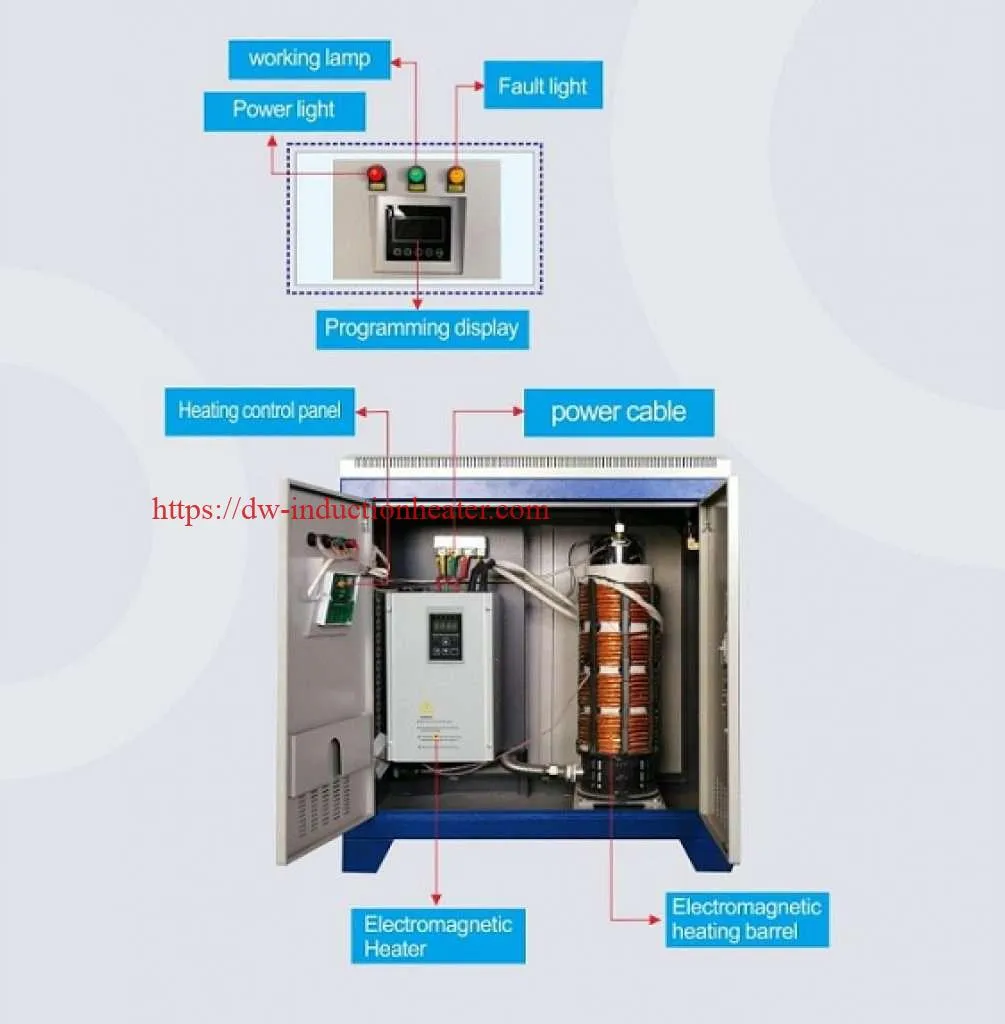

Industrial Hot Water Heating Boiler With Electromagentic Induction-Hot Water Heating Boiler Generator

