Electromagnetic Induction Heating Drum Dryer

Electromagnetic induction heating drum dryer is a kind of equipment widely used for drying food, coffee, soybeans, grains, nuts, peanuts, oil, dry goods and other agricultural and sideline products or food. The heating devices of traditional drum-type frying pans are mostly coal stoves, vaporization furnaces or electric heating devices. The above three heating devices are all indirect heating methods, that is, heat is transferred to the frying pan by means of heat transfer.

Due to the problems of low thermal efficiency and high energy consumption in the traditional drum frying pan, electromagnetic

induction heating drum dryers have appeared on the market, that is, the drum dryer is heated through the principle of electromagnetic induction heating. Its working principle is: drum dryer There are multiple sets of electromagnetic coils on the outside, and the multiple sets of electromagnetic coils generate alternating magnetic fields after passing through the alternating current. Since the drum dryer performs the motion of cutting magnetic field lines in the alternating magnetic field, an alternating current is generated inside the drum dryer. That is, eddy current, which collides and rubs with atoms inside the frying pan at high speed, thereby generating Joule heat for heating. Because the heating source of the electromagnetic drum dryer is the drum dryer itself, it can effectively solve the problem of low thermal efficiency of coal furnaces, vaporization furnaces and electric heating devices.

However, due to the existence of multiple sets of electromagnetic coils, there is a strong alternating magnetic field around the electromagnetic induction heating drum dryer, and the alternating magnetic field will emit electromagnetic radiation. When multiple electromagnetic drum dryers in the industry work at the same time, the electromagnetic radiation It will damage the internal instruments of the mechanical equipment, thereby affecting the service life of the mechanical equipment. In addition, it is also unfavorable for the operators to work in the electromagnetic radiation environment for a long time. Therefore, it is necessary to reduce the electromagnetic radiation generated by the electromagnetic drum dryer.

Induction Heating Schematic for Rotary Drum Dryer

1.

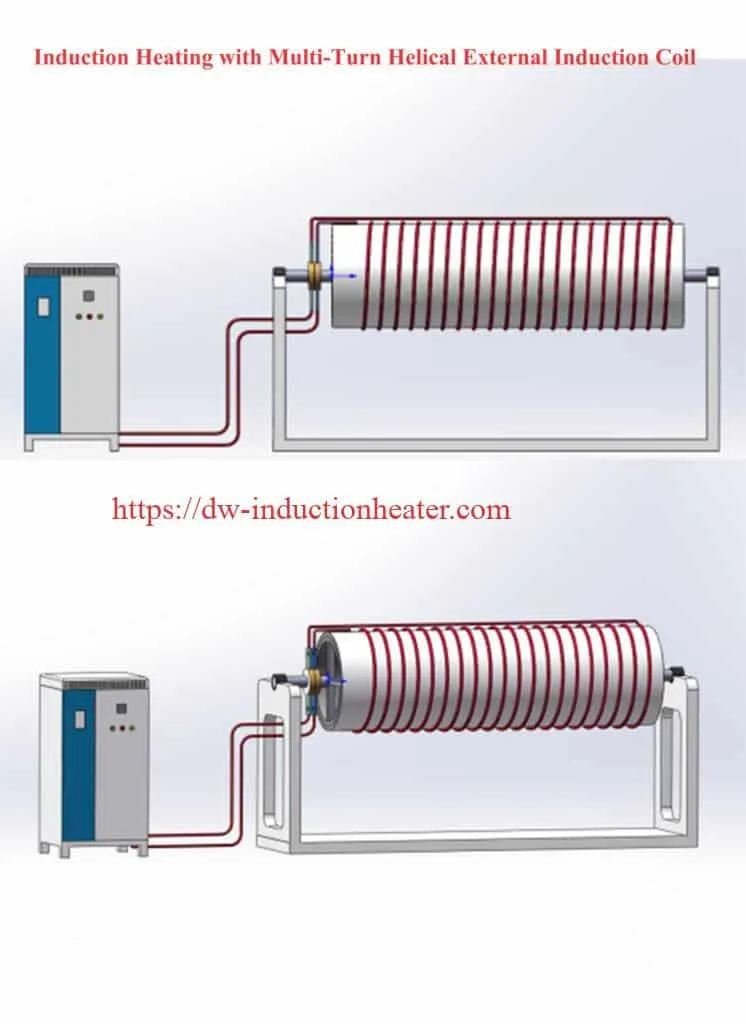

Induction Heating with Multi-Turn Helical External Induction Coil

Induction heating coils are wound around the insulation cotton which is wrapped around the drying drum. The multi-turn helical wound coils and drying drum are rotated simultaneously. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

