The principle of induction steam boiler|

induction steam generator|induction heating steam boiler

This invention relates to an induction steram boiler|electromagnetic induction steam generator which operates with a low-frequency alternating current electric power source. More specifically, this invention relates to an electromagnetic induction steam boiler which is compact and highly efficient being capable of continuous operation, intermittent operation and empty-heating operation.Steamers in current use, such as cooking steamers, convection ovens, cooking steam warmers, steamers for defrosting frozen food, steamers for processing tea leaves, steam baths for household use, steamers for cleaning, and steamers used in restaurants and hotels, are widely used as equipment for utilizing the steam they generate.Generally, fossil fuels (gas, petroleum, crude petroleum, coal and so forth) are burned as heat sources for large steamers in current use. This heating method, however, is not economical for compact steamers.

Relatively compact steamers in current use commonly employ electrical resistance heaters as a heat source. Such steamers obtain steam intermittently by spraying water on an iron plate which has been heated in advance with a heater or the heater's protecting tube from inside or beneath the plate.

Energy saving rate of electromagnetic induction steam boiler:

Because the iron container heats itself, the heat conversion rate is particularly high, which can reach more than 95%; the working principle of electromagnetic steam generator is that when some water enters the container, it will be heated into steam Drain, to ensure a fixed way of replenishing water, there will be continuous steam utilization.

Product Description

Industrial quality high pressure induction steamist boiler pure steam generator from china manufacturers 1) LCD Full-Automatically Intelligent Electronic Control System 2) High-quality Core Component——Electromagnetic induction heater 3) High-quality Components and Parts——Famous Brand Delixi Electrical Appliance 4) Multiple Safety Interlock Protection 5) Scientific Design and Attractive Appearance 6) Easy and Rapid Installation 7) Magnetic induction coil heat up boiling water Generate steam - Is Much More Eco-Friendly and Economical 8) Wide Application Range| Item content / model | Rated power (KW) | Rated steam temperature (℃) | Rated current (A) | Rated steam pressure (mpa) | Evaporation (kg/h) | Thermal efficiency (%) | Input voltage (V/HZ) | Cross section of input power cord (MM2) | Steam outlet diameter | Relief valve diameter | Inlet diameter | Drainage diameter | Overall dimensions (mm) |

