2022年2月6日星期日

Induction Heating Steel Part For Hot Heading

Induction Heating Steel Part For Hot Heading With IGBT Induction Heater

Objective Heating steel parts to 1900ºF (1038ºC) for hot heading application

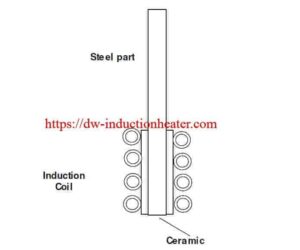

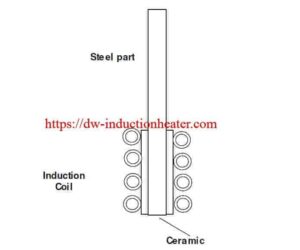

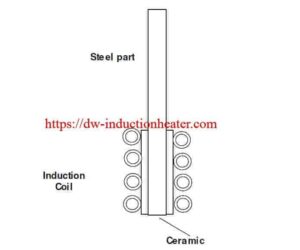

Material Steel parts with 7/16” (11.11mm) OD and ceramic piece

Temperature 1900 ºF (1038ºC)

Frequency 440 kHz

Equipment • DW-UHF-6kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil, designed and developed specifically for this application.

Process A four turn helical coil with ceramic insert is used to heat a 0.75” (19mm) section of the part to 1900ºF (1038ºC) for 7.5 seconds. A ceramic piece is so the part does not come in

contact with the coil.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Direct application of the heat on the work piece with precision and consistency

• Even distribution of heating

• Low pressure and minimal residual part stress

关注者

博客归档

-

▼

2022

(1729)

-

▼

二月

(98)

- Induction Brazing & Soldering Principle

- Induction Annealing Copper Tubes

- Induction Heating Barrel for Plastic Extruder and ...

- Induction Soldering Process Video

- Induction Heating Barrel for Plastic Extruder and ...

- Induction Brazing Aluminum Pipes

- How to design induction heating coil

- induction heating plastic granulator

- Induction heating bearings machine PDF

- induction heating plastic granulator

- induction heating plastic granulator

- induction brazing carbide tip onto steel head teeth

- Induction Brazing Carbide

- Induction Heating Injection Molding Machinery

- induction heating steel casting

- induction heating steel casting

- Induction Heating Plastic Extrusion

- induction heating plastic extrusion

- induction brazing automotive copper heating exchan...

- induction brazing automotive copper heating exchan...

- Brazing Copper Tube with Induction

- Induction Brazing Aluminum Tube T Joints

- Induction straightening deck and bulkhead heating ...

- Induction Soldering Wire To Aluminum Lug

- Induction Soldering Wires Onto Connection

- Shrink Fit Steel Gear onto Shaft

- Induction Brazing Steel Wire

- Induction annealing stainless steel wire

- Induction Preheating Steel Tubes

- Induction Soldering Brass Corner Joint

- Induction Soldering Coaxial Cable

- Induction Heating Automotive Motor

- Induction Melting Videos

- Why Choose Induction Heating and what are its adva...

- induction surface hardening steel screws

- High Frequency Brazing Stainless Steel Fittings

- ultrasonic welding equipment | ultrasonic plastic ...

- induction water boiler

- Brazing carbide shaft with induction

- Small High Frequency Induction Melting Furnace

- Shrink Fittting Part Removal application with Indu...

- Induction Soldering Wires Onto Connection

- Induction Soldering Cables to Terminals

- Induction Brazing Stainless Steel Tubing Joints

- Induction Brazing Carbide Onto Steel Part

- Application of induction aluminum melting furnace

- Induction Boiler

- Induction Heating Steel Part For Hot Heading

- Induction heating of aluminium billets

- Induction Brazing Carbide

- Induction Heating Steel Pipe To Remove plastic coa...

- Induction Brazing Carbide

- Induction Brazing Stainless Steel

- High Frequency Induction Brazing Copper Wire

- Brazing Automotive Parts With Induction

- Induction Brazing Carbide Onto Steel Part

- Brazing carbide shaft with induction

- Induction Heating Valve Head

- What Is Induction Heating?

- ultrasonic welding fabric machine for bonding nonw...

- induction preheating copper rod for hot forging

- Induction Annealing Aluminum

- induction heating stainless steel wire cable

- Induction Annealing Copper Wire

- induction heating for surface quenching of steel

- ELECTRIC INDUCTION FURNACE

- Induction Soldering Copper Pipes to PCB Board

- Induction Preheating Hot Rod Heading

- Plastic Injection Molding with Induction Heating

- Induction Brazing Carbide Onto Steel Part

- Induction Annealing Copper Tubes

- Induction hardening steel screw threads

- induction heating steel cable for cutting

- Induction Heating Valve Head

- Request a Quote

- Brazing Brass to Aluminum with Induction

- Induction Aluminum Brazing Process

- Induction Brazing Stainless Steel

- induction heating system technology PDF

- Induction Aluminum Brazing Process

- Induction Brazing Stainless Steel

- Induction Heating Steel Part For Hot Heading

- Brazing Carbide To Steel With Induction

- Brazing Automotive Parts With Induction

- Induction Brazing Copper Assembly

- Induction Soldering Copper Pipes to PCB Board

- Ultrasonic Welding Machine | Ultrasonic plastic We...

- Induction annealing copper wires

- Induction Brazing Basics

- Induction Billets Heater Video

- Brazing Copper to Brass Pipe With Induction

- What Is Induction Melting?

- Induction Brazing Steel Wire

- induction heating nanoparticle solution

- Induction Soldering Copper Pipes to PCB Board

- Induction Soldering Cable to Metallic Plate

- Aluminium Scraps Recycling Melting and Process

- induction curing

-

▼

二月

(98)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.