Objective

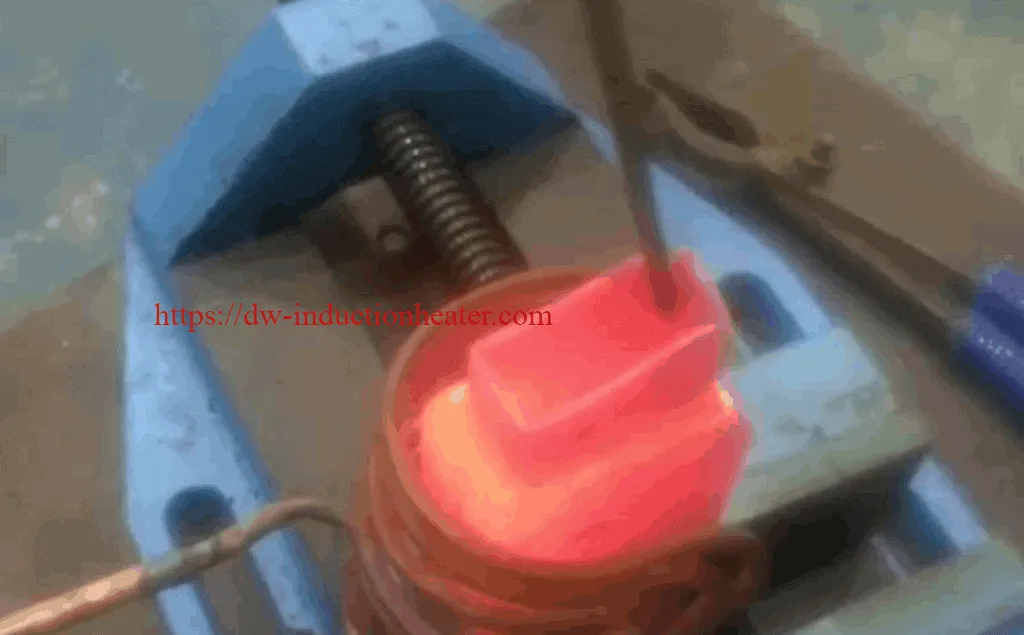

Induction Brazing Copper to Copper parts Spacer. The workpieces were heated to 2012˚F (1100˚C) in 1 minutes.

Recommended Equipment

The recommended equipment for this application is the DW-HF-45kw induction heating machine

- Copper section: 0.55” thick x 1.97” long x 1.18” wide x 0.2” long (14 mm thick & 50 mm long x 30 mm wide x 5 mm long)

- Copper spacer: 0.55” thick x 1.57” long x 0.79” wide x 0.08” long (14 mm thick & 40 mm long x 20 mm wide x 2 mm long)

- Brazing alloy: 5% silver brazing rod

Power: induction heating power supplies up to 30 kW

Temperature: 2012˚F (1100˚C)

Time: 1 minutes

https://dw-inductionheater.com/wp-content/uploads/2020/05/High-frequency-Induction-Brazing-Copper-To-Copper-Parts.png?v=1588728728

https://dw-inductionheater.com/induction-brazing-copper-to-copper-parts.html

brazing, brazing copper, brazing induction, brazing machine manufacturer, High frequency Brazing copper, induction brazing, induction brazing copper, induction brazing copper to copper, induction brazing machine, induction brazing process, induction soldering