5kW

Temperature: 1400ºF to 1600ºF (760ºC to 871ºC)

Time: 9 to 11 seconds

Results and Conclusions:

Induction brazing test with U open coil was able to braze the parts in 9 to 11 seconds for the full braze cycle.

Operator training with this setup will be minimal.

https://dw-inductionheater.com/wp-content/uploads/2020/05/induction-brazing-stainless-steel-to-coppr-pipes.png?v=1588384073

https://dw-inductionheater.com/induction-brazing-stainless-steel-to-copper.html

brazing copper system, brazing stainless steel, brazing stainless steel to copper, brazing stainless steel tube, handheld brazing copper, High frequency Brazing copper, High Frequency brazing stainless steel, induction brazing equipment, induction brazing machine, induction brazing stainless steel, induction brazing stainless steel unit, induction brazing system, induction brazing units, RF brazing stainless steel