High Frequency Heating Steel Pipe With Induction Heating Equipment

Objective To heat a steel pipe to 1100ºF (593ºC) to transport melted magnesium

Material Steel pipe 14.5’ (4.42m) long with a 3.5” (88.9mm)OD

Temperature 1100ºF (593ºC)

Frequency 9 kHz

Equipment • DW-MF-160kW induction heating system, equipped with a remote workhead containing one 25μF capacitor.

• An induction heating coil designed and developed specifically for this application.

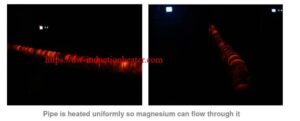

Process A specially designed double U channel coil the length of the pipe is used in this application. The pipe is placed inside the coil and power is supplied. The voltage is set and the power output is 100kW. As the part reaches the Currie point the power drops to 80kW and the voltage must be increased to achieve the 140kW. The pipe reaches 1100ºF (593ºC) in 20 minutes.

Results/Benefits Induction heating provides:

• Controllable and repeatable heat pattern that keeps

material in liquid form

• Environmentally friendly

• Even distribution of heating

• Movable workhead that can be located away from the power supply

High Frequency Heating Steel Pipe With Induction Heating Equipment

Objective To heat a steel pipe to 1100ºF (593ºC) to transport melted magnesium

Material Steel pipe 14.5’ (4.42m) long with a 3.5” (88.9mm)OD

Temperature 1100ºF (593ºC)

Frequency 9 kHz

Equipment • DW-MF-160kW induction heating system, equipped with a remote workhead containing one 25μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A specially designed double U channel coil the length of the pipe is used in this application. The pipe is placed inside the coil and power is supplied. The voltage is set and the power output is 100kW. As the part reaches the Currie point the power drops to 80kW and the voltage must be increased to achieve the 140kW. The pipe reaches 1100ºF (593ºC) in 20 minutes.

Results/Benefits Induction heating provides:

• Controllable and repeatable heat pattern that keeps

material in liquid form

• Environmentally friendly

• Even distribution of heating

• Movable workhead that can be located away from the power supply

https://dw-inductionheater.com/high-frequency-heating-steel-pipe.html?feed_id=247882&_unique_id=6658972ca8f08

https://dw-inductionheater.com/high-frequency-heating-steel-pipe.html?feed_id=247882&_unique_id=6658972ca8f08