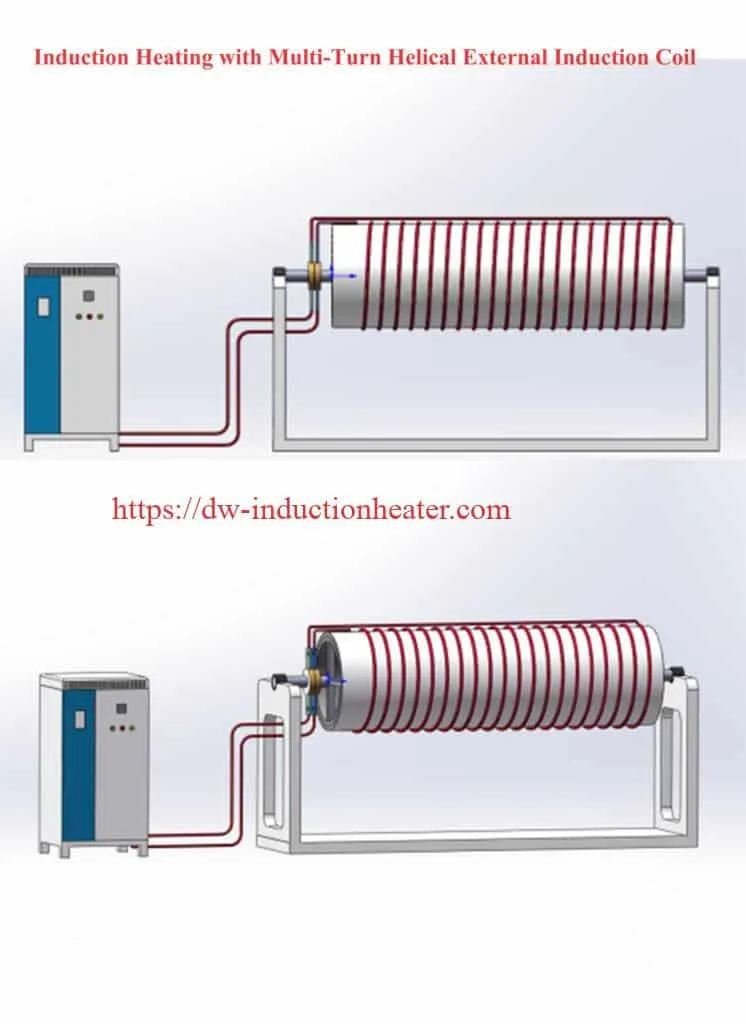

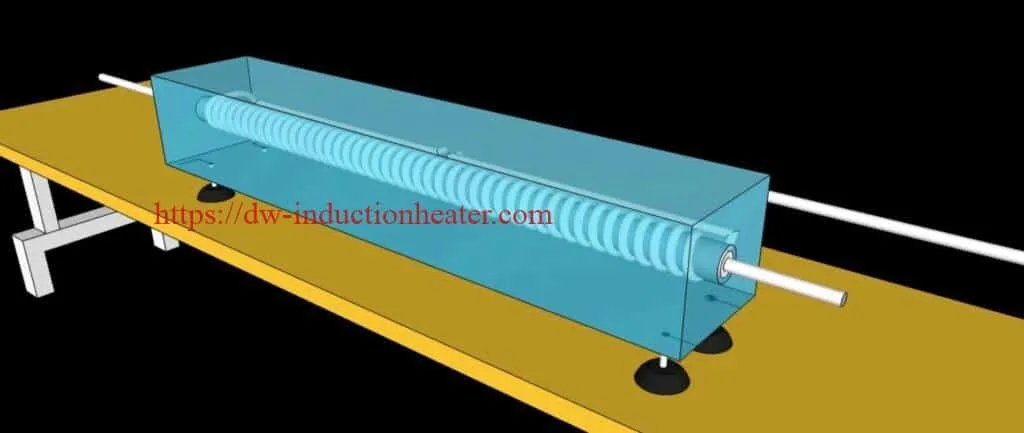

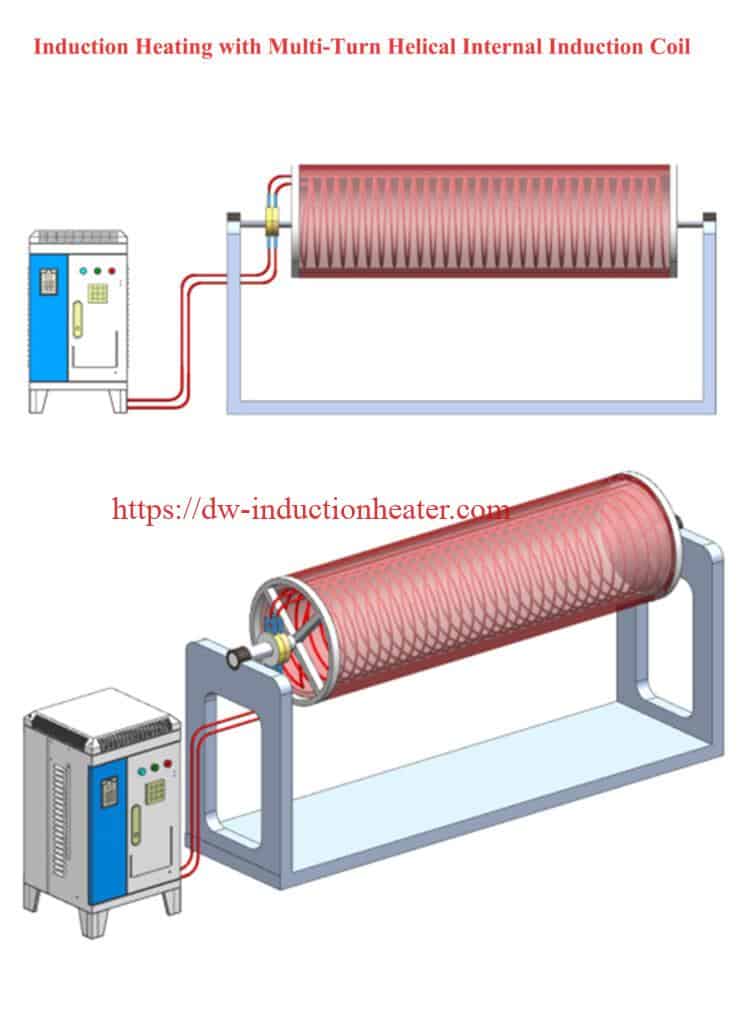

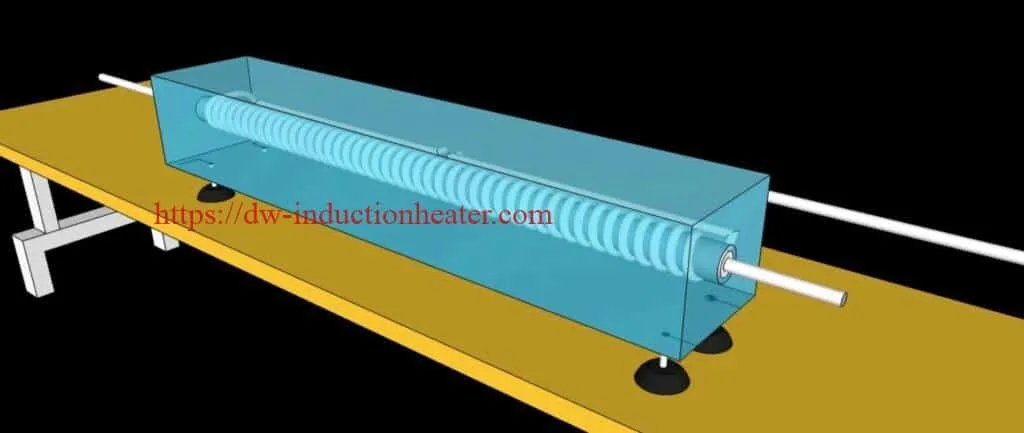

2.Induction Heating with Multi-Turn Helical Internal Induction Coil Induction heating coils are wound inside the drying drum, the multi-turn helical wound coils and drying drum are rotated simultaneously. The induction heating system runs to heat inner temperature of the drying drum.

