Objective

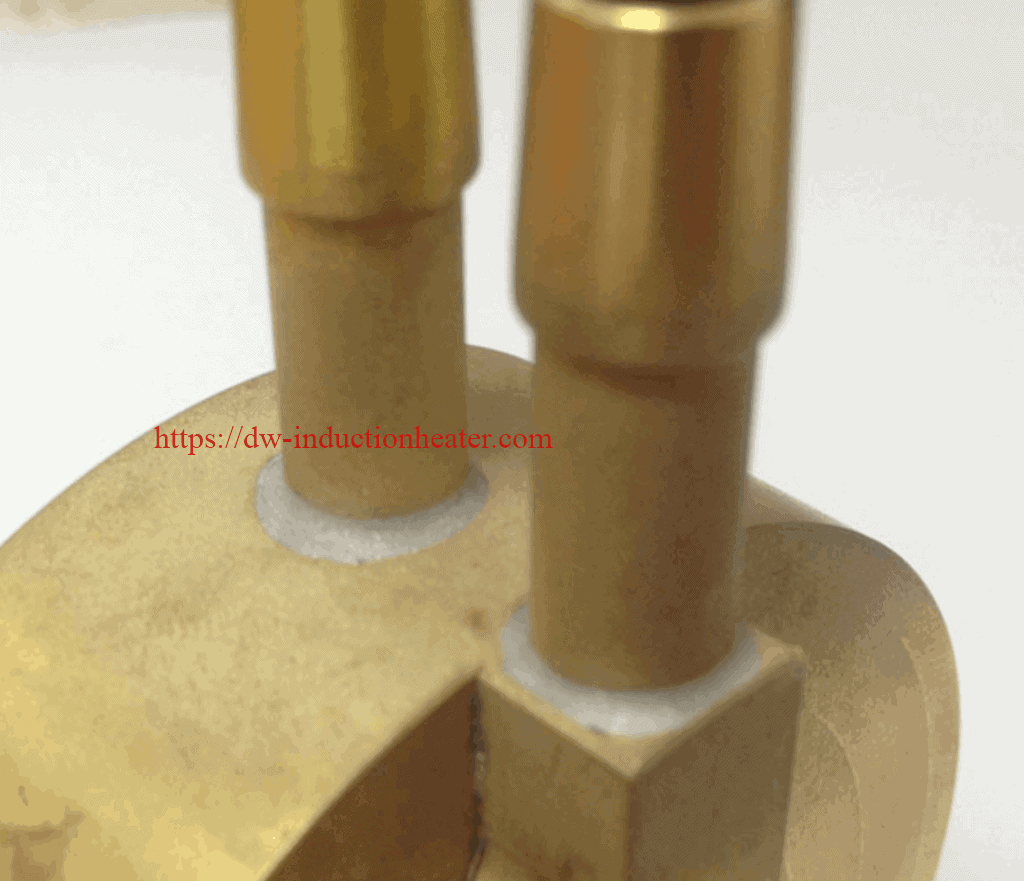

To simultaneously high frequency Induction Soldering Brass Tubessolder to a brass water jacket assembly with induction heating.

Equipment

DW-HF-15KW Induction Heating Machine

Key Parameters

Power: 5 kW

Temperature: 424°F (217°C)

Time: 10 seconds until the alloy flows; 15 seconds to allow alloy to even out around the tube.

TEST 1

Materials

• Brass water jacket assembly

• Lead-free solder alloy

• Utility paste soldering flux

TEST 2

Materials

• Brass water jacket assembly

• Lead-free solder alloy

• Utility paste soldering flux

Results:

Brass inlet/outlet tubes were successfully brazed to the brass assembly with induction heating. The piece needs to be positioned so that the tube is close to the end of the coil. The solder joint on the thin wall of the assembly will reach soldering temperature in 10 seconds. The second solder joint will reach soldering temperature an average of 10 seconds later (15 seconds total). An additional 5 seconds of heating might be necessary to allow the solder to flow evenly around the tubes to improve final quality and appearance.

[wpforms id="3947"]