![]()

Safely Removing Heat Induction Rubber Coatings and Paintings: A Complete Guide

The rubber coatings and paintings industry is constantly evolving to meet the ever-changing demands of customers and the environment. Amongst the many innovative techniques being employed, heat induction has risen as a sustainable, cost-effective, and efficient solution for removing rubber coatings and paintings from various surfaces. In this comprehensive guide, we will explore the ins and outs of heat induction rubber coatings and paintings removal, including its methods, benefits, and applications in various industries.

Heat induction rubber coatings and paintings

Heat induction rubber coatings and paintings are often used on industrial equipment, pipelines, and machinery to help prevent corrosion and extend the life of the equipment. However, over time, these coatings can become damaged, worn, or simply need to be removed. Removing them can be a difficult and dangerous process, especially if proper precautions are not taken. In this blog post, we will provide you with a complete guide on how to safely remove heat induction rubber coatings and paintings. We'll cover important safety measures, the different methods available, and tips to ensure that the process is efficient and effective. Keep reading to learn how to safely remove heat induction rubber coatings and paintings from your equipment.

What is Heat Induction?

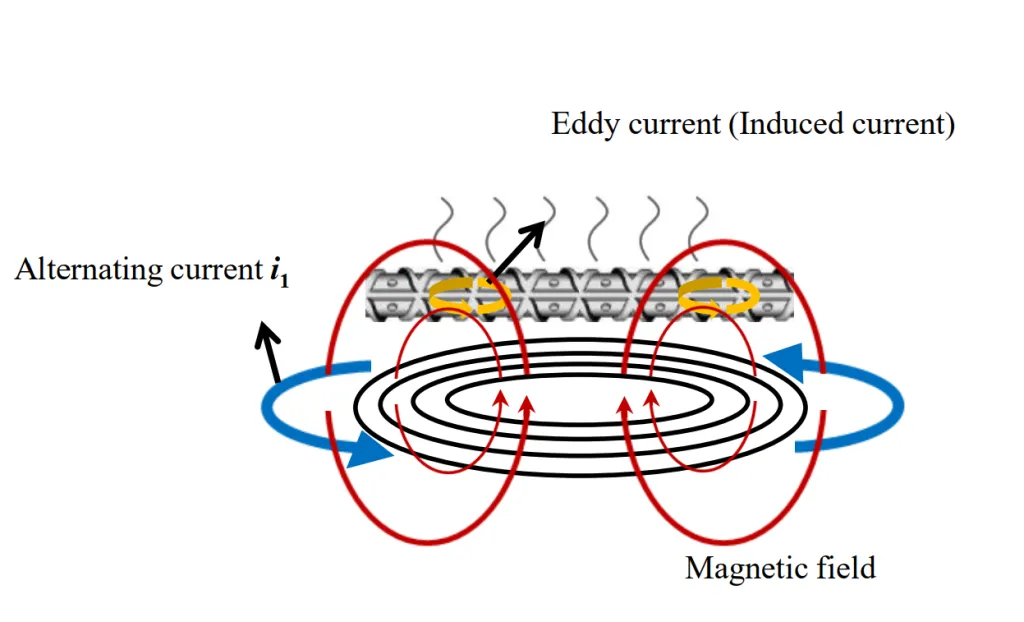

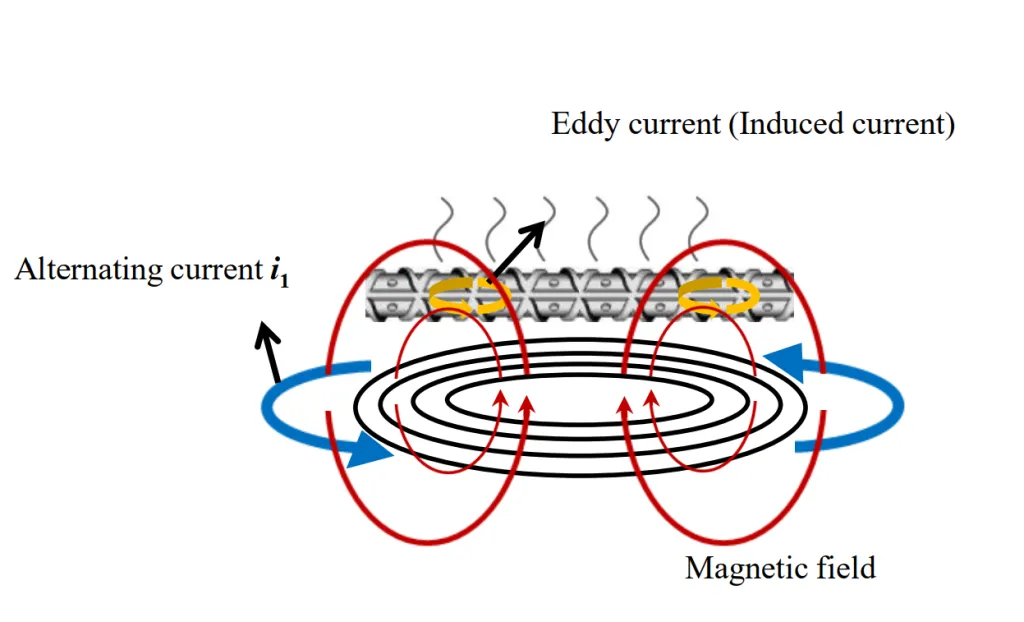