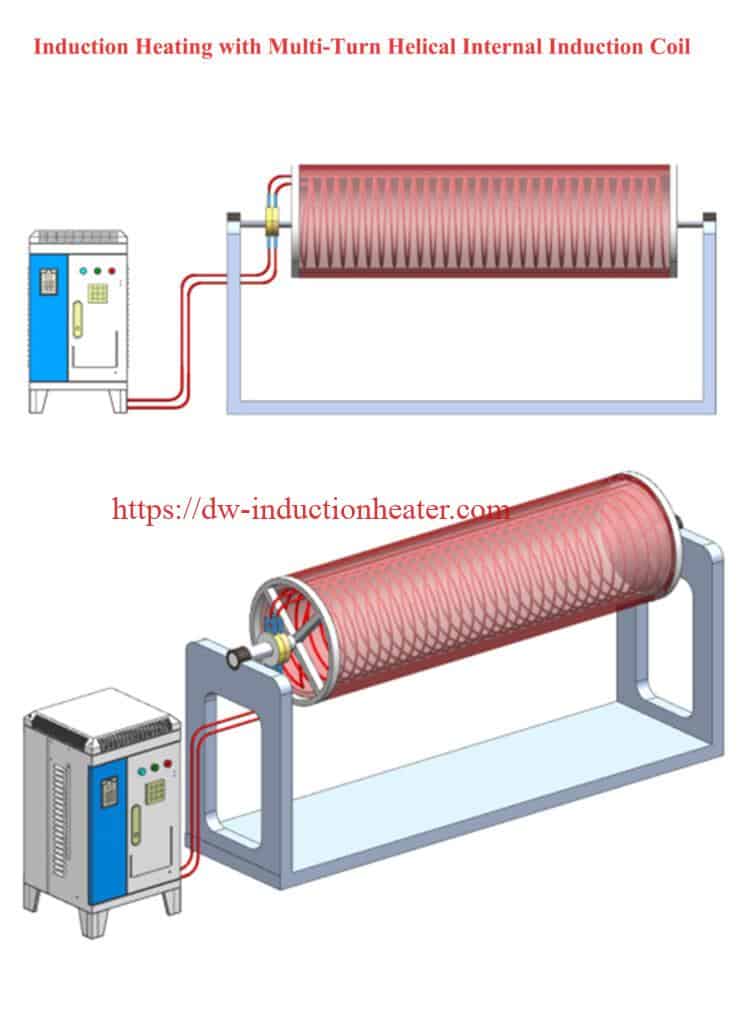

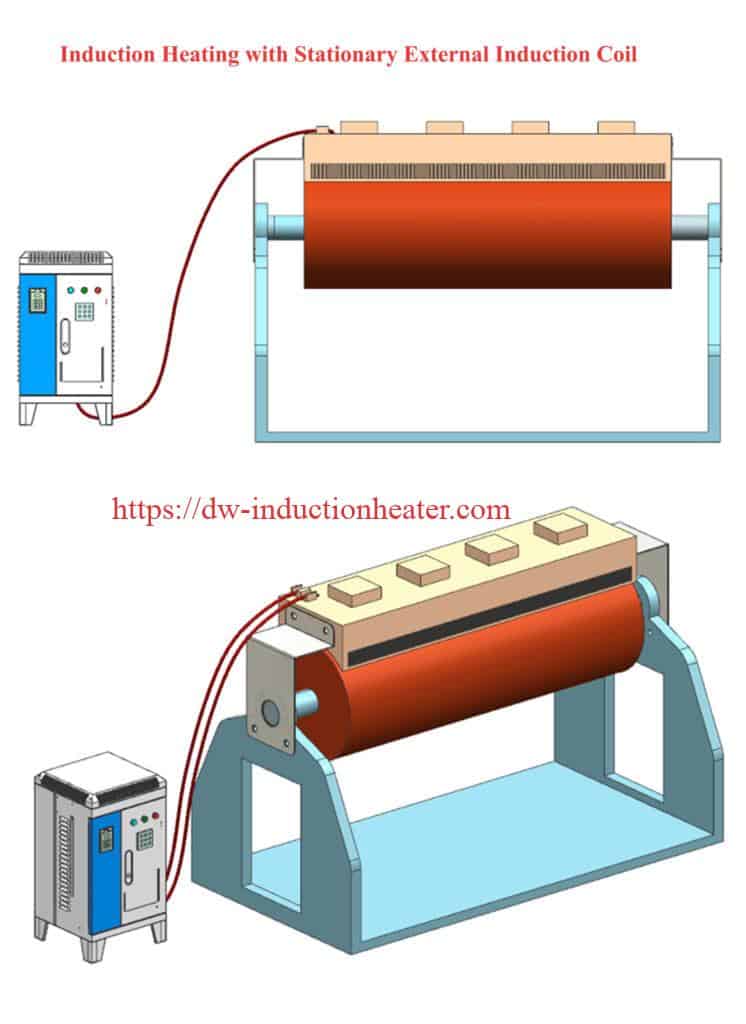

3. Induction Heating with Stationary External Induction Coil

Induction heating coils are wound inside the drying drum, the multi-turn helical wound coils and drying drum are rotated simultaneously. The induction heating system runs to heat inner temperature of the drying drum.