Industrial Hot Water Boiler with Electromagnetic Induction

Parameter

Parameter

|

Items |

Unit |

60KW |

80KW |

100KW |

120KW |

160KW |

180KW |

240KW |

240KW-F |

360KW |

| Rated power |

kW |

60 |

80 |

100 |

120 |

160 |

180 |

240 |

240 |

360 |

| Rated current |

A |

90 |

120 |

150 |

180 |

240 |

270 |

360 |

540 |

540 |

| Voltage/Frequency |

V/H z |

380/50-60 |

| Cross section area of power cable |

mm ² |

≥25 |

≥35 |

≥50 |

≥70 |

≥120 |

≥150 |

≥185 |

≥185 |

≥240 |

| Heating efficiency |

% |

≥98 |

≥98 |

≥98 |

≥98 |

≥98 |

≥98 |

≥98 |

≥98 |

≥98 |

| Max. pressure of heating |

Mp a |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

| Min. flow of pump |

L/m in |

72 |

96 |

120 |

144 |

192 |

216 |

316 |

336 |

384 |

| Expansion tank volume |

L |

60 |

80 |

80 |

120 |

160 |

180 |

240 |

240 |

320 |

| Max. heating temperature |

℃ |

85 |

85 |

85 |

90 |

90 |

90 |

90 |

90 |

90 |

| Temperature of low temperature protection |

℃ |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

| 65ºC hot water output |

L/m |

19.5 |

26 |

26 |

39 |

52 |

58.5 |

78 |

78 |

104 |

| Dimensions |

mm |

1000*650*

1480 |

1000*650*

1480 |

1100*1000*

1720 |

1100*1000*

1720 |

1100*1000*

1720 |

1315*1000*

1910 |

1315*1000*

1910 |

1720*1000*

1910 |

1720*1000*

1910 |

|

| Inlet/outlet connection |

DN |

50 |

50 |

65 |

65 |

65 |

80 |

80 |

100 |

100 |

|

| Heating area |

m² |

480-720 |

720-960 |

860-1100 |

960-1440 |

1280-1920 |

1440-2160 |

1920-2880 |

1920-2880 |

2560-3840 |

|

| Heat dissipation of enclosure |

% |

≤2 |

≤2 |

≤2 |

≤2 |

≤2 |

≤2 |

≤2 |

≤2 |

≤2 |

|

| Max. volume of heating |

L |

1100 |

1480 |

1840 |

2200 |

2960 |

3300 |

4400 |

4400 |

5866 |

|

| Heating space |

m³ |

1920-2400 |

2560-3200 |

2560-3200 |

4150-5740 |

6000-8000 |

6300-8550 |

8300-11480 |

8300-11480 |

11040-

15300 |

|

| Electric meter |

A |

3-phase power meter 1.5-1.6A, metering transformer needs to be installed rationally by professional personnel |

