Objective

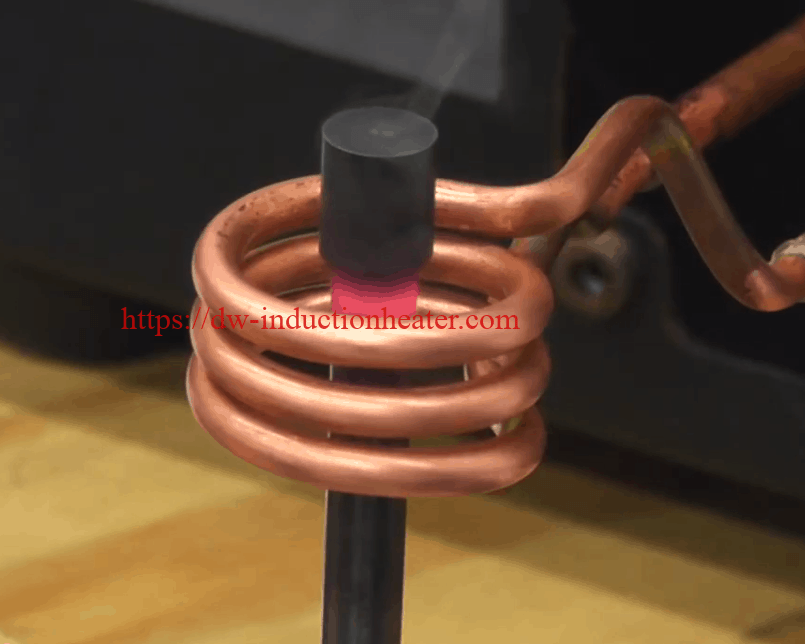

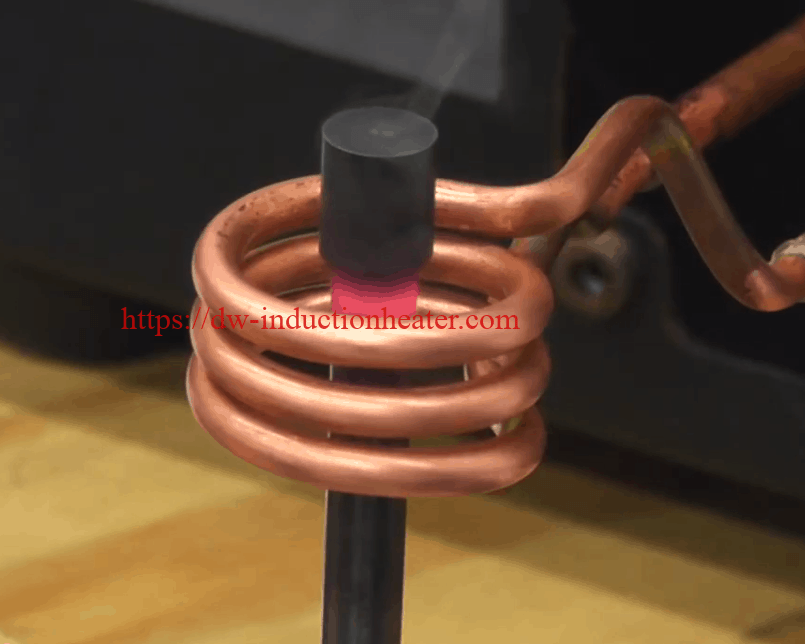

High Frequency Induction brazing steel carbide cap to shaft. Customer currently uses a torch process, but would like to change to induction brazing in order to reduce scrap and rework and improve the quality of the braze.

Equipment

DW-UHF-6kw-III handheld induction brazing heater

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Materials

• Carbon steel

• magnetic carbide caps

• Alloy – EZ Flo 3 paste

• Test 1: Shaft Diameter: 0.5” (12.7 mm)

• Test 2: Shaft Diameter: 0.375” (9.525mm)

• Test 3: Shaft Diameter: 0.312” (7.925mm)

Process:

- Paste alloy was applied to the cone shape top of each steel shaft.

- The cap was set on top and rotated to distribute the paste alloy.

- Each assembly was positioned in the coil and heated.

- Preliminary heat tests were conducted using tempilaq paint to estimate the heat cycle to 1450 degrees F.

- Precise control of the time and temperature resulting in improved quality and consistent result

- Power on demand with rapid heat cycles

- Repeatable process, not operator dependent

- Safe induction heating with no open flames

- Energy efficient heating