High Frequency Induction Brazing Copper to Stainless Steel Process Technology

Objective

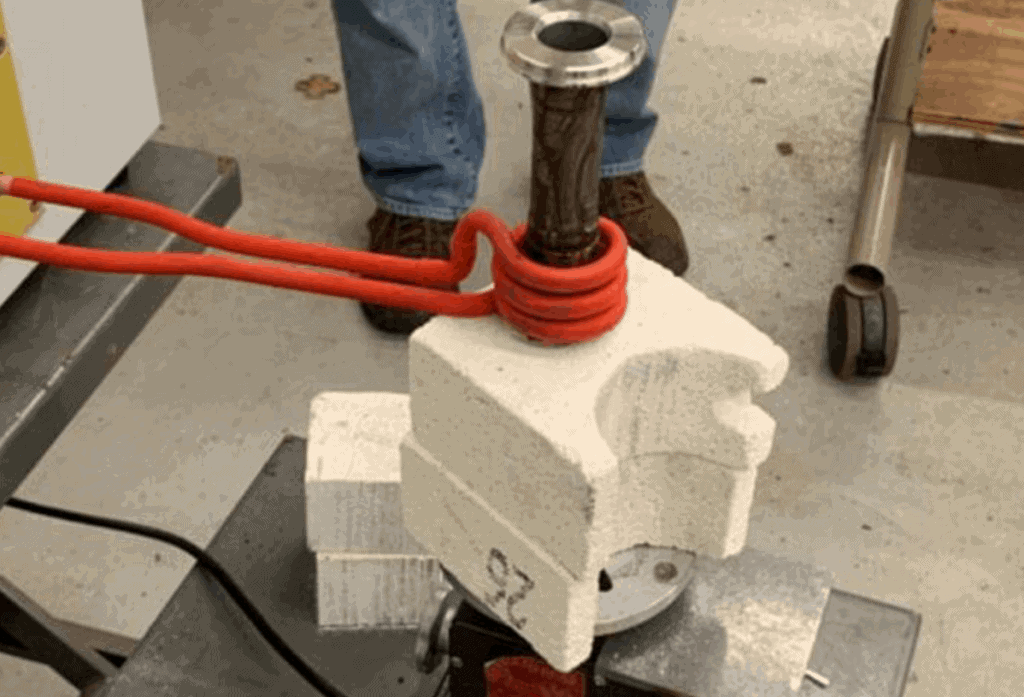

The objective of this induction brazing copper to stainless steel using a DW-UHF-40kw induction heating power supply with a custom heating station

Equipment

DW-UHF-40KW Induction Heating Power Supply

HLQ custom coil

Key Parameters

Power: 23.65 kW

Temperature: Approximately 1300°F (704)°C

Time: 3.5 mins

Process:

In order to start the induction brazing of copper to stainless steel the part was centered on a turntable. The induction brazing coil was then positioned around the copper because it is less efficiently heated than stainless steel. As the part was rotating, approximately 25kW were being applied to the coil. Once the brazed joint was close to the ideal brazing temperature, the alloy was hand fed onto the joint. The induction brazing of cooper to stainless steel was completed and successful.

Results/Benefits:

The result of the induction brazing copper to stainless steel application testing was a positive one, the induction brazing was completed and the copper to stainless steel was done seamlessly. This test resulted in high quality and repeatability of the brazed joints, increased productivity and control of the time and temperature.

https://dw-inductionheater.com/wp-content/uploads/2020/04/induction-brazing-copper-to-stainless-steel.jpg?v=1587209214

https://dw-inductionheater.com/induction-brazing-copper-to-stainless-steel-process.html

brazing copper, brazing copper system, brazing copper to stainless steel, copper to stainless steel brazing, copper to stainless steel HF brazing, HF brazing machine, HF induction brazing, high frequency brazing, High frequency Brazing copper, induction brazing