Maximizing Efficiency and Performance with Induction Heating Machines

As an industrial heating technology,

induction heating has become increasingly popular in recent years. This technology can be used in various industries, including automotive, aerospace, metalworking, and many others.

Induction heating machines offer several advantages over traditional heating methods, including faster and more efficient heating, improved process control, and reduced energy consumption. In this article, we will discuss the benefits of induction heating machines, the different types of equipment available, and how to select the right machine for your needs.Introduction to Industrial Induction Heating

Induction heating is a process that uses electromagnetic induction to heat metal or other conductive materials. With induction heating, an alternating magnetic field is generated by an induction coil, which passes through the metal or other conductive material. This magnetic field induces eddy currents in the metal, which in turn generate heat. The heat is generated directly in the material, which makes induction heating much faster and more efficient than traditional heating methods.

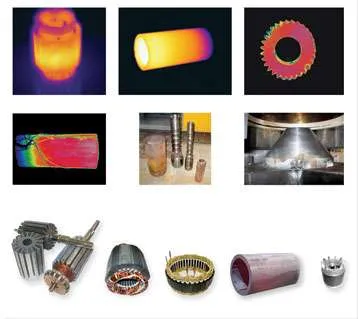

Induction heating is used in various applications, including brazing, annealing, hardening, and melting. It is also used for shrink fitting, forging, and bonding. Induction heating machines are used in many industries, including automotive, aerospace, metalworking, and many others.

Understanding Induction Heating Machines

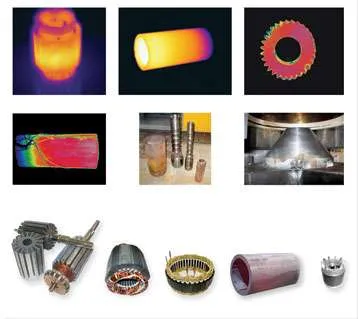

Induction heating machines consist of several components, including an induction coil, a power supply, and a cooling system. The induction coil generates the magnetic field that induces eddy currents in the metal. The power supply provides the electrical energy that is converted into the magnetic field. The cooling system is used to cool the induction coil and other components, as the heat generated during the process can be significant.

There are two main types of induction heating machines: high frequency and medium frequency. High frequency machines operate at frequencies above 100 kHz, while medium frequency machines operate at frequencies between 1 kHz and 100 kHz. High frequency machines are used for smaller parts and surface heating, while medium frequency machines are used for larger parts and bulk heating.

Advantages of Induction Heating Machines

Induction heating machines offer a number of advantages over traditional heating methods. Here are some of the most significant benefits:

- Faster heating: Induction heating is much faster than traditional heating methods, as the heat is generated directly in the material. This means that parts can be heated and cooled much more quickly, which can improve process efficiency and reduce cycle times.

- Improved process control: Induction heating machines offer precise temperature control, which allows for consistent, repeatable results. This is particularly important in industries where quality is critical, such as aerospace and automotive.

- Reduced energy consumption: Induction heating is more energy-efficient than traditional heating methods, as the heat is generated directly in the material. This means that less energy is wasted, which can result in significant cost savings over time.

- Cleaner and safer: Induction heating produces no emissions, which makes it a cleaner and safer alternative to traditional heating methods. It also produces less noise and vibration, which can improve working conditions for employees.

Types of Induction Heating Equipment

There are several types of

induction heating equipment available, including:

- Induction heaters: These are portable induction heating machines that are used for heating small parts or localized areas.

- Induction furnaces: These are large induction heating machines that are used for melting metals or other materials.

- Induction brazing machines: These are induction heating machines that are used for brazing or soldering.

- Induction hardening machines: These are induction heating machines that are used for hardening metal parts.

- Induction annealing machines: These are induction heating machines that are used for annealing metal or other materials.

There are two main parameters of indutcion heating equipment:

one is the output power, another is the frequency.

The depth of heat penetration into the workpiece depends on the frequency, the higher the frequency, the shallower the skin depth; the lower the frequency, the deeper the penetration.

So it is important to select the frequency of the induction heating machine according to the heating desire to achieve best heating effect.

The output power decides the heating speed, power is selected according to the weight of the workpiece and the heating temperature and desired heating speed.

Therefore, high frequency induction heating has a shallow skin effect which is more efficient for small parts. low frequency induction heating has a deeper skin effect which is more efficient for larger parts.

