Vacuum Sintering Furnace

Vacuum Sintering Furnace /

Vacuum Atmosphere Sintering Furnace is a specialized piece of equipment used in the manufacturing and processing of materials, particularly in the field of metallurgy and ceramics. This type of furnace is designed to create an environment with controlled atmospheric conditions, typically involving low pressure and specific gas compositions, in order to achieve precise sintering results.

Application :

Application :

The carbon-free atmosphere, metal injection molding (MIM), metallization, sintering, Superhard alloy, graphite products, etc.

Standard features

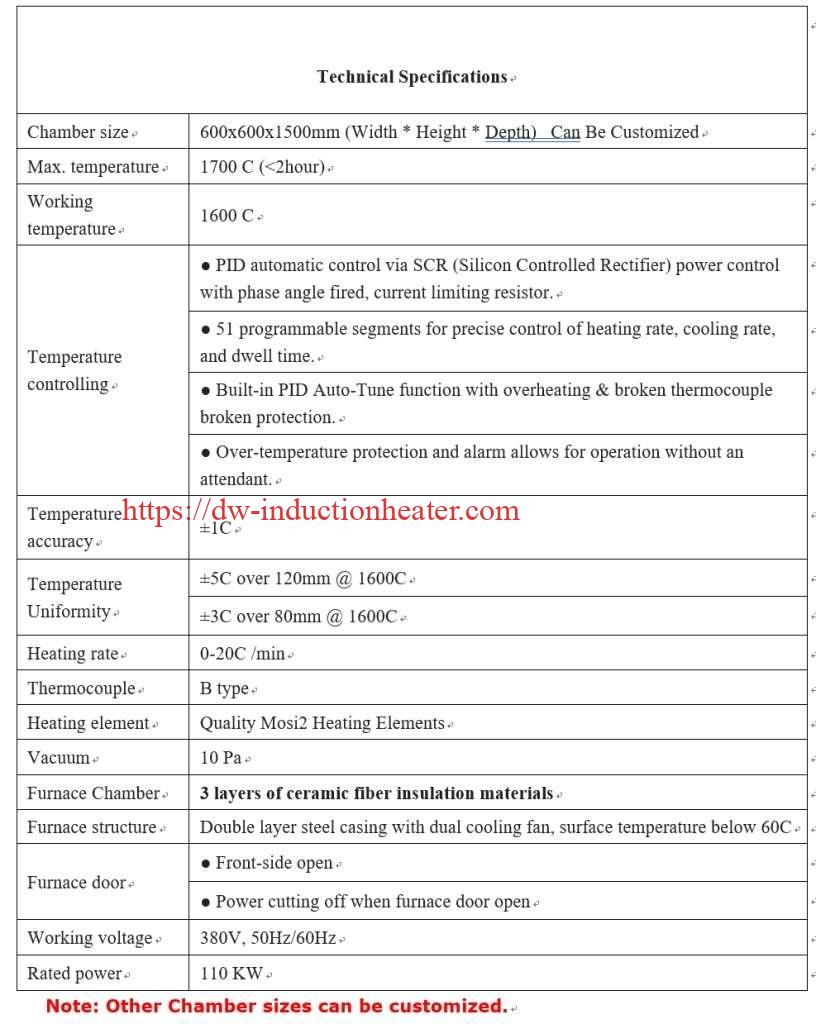

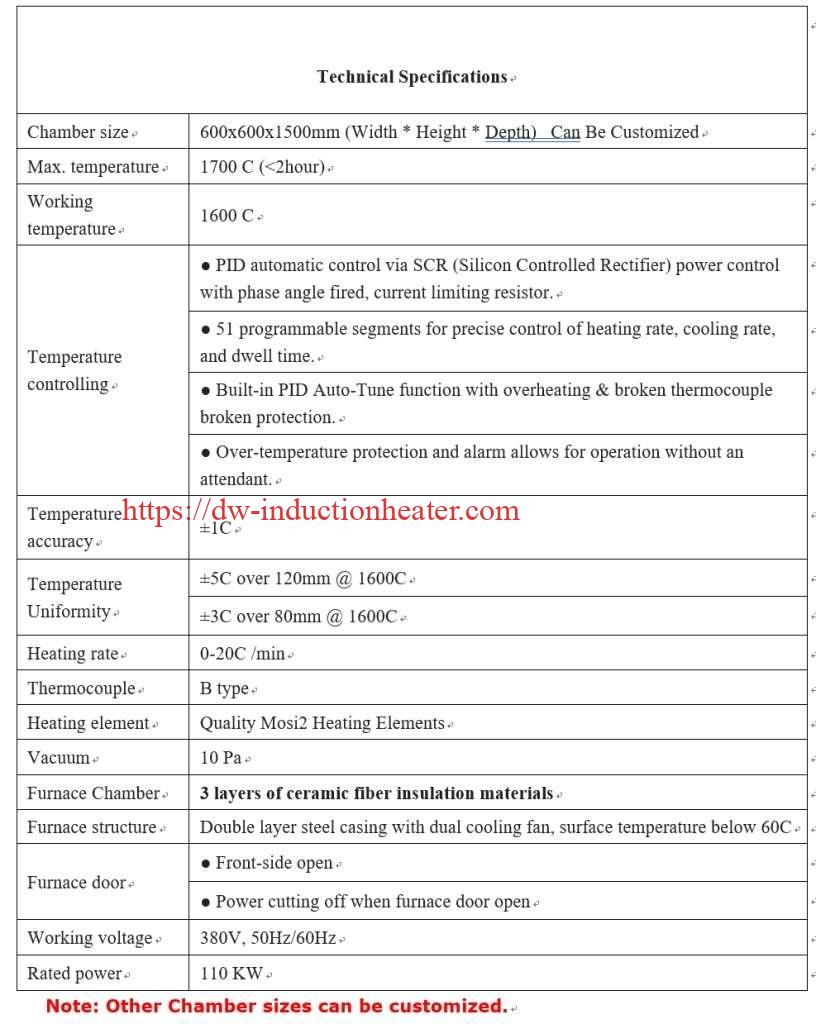

- The furnaces provide a precisely defined atmosphere with the highest possible purity

- Vacuum degree maximum to -0.01Pa

- Maximum using temperature up to 1700c

- High temperature camera internal observation becomes possible

- The furnaces offer the best possible vacuum

- Hydrogen partial pressure operation if requested

- Precisely controlled vacuum pumping speeds appropriate for powders

- Data recording for quality management

- Pressure protection

- Less atmosphere influence

- Cooling structure: Air + Water Cooling

- Double layer loop protection. (Over temperature protection, Power supply protection and so on)

- Touch screen control

Eg Customized Furnace:

Sintering is a process of compacting and forming a solid mass of material by heat and/or pressure without melting it to the point of liquefaction. This process is commonly used in the production of powdered metal parts, ceramics, and other materials where high strength and precision are required. Vacuum atmosphere sintering furnaces play a crucial role in achieving the desired material properties and final product quality.

