Brazing Steel Automotive Parts With Induction Heating System

Automotive Parts Use For Induction Heating

The automotive industry utilizes many different parts that require heat for assembly. Processes such as brazing, soldering, hardening, tempering, and shrink fitting are common thought-out the automotive industry. These heating processes can be improved significantly through the use of

induction heating technology.

Induction heating technology

Induction heating technology can provide many advantages for the auto industry. First and foremost is incredibly precise and consistent control over time and temperature. This means that a process can be performed in exactly the same way with the same results time after time. This reduces the number of rejected parts and thus decreases waste. Induction heating is also extremely clean because it does not involve any sort of combustion. This negates the need for special ventilation and removes key hazards from the workplace such as open flame and compressed gas cylinders. This has the added benefit of opening up more options for plant layout because certain procedures involving heat no longer require transporting parts of the property or to a separate area of the facility. The flexibility of the plant layout is also facilitated by another advantage of induction technology which is the compact footprint. Induction systems often take up less space than other options such as flame, furnace, infrared, or resistance heaters.

Automotive Parts Produced with Induction Equipment

HLQ Induction Equipment Co has a well-established history of designing

induction heating equipment that is used for heat-treating parts for assembly.

Bearings

Brakes

Drive train

Gears

Joints

Shafts

Objective:

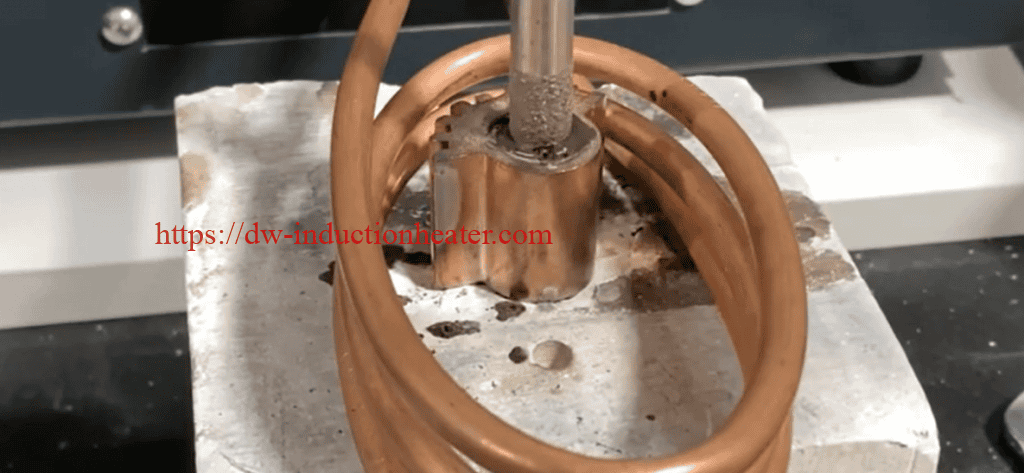

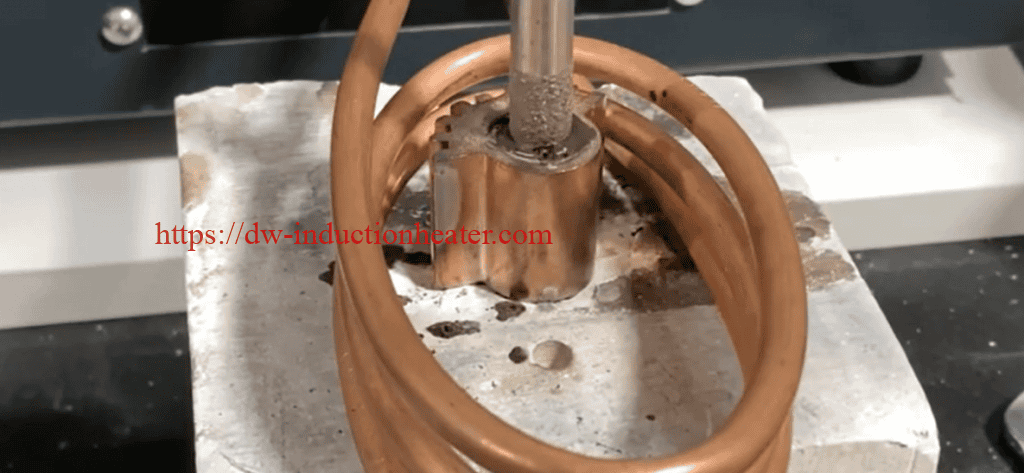

A manufacturer of steel parts for the automotive industry is interested in upgrading their old induction equipment. HLQ Company received samples of steel shafts, plates, and fittings for the

induction brazing test.

A challenge for this application was conducting the tests with our induction heater and the client’s

induction heating coil.

Industry: Automotive & Transportation

Equipment:

The induction heating power supply we chose for the brazing test was

DW-UHF-10kW Induction Heating System.

Process:

Our engineers conducted three tests for the three different parts. With each test, the power supply worked with setups of 10kW of induction heating power and a temperature of 1400°F (760°C).

The heat cycle time for the first test was 40 sec., and the heat cycle time for the second test was 60 sec. Both were performed with the customer’s single-turn coil. For the third test, we used the customer’s three-turn coil, and the processing time was 30 sec.