|

| Protection grade |

IP |

33 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

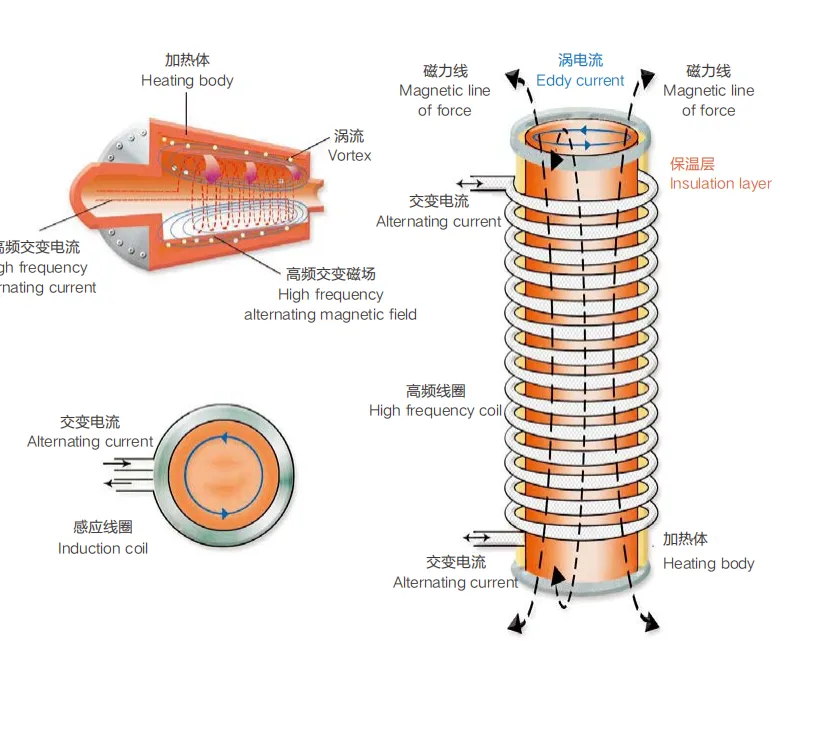

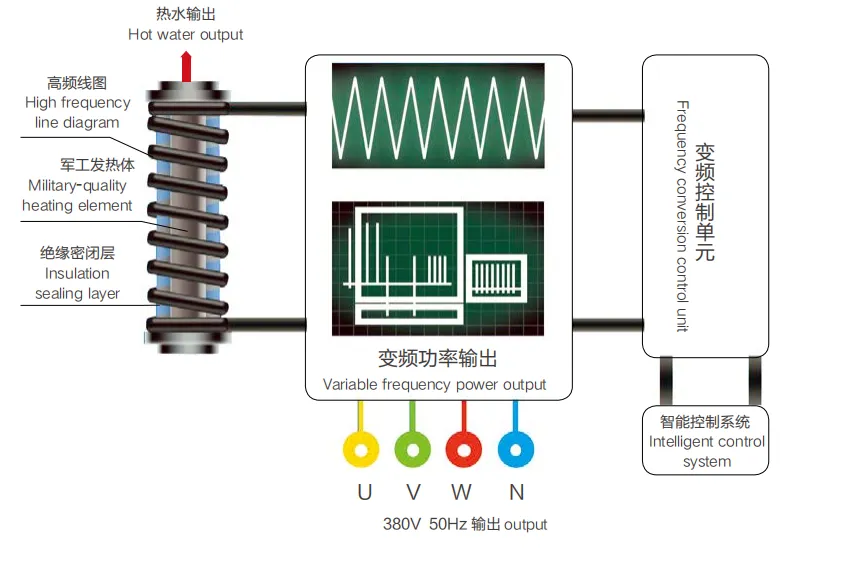

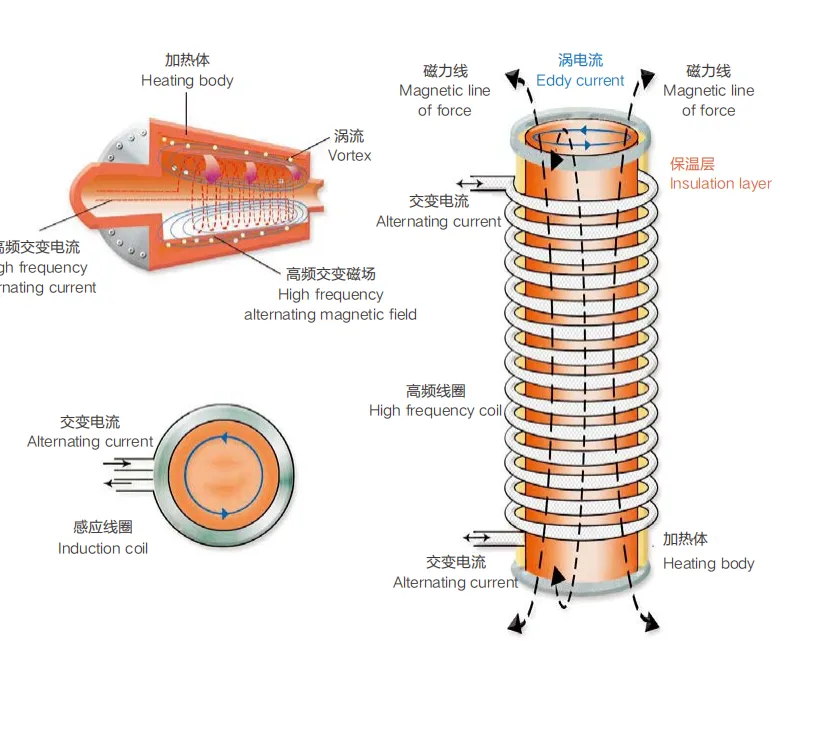

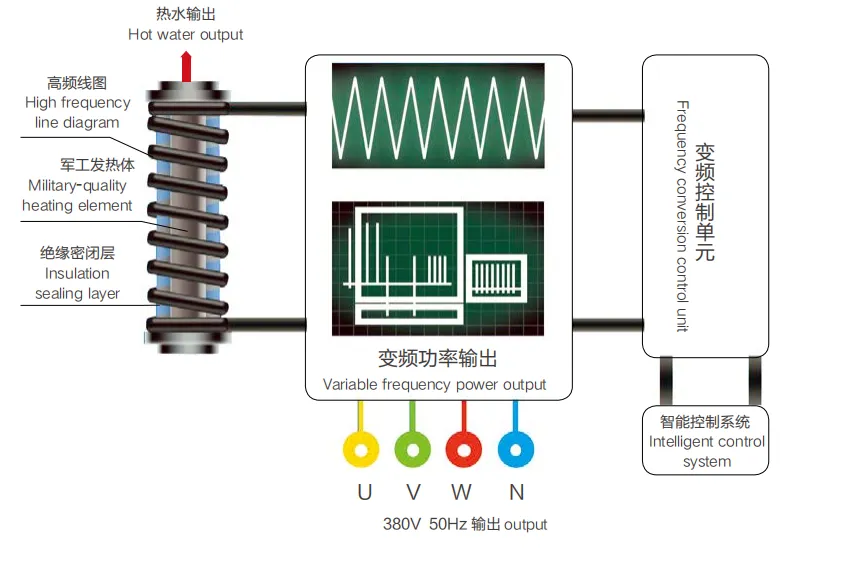

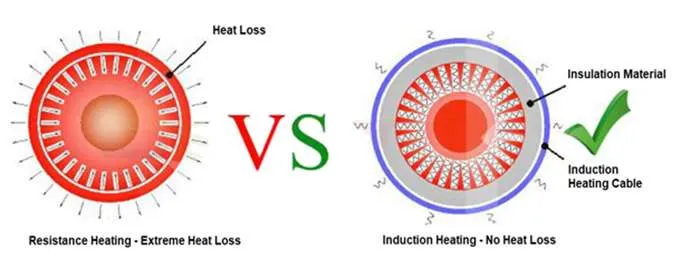

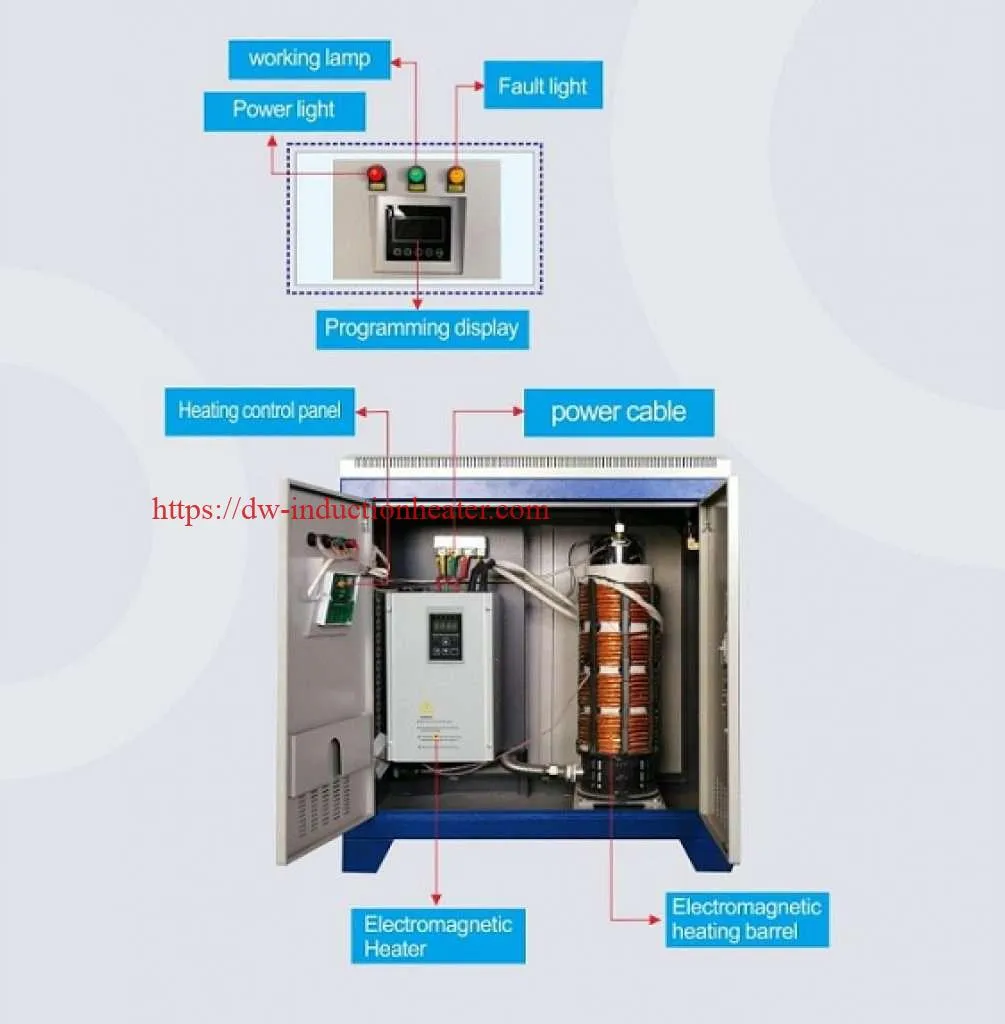

The Principle of Induction Heating Hot Water Boiler

Features

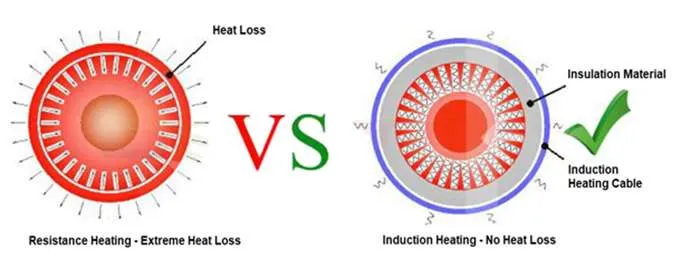

1.Energy Saving

Features

1.Energy Saving

When the indoor temperature exceeds the pre-set value, the central heating boiler will be automatically turned off, thus efficiently saving more than 30% energy. And it can save energy by 20% in comparison with traditional boilers that use resistance heating method.Constant Temperature and Comfortable Space

Water temperature can be controlled within a range of 5~90ºC, and the precision of temperature control can reach ±1ºC, providing a comfortable atmosphere for your space. Unlike air conditioning equipment, induction heating does not create an ideal environment for bacteria to grow.

2.No Noise

