Soldering Steel To Brass With Induction IGBT Soldering Heater

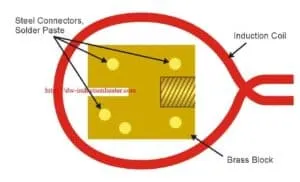

Objective Heat an assembly of small, gold-plated steel connectors to a brass block.

Material Approx. 1/8” (3.2mm) diameter gold-plated steel connectors, 1”(25.4mm) square x 1/4” thick brass block

Temperature 600°F(315.6ºC)

Frequency 240 kHz

Equipment • DW-UHF-6kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

Process A two-turn helical coil is used to provide uniform heat to parts assembly. Solder paste and flux are applied to the joint area and power is applied for 20 seconds to solder the parts. Proper

fixturing is needed to hold the parts in position.

Results/Benefits Induction heating provides:

• Rapid, localized heating to specific regions of part

• Neat and clean joints

• Flameless processing

https://dw-inductionheater.com/soldering-steel-to-brass-with-induction-heater.html?feed_id=247175&_unique_id=665229b5a33ef

https://dw-inductionheater.com/soldering-steel-to-brass-with-induction-heater.html?feed_id=247175&_unique_id=665229b5a33ef

Soldering Steel To Brass With Induction IGBT Soldering Heater

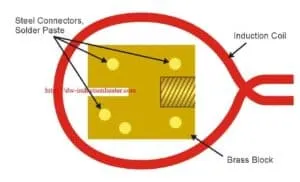

Objective Heat an assembly of small, gold-plated steel connectors to a brass block.

Material Approx. 1/8” (3.2mm) diameter gold-plated steel connectors, 1”(25.4mm) square x 1/4” thick brass block

Temperature 600°F(315.6ºC)

Frequency 240 kHz

Equipment • DW-UHF-6kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

Process A two-turn helical coil is used to provide uniform heat to parts assembly. Solder paste and flux are applied to the joint area and power is applied for 20 seconds to solder the parts. Proper

fixturing is needed to hold the parts in position.

Results/Benefits Induction heating provides:

• Rapid, localized heating to specific regions of part

• Neat and clean joints

• Flameless processing

Soldering Steel To Brass With Induction IGBT Soldering Heater

Objective Heat an assembly of small, gold-plated steel connectors to a brass block.

Material Approx. 1/8” (3.2mm) diameter gold-plated steel connectors, 1”(25.4mm) square x 1/4” thick brass block

Temperature 600°F(315.6ºC)

Frequency 240 kHz

Equipment • DW-UHF-6kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

Process A two-turn helical coil is used to provide uniform heat to parts assembly. Solder paste and flux are applied to the joint area and power is applied for 20 seconds to solder the parts. Proper

fixturing is needed to hold the parts in position.

Results/Benefits Induction heating provides:

• Rapid, localized heating to specific regions of part

• Neat and clean joints

• Flameless processing

https://dw-inductionheater.com/soldering-steel-to-brass-with-induction-heater.html?feed_id=247175&_unique_id=665229b5a33ef

https://dw-inductionheater.com/soldering-steel-to-brass-with-induction-heater.html?feed_id=247175&_unique_id=665229b5a33ef