This application was complete with coils provided by the customer. If a specially designed induction coil is used, the cycle time will be reduced.

Benefits:

Benefits:

Investing in new induction heating equipment can optimize the production process on many levels. One of the main goals is to reduce energy costs, which can be achieved with more efficient technology. Additional benefits of induction heating also include increased repeatability and productivity, as well as low maintenance requirements.

https://dw-inductionheater.com/brazing-steel-automotive-parts-with-induction-heating-system.html?feed_id=208786&_unique_id=6474b6b3789da

https://dw-inductionheater.com/brazing-steel-automotive-parts-with-induction-heating-system.html?feed_id=208786&_unique_id=6474b6b3789da

Induction heating technology can provide many advantages for the auto industry. First and foremost is incredibly precise and consistent control over time and temperature. This means that a process can be performed in exactly the same way with the same results time after time. This reduces the number of rejected parts and thus decreases waste. Induction heating is also extremely clean because it does not involve any sort of combustion. This negates the need for special ventilation and removes key hazards from the workplace such as open flame and compressed gas cylinders. This has the added benefit of opening up more options for plant layout because certain procedures involving heat no longer require transporting parts of the property or to a separate area of the facility. The flexibility of the plant layout is also facilitated by another advantage of induction technology which is the compact footprint. Induction systems often take up less space than other options such as flame, furnace, infrared, or resistance heaters.

Automotive Parts Produced with Induction Equipment

HLQ Induction Equipment Co has a well-established history of designing induction heating equipment that is used for heat-treating parts for assembly.

Bearings

Brakes

Drive train

Gears

Joints

Shafts

Objective:

Induction heating technology can provide many advantages for the auto industry. First and foremost is incredibly precise and consistent control over time and temperature. This means that a process can be performed in exactly the same way with the same results time after time. This reduces the number of rejected parts and thus decreases waste. Induction heating is also extremely clean because it does not involve any sort of combustion. This negates the need for special ventilation and removes key hazards from the workplace such as open flame and compressed gas cylinders. This has the added benefit of opening up more options for plant layout because certain procedures involving heat no longer require transporting parts of the property or to a separate area of the facility. The flexibility of the plant layout is also facilitated by another advantage of induction technology which is the compact footprint. Induction systems often take up less space than other options such as flame, furnace, infrared, or resistance heaters.

Automotive Parts Produced with Induction Equipment

HLQ Induction Equipment Co has a well-established history of designing induction heating equipment that is used for heat-treating parts for assembly.

Bearings

Brakes

Drive train

Gears

Joints

Shafts

Objective:

A manufacturer of steel parts for the automotive industry is interested in upgrading their old induction equipment. HLQ Company received samples of steel shafts, plates, and fittings for the induction brazing test.

A challenge for this application was conducting the tests with our induction heater and the client’s induction heating coil.

Industry: Automotive & Transportation

Equipment:

The induction heating power supply we chose for the brazing test was DW-UHF-10kW Induction Heating System.

Process:

Our engineers conducted three tests for the three different parts. With each test, the power supply worked with setups of 10kW of induction heating power and a temperature of 1400°F (760°C).

The heat cycle time for the first test was 40 sec., and the heat cycle time for the second test was 60 sec. Both were performed with the customer’s single-turn coil. For the third test, we used the customer’s three-turn coil, and the processing time was 30 sec.

A manufacturer of steel parts for the automotive industry is interested in upgrading their old induction equipment. HLQ Company received samples of steel shafts, plates, and fittings for the induction brazing test.

A challenge for this application was conducting the tests with our induction heater and the client’s induction heating coil.

Industry: Automotive & Transportation

Equipment:

The induction heating power supply we chose for the brazing test was DW-UHF-10kW Induction Heating System.

Process:

Our engineers conducted three tests for the three different parts. With each test, the power supply worked with setups of 10kW of induction heating power and a temperature of 1400°F (760°C).

The heat cycle time for the first test was 40 sec., and the heat cycle time for the second test was 60 sec. Both were performed with the customer’s single-turn coil. For the third test, we used the customer’s three-turn coil, and the processing time was 30 sec.

This application was complete with coils provided by the customer. If a specially designed induction coil is used, the cycle time will be reduced.

This application was complete with coils provided by the customer. If a specially designed induction coil is used, the cycle time will be reduced.

Benefits:

Investing in new induction heating equipment can optimize the production process on many levels. One of the main goals is to reduce energy costs, which can be achieved with more efficient technology. Additional benefits of induction heating also include increased repeatability and productivity, as well as low maintenance requirements.

Benefits:

Investing in new induction heating equipment can optimize the production process on many levels. One of the main goals is to reduce energy costs, which can be achieved with more efficient technology. Additional benefits of induction heating also include increased repeatability and productivity, as well as low maintenance requirements.

https://dw-inductionheater.com/brazing-steel-automotive-parts-with-induction-heating-system.html?feed_id=208786&_unique_id=6474b6b3789da

https://dw-inductionheater.com/brazing-steel-automotive-parts-with-induction-heating-system.html?feed_id=208786&_unique_id=6474b6b3789da