induction heating diffusion pump with electromagnetic heater

Induction Heating diffusion pump-Vacuum coating diffusion pump electromagnetic induction heater instead of resistance heating plate can save how much electricity?

The traditional diffusion pump is slow to warm up, and also has broken wires, easy to short circuit, low reliability, and easy failure. It brings a lot of inconvenience to the actual operation. For this reason, HLQ has specially developed a special

electromagnetic induction heater for diffusion pump, which consumes 7-8 kWh of electricity per hour after transformation. The time is shortened by more than half, and the operation is convenient, the installation is easy, and the style is novel, which may bring good news to the vacuum coating industry.

Electromagnetic induction heating is a way of heating the body itself by converting electrical energy into magnetic energy. Electromagnetic induction heating cable disk directly ACTS on the bottom of the pump through induction to generate a magnetic field, so that the pump generates heat itself. The electromagnetic furnace plate does not generate heat, the thermal conversion efficiency reaches more than 98%, the temperature control is accurate, PID can automatically adjust the power.

Advantages of diffusion pump electromagnetic induction heating over resistance wire heating:

Advantages of diffusion pump electromagnetic induction heating over resistance wire heating:

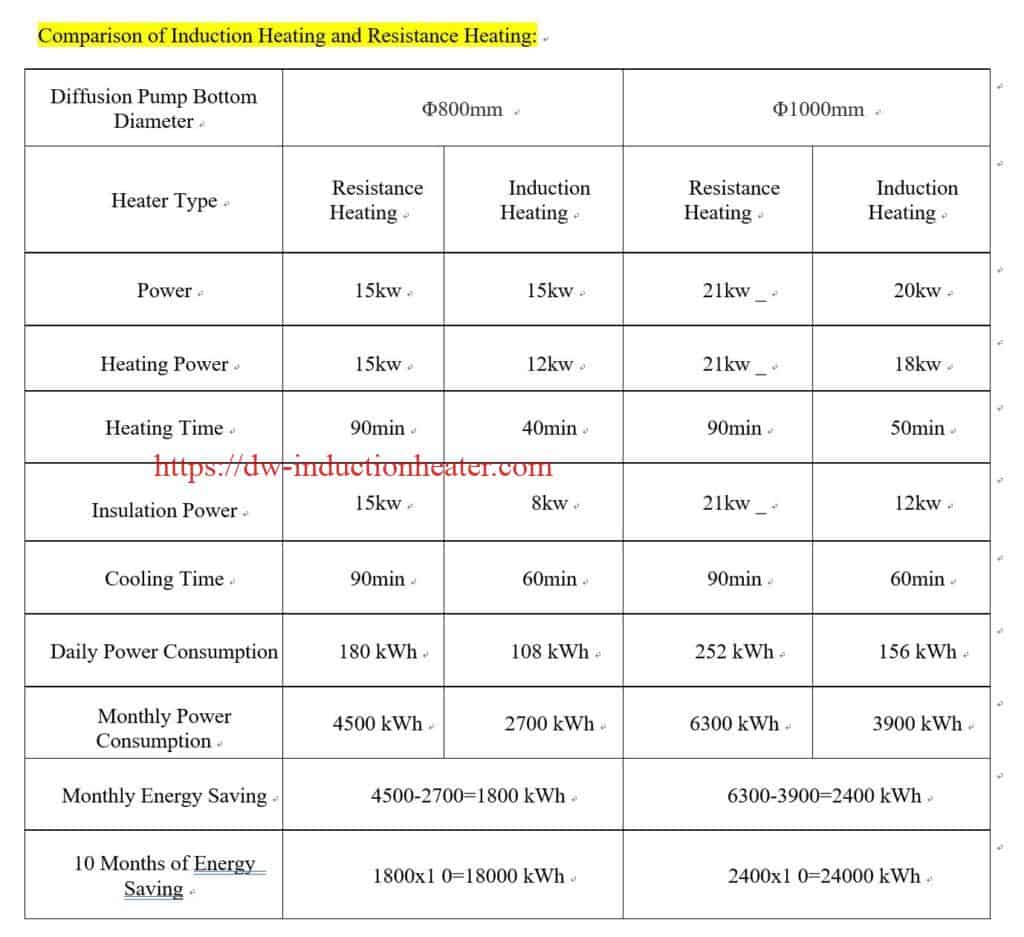

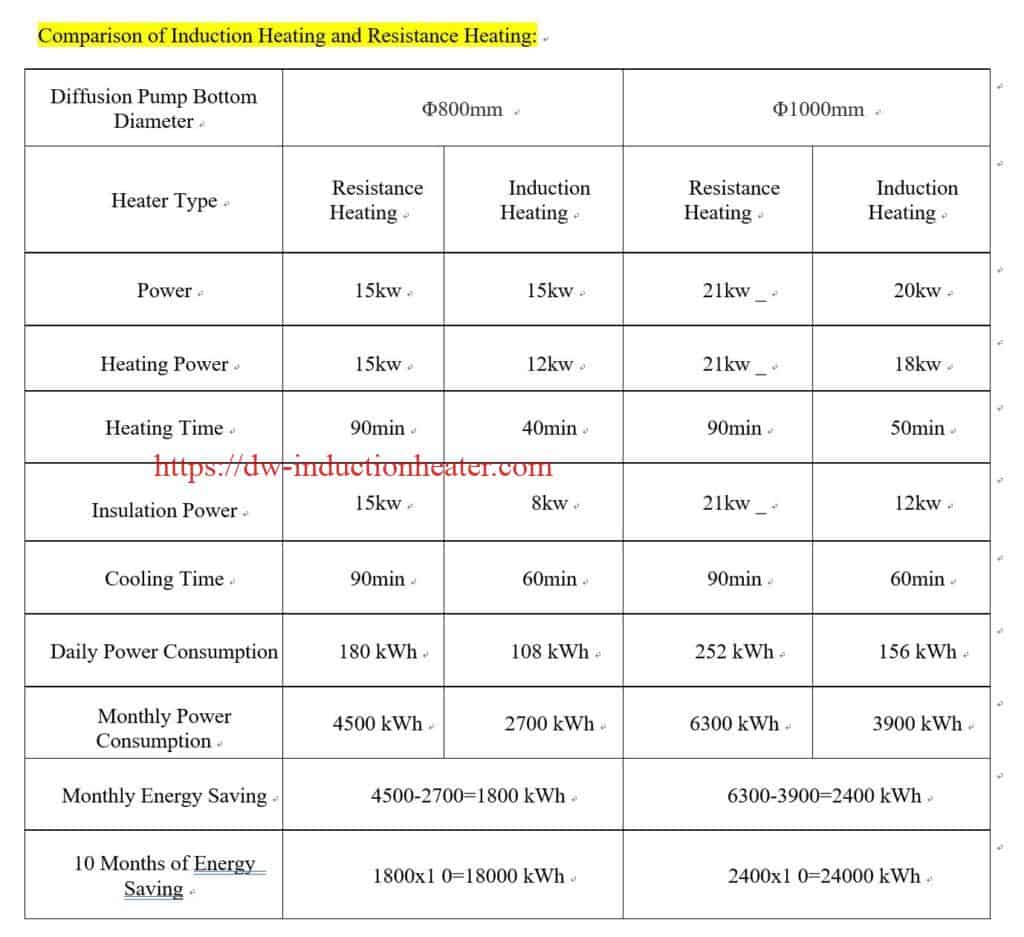

(1) high efficiency and energy saving, saving more than 30% electricity than resistance wire heating.

(2) fast heating speed and even heating.