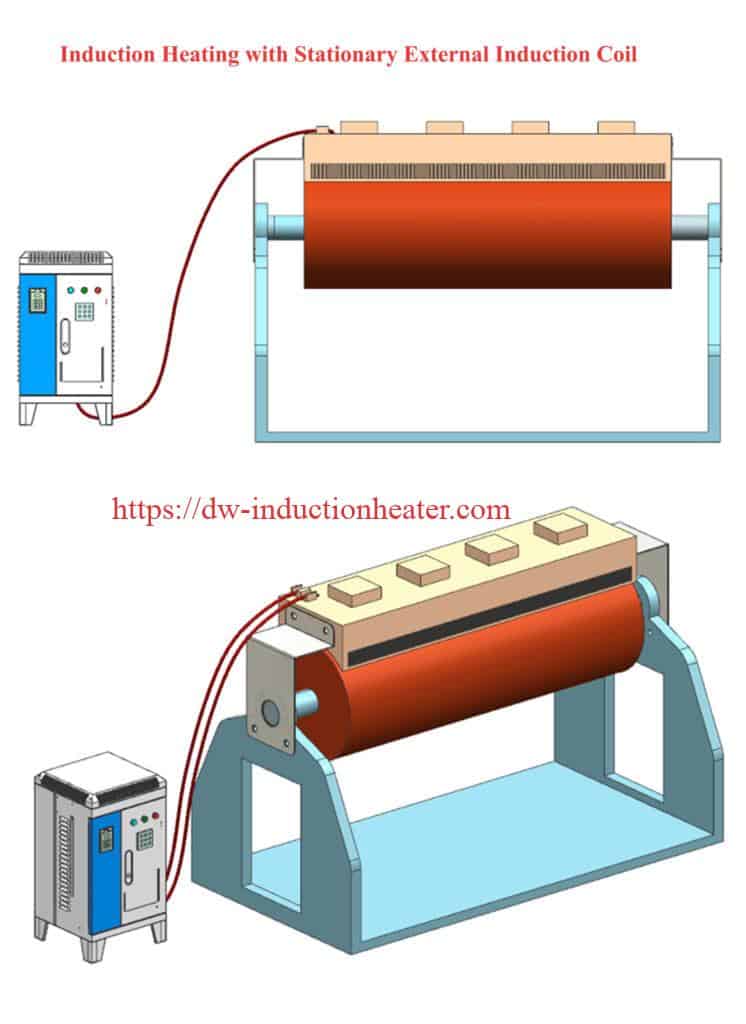

3. Induction Heating with Stationary External Induction Coil Induction heating coils are curved external coils fixed on the support above the drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