| HLQ-10 | 10 | 165 | 15 | 0.7 | 14 | 97 | 380/50HZ | 2.5 | DN20 | DN20 | DN15 | DN15 | 450*750*1000 |

| HLQ-20 | 20 | 165 | 30 | 0.7 | 28 | 97 | 380/50HZ | 6 | DN20 | DN20 | DN15 | DN15 | 450*750*1000 |

| HLQ-30 | 30 | 165 | 45 | 0.7 | 40 | 97 | 380/50HZ | 10 | DN20 | DN20 | DN15 | DN15 | 650*950*1200 |

| HLQ-40 | 40 | 165 | 60 | 0.7 | 55 | 97 | 380/50HZ | 16 | DN20 | DN20 | DN15 | DN15 | 780*950*1470 |

| HLQ-50 | 50 | 165 | 75 | 0.7 | 70 | 97 | 380/50HZ | 25 | DN20 | DN20 | DN15 | DN15 | 780*950*1470 |

| HLQ-60 | 60 | 165 | 90 | 0.7 | 85 | 97 | 380/50HZ | 25 | DN20 | DN20 | DN15 | DN15 | 780*950*1470 |

| HLQ-80 | 80 | 165 | 120 | 0.7 | 110 | 97 | 380/50HZ | 35 | DN25 | DN20 | DN15 | DN15 | 680*1020*1780 |

| HLQ-100 | 100 | 165 | 150 | 0.7 | 140 | 97 | 380/50HZ | 50 | DN25 | DN20 | DN25 | DN15 | 1150*1000*1730 |

| HLQ-120 | 120 | 165 | 180 | 0.7 | 165 | 97 | 380/50HZ | 70 | DN25 | DN20 | DN25 | DN15 | 1150*1000*1730 |

| HLQ-160 | 160 | 165 | 240 | 0.7 | 220 | 97 | 380/50HZ | 95 | DN25 | DN20 | DN25 | DN15 | 1150*1000*1880 |

| HLQ-240 | 240 | 165 | 360 | 0.7 | 330 | 97 | 380/50HZ | 185 | DN40 | DN20 | DN40 | DN15 | 1470*940*2130 |

| HLQ-320 | 320 | 165 | 480 | 0.7 | 450 | 97 | 380/50HZ | 300 | DN50 | DN20 | DN50 | DN15 | 1470*940*2130 |

| HLQ-360 | 360 | 165 | 540 | 0.7 | 500 | 97 | 380/50HZ | 400 | DN50 | DN20 | DN50 | DN15 | 2500*940*2130 |

| HLQ-480 | 480 | 165 | 720 | 0.7 | 670 | 97 | 380/50HZ | 600 | DN50 | DN20 | DN50 | DN15 | 3150*950*2130 |

| HLQ-640 | 640 | 165 | 960 | 0.7 | 900 | 97 | 380/50HZ | 800 | DN50 | DN20 | DN50 | DN15 | 2500*950*2130 |

| HLQ-720 | 720 | 165 | 1080 | 0.7 | 1000 | 97 | 380/50HZ | 900 | DN50 | DN20 | DN50 | DN15 | 3150*950*2130 |

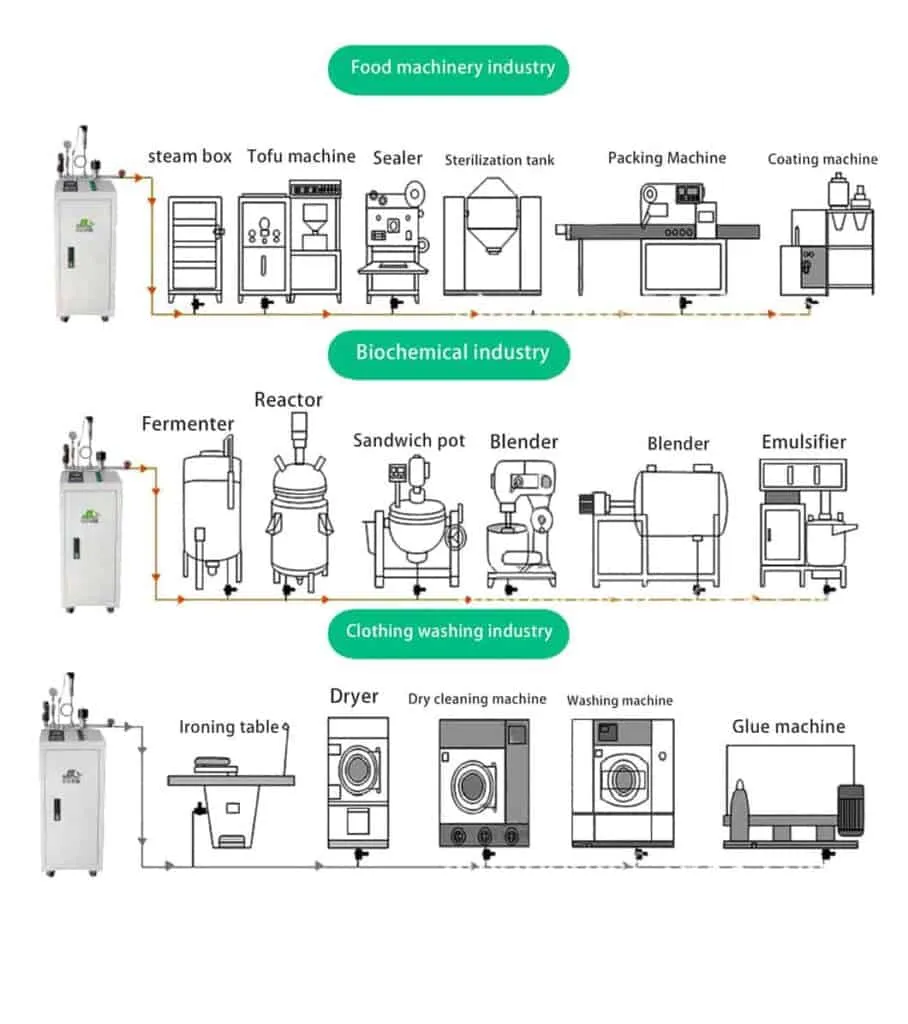

Application of induction steam generator|induction heating steam boiler:

Application of induction steam generator|induction heating steam boiler: