Objective

High Frequency Induction Brazing brass pipe to brass part and a brass tip in under one minute using induction.

Equipment

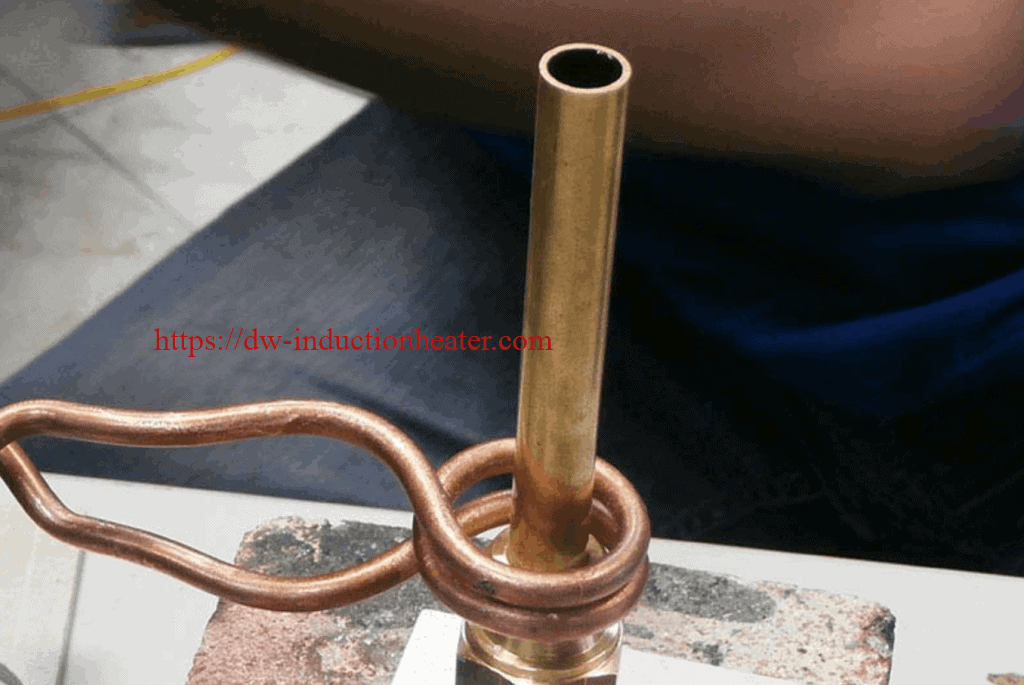

DW-UHF-6KW-III handheld induction brazing machine

2 turns coil

Materials

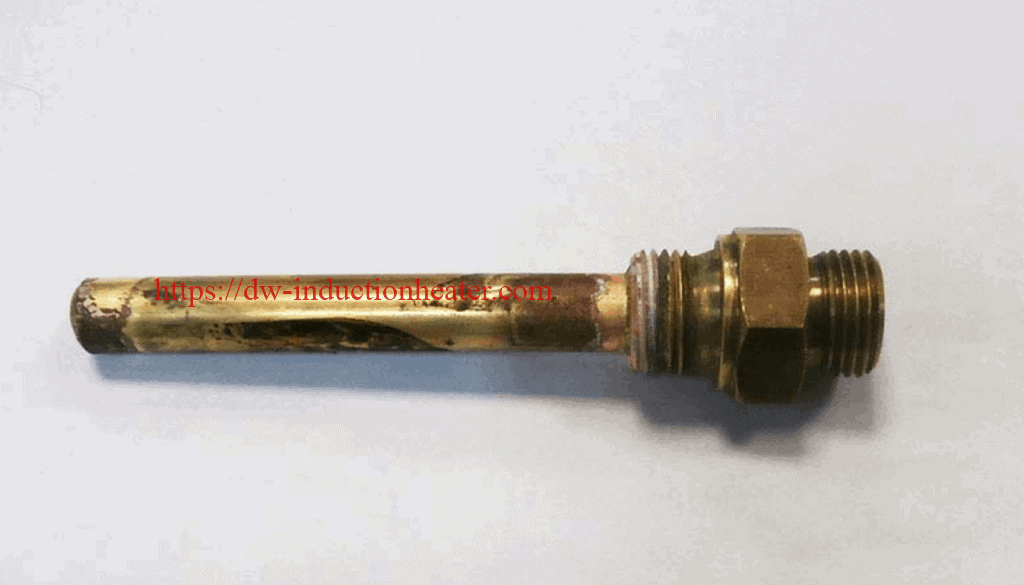

• Wide brass part

• Brass pipe

• Silver-based brazing alloy, provided by customer

Test 1 – Pipe to wide part:

Key Parameters

Power: 4.4 kW

Temperature: Approximately 1400° F (760° C)

Time: 38 sec

Test 2 – Pipe to tip:

Key Parameters

Power: 4.4 kW

Temperature: Approximately 1400° F (760° C)

Time: 17 sec

Process:

Test 1

- The wide part and brass pipe are assembled and a brazing alloy ring is placed between them.

- The assembly is put inside the induction heating coil and induction heat is applied.

- The joint is completed in 38 seconds.

Test 2

- The tip and pipe are assembled and a brazing alloy ring is placed between them.

- The assembly is put inside the coil and induction heat is applied.

- The joint is completed in 17 seconds.

Results/Benefits:

Induction heating provides:

- Strong durable joints

- Selective and precise heat zone, resulting in less part distortion and joint stress than welding

- Less oxidation

- Faster heating cycles

- More consistent results and suitability for large volume production, without the need for batch processing

- Safer process than flame brazing

https://dw-inductionheater.com/wp-content/uploads/2020/05/induction-brazing-brass-pipe-to-brass-part3.png?v=1590326628

https://dw-inductionheater.com/induction-brazing-brass-pipe-to-brass-part.html

brazing brass, Brazing Brass pipe, brazing brass pipe machine, HF brazing brass, HF brazing brass part, HF brazing brass system, induction brass brazing, induction brazing brass, Induction Brazing Brass pipe, radio frequency brazing brass