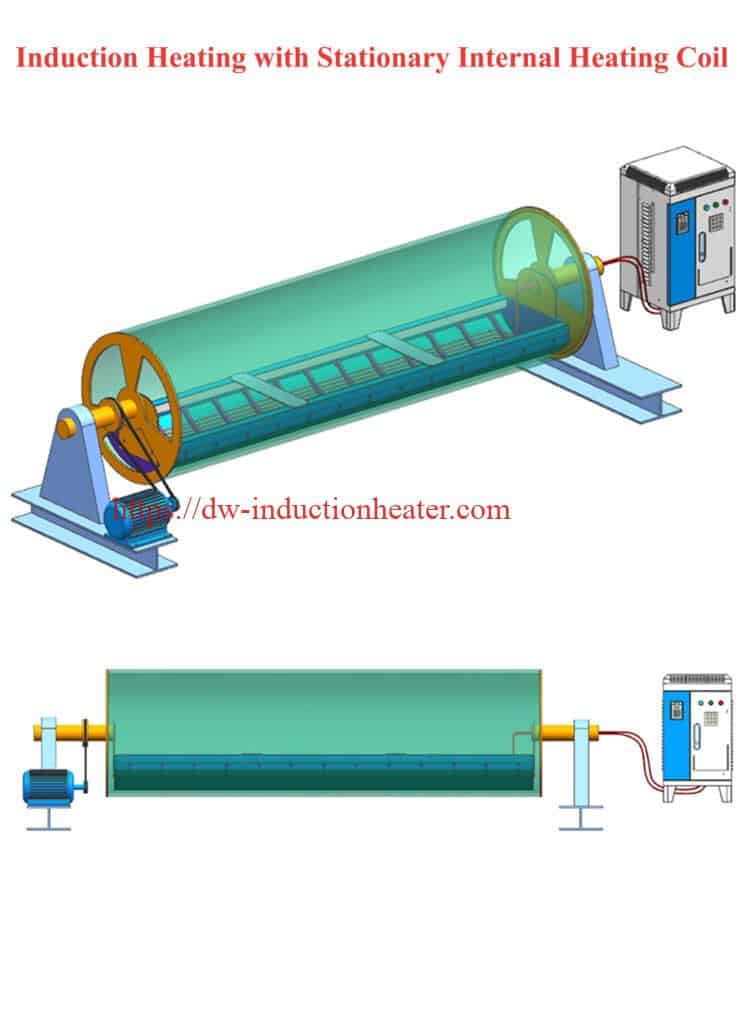

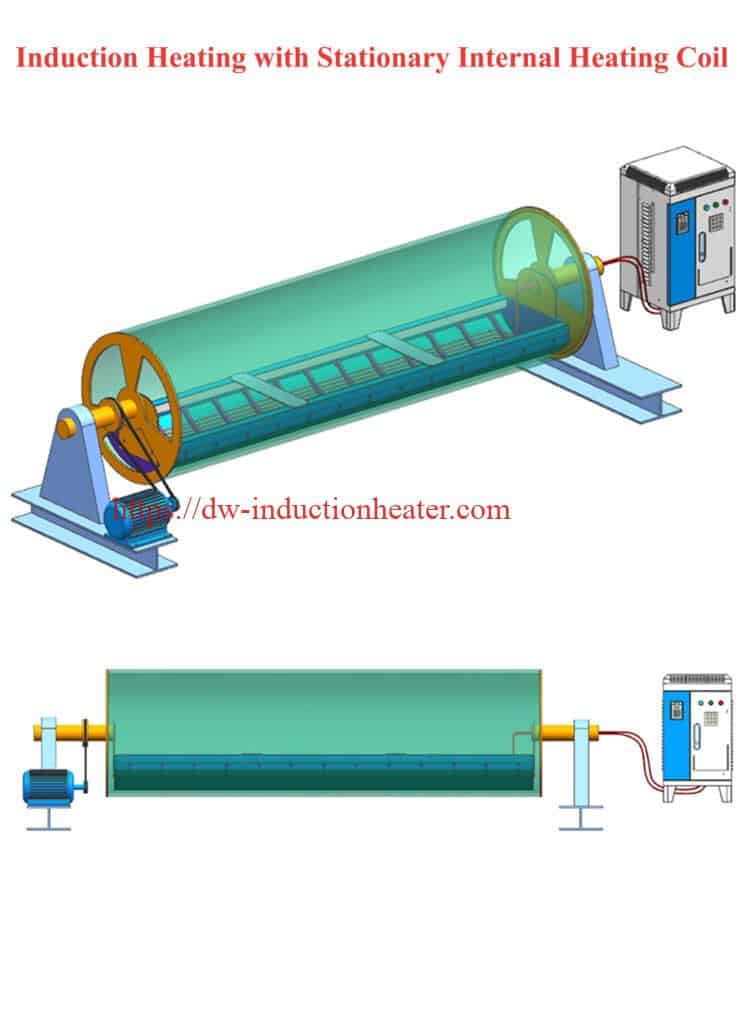

4. Induction Heating with Stationary Internal Induction Coil

Induction heating coils are curved external coils fixed on the support above the drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

4. Induction Heating with Stationary Internal Induction Coil Induction heating coils are produced in accordance with the size of drying drum, and placed inside the drum. When the rotary drum dryer is rotating, the induction heating coil remains stationary. The induction heating system runs to heat inner temperature of the drying drum.

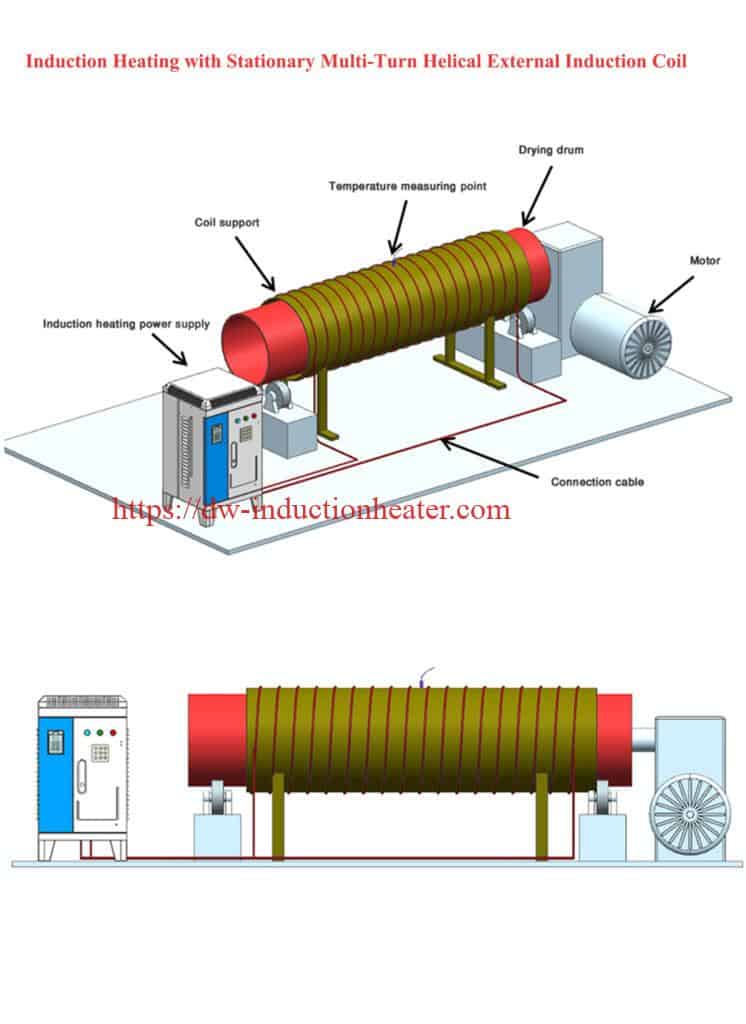

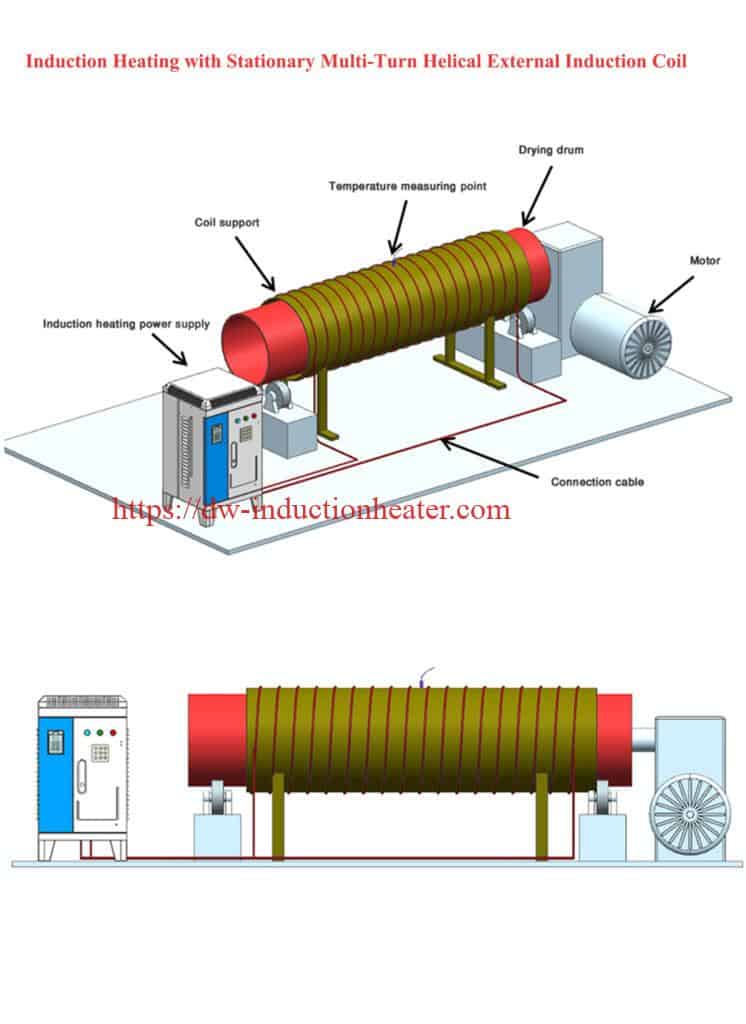

5.Induction Heating with Stationary Multi-Turn Helical External Induction Coil

Induction heating coils are produced in accordance with the size of drying drum, and placed inside the drum. When the rotary drum dryer is rotating, the induction heating coil remains stationary. The induction heating system runs to heat inner temperature of the drying drum.

5.Induction Heating with Stationary Multi-Turn Helical External Induction Coil Induction heating coils are wound closely around the support, and there is certain spacing between the coil support and drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

Induction heating coils are wound closely around the support, and there is certain spacing between the coil support and drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

Electromagnetic induction heating

Electromagnetic heating is also called electromagnetic induction heating, that is, electromagnetic heating (foreign language: Electromagnetic heating abbreviation: EH) technology. The principle of electromagnetic heating is to generate an alternating magnetic field through the components of the electronic circuit board. That is to say, cutting alternating magnetic lines of force generates alternating current (ie eddy current ) in the metal part of the bottom of the container. The eddy current makes the carriers at the bottom of the container move at high speed and irregularly, and the carriers and atoms collide and rub against each other to generate heat energy. So as to have the effect of heating the item. Because the iron container generates heat by itself, the heat conversion rate is particularly high, up to 95%. It is a direct heating method. Induction cooker , induction cooktop and electromagnetic heating rice cooker are all using electromagnetic heating technology.

Disadvantages of traditional resistance heating

Disadvantages of traditional resistance heating

Large heat loss: The heating method specially used by the existing enterprises is made of resistance wire, and the inner and outer sides of the circle generate heat. In the air, it will cause direct loss and waste of electric energy.

Ambient temperature rise: Due to a large amount of heat loss, the surrounding environment temperature rises, especially in summer, which has a great impact on the production environment. Some on-site working temperatures have exceeded 45 degrees. secondary waste.

Short service life and large maintenance: the heating temperature of the electric heating tube is as high as 300 degrees due to the use of resistance wire, the thermal lag is large, it is not easy to accurately control the temperature, and the resistance wire is easily blown due to high temperature aging. The service life of the commonly used electric heating coil is about half a year, so the maintenance workload is relatively large.

Advantages of electromagnetic induction heating products

Long service life:

Advantages of electromagnetic induction heating products

Long service life: The electromagnetic heating coil itself basically does not generate heat, so it has a long service life, no maintenance, and no maintenance and replacement costs; the heating part adopts a ring-shaped cable structure, the cable itself does not generate heat, and can withstand high temperatures above 500 °C, with a service life of up to 10 years. No maintenance is required, and there is basically no maintenance cost in the later period.

Safe and reliable: The outer wall of the barrel is heated by high-frequency electromagnetic action , the heat is fully utilized, and there is basically no loss. The heat is accumulated inside the heating body, and the surface temperature of the electromagnetic coil is slightly higher than the room temperature, which can be touched safely without high temperature protection, which is safe and reliable.

High efficiency and energy saving: The internal heat heating method is adopted, and the molecules in the heating body directly induce magnetic energy to generate heat. The hot start is very fast, and the average preheating time is shortened by more than 60% compared with the resistance coil heating method . Compared with resistance coil heating, it saves 30-70% of electricity, which greatly improves production efficiency.

Accurate temperature control: The coil itself does not generate heat, the thermal retardation is small, the thermal inertia is low, the temperature of the inner and outer walls of the barrel is consistent, the temperature control is accurate in real time, the product quality is significantly improved, and the production efficiency is high.

Good insulation : The electromagnetic coil is made of customized special high-temperature and high-voltage special cables , with good insulation performance, no direct contact with the outer wall of the tank, no leakage, short-circuit failure, and no worries.

Improve the working environment: The injection molding machine that has been transformed by electromagnetic heating equipment adopts the internal heating method, the heat is concentrated inside the heating body, and the external heat dissipation is almost non-existent. The surface temperature of the equipment can be improved to the point where the human body can touch it, and the ambient temperature is reduced from above 100°C when the resistance coil is heated to normal temperature, which greatly improves the working environment of the production site, effectively increases the enthusiasm of production workers, and reduces the cost of ventilation and cooling in the summer plant area. In line with the concept of "people-oriented", we will create an environmentally friendly, safe and comfortable production environment for factories and front-line production personnel.

Applications of induction heating:

Industrial electromagnetic energy-saving transformation is widely used in energy-saving transformation of plastic machinery heating, wood, construction, food, medical, chemical industry, such as plastic injection molding machine , extruder , film blowing machine , wire drawing machine , plastic film, pipe, wire and other machines , food processing, textile, printing and dyeing, metallurgy, light industry, machinery, surface heat treatment and welding, boilers, water boilers and other industries, can replace resistance heating , as well as fuel open fire traditional energy.

Textile printing and dyeing: the use of electromagnetic heating for raw materials can improve energy efficiency , increase heating speed, and improve temperature control accuracy;

Light industry: sealing of cans and other plastic packaging, etc.

Boiler industry: Taking advantage of its fast heating speed, the electromagnetic boiler can abandon the overall heating method of the traditional boiler, and only heat the water outlet of the boiler, so that the water flow completes the heating in the flow, the heating speed is fast, and the space is saved.

Machinery industry: high-frequency electromagnetic heating can be applied to heat treatment with metals, and its effect is significantly improved compared with traditional treatment methods . diathermy before pressure working ;

The application of electromagnetic heating technology is not only conducive to the improvement of product quality, production efficiency, energy saving and cost reduction, but also to improve the technical level of equipment manufacturing enterprises. It is more and more widely accepted and used in traditional industries.

