Objective

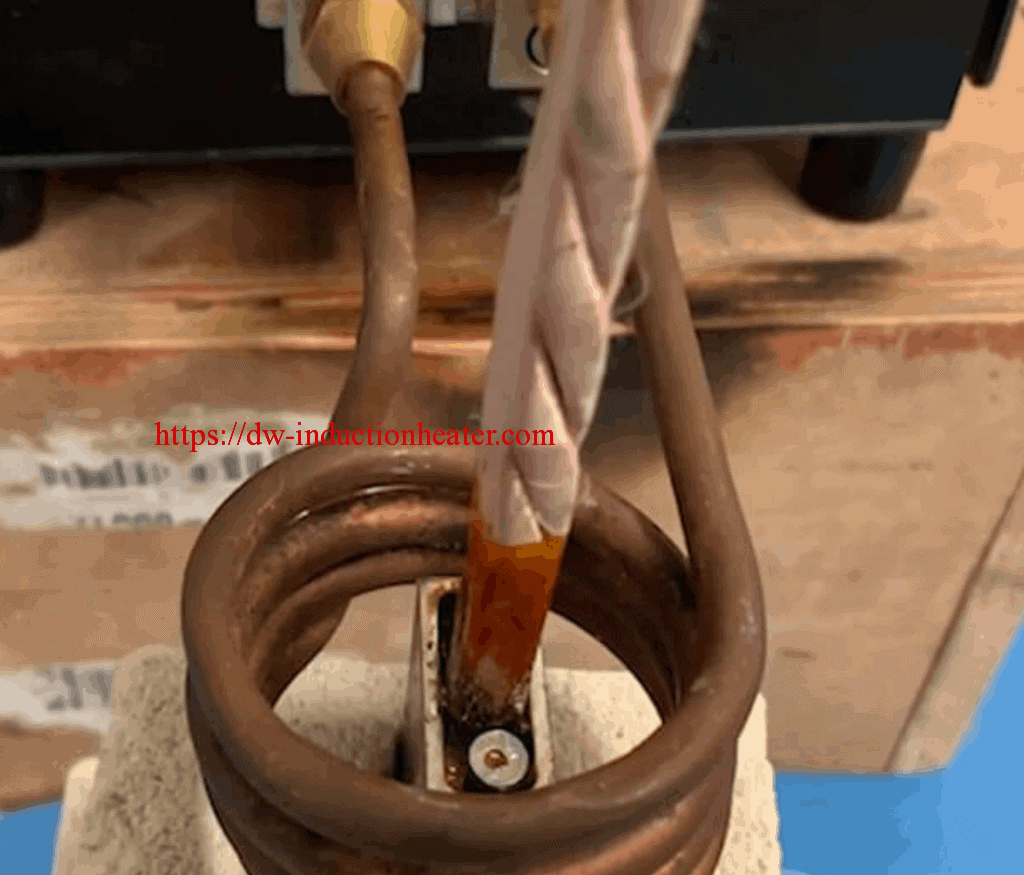

The objective of this induction soldering wire to aluminum lug in under 30 seconds.

Equipment

DW-UHF-6KW-III handheld induction soldering heater

HLQ custom coil

Key Parameters

Power: 1.75 kW

Temperature: Approximately 250°C (482°F)

Time: 25 seconds

Induction Soldering Process:

In order to start the induction soldering process, the aluminum lug was placed in the center of the coil. Then the litz wire was placed into the lug along with the solder. The solder started to melt after 25 seconds at approximately 250°C (482°F). After the solder was completely melted it was left to cool for one minute before proceeding.

Results:

The tests were a success. We were able to prove that induction heating was a much faster method of induction soldering wire to aluminum lug rather than using a torch as the customer had done in the past. The application testing showed an increase in productivity and control over the time and temperature.

https://dw-inductionheater.com/wp-content/uploads/2020/03/induction-soldering-wire-to-aluminum.png?v=1585397654

https://dw-inductionheater.com/induction-soldering-wire-to-aluminum-lug.html

aluminum wire soldering, induction soldering aluminum, induction soldering heater, induction soldering wire, RF soldering aluminum, soldering aluminum wire induction, soldering wire, soldering wire to aluminum