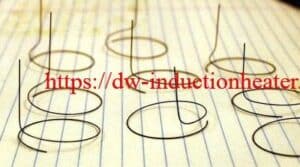

Induction Heat setting Nitinol With High Frequency RF Induction Heating Equipment

Objective To heat a 0.005” (0.13mm) diameter Nitinol wire for a shapesetting application

Material Nitinol wire

Steel fixture

Temperature 930°F (500°C)

Frequency 500 kHz

Equipment DW-UHF-6kW-I solid-state induction power supply equipped with a remote heat station containing two 0.33μF capacitors (total 0.66μF). An induction-heating coil designed and developed specifically for this application.

Process The customer-supplied fixture consists of two concentric cylinders: a 0.1” (2.54mm) thick hollow outer cylinder is slipped over a 1” inch (25.4mm) diameter solid cylinder. The required Nitinol shape is etched on the OD of the inner cylinder. The solid steel fixture supplied is modified to reduce the thermal

mass. The solid inner cylinder is drilled to allow for a coil to be inserted in the ID. A special four-turn internal and external helical coil is used to generate the required heat pattern. Initial tests are conducted (using a thermocouple) on a fixture without a part to establish the heating cycle. The part is placed into the fixture and the induction-heating coil over the part. Power is supplied until the part is heated to the set point and is held at this temperature for 2.5 minutes. The fixture is immediately quenched in water following the heat cycle. Parts are made to the specifications for shape memory.

Results/Benefits The Ameritherm system heats the fixture to the set point at the rates specified and the Nitinol wire is shaped as desired within 4 minutes, using less energy and time than traditional oven

heating methods.

https://dw-inductionheater.com/wp-content/uploads/2015/04/induction-heat-setting.jpg

https://dw-inductionheater.com/induction-heat-setting-nitinol.html

heat setting nitinol, induction heating Nitinol, induction Nitinol heater, induction Nitinol heating, Nitinol heating induction system, Nitinol induction heating, stting Nitinol