Due to the problems of low thermal efficiency and high energy consumption in the traditional drum frying pan, electromagnetic induction heating drum dryers have appeared on the market, that is, the drum dryer is heated through the principle of electromagnetic induction heating. Its working principle is: drum dryer There are multiple sets of electromagnetic coils on the outside, and the multiple sets of electromagnetic coils generate alternating magnetic fields after passing through the alternating current. Since the drum dryer performs the motion of cutting magnetic field lines in the alternating magnetic field, an alternating current is generated inside the drum dryer. That is, eddy current, which collides and rubs with atoms inside the frying pan at high speed, thereby generating Joule heat for heating. Because the heating source of the electromagnetic drum dryer is the drum dryer itself, it can effectively solve the problem of low thermal efficiency of coal furnaces, vaporization furnaces and electric heating devices.

However, due to the existence of multiple sets of electromagnetic coils, there is a strong alternating magnetic field around the electromagnetic induction heating drum dryer, and the alternating magnetic field will emit electromagnetic radiation. When multiple electromagnetic drum dryers in the industry work at the same time, the electromagnetic radiation It will damage the internal instruments of the mechanical equipment, thereby affecting the service life of the mechanical equipment. In addition, it is also unfavorable for the operators to work in the electromagnetic radiation environment for a long time. Therefore, it is necessary to reduce the electromagnetic radiation generated by the electromagnetic drum dryer.

Due to the problems of low thermal efficiency and high energy consumption in the traditional drum frying pan, electromagnetic induction heating drum dryers have appeared on the market, that is, the drum dryer is heated through the principle of electromagnetic induction heating. Its working principle is: drum dryer There are multiple sets of electromagnetic coils on the outside, and the multiple sets of electromagnetic coils generate alternating magnetic fields after passing through the alternating current. Since the drum dryer performs the motion of cutting magnetic field lines in the alternating magnetic field, an alternating current is generated inside the drum dryer. That is, eddy current, which collides and rubs with atoms inside the frying pan at high speed, thereby generating Joule heat for heating. Because the heating source of the electromagnetic drum dryer is the drum dryer itself, it can effectively solve the problem of low thermal efficiency of coal furnaces, vaporization furnaces and electric heating devices.

However, due to the existence of multiple sets of electromagnetic coils, there is a strong alternating magnetic field around the electromagnetic induction heating drum dryer, and the alternating magnetic field will emit electromagnetic radiation. When multiple electromagnetic drum dryers in the industry work at the same time, the electromagnetic radiation It will damage the internal instruments of the mechanical equipment, thereby affecting the service life of the mechanical equipment. In addition, it is also unfavorable for the operators to work in the electromagnetic radiation environment for a long time. Therefore, it is necessary to reduce the electromagnetic radiation generated by the electromagnetic drum dryer.

Induction heating coils are wound inside the drying drum, the multi-turn helical wound coils and drying drum are rotated simultaneously. The induction heating system runs to heat inner temperature of the drying drum.

3. Induction Heating with Stationary External Induction Coil

Induction heating coils are wound inside the drying drum, the multi-turn helical wound coils and drying drum are rotated simultaneously. The induction heating system runs to heat inner temperature of the drying drum.

3. Induction Heating with Stationary External Induction Coil Induction heating coils are curved external coils fixed on the support above the drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

4. Induction Heating with Stationary Internal Induction Coil

Induction heating coils are curved external coils fixed on the support above the drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

4. Induction Heating with Stationary Internal Induction Coil Induction heating coils are produced in accordance with the size of drying drum, and placed inside the drum. When the rotary drum dryer is rotating, the induction heating coil remains stationary. The induction heating system runs to heat inner temperature of the drying drum.

5.Induction Heating with Stationary Multi-Turn Helical External Induction Coil

Induction heating coils are produced in accordance with the size of drying drum, and placed inside the drum. When the rotary drum dryer is rotating, the induction heating coil remains stationary. The induction heating system runs to heat inner temperature of the drying drum.

5.Induction Heating with Stationary Multi-Turn Helical External Induction Coil Induction heating coils are wound closely around the support, and there is certain spacing between the coil support and drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

Induction heating coils are wound closely around the support, and there is certain spacing between the coil support and drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

Disadvantages of traditional resistance heating

Large heat loss: The heating method specially used by the existing enterprises is made of resistance wire, and the inner and outer sides of the circle generate heat. In the air, it will cause direct loss and waste of electric energy.

Ambient temperature rise: Due to a large amount of heat loss, the surrounding environment temperature rises, especially in summer, which has a great impact on the production environment. Some on-site working temperatures have exceeded 45 degrees. secondary waste.

Short service life and large maintenance: the heating temperature of the electric heating tube is as high as 300 degrees due to the use of resistance wire, the thermal lag is large, it is not easy to accurately control the temperature, and the resistance wire is easily blown due to high temperature aging. The service life of the commonly used electric heating coil is about half a year, so the maintenance workload is relatively large.

Disadvantages of traditional resistance heating

Large heat loss: The heating method specially used by the existing enterprises is made of resistance wire, and the inner and outer sides of the circle generate heat. In the air, it will cause direct loss and waste of electric energy.

Ambient temperature rise: Due to a large amount of heat loss, the surrounding environment temperature rises, especially in summer, which has a great impact on the production environment. Some on-site working temperatures have exceeded 45 degrees. secondary waste.

Short service life and large maintenance: the heating temperature of the electric heating tube is as high as 300 degrees due to the use of resistance wire, the thermal lag is large, it is not easy to accurately control the temperature, and the resistance wire is easily blown due to high temperature aging. The service life of the commonly used electric heating coil is about half a year, so the maintenance workload is relatively large.

Advantages of electromagnetic induction heating products

Long service life: The electromagnetic heating coil itself basically does not generate heat, so it has a long service life, no maintenance, and no maintenance and replacement costs; the heating part adopts a ring-shaped cable structure, the cable itself does not generate heat, and can withstand high temperatures above 500 °C, with a service life of up to 10 years. No maintenance is required, and there is basically no maintenance cost in the later period.

Safe and reliable: The outer wall of the barrel is heated by high-frequency electromagnetic action , the heat is fully utilized, and there is basically no loss. The heat is accumulated inside the heating body, and the surface temperature of the electromagnetic coil is slightly higher than the room temperature, which can be touched safely without high temperature protection, which is safe and reliable.