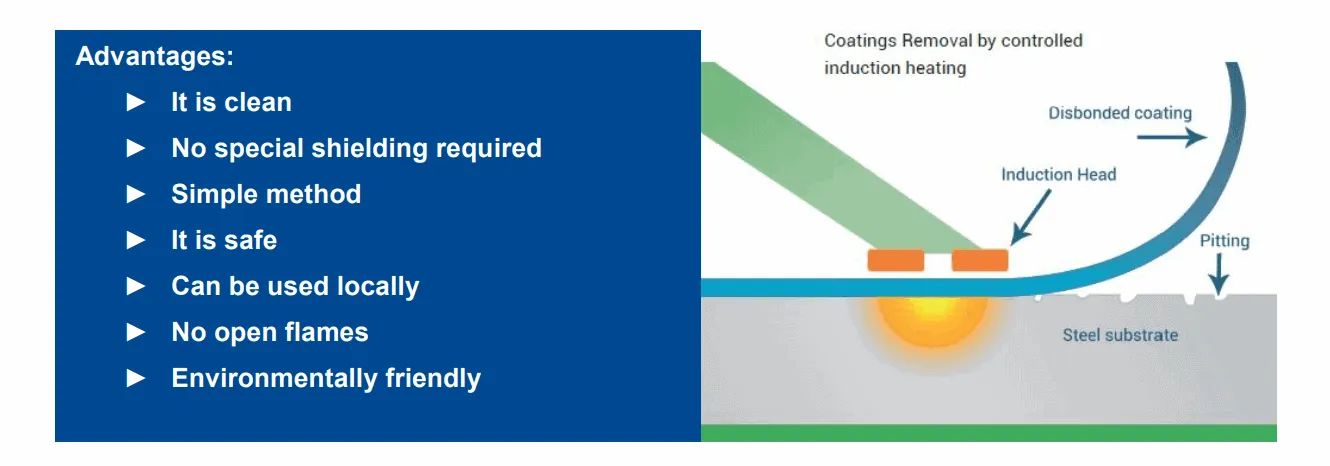

Heat induction is a non-contact method of heating that works through generating eddy currents inside a conductive material.

The process employs an electromagnetic coil called an inductor, creating a varying magnetic field that heats the material. This technique is well suited for removing rubber coatings and paintings as it allows for the efficient transfer of heat energy without harming the underlying surface.

Introduction to heat induction rubber coatings and paintings

Heat induction rubber coatings and paintings are an excellent way to protect surfaces from damage and corrosion. These coatings are widely used in a variety of industries, such as automotive, marine, and industrial, to protect and beautify surfaces.

The coatings are made from durable materials that can withstand exposure to extreme temperatures, chemicals, and abrasion. They are applied using special equipment and techniques that ensure a smooth and even finish. However, there may come a time when you need to remove the heat induction rubber coatings or paintings from a surface. This could be because of damage or wear and tear, or you may want to change the color or texture of the surface. Whatever the reason, it is important to know the proper techniques for safely removing heat induction rubber coatings and paintings. In this guide, we will explore various methods that can be used to safely remove these coatings and paintings, ensuring that your surfaces remain undamaged and ready for their next application.

