Objective

The purpose of this test is to demonstrate the induction soldering wire to connector

Recommended Equipment

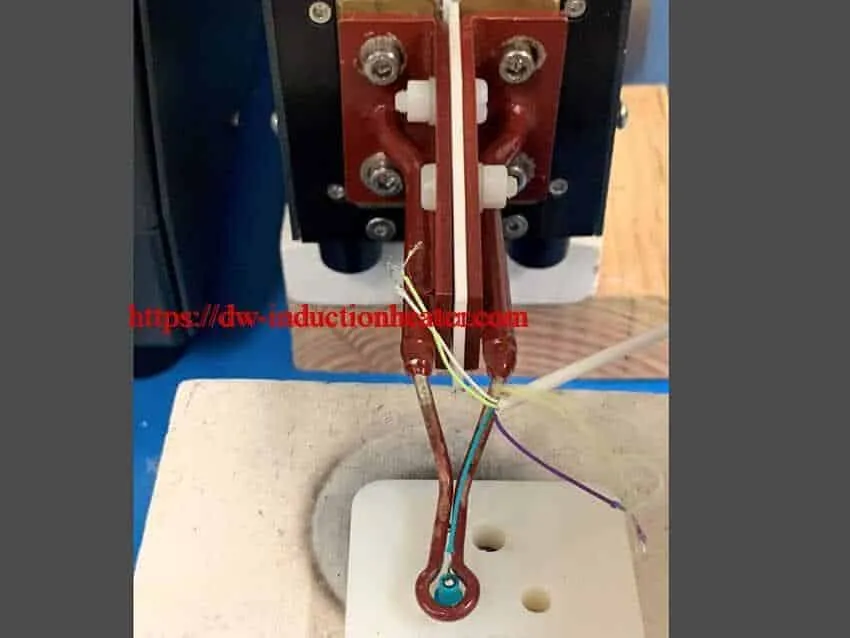

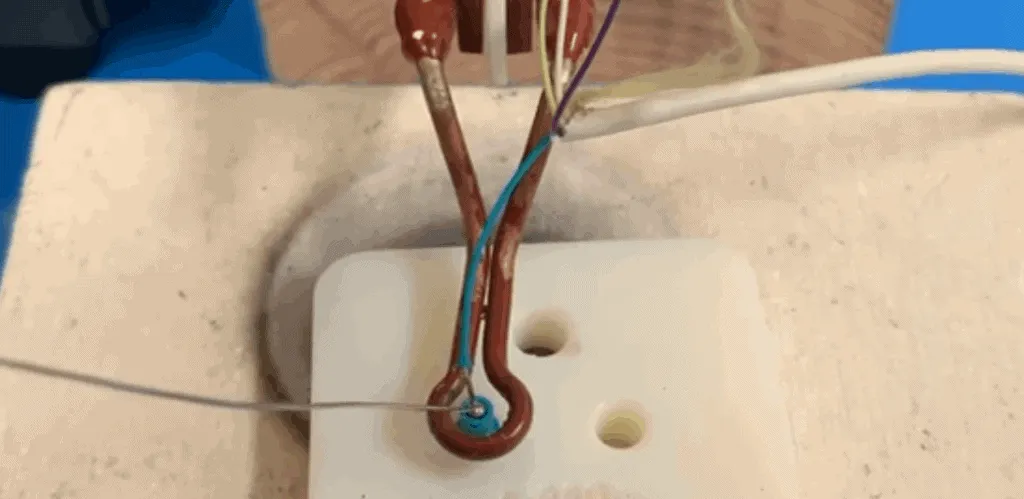

The recommended equipment for this test is the with the customized induction heating coil.

DW-UHF-6KW-I handheld induction heater

Key Parameters

Power: Up to 0.48 kW

Temperature: 392°F (200°C)

Time: 1.5 seconds

Process and Results:

This induction soldering wire to connector process was quick yet effective. The unit was run at 985 kHz, the reason for using such a high frequency was to couple into the small diameter of the wires. The whole process from the heat being turned on to the hardening of the solder took 1.5 seconds. Previously a soldering iron was being used to complete this task, however induction soldering was proven to be much faster and more efficient. The process can now be automated on an assembly line, because the system can remotely be turned on.

https://dw-inductionheater.com/wp-content/uploads/2020/03/induction-soldering-wire-to-connector-process.png?v=1585448637

https://dw-inductionheater.com/high-frequency-induction-soldering-wire-to-connector.html

high frequency soldering, High frequency soldering wire, induction soldering, induction soldering wire, induction soldering wire connector, RF soldering machine, RF soldering wire to connector, soldering wire to connector