2023年2月19日星期日

What is induction welding?

What is induction welding?

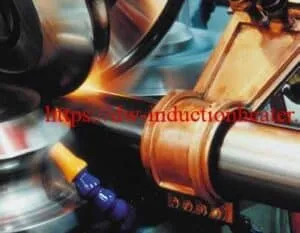

With induction welding the heat is electromagnetically induced in the workpiece. The speed and accuracy

of induction welding make it ideal for edge welding of tubes and pipes. In this process, pipes pass an induction coil at high speed. As they do so, their edges are heated then squeezed together to form a longitudinal weld seam. Induction welding is particularly suitable for high-volume production. Induction welders can also be fitted with contact heads, turning them into

dual purpose welding systems.

What are the benefits?

Automated induction longitudinal welding is a reliable, high-throughput process. The low power consumption and high efficiency of DAWEI Induction welding systems reduce costs. Their controllability and repeatability minimize scrap. Our systems are also flexible—automatic load matching ensures full output power across a wide range of tube sizes. And their small footprints make them easy to integrate or retrofit into production lines.

Where is it used?

Induction welding is used in the tube and pipe industry for the longitudinal welding of stainless steel (magnetic and non-magnetic), aluminum, low-carbon and highstrength low-alloy (HSLA) steels and many other conductive

materials.

关注者

博客归档

-

▼

2023

(1696)

-

▼

二月

(174)

- Jointing Metal with Brazing and Welding

- Magnetic Induction Heater Manufacturer

- Induction annealing copper wires

- induction brazing stainless steel to copper

- brazing short circuit rings with induction heater

- Annealing Metal Stamp With Induction

- Advantages of Induction Heating

- Induction Billets Heater Video

- Brazing Aluminum Tubes with Induction Heating

- Induction Brazing Stainless Steel

- induction soldering copper tubing to brass valves

- Induction Preheating Welding Steel Pipe

- induction Brazing copper rods to brass strips

- Induction Soldering Brass to Steel Plate

- Induction Brazing Copper Assembly

- Induction Preheating Hot Rod Heading

- Automatic Induction Forging Video

- ultrasonic welding equipment | ultrasonic plastic ...

- Brazing Steel To Steel Pipe With Induction

- Brazing Copper Tube with Induction

- Melting Aluminum Tilting Crucible Induction Furnace

- Annealing Metal Stamp With Induction

- Annealing Metal Stamp With Induction

- Induction Soldering Stainless Steel To Wire

- Brazing Aluminum Tubing to Aluminum Parts

- Induction Soldering Coaxial Cable to Connector Ring

- Automatic Induction Forging Video

- Why choose Induction Brazing?

- Induction Heating Steel Part For Hot Heading

- Induction Annealing Copper Tubes

- Brazing Copper Tube with Induction

- Brazing Copper Tube with Induction

- induction preheating titanium billet for rolling

- High Frequency Brazing Stainless Steel Fittings

- Induction Annealing Steel Wire

- Induction Brazing Machine

- Aluminium Scraps Recycling Melting and Process

- Induction Brazing Carbide To Stainless Steel

- Technology of Induction Forming Steel Plate

- Brazing Aluminum Pipes Assembly With Induction

- Soldering Antenna Wire With Induction

- Induction Drying Grain with Induction Heating method

- Continous Billet Heating Furnace with Induction

- Soldering Solar Panels With Induction

- Induction Heat Staking for Spring Wire and Nylon P...

- Induction Brazing Copper T Pipe With Induction Hea...

- Aluminum Can Recycling Furnace with induction heating

- Induction Hot Forming Steel Pipe

- Induction Preheating Hot Heading

- Induction Soldering Wire To Aluminum Lug

- induction small copper tubing brazing connection j...

- Induction Brazing copper wire to copper cylinder

- Induction Annealing Copper Tubes

- Drum Gypsum Dryer-Slag Dryer with Induction Heating

- Annealing Metal Stamp With Induction

- Drum Gypsum Dryer-Slag Dryer with Induction Heating

- Induction heating of cylindrical nonmagnetic ingots

- Induction Brazing Carbide to Steel

- Induction Shrink Fitting Carbide Ring

- Induction Shrink Fitting Aluminum Pump Housing Part

- Induction heating bearings machine PDF

- Induction Drum Heating Coal Slime Dryer

- Induction Drum Heating Coal Slime Dryer

- What is induction welding?

- Induction Heating Aluminum Pipe

- Induction Heating Coils Design and Basic PDF

- refrigeration induction brazing refrigerator coppe...

- How Induction Heating works?

- Application of Induction Heating In Food

- Induction Heating Ore Drum Dryer

- Induction Heating Ore Drum Dryer

- Brazing Aluminum to Copper Tubes with Induction

- Induction Brazing & Soldering Principle

- High Speed Heating by Induction Heating System

- Heating Shrink Fitting Camshaft Gear

- handbook of induction heating eddy current

- induction hot forming and forging process

- Aluminum Billet Heating Furnace

- Brazing Brass To Copper With Induction

- portable ultrasonic mask welding machine for weldi...

- principle of electromagnetic induction heating

- Pipeline Coating Process

- Induction Soldering Wire To Aluminum Lug

- High frequency Induction Soldering Brass Tubes

- Induction Brazing Copper Pipe Fittings

- induction preheating copper rod

- PDF of Induction Heating Principle and Applicatons

- induction preheating before welding steel pipe

- Induction Brazing Aluminum Pipes

- Induction Brazing copper wire to copper cylinder

- Induction Heating Drum Coal Slime Dryer-River Sand...

- Induction Heating Drum Coal Slime Dryer-River Sand...

- Induction Soldering Brass Tube-Pipe

- Induction Heat Treating Surface Process

- Handheld Brazing Stainless Steel Tube

- Technology of Induction Forming Steel Plate

- Advantages of Induction Heating

- What Is Induction Melting?

- induction hardening process

- induction heating nanoparticle solution

-

▼

二月

(174)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.