2023年1月3日星期二

Induction Preheating Hot Rod Heading

Induction Preheating Hot Rod Heading With IGBT Heating Units

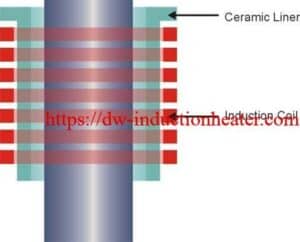

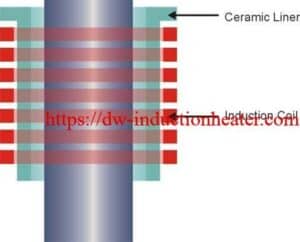

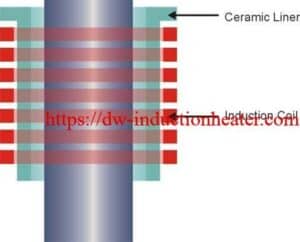

Objective Heat a waspaloy rod to 1500ºF (815.5ºC) for hot heading application

Material Waspaloy rod 0.5” (12.7mm)OD, 1.5” (38.1mm) length, ceramic liner

Temperature 1500 ºF (815.5ºC)

Frequency 75 kHz

Equipment • DW-HF- 20 kW induction heating system, equipped with a remote workhead containing two 1.32μF capacitors for a total of .66μF

• An induction heating coil designed and developed specifically for this application.

Process A seven turn helical coil is used to heat the rod. The rod is placed inside the coil and power is applied for two seconds

providing enough heat to penetrate the inner core. An optical pyrometer is used for close loop temperature control and a

ceramic liner is used so the rod does not touch the coil.

Results/Benefits Induction heating provides:

• Low pressure and minimal residual stress

• Better grain flow and microstructure

• Even distribution of heating

• Improved production rates with minimal defects

关注者

博客归档

-

▼

2023

(1696)

-

▼

一月

(174)

- Brazing Carbide-Steel Tool with Induction

- Induction Brazing Copper Pipe Fittings

- induction brazing stainless steel to steel

- Induction inline wire heating process

- induction coating removal for removing paint

- induction brazing stainless steel to steel

- Brazing Copper Bars with Induction

- Brazing Carbide Tool Tips With Induction

- Soldering Steel To Brass With Induction Heater

- induction Brazing copper rods to brass strips

- RF Soldering Circuit Board

- Induction Heating Steel Mold

- Induction inline wire heating process

- Induction Soldering Circuit Board

- Induction Brazing Heating Exchanger Copper Pipes

- Technology of Induction Forming Steel Plate

- induction heating diffusion pump with electromagne...

- Induction Shrink Fitting Steel Tube

- Induction Brazing Steel Parts to Tungsten Carbide ...

- Hydrogen Atmosphere Brazing Tube To Copper With In...

- Induction Heating Theory PDF

- Induction Annealing Copper Tubes

- Induction Billets Heater Video

- induction Brazing copper rods to brass strips

- induction sealing glass

- Induction Annealing Copper Tubes

- Induction Shrink Fitting Assemblies

- Brazing Copper Bars with Induction

- Induction Brazing Carbide Tipping of Medical Tools

- High Frequency Induction Cap Sealing

- induction brazing copper and brass rods

- Induction Soldering Stainless Steel Tubes to Brass...

- induction hardening steel handheld stamps

- induction coating removal for removing paint

- induction curing

- Induction Aluminum Brazing with Computer Assisted

- induction brazing automotive copper heating exchan...

- Induction Heating Bolts

- Induction Brazing Steel Pipe

- aluminum scrap melting induction furnace

- Induction Annealing Brass Bullet Shells

- Induction Heating Plastic Catheter Tube

- Induction stress relieving flat blanks

- Plastic Injection Molding with Induction Heating

- What is induction tempering?

- Induction Brazing Carbide Onto Steel Part

- Brazing Carbide To Steel Shank

- Melting Aluminum Tilting Crucible Induction Furnace

- Induction Heating Wires For Hot Heading

- Induction Heating Solutions For Cancer Research

- induction small copper tubing brazing connection j...

- Aluminum Billet Heating Furnace

- induction brazing steel carbide cap to shaft

- Induction Brazing Copper Tube For Refrigeration

- Induction Soldering Brass Tube-Pipe

- induction hardening steel handheld stamps

- Brazing Carbide To Steel With Induction

- Induction Heating Steel Mold

- Annealing Metal Stamp With Induction

- Induction Heating Steel Part For Hot Heading

- Induction brazing aluminum pipes

- steel plate-shovels hot forming with induction pre...

- Aluminum Scrap Melting Recycling Induction Furnace

- Induction Heating Solutions For Cancer Research

- Induction Heating Automotive Motor

- refrigeration induction brazing refrigerator coppe...

- Induction brazing aluminum pipes

- Induction Hardening Inner

- High Frequency Welding

- Brazing Copper Tube with Induction

- Induction Hot Forming Steel Pipe

- Induction Brazing Principle-Theory

- Induction Preheating Steel Tubes

- Brazing Brass To Copper With Induction

- high frequency induction soldering wire to connector

- How Induction Heating works?

- induction heating for surface quenching of steel

- induction brazing stainless steel to steel

- Induction Heating Sintering Copper Powder

- RPR Induction Pipeline Coating Removal

- Brazing Brass To Copper With Induction

- induction heating steel cable for cutting

- Induction Soldering Circuit Board

- induction brazing copper and brass rods

- Brazing Carbide-Steel Tool with Induction

- Induction Heating Coils Design and Basic PDF

- INDUCTION HEATING FOR SURFACE QUENCHING

- Induction Brazing Principle-Theory

- Brazing Eyeglass Frames With Induction

- Induction Soldering Aluminum Housing

- Induction Melting Furnace with Manual Tilting Device

- induction heating system technology PDF

- Induction hardening steel screw threads

- Induction Brazing Carbide to Steel

- induction preheating titanium billet for rolling

- brazing short circuit rings with induction heater

- Induction Soldering Copper Pipes to PCB Board

- Induction Soldering Brass Rings

- Induction Soldering Brass Tube-Pipe

- Induction Heating Stainless Steel

-

▼

一月

(174)

我的简介

- HLQ induction heating machine

- HLQ induction heating machine manufacturer provides the service of induction brazing,melting,hot forming,hardening surface,annealing,shrink fitting,PWHT,etc.