Soldering Antenna Wire of Radio With IGBT High Frequency Induction Heater

Soldering Antenna Wire of Radio With IGBT High Frequency Induction Heater

Objective To heat a coaxial antenna assembly to 600°F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.

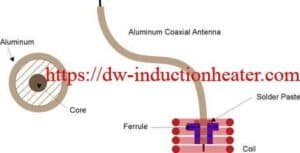

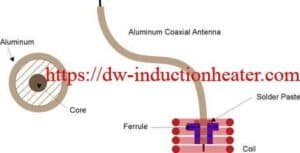

Material .250” diameter aluminum antenna assembly, aluminum ferrule, solder paste, temperature indicating paint

Temperature 600°F

Frequency 333 kHz

Equipment DW-UHF-4.5kW power supply, remote heat station with one 1.2 μF capacitor and a specially designed induction coil.

Process Initial tests were conducted with temperature indicating paint to establish a heating profile and determine time-to-temperature. The solder paste was then applied to the antenna assembly and aluminum ferrule. RF power was applied for two seconds to heat and flow the solder joint.

Results Consistent and repeatable results were achieved within the required two-second time frame. A close examination of the solder joint indicated that the solder flowed well and formed a good, solid joint.

https://dw-inductionheater.com/soldering-antenna-wire-with-induction.html?feed_id=247107&_unique_id=665172fa95e7b

https://dw-inductionheater.com/soldering-antenna-wire-with-induction.html?feed_id=247107&_unique_id=665172fa95e7b

Soldering Antenna Wire of Radio With IGBT High Frequency Induction Heater

Objective To heat a coaxial antenna assembly to 600°F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.

Material .250” diameter aluminum antenna assembly, aluminum ferrule, solder paste, temperature indicating paint

Temperature 600°F

Frequency 333 kHz

Equipment DW-UHF-4.5kW power supply, remote heat station with one 1.2 μF capacitor and a specially designed induction coil.

Process Initial tests were conducted with temperature indicating paint to establish a heating profile and determine time-to-temperature. The solder paste was then applied to the antenna assembly and aluminum ferrule. RF power was applied for two seconds to heat and flow the solder joint.

Results Consistent and repeatable results were achieved within the required two-second time frame. A close examination of the solder joint indicated that the solder flowed well and formed a good, solid joint.

Soldering Antenna Wire of Radio With IGBT High Frequency Induction Heater

Objective To heat a coaxial antenna assembly to 600°F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.

Material .250” diameter aluminum antenna assembly, aluminum ferrule, solder paste, temperature indicating paint

Temperature 600°F

Frequency 333 kHz

Equipment DW-UHF-4.5kW power supply, remote heat station with one 1.2 μF capacitor and a specially designed induction coil.

Process Initial tests were conducted with temperature indicating paint to establish a heating profile and determine time-to-temperature. The solder paste was then applied to the antenna assembly and aluminum ferrule. RF power was applied for two seconds to heat and flow the solder joint.

Results Consistent and repeatable results were achieved within the required two-second time frame. A close examination of the solder joint indicated that the solder flowed well and formed a good, solid joint.

https://dw-inductionheater.com/soldering-antenna-wire-with-induction.html?feed_id=247107&_unique_id=665172fa95e7b

https://dw-inductionheater.com/soldering-antenna-wire-with-induction.html?feed_id=247107&_unique_id=665172fa95e7b