Objective

The objective of the application test is to braze copper and brass plates overlay joints with induction to replace torch operation. Overylay joints may be brass to brass or copper to copper.

The current torch process results in excessive contaminants on the assembly and requires extensive rework after the brazing operation.

Equipment

DW-HF-25kw induction heating machine

Materials

• Copper and brass coupon plates

• Braze alloy – EZ Flo 45

Key Parameters – Copper plates

Power: 15 kW

Heat to Temp: Approximately 1350° F (732° C)

Time: Average time – 2 minutes

Process and Results:

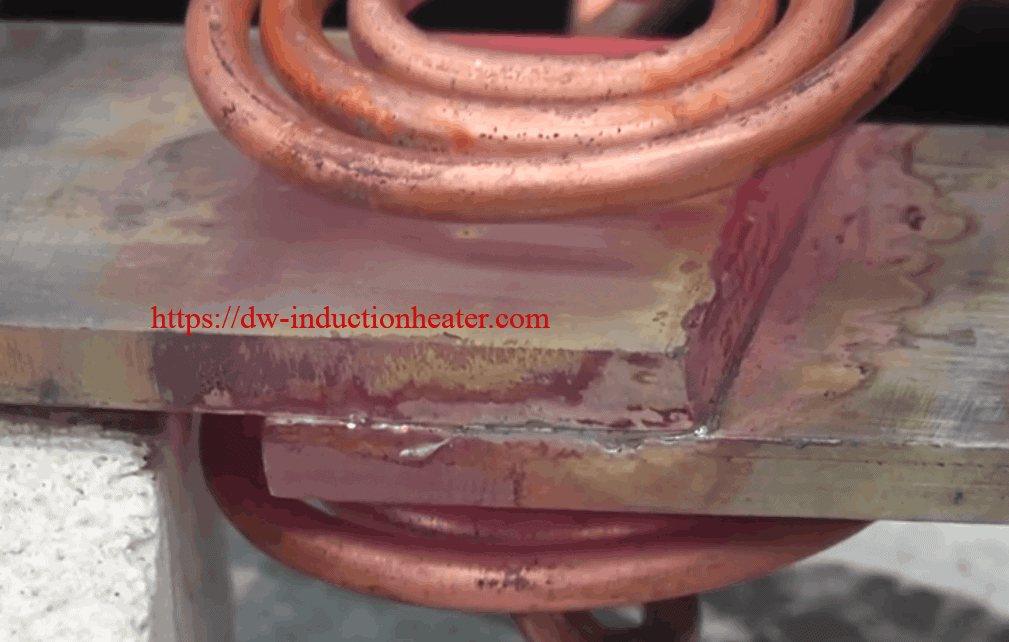

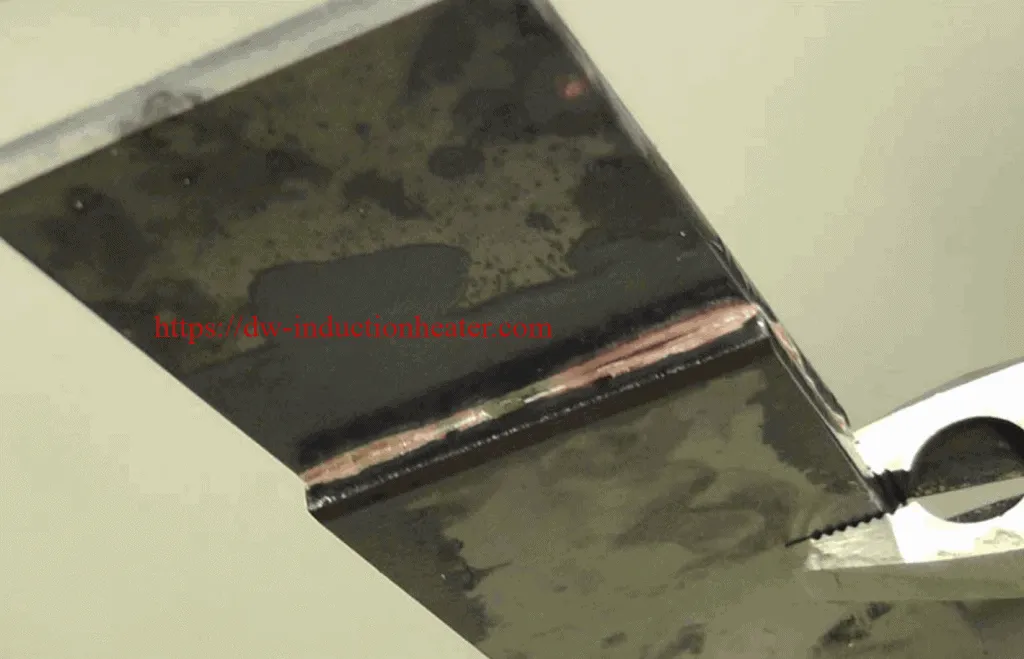

- EZ Flo 45 braze wire was cut into 2” (50.8mm) lengths and placed in the interface area.

- The assemblies were set up (see photos) and heated with induction heating for an average time of 2 minutes to flow the alloy and achieve the braze.

Key Parameters –Copper Brass coupon plates

Power: 15 kW

Heat to temp: Approximately 1350° F (732° C)

Time: Average time – 2 minutes

Process and Results:

- EZ Flo 45 braze wire was cut into 2” (50.8mm) lengths and placed in the interface area.

- The assemblies were set up (see photos) and heated for an average time of 2 minutes to flow the alloy and achieve the induction brazing.

https://dw-inductionheater.com/wp-content/uploads/2020/05/induction-brazing-copper-and-brass-plate-lap-joints.png?v=1589507546

https://dw-inductionheater.com/Induction-brazing-copper-plates-overlay-joints.html

brass plates soldering, brazing copper joints, brazing copper plates, copper plates, copper plates joints, inductino brazing brass plates joints, induction copper plates brazing, induction joints copper plates, inducton brazing copper plates machine, RF brass plates induction