Safety measures to take before removing heat induction rubber coatings and paintings

Before you begin removing heat induction rubber coatings and paintings, it is important to take necessary safety precautions. The first step is to ensure that you are wearing appropriate personal protective equipment (PPE). This may include gloves, eye protection, a respirator mask, and protective clothing. It's crucial to read the manufacturer's instructions on the PPE before using it. Secondly, ensure that the area where you will be working is well-ventilated.

Open windows and doors and use fans to circulate the air. This helps to prevent the accumulation of fumes from the chemicals used in the removal process. It is also important to have a fire extinguisher nearby as

heat induction rubber coatings and paintings can be highly flammable. In case of accidental ignition, you will be able to quickly extinguish the fire. Before starting the removal process, make sure that you have the proper tools. This may include a scraper, heat gun, and chemical remover. Ensure that you read the instructions on the tools before using them and always follow the manufacturer's recommended safety measures. Lastly, it is essential to dispose of any waste or debris generated from the removal process carefully. Follow the local regulations for hazardous waste disposal and recycling. By following these safety measures, you can safely remove heat induction rubber coatings and paintings.

Methods for removing heat induction rubber coatings and paintings

There are several methods for removing heat induction rubber coatings and paintings from a surface. One common method is to use a heat gun or heat lamp to soften the rubber coating or paint. Once the coating or paint has been heated, a scraper or putty knife can be used to remove it from the surface. This method works best on smaller areas and should be done with caution as the heat can damage the surface underneath. Another method is to use a chemical paint stripper or rubber coating remover.

These products can be applied to the surface and allowed to sit for a period of time before being scraped off. It is important to follow the manufacturer's instructions when using these products and wear protective gear such as gloves and a mask. A third method is to use sandblasting or abrasive blasting to remove the rubber coating or paint. This method uses high-pressure air or water mixed with abrasive material to blast away the coating or paint from the surface. This method is best used on large surfaces or objects and should be done by a professional. No matter which method is used, it is important to take safety precautions such as wearing protective gear, working in a well-ventilated area, and following manufacturer's instructions. By following these methods, you can safely remove heat induction rubber coatings and paintings from a surface.

Benefits of Heat Induction Rubber Coatings and Paintings Removal

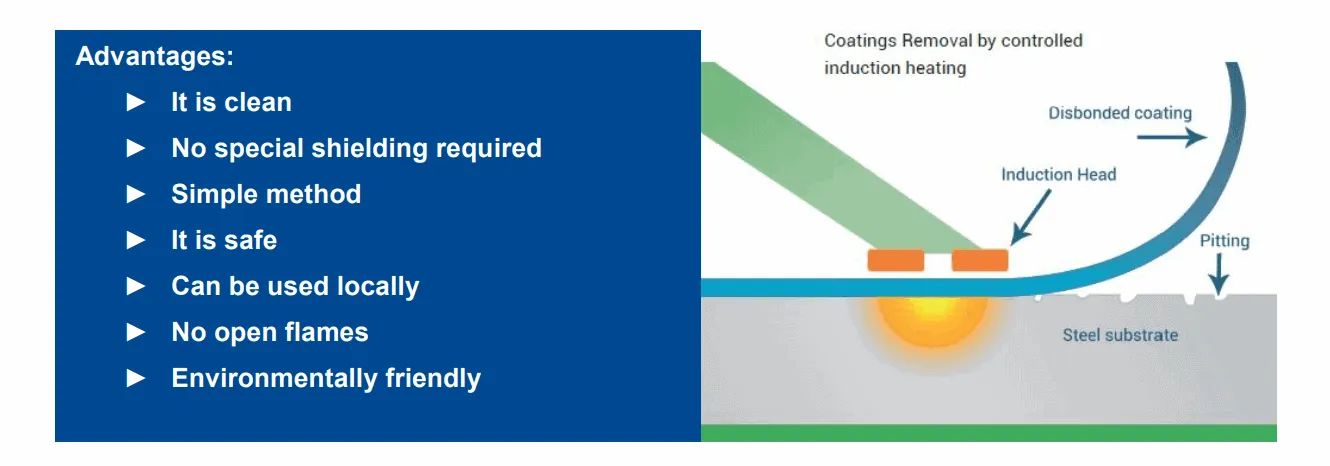

1. Environmentally friendly: Heat induction is a chemical-free process that generates little to no harmful emissions or waste. This makes it an eco-conscious choice for removing rubber coatings and paintings.