High efficiency and energy saving: The internal heat heating method is adopted, and the molecules in the heating body directly induce magnetic energy to generate heat. The hot start is very fast, and the average preheating time is shortened by more than 60% compared with the resistance coil heating method . Compared with resistance coil heating, it saves 30-70% of electricity, which greatly improves production efficiency.

Accurate temperature control: The coil itself does not generate heat, the thermal retardation is small, the thermal inertia is low, the temperature of the inner and outer walls of the barrel is consistent, the temperature control is accurate in real time, the product quality is significantly improved, and the production efficiency is high.

Good insulation : The electromagnetic coil is made of customized special high-temperature and high-voltage special cables , with good insulation performance, no direct contact with the outer wall of the tank, no leakage, short-circuit failure, and no worries.

Improve the working environment: The injection molding machine that has been transformed by electromagnetic heating equipment adopts the internal heating method, the heat is concentrated inside the heating body, and the external heat dissipation is almost non-existent. The surface temperature of the equipment can be improved to the point where the human body can touch it, and the ambient temperature is reduced from above 100°C when the resistance coil is heated to normal temperature, which greatly improves the working environment of the production site, effectively increases the enthusiasm of production workers, and reduces the cost of ventilation and cooling in the summer plant area. In line with the concept of "people-oriented", we will create an environmentally friendly, safe and comfortable production environment for factories and front-line production personnel.

Applications of induction heating:

Industrial electromagnetic energy-saving transformation is widely used in energy-saving transformation of plastic machinery heating, wood, construction, food, medical, chemical industry, such as plastic injection molding machine , extruder , film blowing machine , wire drawing machine , plastic film, pipe, wire and other machines , food processing, textile, printing and dyeing, metallurgy, light industry, machinery, surface heat treatment and welding, boilers, water boilers and other industries, can replace resistance heating , as well as fuel open fire traditional energy.

Textile printing and dyeing: the use of electromagnetic heating for raw materials can improve energy efficiency , increase heating speed, and improve temperature control accuracy;

Light industry: sealing of cans and other plastic packaging, etc.

Boiler industry: Taking advantage of its fast heating speed, the electromagnetic boiler can abandon the overall heating method of the traditional boiler, and only heat the water outlet of the boiler, so that the water flow completes the heating in the flow, the heating speed is fast, and the space is saved.

Machinery industry: high-frequency electromagnetic heating can be applied to heat treatment with metals, and its effect is significantly improved compared with traditional treatment methods . diathermy before pressure working ;

The application of electromagnetic heating technology is not only conducive to the improvement of product quality, production efficiency, energy saving and cost reduction, but also to improve the technical level of equipment manufacturing enterprises. It is more and more widely accepted and used in traditional industries.

Advantages of electromagnetic induction heating products

Long service life: The electromagnetic heating coil itself basically does not generate heat, so it has a long service life, no maintenance, and no maintenance and replacement costs; the heating part adopts a ring-shaped cable structure, the cable itself does not generate heat, and can withstand high temperatures above 500 °C, with a service life of up to 10 years. No maintenance is required, and there is basically no maintenance cost in the later period.

Safe and reliable: The outer wall of the barrel is heated by high-frequency electromagnetic action , the heat is fully utilized, and there is basically no loss. The heat is accumulated inside the heating body, and the surface temperature of the electromagnetic coil is slightly higher than the room temperature, which can be touched safely without high temperature protection, which is safe and reliable.

High efficiency and energy saving: The internal heat heating method is adopted, and the molecules in the heating body directly induce magnetic energy to generate heat. The hot start is very fast, and the average preheating time is shortened by more than 60% compared with the resistance coil heating method . Compared with resistance coil heating, it saves 30-70% of electricity, which greatly improves production efficiency.

Accurate temperature control: The coil itself does not generate heat, the thermal retardation is small, the thermal inertia is low, the temperature of the inner and outer walls of the barrel is consistent, the temperature control is accurate in real time, the product quality is significantly improved, and the production efficiency is high.

Good insulation : The electromagnetic coil is made of customized special high-temperature and high-voltage special cables , with good insulation performance, no direct contact with the outer wall of the tank, no leakage, short-circuit failure, and no worries.

Improve the working environment: The injection molding machine that has been transformed by electromagnetic heating equipment adopts the internal heating method, the heat is concentrated inside the heating body, and the external heat dissipation is almost non-existent. The surface temperature of the equipment can be improved to the point where the human body can touch it, and the ambient temperature is reduced from above 100°C when the resistance coil is heated to normal temperature, which greatly improves the working environment of the production site, effectively increases the enthusiasm of production workers, and reduces the cost of ventilation and cooling in the summer plant area. In line with the concept of "people-oriented", we will create an environmentally friendly, safe and comfortable production environment for factories and front-line production personnel.

Applications of induction heating:

Industrial electromagnetic energy-saving transformation is widely used in energy-saving transformation of plastic machinery heating, wood, construction, food, medical, chemical industry, such as plastic injection molding machine , extruder , film blowing machine , wire drawing machine , plastic film, pipe, wire and other machines , food processing, textile, printing and dyeing, metallurgy, light industry, machinery, surface heat treatment and welding, boilers, water boilers and other industries, can replace resistance heating , as well as fuel open fire traditional energy.

Textile printing and dyeing: the use of electromagnetic heating for raw materials can improve energy efficiency , increase heating speed, and improve temperature control accuracy;

Light industry: sealing of cans and other plastic packaging, etc.

Boiler industry: Taking advantage of its fast heating speed, the electromagnetic boiler can abandon the overall heating method of the traditional boiler, and only heat the water outlet of the boiler, so that the water flow completes the heating in the flow, the heating speed is fast, and the space is saved.

Machinery industry: high-frequency electromagnetic heating can be applied to heat treatment with metals, and its effect is significantly improved compared with traditional treatment methods . diathermy before pressure working ;

The application of electromagnetic heating technology is not only conducive to the improvement of product quality, production efficiency, energy saving and cost reduction, but also to improve the technical level of equipment manufacturing enterprises. It is more and more widely accepted and used in traditional industries.