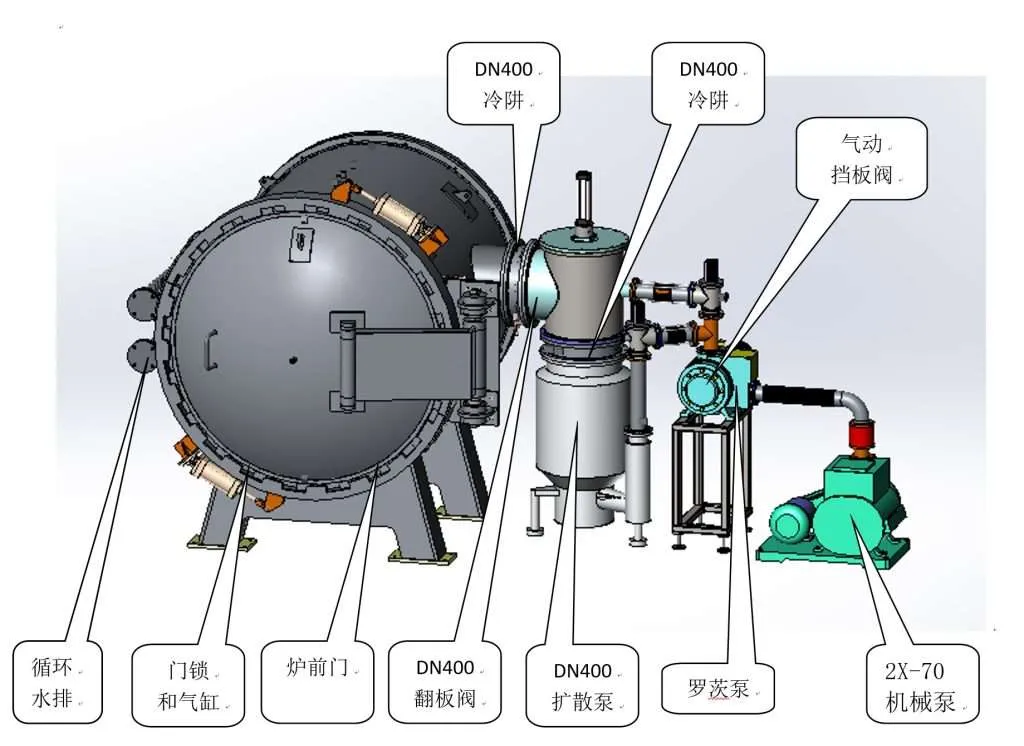

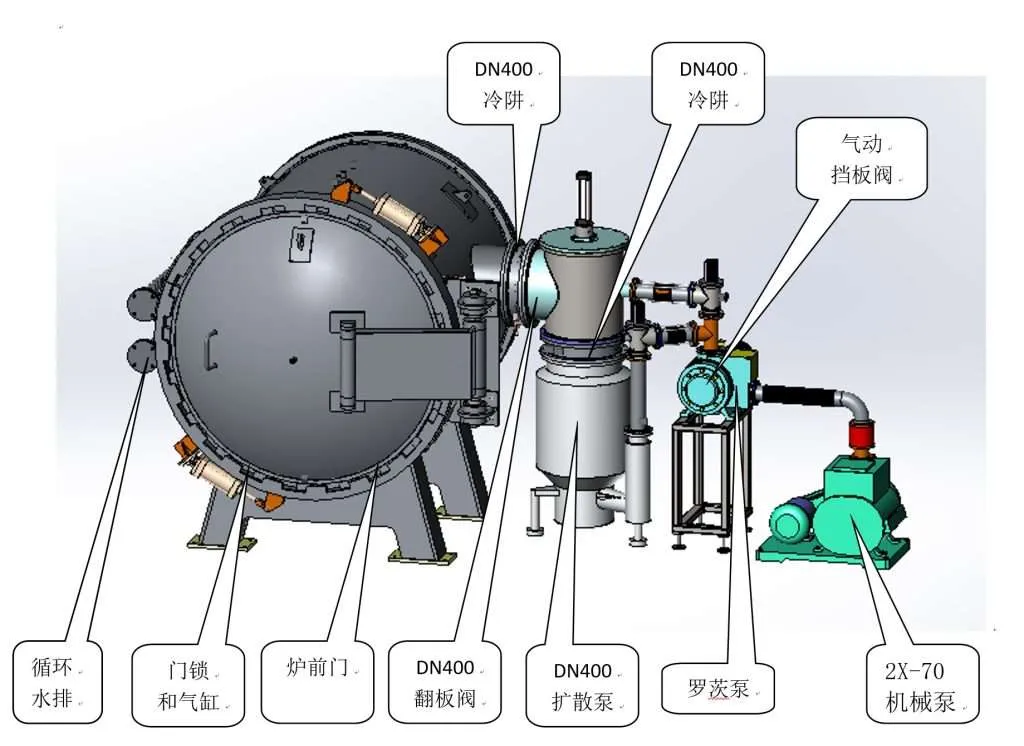

The key components of a

vacuum atmosphere sintering furnace include a vacuum chamber, heating elements, gas supply systems, temperature control systems, and insulation materials. The vacuum chamber is a sealed enclosure where the sintering process takes place under low-pressure conditions. This helps to prevent oxidation and contamination of the materials being processed, which is essential for achieving high-quality sintered products.

The heating elements are responsible for providing the necessary heat energy to raise the temperature inside the furnace to the levels required for sintering. These elements are carefully designed to ensure uniform heating throughout the sintering chamber, which is essential for achieving consistent results across the entire batch of materials being processed.

Gas supply systems are used to introduce specific gases into the sintering chamber to create the desired atmosphere for the sintering process. Common gases used in vacuum atmosphere sintering include hydrogen, nitrogen, argon, and forming gas (a mixture of hydrogen and nitrogen). The precise control of gas composition and pressure is critical for achieving the desired material properties and for preventing unwanted reactions during the sintering process.

Temperature control systems are essential for maintaining precise temperature profiles throughout the sintering process. These systems typically include thermocouples, temperature controllers, and heating element power modulation to ensure that the materials being processed are subjected to the exact thermal conditions required for successful sintering.

Insulation materials are used to minimize heat loss from the sintering chamber and to provide thermal protection for the surrounding environment. This helps to improve energy efficiency and maintain stable operating conditions inside the furnace.