2. Efficient and effective: Heat induction allows for targeted heating, limiting damage to the underlying surface, and ensures a faster removal process.

3. Safe: The non-contact nature of heat induction reduces the risk of burns or other accidents associated with traditional techniques.

4. Cost-effective: Heat induction offers a high return on investment due to its low energy consumption, reduced labor costs, and minimal downtime.

Applications of Heat Induction Removal

Heat induction rubber coatings and paintings removal can be employed across various industries. Some of its notable applications include:

1. Automotive: Removing rubber coatings and paint from auto body parts, car frames, or engine components.

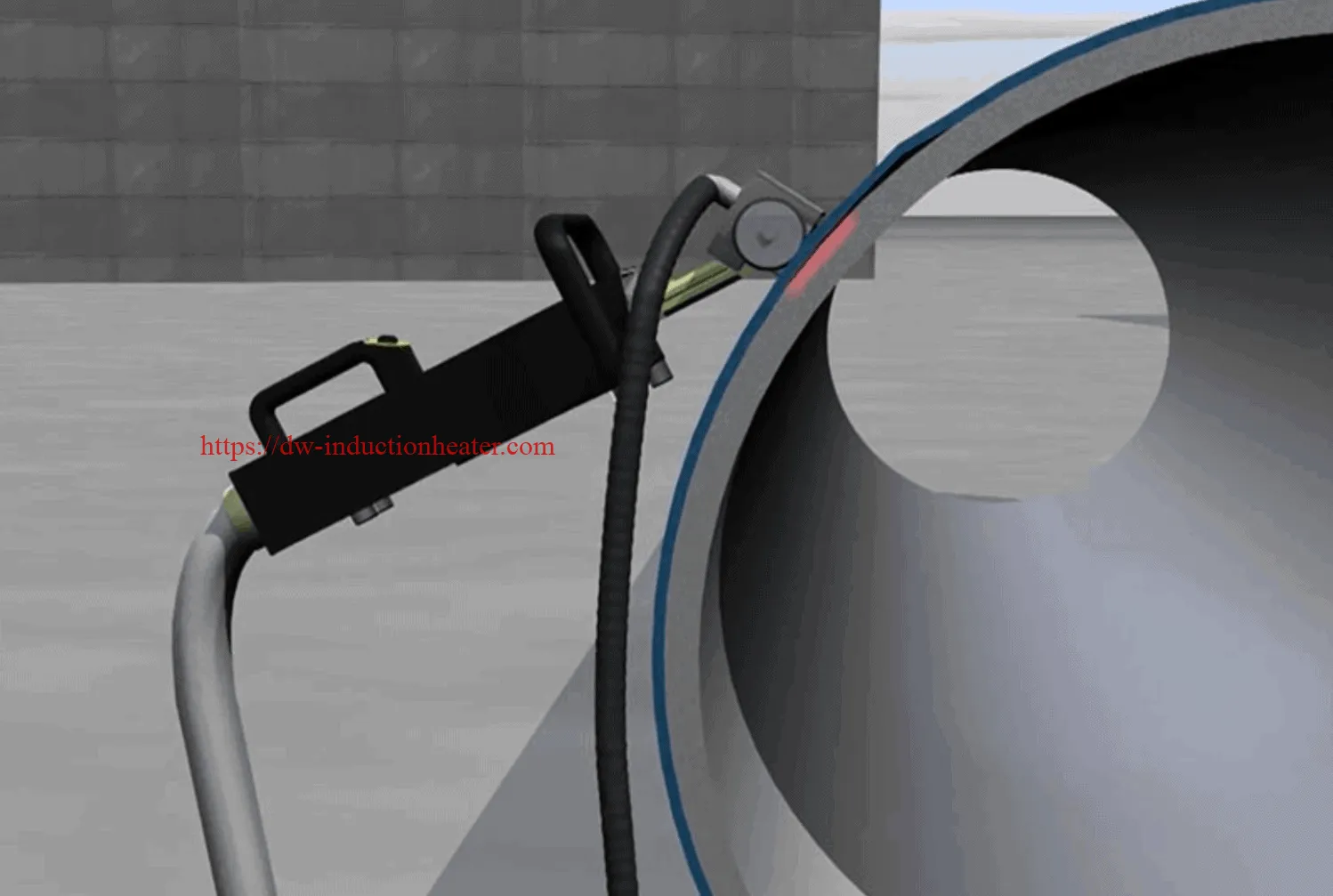

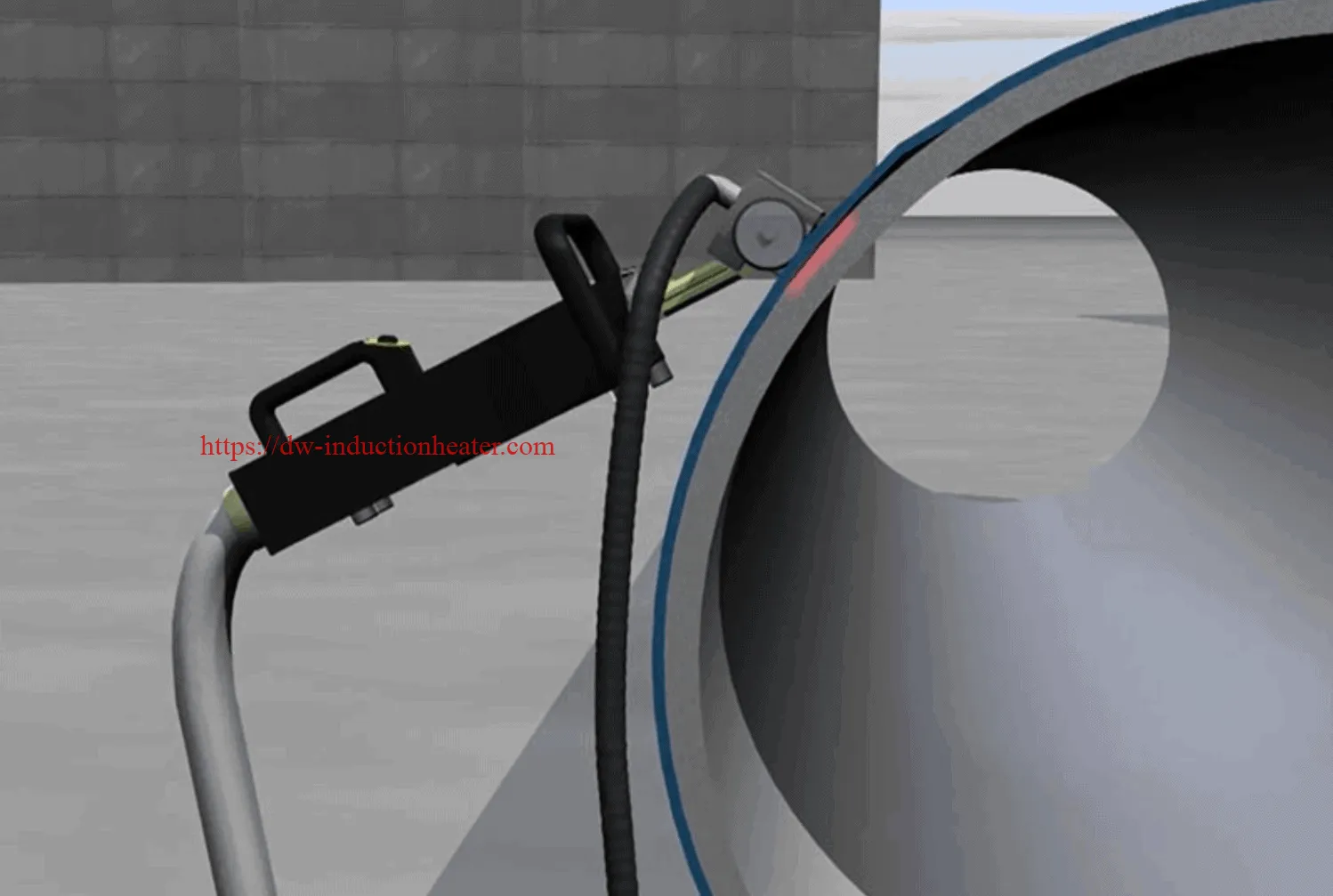

2. Marine: Stripping rubberized coatings and paint from ships, boats, and other marine vessels.

3. Aviation: Removing rubberized coatings or specialized paints from airplane parts and structures.

4. Infrastructure: Stripping coatings from bridges or other structures to prevent corrosion and facilitate maintenance.

5. Manufacturing: Removing coatings from tools, equipment, and production line components.

Final Thoughts

Heat induction rubber coatings and paintings removal is a complex process that requires specialized equipment and expertise. If you need rubber coatings or paintings removed from a surface, it's important to work with a professional who has experience in this area. At our company, we have the tools and expertise to safely and effectively remove rubber coatings and paintings using heat induction technology. Our team of experts will work with you to understand your needs and develop a plan that meets your specific requirements. So if you need rubber coatings or paintings removed, don't hesitate to contact us today. We'll help you get the job done right.

