Shrink Fittting Part Removal application with Induction Heating

Objective

This is a Shrinkfit Part Removal application. The customer’s current process uses a press to push the inserted part out. However, this requires significant force and time. By applying heat, the housing can expand just enough to allow for the easy removal of the inserted part with minimal force. The customer’s time requirement is to complete the Shrinkfit Part Removal within 7 minutes.

Equipment

DW-HF-15kw induction heating machine

Materials

• Aluminum pump housing Part OD 2.885” (73.279mm), wall 0.021” (.533mm)

Key Parameters

Temperature: Approximately 400°F (204°C)

Power: 4 kW

Time: 100 seconds

Process:

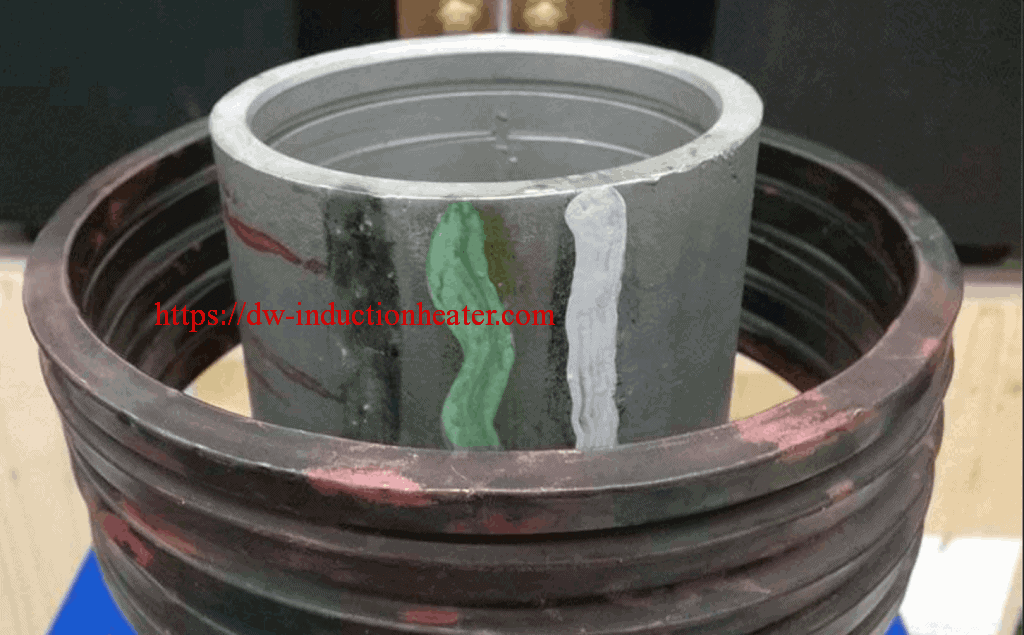

- To complete the Shrinkfit Part Removal, place part into coil, so the top of the housing is as close as possible to the top of the coil.

- Some experimentation was needed to determine the ideal time and power. We found that 100 seconds was ideal for removal of the part, which was significantly lower than the customer’s limit of 7 minutes

The tested assembly can be heated to the required temperature in less than 7 minutes using the DW-HF-15kw induction heating system and custom designed coil. Heat time for the Custom Coil was 100 seconds, Temperature needed to be close to 400°F (204°C) in order to expand the part sufficiently for removal. The part was removed with some pulling force applied to it as the pump housing was reaching 400°F (204°C).

This Shrink Fit application was further reviewed to determine if a lower power induction heating system could be used. In this case, the customer’s requirement was 7 minutes, and we achieved the part removal in 100 seconds. Could a lower power system remove the part at a lower cost? A lower power system would be acceptable if our goal is part insertion. For Shrink Fit – Part Insertion, a slower heating rate would still result in a successful process. However, with Shrink Fit – Part Removal, it is important to heat rapidly. A slower heat rate would result in the inserted part also heating, and also expanding. The inserted part potentially would remain “stuck”. By heating rapidly, we avoid this issue. The customer in this case has decided to both use a system for part insertion AND part removal. A 4 kW system is fine for the Shrink Fit – Part Insertion; and the 7 kW DW-HF-15kw induction heating system will be used for the Shrink Fit – Part Removal

- Precise control of the time and temperature

- Power on demand with rapid heat cycles

- Repeatable process, not operator dependent

- Safe heating with no open flames

- Energy efficient heating

Shrink Fittting Part Removal application with Induction Heating

Objective

This is a Shrinkfit Part Removal application. The customer’s current process uses a press to push the inserted part out. However, this requires significant force and time. By applying heat, the housing can expand just enough to allow for the easy removal of the inserted part with minimal force. The customer’s time requirement is to complete the Shrinkfit Part Removal within 7 minutes.

Equipment

DW-HF-15kw induction heating machine

Materials

• Aluminum pump housing Part OD 2.885” (73.279mm), wall 0.021” (.533mm)

Key Parameters

Temperature: Approximately 400°F (204°C)

Power: 4 kW

Time: 100 seconds

Process:

- To complete the Shrinkfit Part Removal, place part into coil, so the top of the housing is as close as possible to the top of the coil.

- Some experimentation was needed to determine the ideal time and power. We found that 100 seconds was ideal for removal of the part, which was significantly lower than the customer’s limit of 7 minutes

Results/Benefits:

The tested assembly can be heated to the required temperature in less than 7 minutes using the DW-HF-15kw induction heating system and custom designed coil. Heat time for the Custom Coil was 100 seconds, Temperature needed to be close to 400°F (204°C) in order to expand the part sufficiently for removal. The part was removed with some pulling force applied to it as the pump housing was reaching 400°F (204°C).

This Shrink Fit application was further reviewed to determine if a lower power induction heating system could be used. In this case, the customer’s requirement was 7 minutes, and we achieved the part removal in 100 seconds. Could a lower power system remove the part at a lower cost? A lower power system would be acceptable if our goal is part insertion. For Shrink Fit – Part Insertion, a slower heating rate would still result in a successful process. However, with Shrink Fit – Part Removal, it is important to heat rapidly. A slower heat rate would result in the inserted part also heating, and also expanding. The inserted part potentially would remain “stuck”. By heating rapidly, we avoid this issue. The customer in this case has decided to both use a system for part insertion AND part removal. A 4 kW system is fine for the Shrink Fit – Part Insertion; and the 7 kW DW-HF-15kw induction heating system will be used for the Shrink Fit – Part Removal

- Precise control of the time and temperature

- Power on demand with rapid heat cycles

- Repeatable process, not operator dependent

- Safe heating with no open flames

- Energy efficient heating

https://dw-inductionheater.com/wp-content/uploads/2020/03/induction-shrink-fitting.png?v=1584435432

https://dw-inductionheater.com/shrink-fittting-part-removal-application-with-induction-heating.html