The operation of a vacuum atmosphere

sintering furnace involves several key steps. First, the materials to be sintered are loaded into the furnace chamber, which is then sealed and evacuated to create a low-pressure environment. Once the desired vacuum level is achieved, the heating elements are activated to raise the temperature inside the chamber to the required sintering temperature. At the same time, specific gases are introduced into the chamber to create the desired atmosphere for the sintering process. The temperature and gas composition are carefully controlled throughout the sintering cycle to ensure that the materials undergo the necessary thermal and chemical transformations to achieve the desired properties.

The advantages of using a

vacuum atmosphere sintering furnace include precise control over the sintering process, resulting in high-quality products with uniform properties. The ability to create specific atmospheric conditions allows for tailored material processing, such as reducing oxidation, controlling grain growth, and promoting specific phase transformations. Additionally, the use of a vacuum environment can minimize contamination and improve the overall purity of the sintered materials.

In summary, a vacuum sintering furnace-

vacuum atmosphere sintering furnace is a sophisticated piece of equipment that plays a crucial role in the production of high-quality sintered materials. By providing controlled atmospheric conditions, precise temperature control, and uniform heating, these furnaces enable manufacturers to achieve consistent and reliable results in the production of powdered metal parts, ceramics, and other advanced materials.

[pdf-embedder url="https://dw-inductionheater.com/wp-content/uploads/2024/03/Vacuum-Atmosphere-Furnace-En.pdf" title="Vacuum Atmosphere Furnace En"]

https://dw-inductionheater.com/product/vacuum-sintering-furnace-high-temperature-vacuum-atmosphere-sintering-furnace?feed_id=236158&_unique_id=65eef583b5cd2

Vacuum Sintering Furnace / Vacuum Atmosphere Sintering Furnace is a specialized piece of equipment used in the manufacturing and processing of materials, particularly in the field of metallurgy and ceramics. This type of furnace is designed to create an environment with controlled atmospheric conditions, typically involving low pressure and specific gas compositions, in order to achieve precise sintering results.

Vacuum Sintering Furnace / Vacuum Atmosphere Sintering Furnace is a specialized piece of equipment used in the manufacturing and processing of materials, particularly in the field of metallurgy and ceramics. This type of furnace is designed to create an environment with controlled atmospheric conditions, typically involving low pressure and specific gas compositions, in order to achieve precise sintering results. Application :

The carbon-free atmosphere, metal injection molding (MIM), metallization, sintering, Superhard alloy, graphite products, etc.

Standard features

Application :

The carbon-free atmosphere, metal injection molding (MIM), metallization, sintering, Superhard alloy, graphite products, etc.

Standard features

Sintering is a process of compacting and forming a solid mass of material by heat and/or pressure without melting it to the point of liquefaction. This process is commonly used in the production of powdered metal parts, ceramics, and other materials where high strength and precision are required. Vacuum atmosphere sintering furnaces play a crucial role in achieving the desired material properties and final product quality.

The key components of a vacuum atmosphere sintering furnace include a vacuum chamber, heating elements, gas supply systems, temperature control systems, and insulation materials. The vacuum chamber is a sealed enclosure where the sintering process takes place under low-pressure conditions. This helps to prevent oxidation and contamination of the materials being processed, which is essential for achieving high-quality sintered products.

The heating elements are responsible for providing the necessary heat energy to raise the temperature inside the furnace to the levels required for sintering. These elements are carefully designed to ensure uniform heating throughout the sintering chamber, which is essential for achieving consistent results across the entire batch of materials being processed.

Gas supply systems are used to introduce specific gases into the sintering chamber to create the desired atmosphere for the sintering process. Common gases used in vacuum atmosphere sintering include hydrogen, nitrogen, argon, and forming gas (a mixture of hydrogen and nitrogen). The precise control of gas composition and pressure is critical for achieving the desired material properties and for preventing unwanted reactions during the sintering process.

Sintering is a process of compacting and forming a solid mass of material by heat and/or pressure without melting it to the point of liquefaction. This process is commonly used in the production of powdered metal parts, ceramics, and other materials where high strength and precision are required. Vacuum atmosphere sintering furnaces play a crucial role in achieving the desired material properties and final product quality.

The key components of a vacuum atmosphere sintering furnace include a vacuum chamber, heating elements, gas supply systems, temperature control systems, and insulation materials. The vacuum chamber is a sealed enclosure where the sintering process takes place under low-pressure conditions. This helps to prevent oxidation and contamination of the materials being processed, which is essential for achieving high-quality sintered products.

The heating elements are responsible for providing the necessary heat energy to raise the temperature inside the furnace to the levels required for sintering. These elements are carefully designed to ensure uniform heating throughout the sintering chamber, which is essential for achieving consistent results across the entire batch of materials being processed.