https://dw-inductionheater.com/the-ultimate-guide-to-heat-induction-rubber-coatings-and-paintings-removal.html?feed_id=202352&_unique_id=645473c26da70

https://dw-inductionheater.com/the-ultimate-guide-to-heat-induction-rubber-coatings-and-paintings-removal.html?feed_id=202352&_unique_id=645473c26da70

Heat induction rubber coatings and paintings are often used on industrial equipment, pipelines, and machinery to help prevent corrosion and extend the life of the equipment. However, over time, these coatings can become damaged, worn, or simply need to be removed. Removing them can be a difficult and dangerous process, especially if proper precautions are not taken. In this blog post, we will provide you with a complete guide on how to safely remove heat induction rubber coatings and paintings. We'll cover important safety measures, the different methods available, and tips to ensure that the process is efficient and effective. Keep reading to learn how to safely remove heat induction rubber coatings and paintings from your equipment.

Heat induction rubber coatings and paintings are often used on industrial equipment, pipelines, and machinery to help prevent corrosion and extend the life of the equipment. However, over time, these coatings can become damaged, worn, or simply need to be removed. Removing them can be a difficult and dangerous process, especially if proper precautions are not taken. In this blog post, we will provide you with a complete guide on how to safely remove heat induction rubber coatings and paintings. We'll cover important safety measures, the different methods available, and tips to ensure that the process is efficient and effective. Keep reading to learn how to safely remove heat induction rubber coatings and paintings from your equipment.

The process employs an electromagnetic coil called an inductor, creating a varying magnetic field that heats the material. This technique is well suited for removing rubber coatings and paintings as it allows for the efficient transfer of heat energy without harming the underlying surface.

