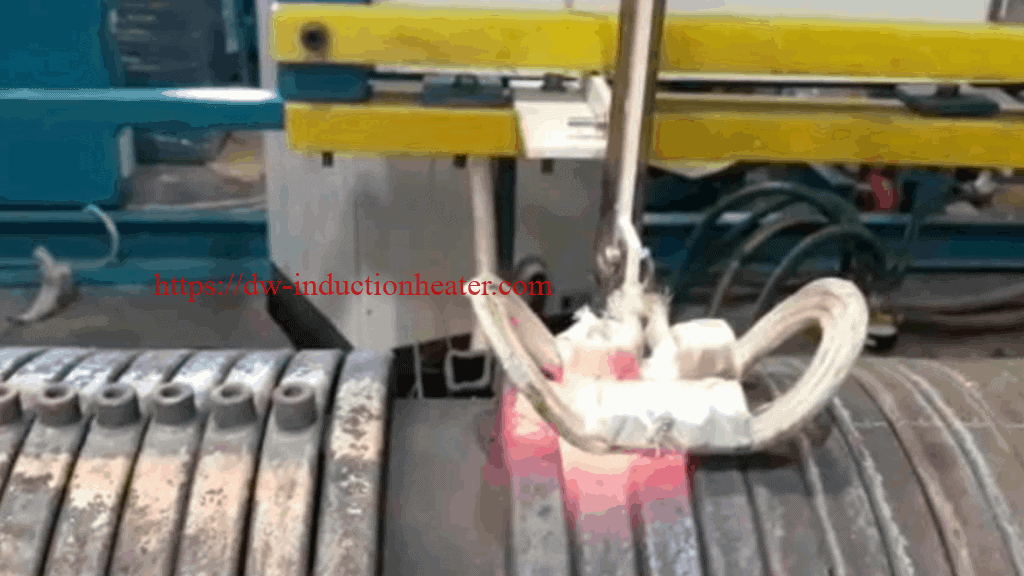

Induction Brazing Brass Studs to Copper Pipes

Objective:

Induction brazing brass studs to copper pipes

The Client:

A manufacturer of coils for industrial heating applications.

Equipment:

DW-UHF-40KW Induction Brazing Systems – two modules.

Materials: Brass stud ( size: 25mm diameter, 20 mm height )

Power: 30 kW

The main challenge during this induction brazing process is to ensure that the design of the coil is one that eases the technician to position it in the most convenient way. The induction coil should allow for the second stud to be pre-heated without melting the first one.

First, the electrolytic copper section is wound on a steel former by a gas torch while an equal spacing between the turns is maintained. Then, the copper turn is heated close to the required temperature and while the power is ON, the technician should make sure to manually position the brass stud with the brazing ring at the designated centre. During the process of brazing, the induction coil is moving at a speed of 58 mm per minute – 33 kW.

If the power is increased, the speed changes accordingly.

Results and Conclusions:

- A fast, clean and safe induction brazing process

- Guaranteed repeatability

- Precise control of time and temperature

https://dw-inductionheater.com/wp-content/uploads/2020/04/induction-brazing-brass-studs-to-copper.png?v=1587644202

https://dw-inductionheater.com/induction-brazing-brass-studs-to-copper-pipes.html

brass studs brazing, brazing brass, brazing brass studs, brazing brass to copper, High Frequency Brazing brass, induction brazer, induction brazing brass, induction brazing copper, induction brazing copper system, induction brazing equipment, induction brazing system, induction brazing units