Our Induction heating machines are divided into five major series according to the frequency:

Medium Frequency with Parallel oscillating circuit (abbr. MF series): 1 - 20KHZ

Medium frequency with Series oscillating circuit (abbr. MFS series): 0.5-10KHZ

High Frequency series (abbr: HF series): 30-80KHZ

Super-audio Frequency series (abbr. SF series) : 8-40KHZ

Ultra-high Frequency series (abbr.UHF series): 30-1100KHZ

| Category |

Model |

Max power |

Oscillating frequency |

Max input current |

Input voltage |

operating voltage |

Duty cycle |

| MF series |

MF-15 |

15KW |

1-20KHZ |

23A |

3P 380V50Hz |

70-550V |

100% |

| MF-25 |

25KW |

36A |

| MF-35 |

35KW |

51A |

| MF-45 |

45KW |

68A |

| MF-70 |

70KW |

105A |

| MF-90 |

90KW |

135A |

| MF-110 |

110KW |

170A |

| MF-160 |

160KW |

240A |

| MFS series |

MFS-100 |

100KW |

0.5-10KHZ |

160A |

3P 380V50Hz |

342-430V |

100% |

| MFS-160 |

160KW |

250A |

| MFS-200 |

200KW |

310A |

| MFS-250 |

250KW |

380A |

| MFS-300 |

300KW |

0.5-8KHZ |

460A |

| MFS-400 |

400KW |

610A |

| MFS-500 |

500KW |

760A |

| MFS-600 |

600KW |

920A |

| MFS-750 |

750KW |

0.5-6KHZ |

1150A |

| MFS-800 |

800KW |

1300A |

| HF series |

HF-04A |

4KW |

100-250KHZ |

15A |

1P 220V/ 50Hz |

180V-250V |

80% |

| HF-15A |

7KW |

30-100KHZ |

32A |

1P 220V/ 50Hz |

180V-250V |

80% |

| HF-15AB |

7KW |

32A |

| HF-25A |

15KW |

30-80KHZ |

23A |

3P 380V/ 50Hz |

340-430V |

100% |

| HF-25AB |

15KW |

23A |

| HF-40AB |

25KW |

38A |

| HF-35AB |

35KW |

53A |

| HF-45AB |

45KW |

68A |

| HF-60AB |

60KW |

80A |

| HF-70AB |

70KW |

105A |

| HF-80AB |

80KW |

130A |

| SF series |

SF-30A |

30KW |

10-40KHZ |

48A |

3P 380V/ 50Hz |

342-430V |

100% |

| SF-30ABS |

30KW |

48A |

| SF-40ABS |

40KW |

62A |

| SF-50ABS |

50KW |

75A |

| SF-40AB |

40KW |

62A |

| SF-50AB |

50KW |

75A |

| SF-60AB |

60KW |

90A |

| SF-80AB |

80KW |

125A |

| SF-100AB |

100KW |

155A |

| SF-120AB |

120KW |

185A |

| SF-160AB |

160KW |

8-30KHZ |

245A |

| SF-200AB |

200KW |

310A |

| SF-250AB |

250KW |

380A |

| SF-300AB |

300KW |

455A |

| UHF series |

UHF-05AB |

5KW |

0.5-1.1MHZ |

15A |

1P 220V/ 50Hz |

180V-250V |

80% |

| UHF-06A-I |

6.6KW |

200-500KHZ |

30A |

1P 220V/ 50Hz |

180V-250V |

80% |

| UHF-06A-II |

6.6KW |

200-700KHZ |

| UHF-06A/AB-III |

6KW |

0.5-1.1MHZ |

| UHF-10A-I |

10KW |

50-300KHZ |

15A |

3P 380V/50Hz |

342-430V |

100% |

| UHF-10A-II |

10KW |

200-500KHZ |

45A |

1P 220V/50Hz |

180-250V |

80% |

| UHF-20AB |

20KW |

50-250KHZ |

30A |

3P 380V/50Hz |

342-430V |

100% |

| UHF-30AB |

30KW |

50-200KHZ |

45A |

| UHF-40AB |

40KW |

60A |

| UHF-60AB |

60KW |

30-120KHZ |

90A |

|

|

|

Except Analog circuit heating equipment, HLQ have DSP Full Digital Control Induction Heating Machines :

| Category |

Model |

Max power |

Oscillating frequency |

Max input current |

Input voltage |

|

| DSP full digital super audio frequency |

D-SF160 |

160KW |

2-50Khz |

240A |

3P 380V50Hz |

|

| D-SF200 |

200KW |

300A |

|

| D-SF250 |

250KW |

380A |

|

| D-SF300 |

300KW |

450A |

|

| D-SF350 |

350KW |

530A |

|

| D-SF400 |

400KW |

610A |

|

| D-SF450 |

450KW |

685A |

|

| D-SF500 |

500KW |

760A |

|

| D-SF550 |

550KW |

835A |

|

| D-SF600 |

600KW |

910A |

|

| DSP full digital High frequency |

D-HF160 |

160KW |

50-100Khz |

240A |

3p 380V50Hz |

|

| D-HF200 |

200KW |

300A |

|

| D-HF250 |

250KW |

380A |

|

| D-HF300 |

300KW |

450A |

|

| D-HF350 |

350KW |

530A |

|

| D-HF400 |

400KW |

610A |

|

| D-HF450 |

450KW |

685A |

|

| D-HF500 |

500KW |

760A |

|

| D-HF550 |

550KW |

835A |

|

| D-HF600 |

600KW |

910A |

|

| DSP full digital Ultrahigh frequency |

D-UF100 |

100KW |

100-150Khz |

150A |

3p 380V50Hz |

|

| D-UF160 |

160KW |

240A |

|

| D-UF200 |

200KW |

300A |

|

| DSP full digital Medium frequency |

D-MFS100-2000 |

100-2000kw |

1-10khz |

|

3p 380V,50Hz |

|

|

Factors to Consider When Choosing an Induction Heating Machine

When choosing an induction heating machine, there are several factors to consider, including:

- Material type and thickness: Different materials require different heating times and frequencies. The thickness of the material will also affect the heating time.