The process employs an electromagnetic coil called an inductor, creating a varying magnetic field that heats the material. This technique is well suited for removing rubber coatings and paintings as it allows for the efficient transfer of heat energy without harming the underlying surface.

The coatings are made from durable materials that can withstand exposure to extreme temperatures, chemicals, and abrasion. They are applied using special equipment and techniques that ensure a smooth and even finish. However, there may come a time when you need to remove the heat induction rubber coatings or paintings from a surface. This could be because of damage or wear and tear, or you may want to change the color or texture of the surface. Whatever the reason, it is important to know the proper techniques for safely removing heat induction rubber coatings and paintings. In this guide, we will explore various methods that can be used to safely remove these coatings and paintings, ensuring that your surfaces remain undamaged and ready for their next application.

The coatings are made from durable materials that can withstand exposure to extreme temperatures, chemicals, and abrasion. They are applied using special equipment and techniques that ensure a smooth and even finish. However, there may come a time when you need to remove the heat induction rubber coatings or paintings from a surface. This could be because of damage or wear and tear, or you may want to change the color or texture of the surface. Whatever the reason, it is important to know the proper techniques for safely removing heat induction rubber coatings and paintings. In this guide, we will explore various methods that can be used to safely remove these coatings and paintings, ensuring that your surfaces remain undamaged and ready for their next application.