(3) stable operation and accurate temperature control

(4) easy operation and long service life

At room temperature, it takes 70-90 minutes for a traditional 15kw resistance wire for a diffusion pump with a diameter of 830mm to rise to 230 degrees and can no longer be heated up, while the 15kw electromagnetic heating coil only takes 35-40 minutes to raise the temperature to 230 degrees , greatly shorten the preheating time, improve the production efficiency, and save a lot of power. When the equipment is shut down, when the resistance wire heating method is used, because the electric furnace has residual heat, the cooling pump will work for a long time before it can stop, and the coil used for electromagnetic heating has no heat. After the equipment is shut down, it can be quickly Stop the cooling pump. This also saves the power consumption of the cooling pump. It can be seen that electromagnetic heating saves at least 30%-60% energy than traditional resistance wire heating. Electromagnetic induction heating evaporation coating can greatly improve the evaporation rate, and the evaporation temperature is stable, which can avoid the splash phenomenon of the coating material, the film will not have the effect of pinholes, greatly improve the qualification rate of the product, and the purity requirements of the coating material are also higher than the resistance. The requirements of the furnace are lower. The high-purity material required by the resistance furnace (electric furnace wire) must reach 99.99% purity, while the electromagnetic heating evaporation only needs to reach 99.9%. From every point, it can be seen that the electromagnetic heating evaporation technology has reduced Coating production cost.

Diffusion pump induction heating has automatic constant temperature, automatic shifting and adjustable functions, energy saving, environmental protection, durability and longevity

Up to 50,000 hours or more, no open flame, can reduce the indoor temperature and prolong the life of the cooling water pipe.

Easy installation and disassembly, as well as maintenance of the diffusion pump.

After installation, it does not affect the vacuum, does not affect the product, and does not affect the time to make a furnace product.

product is guaranteed for 12 months free of charge, and technical support is provided for life.

The product is not easy to break, and can be easily replaced with a resistance furnace.

Once there is a problem with the product, the manufacturer will send a spare machine to replace it in time.

Induction heating machine is widely used in heat transfer forging, quenching, tempering, annealing, quenching and other heat treatment industries, as well as preheating, hot charging and other industries.

Induction heating machine is widely used in heat transfer forging, quenching, tempering, annealing, quenching and other heat treatment industries, as well as preheating, hot charging and other industries.

So what are the advantages of electromagnetic

induction heating system that make it widely used in all walks of life?

Nowadays, many users are using this induction heater. Users use it because it has its own advantages.

Induction heating machine adopts electromagnetic induction heating process to directly heat the workpiece. It has the advantages of fast on-off speed and high working frequency.

- Energy saving and environmental protection. Now the state's control of air pollution is becoming more and more strict. This is the advantage of induction heating machine

- The use of induction heating machine can reduce the production cost.

- Induction heating machine has high technical content, so its energy efficiency is also very good.

- Induction heating machine can be used with very good performance and high efficiency.

Advantages of diffusion pump electromagnetic induction heating over resistance wire heating:

Advantages of diffusion pump electromagnetic induction heating over resistance wire heating: Diffusion pump induction heating has automatic constant temperature, automatic shifting and adjustable functions, energy saving, environmental protection, durability and longevity

Up to 50,000 hours or more, no open flame, can reduce the indoor temperature and prolong the life of the cooling water pipe.

Easy installation and disassembly, as well as maintenance of the diffusion pump.

After installation, it does not affect the vacuum, does not affect the product, and does not affect the time to make a furnace product.

product is guaranteed for 12 months free of charge, and technical support is provided for life.

The product is not easy to break, and can be easily replaced with a resistance furnace.

Once there is a problem with the product, the manufacturer will send a spare machine to replace it in time.

Diffusion pump induction heating has automatic constant temperature, automatic shifting and adjustable functions, energy saving, environmental protection, durability and longevity

Up to 50,000 hours or more, no open flame, can reduce the indoor temperature and prolong the life of the cooling water pipe.

Easy installation and disassembly, as well as maintenance of the diffusion pump.

After installation, it does not affect the vacuum, does not affect the product, and does not affect the time to make a furnace product.

product is guaranteed for 12 months free of charge, and technical support is provided for life.

The product is not easy to break, and can be easily replaced with a resistance furnace.

Once there is a problem with the product, the manufacturer will send a spare machine to replace it in time.

Induction heating machine is widely used in heat transfer forging, quenching, tempering, annealing, quenching and other heat treatment industries, as well as preheating, hot charging and other industries.

Induction heating machine is widely used in heat transfer forging, quenching, tempering, annealing, quenching and other heat treatment industries, as well as preheating, hot charging and other industries.