2.No Noise

In contrast to central heating boilers using air cooling method, water cooled heating boilers are more quiet and unobtrusive.

3.Safe Operation

3.Safe Operation

Utilizing induction heating achieves separation of electricity and water, providing a safer operation. Besides, multiple protection functions such as antifreeze protection, electricity leakage protection, short circuit protection, phase loss protection, overheating protection, overcurrent protection, overvoltage protection, undervoltage protection, self-inspection protection are equipped. Safe usage is guaranteed for 10 years.

4.Intelligent Control

4.Intelligent Control

Our induction water heating boilers can be WIFI remotely controlled by smart phones.

5.Easy to Maintain

5.Easy to Maintain

Induction heating do not constitute the condition of fouling, eliminating the need for fouling removing treatment.

FAQ

Please Contact Our Customer Service before Make a Purchase

FAQ

Please Contact Our Customer Service before Make a Purchase

About Choosing Appropriate Power

Choosing a suitable boiler based on your actual heating area

For low-energy buildings, 60~80W/m² boilers are suitable;

For general buildings, 80~100W/m² boilers are suitable;

For villas and bungalows, 100~150W/m² boilers are suitable;

For those buildings where sealing performance is not well and room height is greater than 2.7m or people frequently enter, the building heat load is correspondingly increased and the power of central heating boiler should be higher.

About Installation Conditions

What are installation conditions

Take a 15kW induction central heating boiler as an example:

The cross section are of main power cable should not be less than 6mm3, main switch 32~45A, voltage 380V/50, minimum water flow of pump is 25L/min, the water pump needs to be selected according to building height.

About Accessories

About Accessories

What accessories are required

Since every installation site of customer is different, so that various accessories are required. We only provide central heating boilers, other accessories such as pump valve, piping and union connectors need to be purchased by customers.