Open windows and doors and use fans to circulate the air. This helps to prevent the accumulation of fumes from the chemicals used in the removal process. It is also important to have a fire extinguisher nearby as heat induction rubber coatings and paintings can be highly flammable. In case of accidental ignition, you will be able to quickly extinguish the fire. Before starting the removal process, make sure that you have the proper tools. This may include a scraper, heat gun, and chemical remover. Ensure that you read the instructions on the tools before using them and always follow the manufacturer's recommended safety measures. Lastly, it is essential to dispose of any waste or debris generated from the removal process carefully. Follow the local regulations for hazardous waste disposal and recycling. By following these safety measures, you can safely remove heat induction rubber coatings and paintings.

Open windows and doors and use fans to circulate the air. This helps to prevent the accumulation of fumes from the chemicals used in the removal process. It is also important to have a fire extinguisher nearby as heat induction rubber coatings and paintings can be highly flammable. In case of accidental ignition, you will be able to quickly extinguish the fire. Before starting the removal process, make sure that you have the proper tools. This may include a scraper, heat gun, and chemical remover. Ensure that you read the instructions on the tools before using them and always follow the manufacturer's recommended safety measures. Lastly, it is essential to dispose of any waste or debris generated from the removal process carefully. Follow the local regulations for hazardous waste disposal and recycling. By following these safety measures, you can safely remove heat induction rubber coatings and paintings.

These products can be applied to the surface and allowed to sit for a period of time before being scraped off. It is important to follow the manufacturer's instructions when using these products and wear protective gear such as gloves and a mask. A third method is to use sandblasting or abrasive blasting to remove the rubber coating or paint. This method uses high-pressure air or water mixed with abrasive material to blast away the coating or paint from the surface. This method is best used on large surfaces or objects and should be done by a professional. No matter which method is used, it is important to take safety precautions such as wearing protective gear, working in a well-ventilated area, and following manufacturer's instructions. By following these methods, you can safely remove heat induction rubber coatings and paintings from a surface.

These products can be applied to the surface and allowed to sit for a period of time before being scraped off. It is important to follow the manufacturer's instructions when using these products and wear protective gear such as gloves and a mask. A third method is to use sandblasting or abrasive blasting to remove the rubber coating or paint. This method uses high-pressure air or water mixed with abrasive material to blast away the coating or paint from the surface. This method is best used on large surfaces or objects and should be done by a professional. No matter which method is used, it is important to take safety precautions such as wearing protective gear, working in a well-ventilated area, and following manufacturer's instructions. By following these methods, you can safely remove heat induction rubber coatings and paintings from a surface.

2. Efficient and effective: Heat induction allows for targeted heating, limiting damage to the underlying surface, and ensures a faster removal process.

3. Safe: The non-contact nature of heat induction reduces the risk of burns or other accidents associated with traditional techniques.

4. Cost-effective: Heat induction offers a high return on investment due to its low energy consumption, reduced labor costs, and minimal downtime.

2. Efficient and effective: Heat induction allows for targeted heating, limiting damage to the underlying surface, and ensures a faster removal process.

3. Safe: The non-contact nature of heat induction reduces the risk of burns or other accidents associated with traditional techniques.

4. Cost-effective: Heat induction offers a high return on investment due to its low energy consumption, reduced labor costs, and minimal downtime.

1. Automotive: Removing rubber coatings and paint from auto body parts, car frames, or engine components.

2. Marine: Stripping rubberized coatings and paint from ships, boats, and other marine vessels.

3. Aviation: Removing rubberized coatings or specialized paints from airplane parts and structures.

4. Infrastructure: Stripping coatings from bridges or other structures to prevent corrosion and facilitate maintenance.

5. Manufacturing: Removing coatings from tools, equipment, and production line components.

1. Automotive: Removing rubber coatings and paint from auto body parts, car frames, or engine components.

2. Marine: Stripping rubberized coatings and paint from ships, boats, and other marine vessels.

3. Aviation: Removing rubberized coatings or specialized paints from airplane parts and structures.

4. Infrastructure: Stripping coatings from bridges or other structures to prevent corrosion and facilitate maintenance.

5. Manufacturing: Removing coatings from tools, equipment, and production line components.

https://dw-inductionheater.com/the-ultimate-guide-to-heat-induction-rubber-coatings-and-paintings-removal.html?feed_id=202352&_unique_id=645473c26da70

https://dw-inductionheater.com/the-ultimate-guide-to-heat-induction-rubber-coatings-and-paintings-removal.html?feed_id=202352&_unique_id=645473c26da70