Coil springs or leaf springs are made by thermal deformation of steel profiles. Because of the characteristics of spring steel, there are certain requirements for heating temperature and time during the heating process. Except the preheating before rolling into spring coils or forging press into leaf springs, there are also other requests of different heat treatment, such as spring rod wire annealing, and steel panel induction surface hardening. Having the characteristics of rapid heating, fast shut down, accurate power output control, and varies frequency ranges, HLQ's induction heating power supply is very suitable for thermal deformation heating of spring steel, especially in the auto parts industry involving leaf springs or load-bearing spring manufacturing plants. Designed by the professionals at HLQ, our induction heating devices are all well-equipped with the advantages of energy-saving, fast start/stop, 24 hours duty cycle time, high power-point, high automation, high efficiency, easy maintenance, and long use life. Our induction heaters have been widely recognized by customers in the spring steel production industry.

Coil springs or leaf springs are made by thermal deformation of steel profiles. Because of the characteristics of spring steel, there are certain requirements for heating temperature and time during the heating process. Except the preheating before rolling into spring coils or forging press into leaf springs, there are also other requests of different heat treatment, such as spring rod wire annealing, and steel panel induction surface hardening. Having the characteristics of rapid heating, fast shut down, accurate power output control, and varies frequency ranges, HLQ's induction heating power supply is very suitable for thermal deformation heating of spring steel, especially in the auto parts industry involving leaf springs or load-bearing spring manufacturing plants. Designed by the professionals at HLQ, our induction heating devices are all well-equipped with the advantages of energy-saving, fast start/stop, 24 hours duty cycle time, high power-point, high automation, high efficiency, easy maintenance, and long use life. Our induction heaters have been widely recognized by customers in the spring steel production industry.

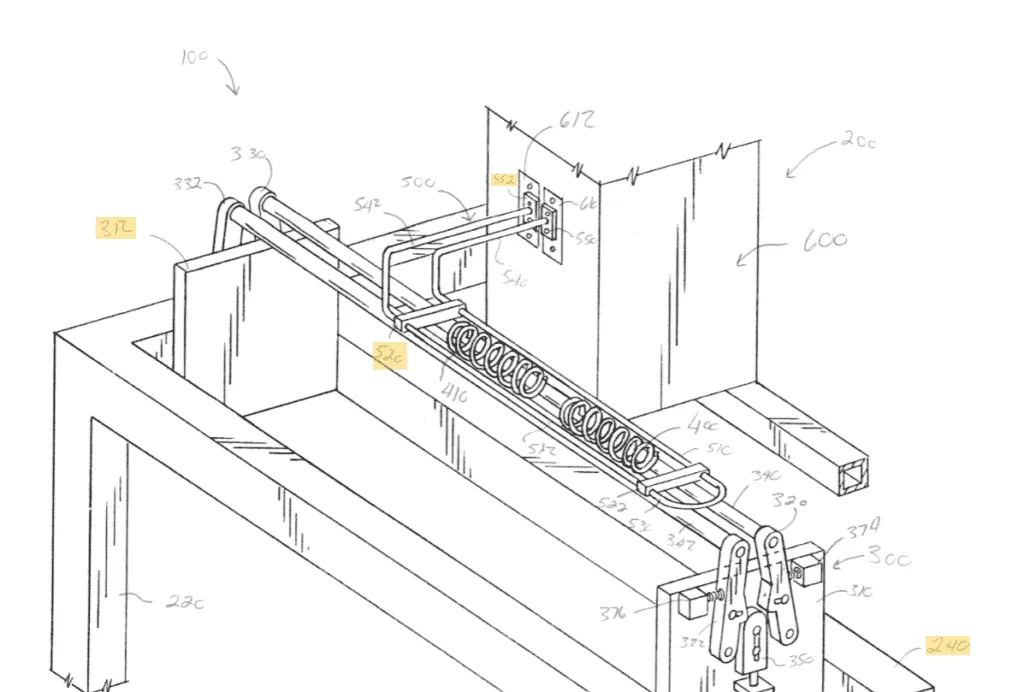

The metal induction hardening process is a standard process used in spring fabrication. One common hardening process consists of a traditional atmospheric furnace. Such hardening processes are very slow. Springs can be formed from a variety of metals (e.g., stainless steel, carbon steel, alloy steel, etc.). When the metal of the spring is properly hardened and tempered, specific metallurgical parameters such as hardness and micro-structure can be attained.

When a spring is hardened by a traditional atmospheric furnace, the spring is first placed in an oven set at a certain temperature for a particular period of time. Thereafter, the spring is removed and quenched in oil or some other quenching liquid. After this initial hardening process, the spring hardness is generally higher than desired. As such, the spring is generally subjected to a tempering process until the spring obtains the desired physical properties. When the spring is properly processed, some of the crystalline structure of the steel is changed to tempered martensite with much of the carbides dissolved so as to provide the desired core structure of the spring and desired surface hardness of the spring.

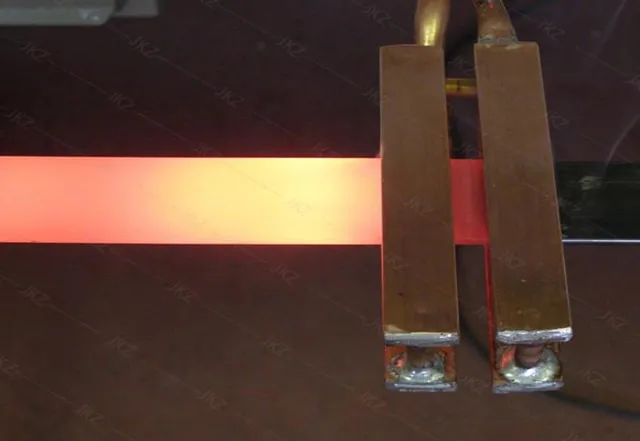

Another process that is used for hardening springs is induction heating. The induction heating process occurs by inducing an electromagnetic field in a conductive material of the spring. Eddy currents are generated within the conductive material whose resistance leads to Joule heating. Induction heating can be used to heat steel to its melting point if need be which is more than sufficient to austenitize the product.

The induction heating process can provide a faster heating cycle time than heating by traditional atmospheric furnaces, and the induction heating process can simplify the material handling of the springs, and can potentially enable automation of the material handling of the spring in the hardening process. Although induction heating has several advantages over traditional atmospheric furnaces, induction heating of springs has problems with evenly heating the spring throughout spring length, overheating the ends of the spring, and the maintaining of induction heating coil efficiency.