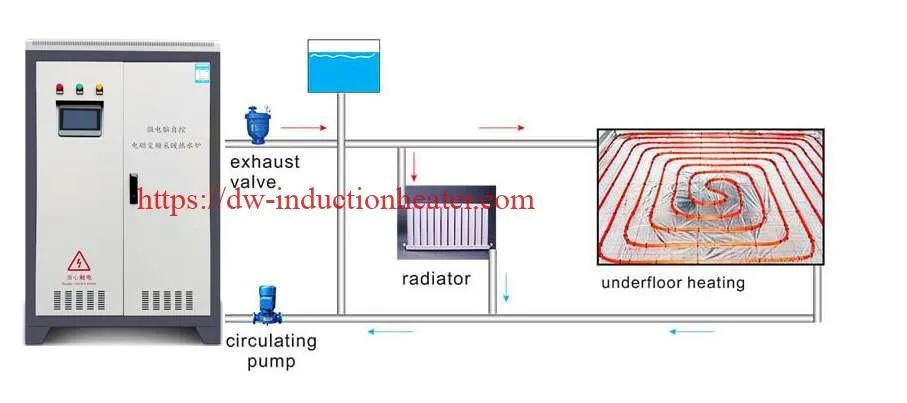

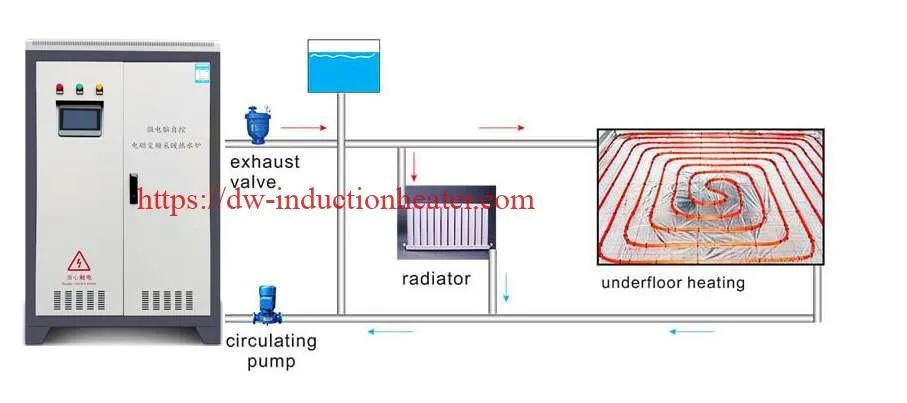

About Connections For Heating

What are applicable connections for heating

HLQ’s induction central heating boilers can be flexibly connected to floor heating system, radiator, hot water storage tank, fan coil unit (FCU), etc.

About Installation Service

Our products can be installed by our authorized local dealers. We also accept advance reservation, and we designate engineers to offer installation service and technical guidance on site.

About Logistics

Shipping time and logistic distribution

We promise to ship our ready-to-ship products within 24 hours, and ship our made-to-order products within 7-10 days. And the logistics service is based on customers’ requirements.

About Service Life

How long is this product’s service life

HLQ’s induction central heating boiler adopts high-frequency induction coil and industrial grade inverter, all key parts are made of imported high grade materials, its service life can reach 15 years or more.

Parameter

Parameter

Features

1.Energy Saving

When the indoor temperature exceeds the pre-set value, the central heating boiler will be automatically turned off, thus efficiently saving more than 30% energy. And it can save energy by 20% in comparison with traditional boilers that use resistance heating method.Constant Temperature and Comfortable Space

Features

1.Energy Saving

When the indoor temperature exceeds the pre-set value, the central heating boiler will be automatically turned off, thus efficiently saving more than 30% energy. And it can save energy by 20% in comparison with traditional boilers that use resistance heating method.Constant Temperature and Comfortable Space Water temperature can be controlled within a range of 5~90ºC, and the precision of temperature control can reach ±1ºC, providing a comfortable atmosphere for your space. Unlike air conditioning equipment, induction heating does not create an ideal environment for bacteria to grow.

Water temperature can be controlled within a range of 5~90ºC, and the precision of temperature control can reach ±1ºC, providing a comfortable atmosphere for your space. Unlike air conditioning equipment, induction heating does not create an ideal environment for bacteria to grow.

2.No Noise

In contrast to central heating boilers using air cooling method, water cooled heating boilers are more quiet and unobtrusive.

2.No Noise

In contrast to central heating boilers using air cooling method, water cooled heating boilers are more quiet and unobtrusive.

3.Safe Operation

Utilizing induction heating achieves separation of electricity and water, providing a safer operation. Besides, multiple protection functions such as antifreeze protection, electricity leakage protection, short circuit protection, phase loss protection, overheating protection, overcurrent protection, overvoltage protection, undervoltage protection, self-inspection protection are equipped. Safe usage is guaranteed for 10 years.

