induction hardening steel handheld stamps

Objective

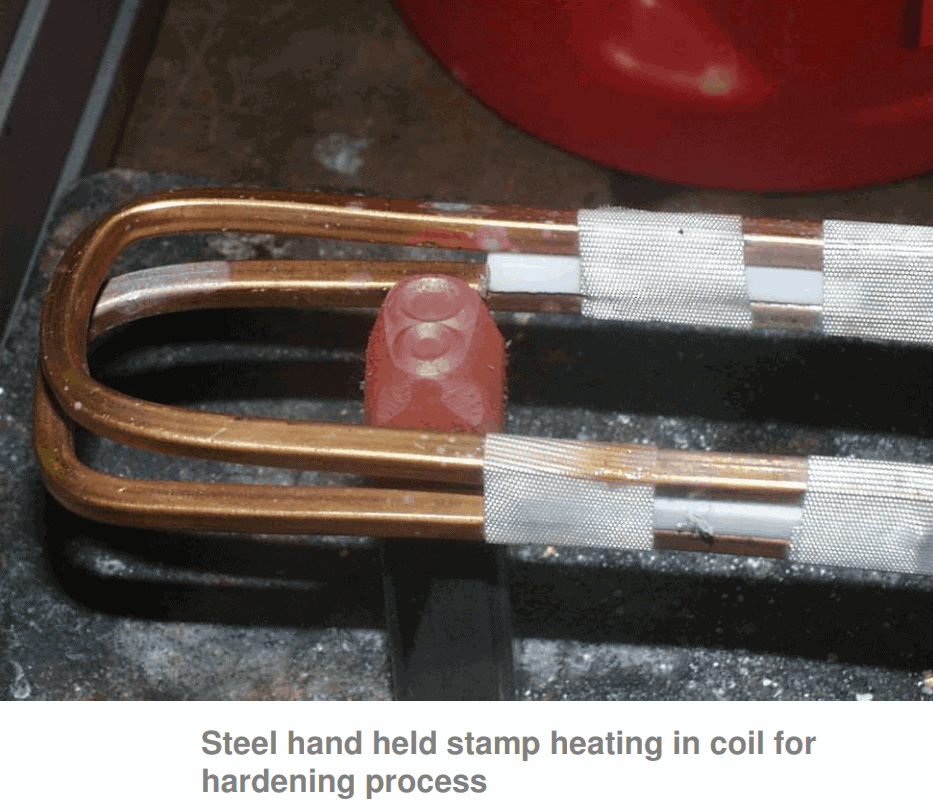

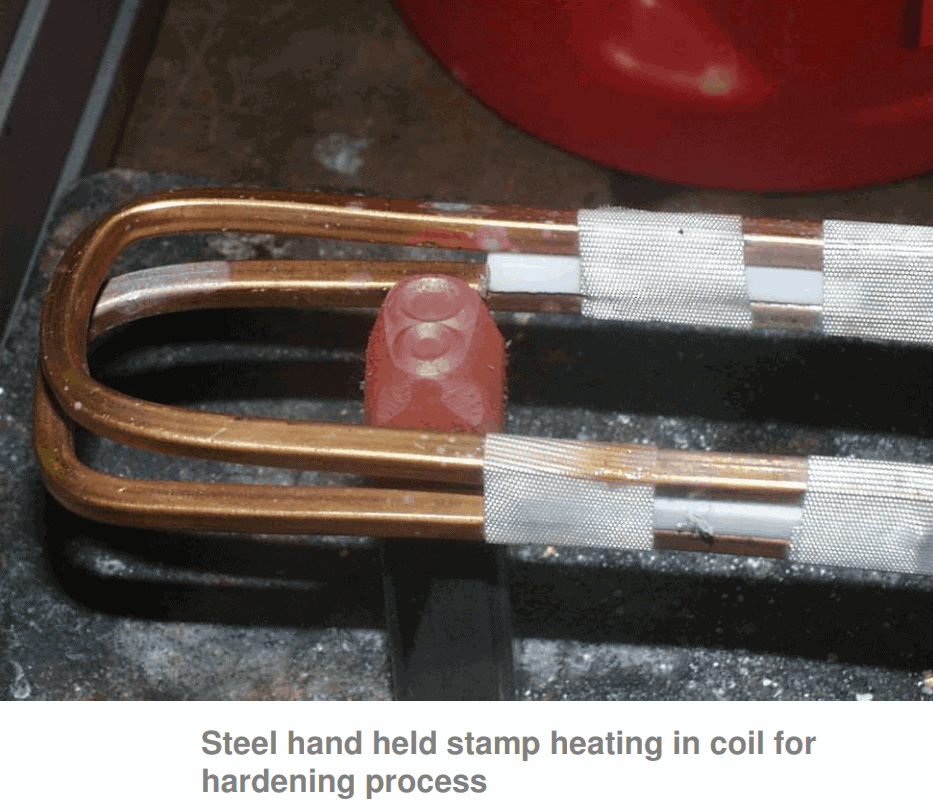

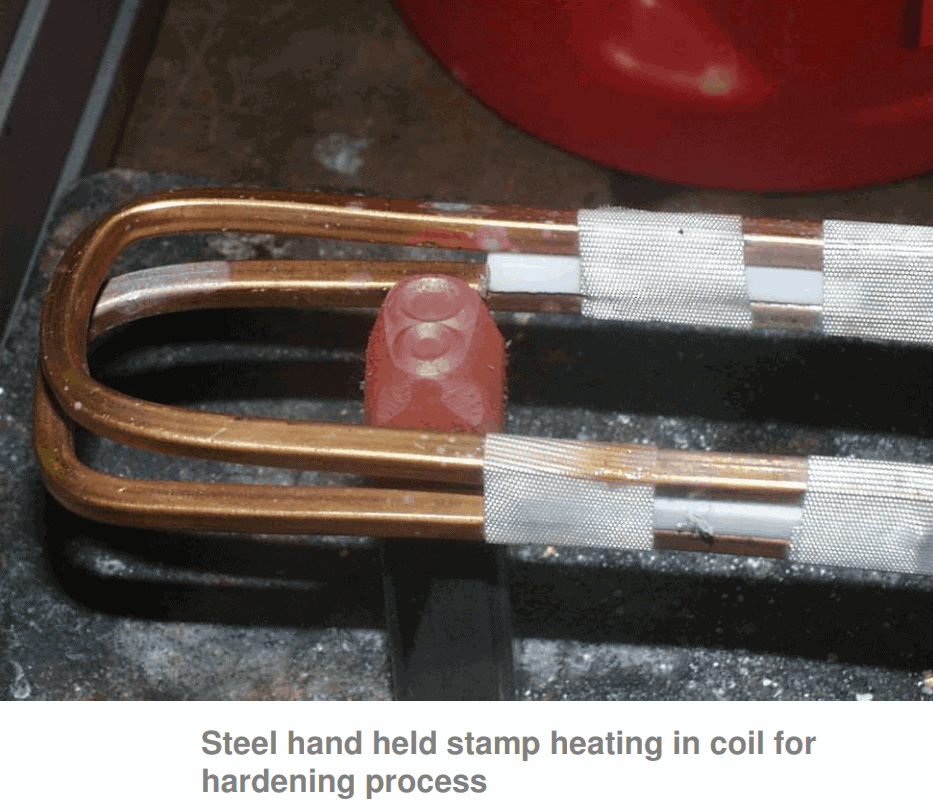

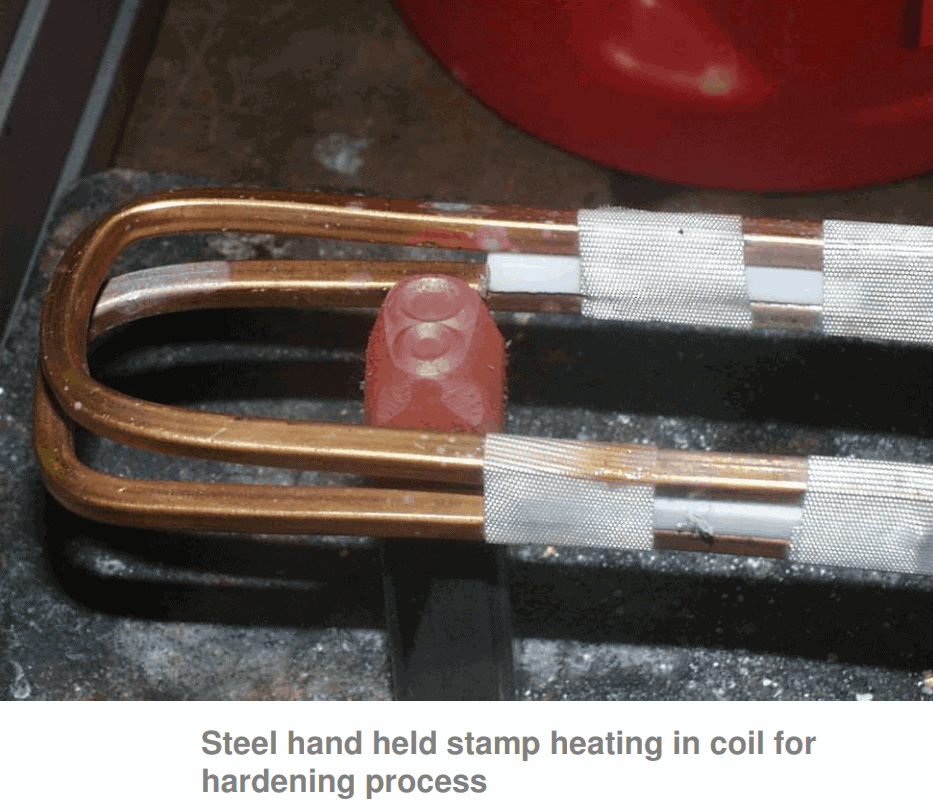

Induction hardening various size ends of handheld marking stamps.

The area to be hardened is 3/4” (19mm) up the shank.

Material : Steel stamps 1/4” (6.3mm), 3/8” (9.5mm), 1/2” (12.7mm) and 5/8” (15.8mm) square

Temperature :1550 ºF (843 ºC)

Frequency 99 kHz

Equipment •

DW-HF-45kW induction heating system, equipped with a remote workhead containing eight 1.0µF capacitors for a total of 2.0µF

