Induction Surface Hardening for Armature Shaft

Objective

Induction Surface Hardening the gear end of an armature shaft to 58-65 Rockwell C at a depth of 0.02"(.51mm) on the center line of the teeth and to 49-55 Rockwell C at a depth of .010" (.3mm) on the center line of the root.

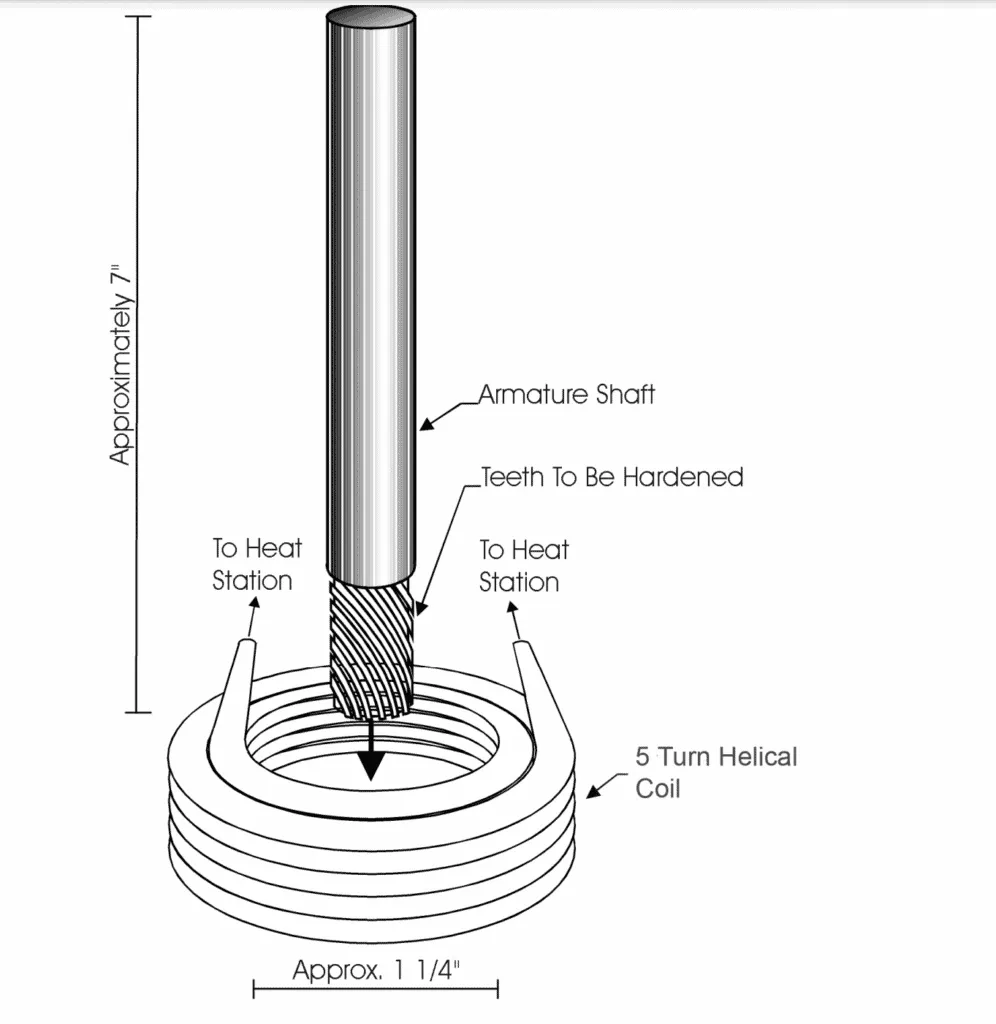

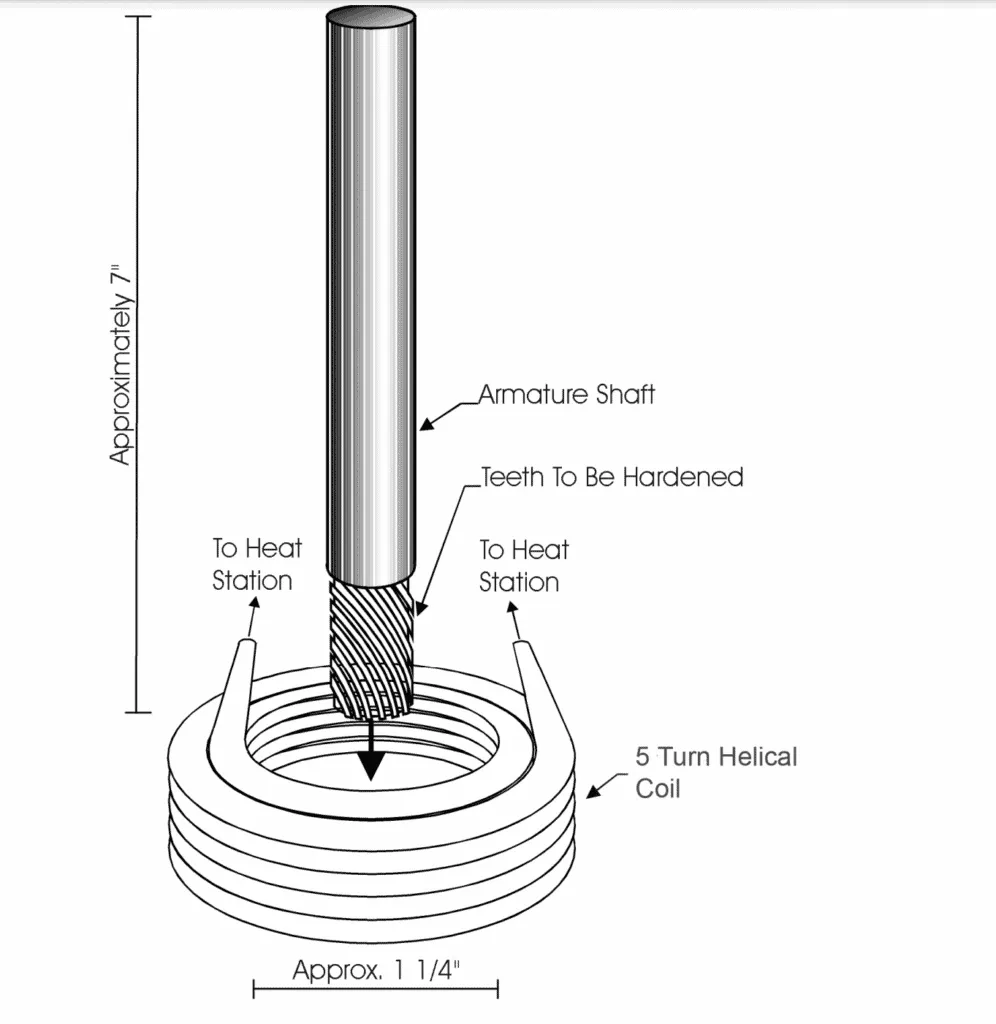

Material: Steel armature shaft measuring 7" (177.8mm) in length with a gear diameter of approximately 1/2 (12.7mm).

Temperature: 1700ºF(926.7ºC)

Frequency: 140 kHz

Equipment

• DW-UHF-30kW induction heating system equipped with a remote workhead containing two (2) capacitors

totaling 0.5 µF

• 4-20 mA input simulator

• An induction heating coil designed and developed specifically for this application.

Process

A five turn helical coil is used to heat the gear end of the shaft to 1700ºF (926.7ºC) for 2.5 seconds to achieve the desired hardness.

Results/Benefits

Induction Heating Provides:

• Pin-point accuracy

• Maximum repeatability

• Faster cycle time

Temperature: 1700ºF(926.7ºC)

Frequency: 140 kHz

Equipment

Temperature: 1700ºF(926.7ºC)

Frequency: 140 kHz

Equipment

• DW-UHF-30kW induction heating system equipped with a remote workhead containing two (2) capacitors

totaling 0.5 µF

• 4-20 mA input simulator

• An induction heating coil designed and developed specifically for this application.

• DW-UHF-30kW induction heating system equipped with a remote workhead containing two (2) capacitors

totaling 0.5 µF

• 4-20 mA input simulator

• An induction heating coil designed and developed specifically for this application.

Process

A five turn helical coil is used to heat the gear end of the shaft to 1700ºF (926.7ºC) for 2.5 seconds to achieve the desired hardness.

Results/Benefits

Induction Heating Provides:

• Pin-point accuracy

• Maximum repeatability

• Faster cycle time

Process

A five turn helical coil is used to heat the gear end of the shaft to 1700ºF (926.7ºC) for 2.5 seconds to achieve the desired hardness.

Results/Benefits

Induction Heating Provides:

• Pin-point accuracy

• Maximum repeatability

• Faster cycle time