- Heating requirements: The temperature and duration of the heating process will depend on the application.

- Part size and shape: The size and shape of the part will determine the type and size of the induction coil that is required.

- Power requirements: The power supply will depend on the size and type of the machine, as well as the heating requirements.

How to Select the Right Induction Heating Unit

To select the right induction heating machine for your needs, it is important to consider the factors listed above. You should also consider the reputation of the manufacturer, the price of the machine, and the availability of spare parts and technical support.

It is also important to choose a machine that is easy to use and maintain. Some machines require more maintenance than others, and this can impact the overall cost of ownership.

Cost of Induction Heating Machines

The cost of induction heating machines can vary widely depending on the size, type, and manufacturer. Portable induction heaters can cost as little as a few hundred dollars, while large induction furnaces can cost hundreds of thousands of dollars.

It is important to consider not only the upfront cost of the machine, but also the cost of ownership over time. This includes the cost of electricity, maintenance, and repair.

Maintenance and Repair of Induction Heating Equipment

Regular maintenance is important to ensure the longevity and performance of induction heating machines. This includes cleaning the induction coil, checking the power supply and cooling system, and inspecting the machine for signs of wear and tear.

If repairs are needed, it is important to work with a qualified technician who has experience with induction heating machines. This will ensure that the repairs are done correctly and safely.

Conclusion: The Future of Induction Heating Technology

Induction heating technology has come a long way in recent years, and it is likely to continue to evolve and improve in the future. As industries seek to improve efficiency and reduce costs, induction heating machines will play an increasingly important role.

If you are considering an induction heating machine for your business, it is important to choose a machine that meets your specific needs and requirements. By considering the factors listed above and working with a reputable manufacturer and technician, you can ensure that you get the most out of your induction heating machine.

https://dw-inductionheater.com/induction-heating-machines-with-maximizing-efficiency-and-performance.html?feed_id=208036&_unique_id=6470b3b66f7c7

https://dw-inductionheater.com/induction-heating-machines-with-maximizing-efficiency-and-performance.html?feed_id=208036&_unique_id=6470b3b66f7c7

There are two main parameters of indutcion heating equipment: one is the output power, another is the frequency.

The depth of heat penetration into the workpiece depends on the frequency, the higher the frequency, the shallower the skin depth; the lower the frequency, the deeper the penetration.

So it is important to select the frequency of the induction heating machine according to the heating desire to achieve best heating effect.

The output power decides the heating speed, power is selected according to the weight of the workpiece and the heating temperature and desired heating speed.

Therefore, high frequency induction heating has a shallow skin effect which is more efficient for small parts. low frequency induction heating has a deeper skin effect which is more efficient for larger parts.

Our Induction heating machines are divided into five major series according to the frequency:

Medium Frequency with Parallel oscillating circuit (abbr. MF series): 1 - 20KHZ

Medium frequency with Series oscillating circuit (abbr. MFS series): 0.5-10KHZ

High Frequency series (abbr: HF series): 30-80KHZ

Super-audio Frequency series (abbr. SF series) : 8-40KHZ

Ultra-high Frequency series (abbr.UHF series): 30-1100KHZ

There are two main parameters of indutcion heating equipment: one is the output power, another is the frequency.

The depth of heat penetration into the workpiece depends on the frequency, the higher the frequency, the shallower the skin depth; the lower the frequency, the deeper the penetration.

So it is important to select the frequency of the induction heating machine according to the heating desire to achieve best heating effect.

The output power decides the heating speed, power is selected according to the weight of the workpiece and the heating temperature and desired heating speed.

Therefore, high frequency induction heating has a shallow skin effect which is more efficient for small parts. low frequency induction heating has a deeper skin effect which is more efficient for larger parts.

Our Induction heating machines are divided into five major series according to the frequency:

Medium Frequency with Parallel oscillating circuit (abbr. MF series): 1 - 20KHZ

Medium frequency with Series oscillating circuit (abbr. MFS series): 0.5-10KHZ

High Frequency series (abbr: HF series): 30-80KHZ

Super-audio Frequency series (abbr. SF series) : 8-40KHZ

Ultra-high Frequency series (abbr.UHF series): 30-1100KHZ

https://dw-inductionheater.com/induction-heating-machines-with-maximizing-efficiency-and-performance.html?feed_id=208036&_unique_id=6470b3b66f7c7

https://dw-inductionheater.com/induction-heating-machines-with-maximizing-efficiency-and-performance.html?feed_id=208036&_unique_id=6470b3b66f7c7