3.Safe Operation

Utilizing induction heating achieves separation of electricity and water, providing a safer operation. Besides, multiple protection functions such as antifreeze protection, electricity leakage protection, short circuit protection, phase loss protection, overheating protection, overcurrent protection, overvoltage protection, undervoltage protection, self-inspection protection are equipped. Safe usage is guaranteed for 10 years.

4.Intelligent Control

Our induction water heating boilers can be WIFI remotely controlled by smart phones.

4.Intelligent Control

Our induction water heating boilers can be WIFI remotely controlled by smart phones.

5.Easy to Maintain

Induction heating do not constitute the condition of fouling, eliminating the need for fouling removing treatment.

5.Easy to Maintain

Induction heating do not constitute the condition of fouling, eliminating the need for fouling removing treatment.

FAQ

Please Contact Our Customer Service before Make a Purchase

About Choosing Appropriate Power

Choosing a suitable boiler based on your actual heating area

For low-energy buildings, 60~80W/m² boilers are suitable;

For general buildings, 80~100W/m² boilers are suitable;

For villas and bungalows, 100~150W/m² boilers are suitable;

For those buildings where sealing performance is not well and room height is greater than 2.7m or people frequently enter, the building heat load is correspondingly increased and the power of central heating boiler should be higher.

About Installation Conditions

What are installation conditions

Take a 15kW induction central heating boiler as an example:

The cross section are of main power cable should not be less than 6mm3, main switch 32~45A, voltage 380V/50, minimum water flow of pump is 25L/min, the water pump needs to be selected according to building height.

FAQ

Please Contact Our Customer Service before Make a Purchase

About Choosing Appropriate Power

Choosing a suitable boiler based on your actual heating area

For low-energy buildings, 60~80W/m² boilers are suitable;

For general buildings, 80~100W/m² boilers are suitable;

For villas and bungalows, 100~150W/m² boilers are suitable;

For those buildings where sealing performance is not well and room height is greater than 2.7m or people frequently enter, the building heat load is correspondingly increased and the power of central heating boiler should be higher.

About Installation Conditions

What are installation conditions

Take a 15kW induction central heating boiler as an example:

The cross section are of main power cable should not be less than 6mm3, main switch 32~45A, voltage 380V/50, minimum water flow of pump is 25L/min, the water pump needs to be selected according to building height.

About Accessories

What accessories are required

Since every installation site of customer is different, so that various accessories are required. We only provide central heating boilers, other accessories such as pump valve, piping and union connectors need to be purchased by customers.

About Connections For Heating

What are applicable connections for heating

HLQ’s induction central heating boilers can be flexibly connected to floor heating system, radiator, hot water storage tank, fan coil unit (FCU), etc.

About Installation Service

Our products can be installed by our authorized local dealers. We also accept advance reservation, and we designate engineers to offer installation service and technical guidance on site.

About Logistics

Shipping time and logistic distribution

We promise to ship our ready-to-ship products within 24 hours, and ship our made-to-order products within 7-10 days. And the logistics service is based on customers’ requirements.

About Service Life

How long is this product’s service life

HLQ’s induction central heating boiler adopts high-frequency induction coil and industrial grade inverter, all key parts are made of imported high grade materials, its service life can reach 15 years or more.

About Accessories

What accessories are required

Since every installation site of customer is different, so that various accessories are required. We only provide central heating boilers, other accessories such as pump valve, piping and union connectors need to be purchased by customers.

About Connections For Heating

What are applicable connections for heating

HLQ’s induction central heating boilers can be flexibly connected to floor heating system, radiator, hot water storage tank, fan coil unit (FCU), etc.

About Installation Service

Our products can be installed by our authorized local dealers. We also accept advance reservation, and we designate engineers to offer installation service and technical guidance on site.

About Logistics

Shipping time and logistic distribution

We promise to ship our ready-to-ship products within 24 hours, and ship our made-to-order products within 7-10 days. And the logistics service is based on customers’ requirements.

About Service Life

How long is this product’s service life

HLQ’s induction central heating boiler adopts high-frequency induction coil and industrial grade inverter, all key parts are made of imported high grade materials, its service life can reach 15 years or more.