Objective

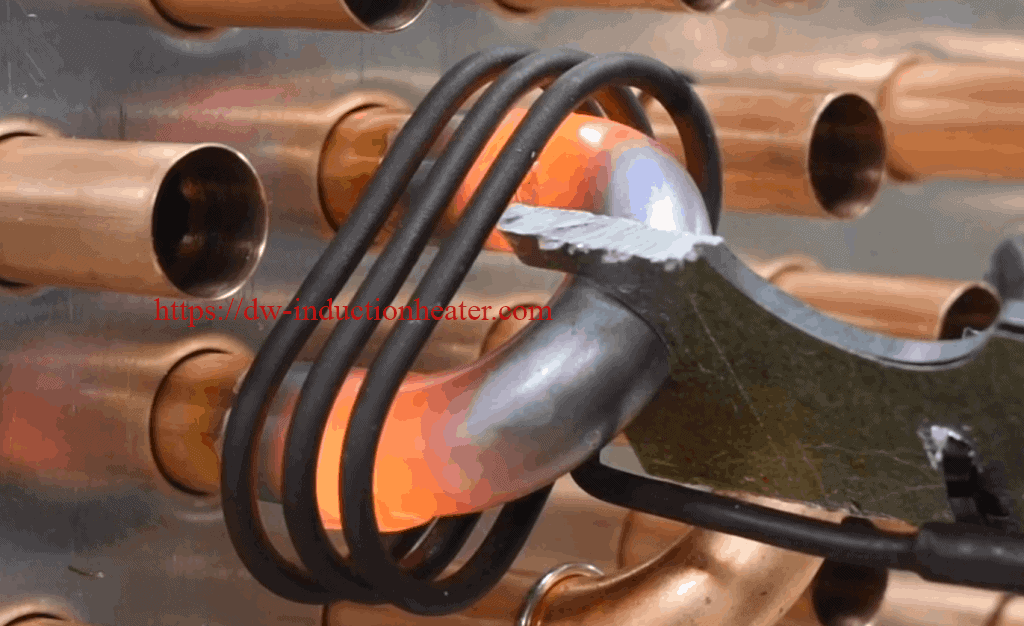

Induction brazing copper pipe of heating exchanger assembly using stationary C coil or U shape induction heating system.

Target speed for assembling all 6 joints was 30 seconds, or approximately 5 seconds per joint.

The requirement was to braze all of the joints inside the housing without affecting the plastic covers.

Equipment

DWS-20 handheld induction brazing machine

Materials

• Copper tubing

• Brazing flux

Key Parameters

Temperature: Approximately 1292°F (700°C)

Power: 15 kW

Time: 5 sec per joint

Process:

U shape custom coil is suitable for induction brazing of custom samples.

Results/Benefits:

Prior to induction brazing copper pipe, the customer was using flame brazing and had to braze the joints outside of the enclosure.

With the induction brazing, they were able to achieve the following benefits:

- Braze inside the enclosure

- Improve productivity of the brazing operation

- Precise control of the time and temperature

- Safe heating with no open flames

- Higher energy efficiency

https://dw-inductionheater.com/wp-content/uploads/2020/05/induction-brazing-copper-tube-of-heating-exchanger.png?v=1589331618

https://dw-inductionheater.com/induction-brazing-copper-pipe-of-heating-exchanger.html

brazing heat exchanger, copper pipe induction brazing, heat exchanger brazer, heat exchanger HF brazing machine, heating exchanger brazing, heating exchanger induction heater, HF brazing heat exchanger, induction brazing copper, induction brazing heat exchanger, induction brazing heat exchanger machine, RF brazing heat exchanger