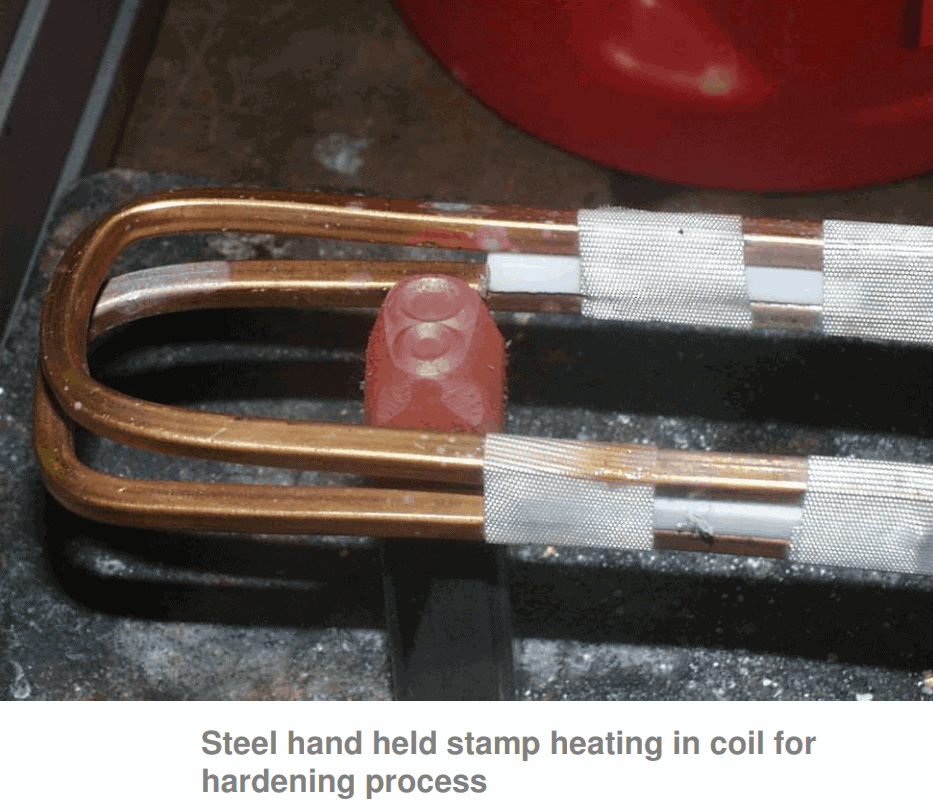

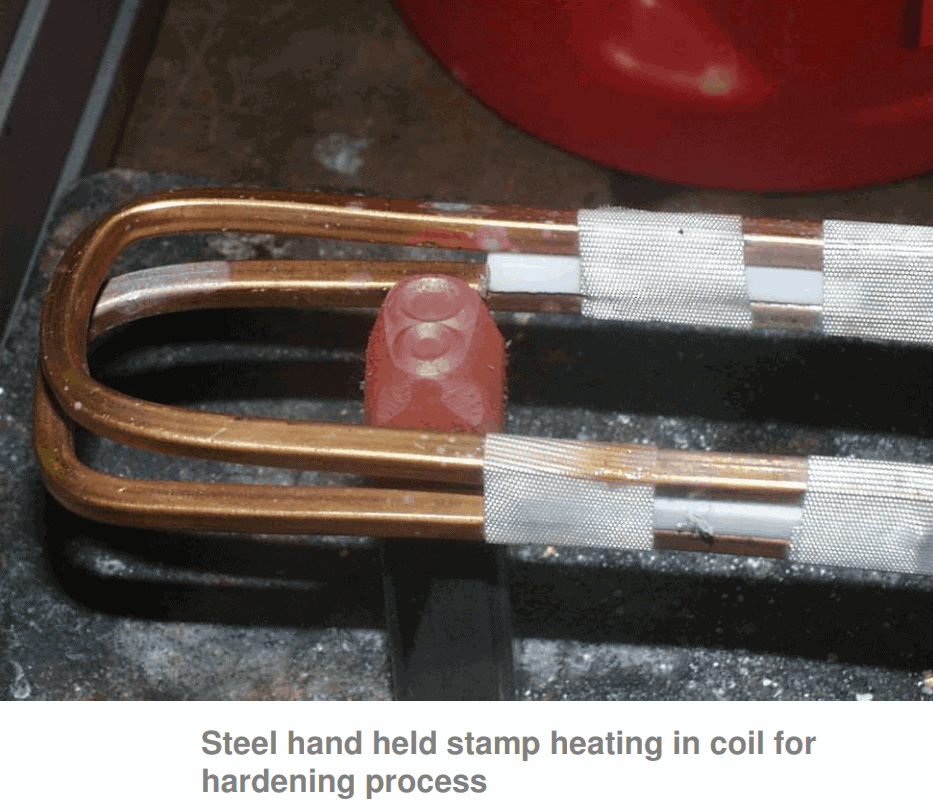

• An induction heating coil designed and developed specifically for this application.

Induction Hardening Process:

A two turn channel coil is used to cover the range of steel stamps being heated. The 5/8” steel stamp is heated for 60 seconds to reach 1550 ºF (843 ºC) and the desired hardness. Smaller parts will also heat easily.

Results/Benefits

Induction heating provides:

• Faster process time and production rates

• Hands-free heating that involves no operator skill for manufacturing

• Controlled precise application of heat

https://dw-inductionheater.com/induction-hardening-steel-handheld-stamps.html?feed_id=235397&_unique_id=65e20c4fb4fdb

https://dw-inductionheater.com/induction-hardening-steel-handheld-stamps.html?feed_id=235397&_unique_id=65e20c4fb4fdb

Induction Hardening Process:

A two turn channel coil is used to cover the range of steel stamps being heated. The 5/8” steel stamp is heated for 60 seconds to reach 1550 ºF (843 ºC) and the desired hardness. Smaller parts will also heat easily.

Results/Benefits

Induction heating provides:

• Faster process time and production rates

• Hands-free heating that involves no operator skill for manufacturing

• Controlled precise application of heat

Induction Hardening Process:

A two turn channel coil is used to cover the range of steel stamps being heated. The 5/8” steel stamp is heated for 60 seconds to reach 1550 ºF (843 ºC) and the desired hardness. Smaller parts will also heat easily.

Results/Benefits

Induction heating provides:

• Faster process time and production rates

• Hands-free heating that involves no operator skill for manufacturing

• Controlled precise application of heat

https://dw-inductionheater.com/induction-hardening-steel-handheld-stamps.html?feed_id=235397&_unique_id=65e20c4fb4fdb

https://dw-inductionheater.com/induction-hardening-steel-handheld-stamps.html?feed_id=235397&_unique_id=65e20c4fb4fdb