induction surface hardening steel screws

Objective:

Rapid surface induction hardening steel screws

Material: Steel screws .25” (6.3mm) diameter

Temperature: 932 ºF (500 ºC)

Frequency: 344 kHz

Equipment

• DW-UHF-10kW induction heating system, equipped with a remote workhead containing two 0.3μF capacitors for a total of 0.17μF

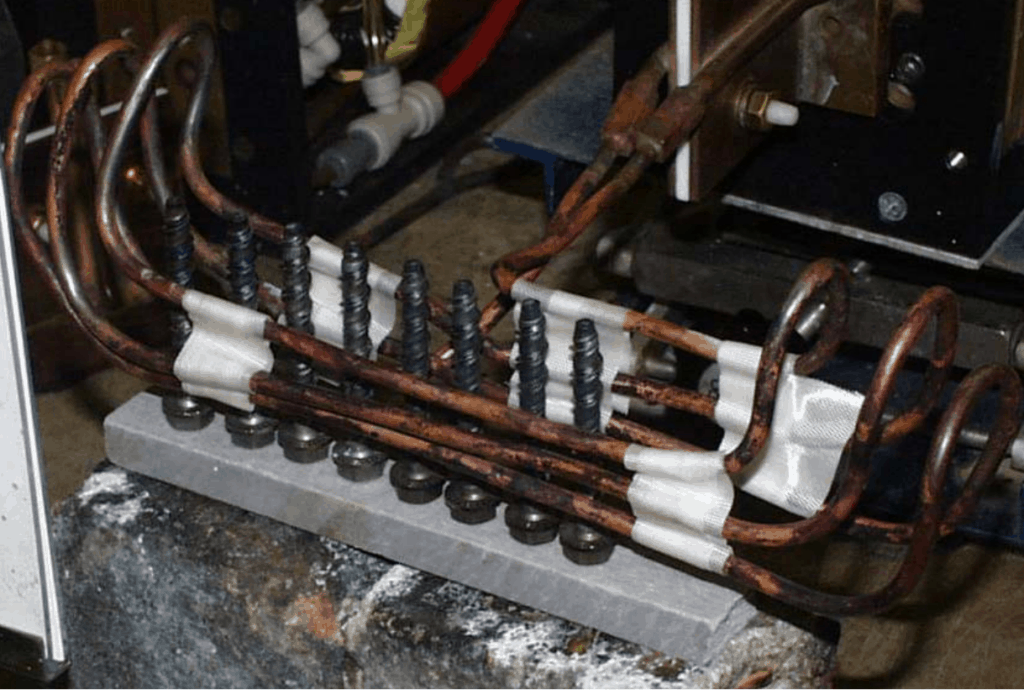

• An induction heating coil designed and developed specifically for this application.

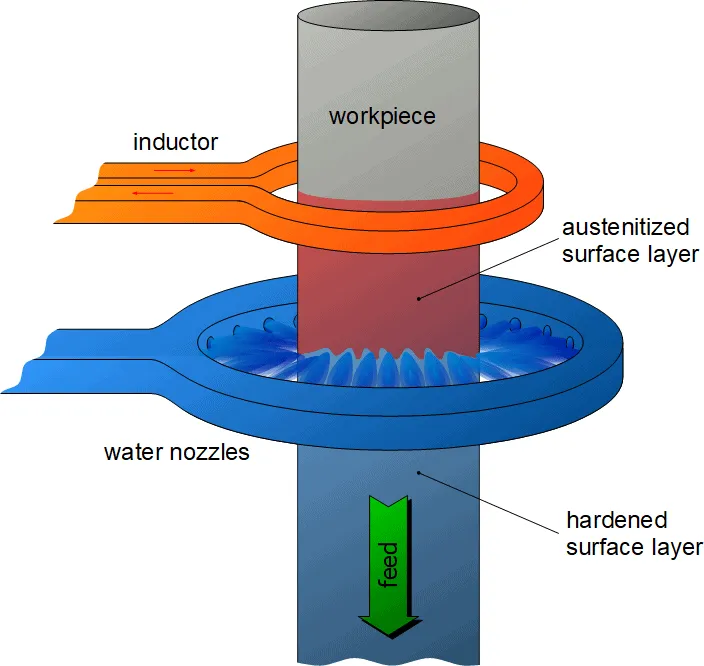

Induction Hardening Process

A three turn channel coil is used to heat 9 screws at a time.

Power is applied for 3 seconds to reach 932 ºF (500 ºC) and achieve the required hardness. The screws travel through the coil head down in an automated system at a rate of 200 screws per minute

Results/Benefits Induction heating provides:

• Precise application of heat

• Faster process time and production rates

• Ability to incorporate into existing production lines

• Repeatable, consistent results