Gas supply systems are used to introduce specific gases into the sintering chamber to create the desired atmosphere for the sintering process. Common gases used in vacuum atmosphere sintering include hydrogen, nitrogen, argon, and forming gas (a mixture of hydrogen and nitrogen). The precise control of gas composition and pressure is critical for achieving the desired material properties and for preventing unwanted reactions during the sintering process. Temperature control systems are essential for maintaining precise temperature profiles throughout the sintering process. These systems typically include thermocouples, temperature controllers, and heating element power modulation to ensure that the materials being processed are subjected to the exact thermal conditions required for successful sintering.

Insulation materials are used to minimize heat loss from the sintering chamber and to provide thermal protection for the surrounding environment. This helps to improve energy efficiency and maintain stable operating conditions inside the furnace.

The operation of a vacuum atmosphere sintering furnace involves several key steps. First, the materials to be sintered are loaded into the furnace chamber, which is then sealed and evacuated to create a low-pressure environment. Once the desired vacuum level is achieved, the heating elements are activated to raise the temperature inside the chamber to the required sintering temperature. At the same time, specific gases are introduced into the chamber to create the desired atmosphere for the sintering process. The temperature and gas composition are carefully controlled throughout the sintering cycle to ensure that the materials undergo the necessary thermal and chemical transformations to achieve the desired properties.

Temperature control systems are essential for maintaining precise temperature profiles throughout the sintering process. These systems typically include thermocouples, temperature controllers, and heating element power modulation to ensure that the materials being processed are subjected to the exact thermal conditions required for successful sintering.

Insulation materials are used to minimize heat loss from the sintering chamber and to provide thermal protection for the surrounding environment. This helps to improve energy efficiency and maintain stable operating conditions inside the furnace.

The operation of a vacuum atmosphere sintering furnace involves several key steps. First, the materials to be sintered are loaded into the furnace chamber, which is then sealed and evacuated to create a low-pressure environment. Once the desired vacuum level is achieved, the heating elements are activated to raise the temperature inside the chamber to the required sintering temperature. At the same time, specific gases are introduced into the chamber to create the desired atmosphere for the sintering process. The temperature and gas composition are carefully controlled throughout the sintering cycle to ensure that the materials undergo the necessary thermal and chemical transformations to achieve the desired properties. The advantages of using a vacuum atmosphere sintering furnace include precise control over the sintering process, resulting in high-quality products with uniform properties. The ability to create specific atmospheric conditions allows for tailored material processing, such as reducing oxidation, controlling grain growth, and promoting specific phase transformations. Additionally, the use of a vacuum environment can minimize contamination and improve the overall purity of the sintered materials.

In summary, a vacuum sintering furnace-vacuum atmosphere sintering furnace is a sophisticated piece of equipment that plays a crucial role in the production of high-quality sintered materials. By providing controlled atmospheric conditions, precise temperature control, and uniform heating, these furnaces enable manufacturers to achieve consistent and reliable results in the production of powdered metal parts, ceramics, and other advanced materials.

[pdf-embedder url="https://dw-inductionheater.com/wp-content/uploads/2024/03/Vacuum-Atmosphere-Furnace-En.pdf" title="Vacuum Atmosphere Furnace En"]

https://dw-inductionheater.com/product/vacuum-sintering-furnace-high-temperature-vacuum-atmosphere-sintering-furnace?feed_id=236158&_unique_id=65eef583b5cd2

The advantages of using a vacuum atmosphere sintering furnace include precise control over the sintering process, resulting in high-quality products with uniform properties. The ability to create specific atmospheric conditions allows for tailored material processing, such as reducing oxidation, controlling grain growth, and promoting specific phase transformations. Additionally, the use of a vacuum environment can minimize contamination and improve the overall purity of the sintered materials.

In summary, a vacuum sintering furnace-vacuum atmosphere sintering furnace is a sophisticated piece of equipment that plays a crucial role in the production of high-quality sintered materials. By providing controlled atmospheric conditions, precise temperature control, and uniform heating, these furnaces enable manufacturers to achieve consistent and reliable results in the production of powdered metal parts, ceramics, and other advanced materials.

[pdf-embedder url="https://dw-inductionheater.com/wp-content/uploads/2024/03/Vacuum-Atmosphere-Furnace-En.pdf" title="Vacuum Atmosphere Furnace En"]

https://dw-inductionheater.com/product/vacuum-sintering-furnace-high-temperature-vacuum-atmosphere-sintering-furnace?feed_id=236158&_unique_id=65eef583b5cd2